Radiographic Film Systems Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439202 | Date : Jan, 2026 | Pages : 258 | Region : Global | Publisher : MRU

Radiographic Film Systems Market Size

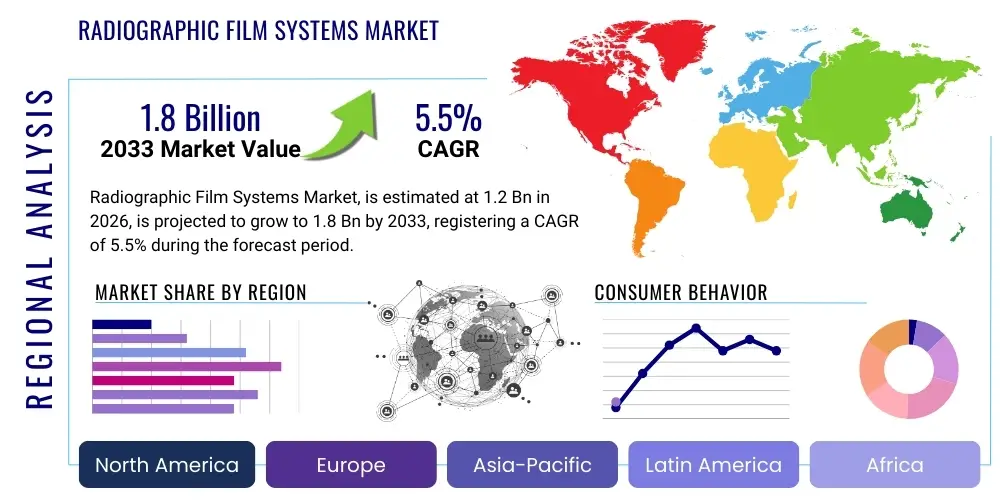

The Radiographic Film Systems Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.5% between 2026 and 2033. The market is estimated at USD 1.2 billion in 2026 and is projected to reach USD 1.8 billion by the end of the forecast period in 2033. This growth is primarily driven by the consistent demand for cost-effective and reliable imaging solutions in industrial inspection, non-destructive testing (NDT), and specialized medical applications, particularly in emerging economies where digital radiography adoption is still evolving or where specific regulatory requirements mandate film use for archival and diagnostic purposes.

Radiographic Film Systems Market introduction

The Radiographic Film Systems Market encompasses the manufacturing, distribution, and utilization of X-ray films, processing chemicals, and related equipment essential for producing radiographic images. These systems rely on the principles of X-ray absorption and subsequent chemical development to create a permanent visual record, widely utilized across various sectors. The inherent stability and archival quality of radiographic film continue to make it a preferred choice for applications requiring high-resolution, long-term data storage, and verifiable documentation, even amidst the widespread adoption of digital imaging technologies.

Major applications for radiographic film systems span industrial inspection, including aerospace, oil and gas, and manufacturing, where it is critical for defect detection in welds, castings, and composites. In the medical field, while largely superseded by digital methods, film radiography still finds niche applications in dentistry, mammography, and in regions with limited access to advanced digital infrastructure. Furthermore, it plays a vital role in veterinary medicine and security screening. The enduring benefits include excellent image resolution, relatively low initial equipment cost, and robustness in diverse operational environments, making it suitable for field applications where digital alternatives might be impractical or cost-prohibitive.

Driving factors for this market include the sustained demand from the non-destructive testing (NDT) industry, particularly in infrastructure development and maintenance projects globally. Regulatory mandates in certain sectors, such as nuclear power and aerospace, often specify film radiography for its verifiable image integrity and long-term archival properties. The growth in emerging markets, characterized by increasing industrialization and accessible healthcare initiatives, also fuels demand, as these regions often prioritize cost-effective and established imaging solutions before fully transitioning to digital platforms. The reliability and established workflows associated with film systems further contribute to their continued market presence.

Radiographic Film Systems Market Executive Summary

The Radiographic Film Systems Market is experiencing a nuanced trajectory, influenced by a blend of technological advancements in digital imaging and the persistent requirements of specialized industries. Business trends indicate a strategic pivot by manufacturers towards offering hybrid solutions that integrate film systems with digital conversion kits, extending the utility of existing infrastructure. There is also a concentrated effort on developing environmentally friendlier film processing chemicals and more efficient film handling systems to address sustainability concerns and operational costs. Market players are increasingly focusing on providing comprehensive service and support packages, recognizing the importance of maintaining legacy systems and ensuring their optimal performance for critical applications. This strategic focus helps in retaining a loyal customer base, particularly in sectors where compliance and proven methodologies are paramount.

Regionally, the market exhibits varying dynamics. Asia Pacific, driven by rapid industrialization, infrastructure development, and growing healthcare access, stands out as a significant growth engine, particularly in countries like China and India, where the cost-effectiveness of film systems appeals to a broad range of end-users. North America and Europe, while seeing a gradual decline in traditional medical film use, maintain stable demand from robust NDT industries, aerospace, and energy sectors that rely on film for stringent quality control and regulatory compliance. Latin America, the Middle East, and Africa are also showing steady demand, fueled by expanding industrial bases and healthcare improvements, often preferring the lower capital expenditure associated with film systems over expensive digital alternatives. The diversity in regional market maturity and technological adoption creates distinct opportunities for manufacturers and suppliers.

Segmentation trends highlight the resilience of industrial radiography film, which continues to dominate the market due to its indispensable role in quality assurance and safety protocols across heavy industries. The demand for specialized film types, such as those with enhanced sensitivity or specific contrast characteristics, remains strong within NDT applications. In the medical segment, while general radiography has largely shifted to digital, specific areas like dental and some specialty clinics still utilize film due to equipment familiarity, existing infrastructure, and cost efficiencies. The market also observes an emphasis on improving film quality, reducing processing times, and enhancing the overall workflow efficiency to provide competitive advantages in a hybrid imaging landscape. This continuous refinement underscores the market's adaptability and commitment to serving its dedicated user base effectively.

AI Impact Analysis on Radiographic Film Systems Market

Users frequently inquire about the potential for Artificial Intelligence to completely displace traditional radiographic film systems, questioning the long-term viability of film technology in an AI-driven future. Concerns often revolve around whether AI-powered digital imaging solutions offer superior diagnostic accuracy, faster throughput, and reduced operational costs, thereby rendering film obsolete. Conversely, there is also interest in understanding how AI might augment, rather than replace, existing film-based workflows, particularly in areas like image analysis, quality control, and archival management, thereby extending the lifecycle and improving the efficiency of film systems. Key themes highlight a desire for clarity on the competitive landscape and the specific ways AI integration could either accelerate the transition away from film or create new hybrid opportunities for its continued use, especially in highly specialized or resource-constrained environments.

- AI-driven image enhancement for film-based scans, improving clarity and contrast during digitization.

- Automated defect detection and analysis in industrial radiography films, reducing manual review time.

- Predictive maintenance for film processing equipment, optimizing uptime and reducing operational costs.

- Development of AI algorithms to assist in the interpretation of complex film images, supporting human experts.

- Integration of AI with hybrid film-to-digital solutions, enabling seamless data management and archival.

- Optimized exposure parameter recommendations for film systems using AI, minimizing retakes and waste.

- AI-powered quality control systems for film manufacturing, ensuring consistent product quality.

DRO & Impact Forces Of Radiographic Film Systems Market

The Radiographic Film Systems Market is shaped by a confluence of influential factors. A primary driver is the enduring demand from the Non-Destructive Testing (NDT) sector, particularly in critical infrastructure, aerospace, and energy industries, where radiographic film offers unparalleled resolution, reliability, and verifiable archival records essential for safety and compliance. Furthermore, the lower initial capital expenditure for film systems compared to digital alternatives makes them attractive to developing economies and smaller enterprises. The proven track record and established regulatory frameworks that often mandate film use in specific applications, such as welding inspections and certain medical diagnoses, also contribute significantly to market stability. These drivers collectively underpin the continued relevance and adoption of film-based radiography despite technological shifts.

However, the market faces significant restraints, predominantly the rapid advancement and widespread adoption of digital radiography (DR) and computed radiography (CR) technologies. Digital systems offer immediate image acquisition, reduced radiation exposure, enhanced post-processing capabilities, and easier image sharing and storage, posing a strong competitive challenge. The environmental impact associated with chemical processing and film disposal, coupled with the rising costs of traditional film chemicals, presents additional hurdles. The workflow associated with film radiography, which involves darkrooms and chemical baths, is often perceived as slower and more cumbersome than digital alternatives, leading to operational inefficiencies in modern medical and industrial settings. These factors collectively exert downward pressure on market growth.

Opportunities within this market primarily lie in the development of hybrid imaging solutions that leverage the benefits of both film and digital technologies, enabling a smooth transition and extended utility of existing film infrastructure. Innovation in environmentally sustainable film processing and digital conversion technologies, such as advanced film digitizers, can open new avenues. Expanding applications in specialized NDT fields requiring ultra-high resolution and the growing industrial base in emerging markets present significant growth prospects. Moreover, tailoring products and services to specific niche applications where film remains indispensable, such as forensic imaging, specialized art conservation, and specific research applications, can create resilient market segments. The continued need for robust, verifiable, and archival imaging solutions ensures a sustained, albeit evolving, role for radiographic film systems.

Segmentation Analysis

The Radiographic Film Systems Market is segmented to provide a granular view of its diverse applications and product types, allowing for a comprehensive understanding of market dynamics across various end-user industries and geographical regions. This segmentation aids in identifying key growth areas, market saturation points, and the specific needs of different customer bases, ensuring targeted product development and marketing strategies. The primary segmentation criteria generally include product type, application, and end-user, each revealing unique market trends and consumption patterns within the broader radiographic imaging landscape. This systematic breakdown highlights the intricate structure of demand and supply in this specialized market.

- By Product Type:

- Medical Radiographic Film

- Industrial Radiographic Film

- Dental Radiographic Film

- Specialty Films (e.g., Veterinary, Security)

- By Film Speed:

- High Speed Film

- Medium Speed Film

- Slow Speed Film

- By Application:

- Non-Destructive Testing (NDT)

- Medical Diagnostics (General Radiography, Mammography)

- Dental Imaging

- Security Screening

- Research and Development

- By End User:

- Hospitals and Clinics

- Diagnostic Imaging Centers

- Industrial Inspection Companies

- Aerospace and Defense

- Oil and Gas Industry

- Automotive Industry

- Veterinary Hospitals

- Academic and Research Institutes

Value Chain Analysis For Radiographic Film Systems Market

The value chain for the Radiographic Film Systems Market commences with the upstream analysis, involving the raw material suppliers. Key raw materials include silver halides, polyester film base, and various chemical compounds essential for emulsion coating and processing. Manufacturers often rely on a specialized supply chain for these high-purity components, which are crucial for image quality and film sensitivity. The procurement of these materials, often from a limited number of specialized chemical and film base producers, significantly impacts production costs and supply stability. Strategic partnerships with raw material suppliers are vital for ensuring consistent quality and managing price fluctuations in critical inputs, such as silver.

Midstream activities involve the manufacturing process, where raw materials are converted into finished radiographic films and processing chemicals. This stage is complex, involving precision coating of emulsions, quality control, and packaging. Companies in this segment invest heavily in research and development to improve film characteristics, such as speed, contrast, and archival properties, and to innovate more environmentally friendly chemical formulations. Following manufacturing, products move through distribution channels, which can be direct or indirect. Direct channels involve manufacturers selling directly to large end-users, such as major hospital groups or large industrial NDT firms. This allows for greater control over sales and customer relationships, often accompanied by technical support and specialized training.

Indirect distribution channels involve a network of wholesalers, distributors, and resellers who bridge the gap between manufacturers and a fragmented customer base, including smaller clinics, independent NDT labs, and specialized veterinary practices. These intermediaries play a crucial role in market penetration, inventory management, and providing local support. Downstream analysis focuses on the end-users, who consume the film and chemicals for diagnostic or inspection purposes, often requiring supplementary equipment like X-ray machines, film processors, and darkroom accessories. The provision of comprehensive after-sales service, technical support, and disposal solutions also forms a critical part of the downstream value chain, ensuring customer satisfaction and repeat business in a market that relies on established workflows and high precision.

Radiographic Film Systems Market Potential Customers

The primary potential customers for Radiographic Film Systems are diverse and span across various industries requiring precise and verifiable imaging capabilities. In the medical sector, despite the widespread shift to digital, a significant customer base remains in smaller clinics, dental practices, and rural hospitals, particularly in developing regions, that prioritize cost-effectiveness and familiar workflows over significant capital investment in digital equipment. These entities often rely on existing film processors and find the archival quality of film to be a critical advantage for long-term patient records. Furthermore, specialized medical applications, such as certain forensic departments and research institutions, may continue to utilize film for its distinct imaging characteristics and historical compatibility, reinforcing its niche demand within healthcare.

Beyond healthcare, the industrial sector represents a robust and enduring customer segment. Non-Destructive Testing (NDT) companies are significant buyers, serving critical industries such as aerospace, oil and gas, shipbuilding, automotive, and power generation. These industries mandate high-resolution imaging for quality control, defect detection in welds, castings, and composite materials, where the superior detail and verifiable nature of radiographic film are often preferred or even legally required. Construction companies involved in large-scale infrastructure projects also form a considerable customer group, using film radiography to ensure structural integrity and compliance with safety standards. The reliance on established, highly regulated inspection protocols within these sectors ensures a steady demand for reliable film systems.

Additionally, other niche end-users contribute to the customer base, including veterinary hospitals and clinics that utilize film for animal diagnostics, particularly in areas where digital solutions are economically unfeasible or when working with specialized animal anatomies. Educational and research institutions also procure radiographic film systems for training purposes and specific scientific investigations that benefit from the tactile and archival aspects of film. Security agencies and customs departments, though often employing advanced digital methods, may still find use for film in certain screening applications or for specific analytical tasks. This broad spectrum of customers, from large industrial corporations to individual clinics, underscores the diversified demand landscape for radiographic film systems.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.2 billion |

| Market Forecast in 2033 | USD 1.8 billion |

| Growth Rate | 5.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Carestream Health, Fujifilm Corporation, AGFA-Gevaert N.V., Konica Minolta Inc., FOMA BOHEMIA spol. s r.o., Sino Medical-Device Technology Co., Ltd. (SINOMDT), Shanghai Lucky Film Co., Ltd., Macroscopics Inc., Sterling NDT, Trivitron Healthcare, Eastern Kodak Co., Teledyne ICM, M/s Universal X-ray, Rayence Inc., DIGIRAY. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Radiographic Film Systems Market Key Technology Landscape

The technology landscape for Radiographic Film Systems, while rooted in established principles, continues to evolve through subtle yet significant innovations aimed at improving performance, sustainability, and integration. Core technologies include the advancements in silver halide emulsion formulations, which are critical for determining film speed, contrast, and grain size. Manufacturers continuously refine these emulsions to offer films with higher sensitivity, allowing for reduced radiation exposure, or specialized contrast characteristics tailored for specific industrial or medical applications, enhancing defect detectability and diagnostic accuracy. The substrate materials, typically polyester, also see ongoing development to improve dimensional stability, flexibility, and archival properties, ensuring the longevity and integrity of the radiographic image over time.

Beyond the film itself, significant technological considerations lie in the processing chemicals and equipment. There is a strong trend towards developing more environmentally friendly processing solutions, including low-replenishment or non-toxic fixers and developers, to reduce ecological impact and improve workplace safety. Automatic film processors have been refined to offer more consistent results, faster processing times, and greater energy efficiency, optimizing workflow in high-volume environments. Innovations in film handling systems, such as daylight loading systems, also aim to streamline operations and minimize the need for traditional darkroom setups, making film radiography more accessible and efficient in various settings, including mobile NDT units.

Furthermore, the integration of digital technologies with film systems is a crucial aspect of the modern landscape. Film digitizers, which convert analog film images into digital format, represent a significant technological bridge. These devices employ high-resolution scanning technology to capture film images, allowing for digital archiving, transmission, and post-processing, thereby extending the utility of existing film archives and enabling hybrid workflows. The ongoing development of software platforms that manage these digitized images, often incorporating basic image enhancement and measurement tools, exemplifies the blend of traditional film capabilities with the advantages of digital data management, ensuring that film systems remain relevant in an increasingly digital world while preserving their unique benefits.

Regional Highlights

- North America: A mature market with stable demand from highly regulated aerospace, defense, and oil & gas NDT sectors. Medical film use has largely transitioned to digital, but niche applications and existing infrastructure support continued film usage. Strong emphasis on high-quality industrial film and advanced processing solutions.

- Europe: Similar to North America, significant demand from industrial NDT, particularly in Germany, UK, and France, driven by automotive, manufacturing, and energy industries. Strict regulatory compliance and the need for verifiable records underpin film's importance. Growing focus on sustainable film processing.

- Asia Pacific (APAC): The fastest-growing region, fueled by rapid industrialization, infrastructure development, and expanding healthcare access in countries like China, India, and Southeast Asia. Cost-effectiveness of film systems and increasing NDT activity contribute to robust demand. Emerging economies continue to be strong adopters due to lower initial investment.

- Latin America: Steady market growth, influenced by industrial development in countries like Brazil and Mexico. Film systems offer an affordable imaging solution for developing healthcare infrastructure and growing NDT requirements in oil & gas and mining sectors.

- Middle East and Africa (MEA): Emerging market with increasing adoption due to rising investments in oil & gas, construction, and healthcare. Film systems provide practical and economical solutions, especially in regions with nascent digital infrastructure. Demand is primarily driven by industrial inspection and basic medical diagnostics.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Radiographic Film Systems Market.- Carestream Health

- Fujifilm Corporation

- AGFA-Gevaert N.V.

- Konica Minolta Inc.

- FOMA BOHEMIA spol. s r.o.

- Sino Medical-Device Technology Co., Ltd. (SINOMDT)

- Shanghai Lucky Film Co., Ltd.

- Macroscopics Inc.

- Sterling NDT

- Trivitron Healthcare

- Eastern Kodak Co.

- Teledyne ICM

- M/s Universal X-ray

- Rayence Inc.

- DIGIRAY

Frequently Asked Questions

What is the projected growth rate for the Radiographic Film Systems Market?

The Radiographic Film Systems Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.5% between 2026 and 2033, driven by sustained industrial demand and niche medical applications.

How does AI impact the Radiographic Film Systems Market?

AI is primarily impacting the market by enhancing existing film-based workflows through improved image analysis, automated defect detection, and predictive maintenance for equipment, rather than direct replacement, also facilitating hybrid digital-film solutions.

What are the main applications of radiographic film systems?

Radiographic film systems are primarily used in Non-Destructive Testing (NDT) for industrial inspection, specialized medical diagnostics (e.g., dental, niche mammography), and forensic applications, valued for their high resolution and archival quality.

Which region shows the highest growth in the Radiographic Film Systems Market?

The Asia Pacific region is experiencing the highest growth, fueled by rapid industrialization, infrastructure development, and increasing healthcare access, where film systems offer a cost-effective imaging solution.

What are the key restraints affecting the Radiographic Film Systems Market?

Key restraints include the widespread adoption of digital radiography technologies, environmental concerns related to chemical processing and disposal, and the slower workflow compared to digital alternatives.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager