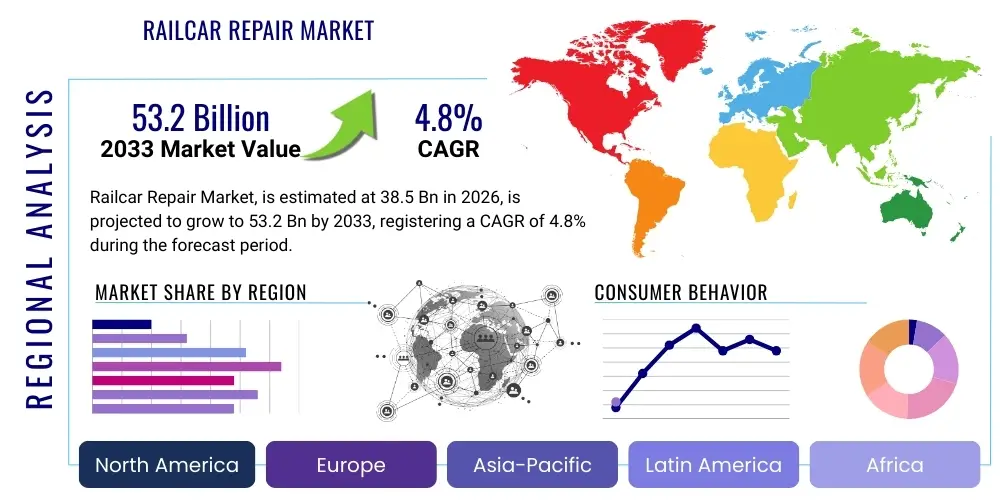

Railcar Repair Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439711 | Date : Jan, 2026 | Pages : 253 | Region : Global | Publisher : MRU

Railcar Repair Market Size

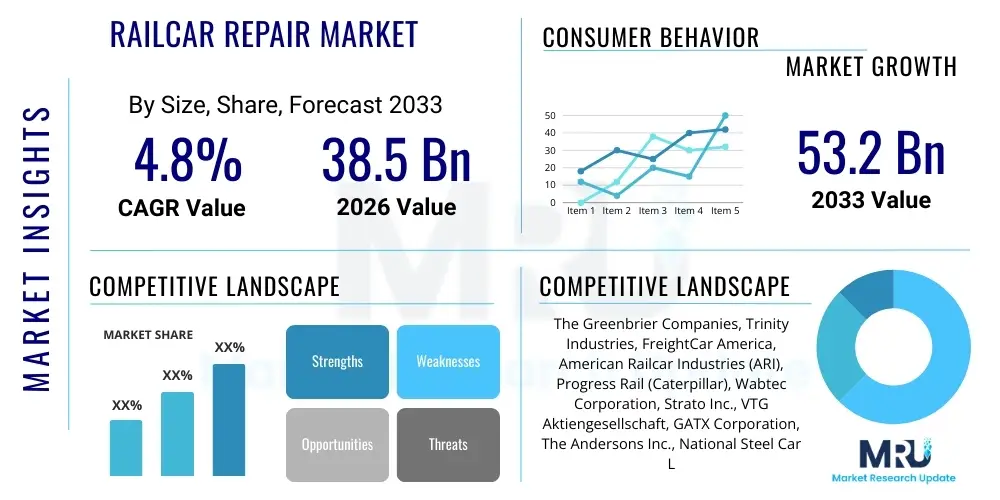

The Railcar Repair Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.8% between 2026 and 2033. The market is estimated at USD 38.5 billion in 2026 and is projected to reach USD 53.2 billion by the end of the forecast period in 2033.

Railcar Repair Market introduction

The Railcar Repair Market encompasses a vast array of services essential for maintaining the operational integrity, safety, and longevity of various types of railcars, including freight cars, passenger coaches, locomotives, and specialized industrial wagons. This critical industry ensures that rail transportation, a backbone of global logistics and mobility, remains efficient and reliable. Services range from routine maintenance, preventative inspections, and component overhauls to extensive accident repairs, refurbishment, and modernization efforts. The core product offered is the expertise and labor involved in these repair and maintenance activities, often complemented by the supply of spare parts and advanced diagnostic tools. Major applications span across freight transportation for commodities like coal, grain, chemicals, and automotive components, as well as passenger transport for commuter and intercity travel. Benefits derived from robust railcar repair services include enhanced operational safety, reduced downtime, extended asset lifespan, improved fuel efficiency, and compliance with stringent regulatory standards. Key driving factors propelling this market include the global expansion of rail networks, an aging fleet of railcars requiring continuous upkeep, increasing freight volumes necessitating higher fleet utilization, technological advancements in repair methodologies and diagnostics, and escalating regulatory mandates for safety and environmental performance. Additionally, the growing emphasis on sustainable transportation solutions further boosts the demand for well-maintained and energy-efficient railcars, underpinning the market's sustained growth trajectory. The industry is highly specialized, requiring specific certifications, skilled labor, and significant infrastructure investments, making it a pivotal segment within the broader railway ecosystem.

Railcar Repair Market Executive Summary

The Railcar Repair Market is experiencing robust expansion, driven by multifaceted business trends, evolving regional dynamics, and specialized segment growth. From a business trends perspective, the industry is witnessing a significant push towards digitalization, integrating predictive maintenance solutions, IoT sensors, and advanced data analytics to optimize repair schedules, minimize unscheduled downtime, and enhance operational efficiency. There is also a growing trend towards consolidation among service providers and manufacturers, aiming to offer integrated solutions and leverage economies of scale. Sustainability initiatives are increasingly influencing business decisions, leading to a greater focus on eco-friendly repair processes, energy-efficient components, and refurbishment programs that extend the lifespan of existing railcars rather than outright replacement. Supply chain resilience has become a paramount concern, prompting efforts to localize spare parts manufacturing and diversify supplier bases to mitigate disruptions. Regionally, North America and Europe remain mature markets characterized by stringent safety regulations and significant investments in modernizing aging infrastructure, driving demand for advanced repair services and technology adoption. Asia Pacific, particularly countries like China and India, represents a high-growth region due to extensive new rail network developments, increasing freight and passenger traffic, and corresponding demand for new fleet maintenance and repair. Latin America, the Middle East, and Africa are also emerging with substantial investment in railway infrastructure, creating burgeoning opportunities for repair and maintenance services, albeit with varying levels of technological sophistication and regulatory frameworks. Segment-wise, the market is seeing strong demand in freight railcar repairs due to surging e-commerce and industrial production, alongside a steady requirement for passenger railcar maintenance driven by urban transit expansion. Specialized services such as accident repair, component overhaul (especially for wheels, axles, and braking systems), and advanced diagnostics are showing particular growth. Furthermore, the increasing complexity of modern railcars, equipped with advanced electrical systems and digital controls, necessitates specialized technical expertise, further segmenting the repair market into niche areas of high value. The shift towards comprehensive service contracts and long-term maintenance agreements is also a notable trend across all segments, ensuring predictable revenue streams for service providers and enhanced asset reliability for operators.

AI Impact Analysis on Railcar Repair Market

Users frequently inquire about artificial intelligence's transformative potential in the Railcar Repair Market, focusing on how AI can enhance efficiency, reduce costs, and improve safety. Common questions revolve around the practical applications of AI in predictive maintenance, automated inspection, and optimized scheduling, alongside concerns regarding data privacy, job displacement, and the initial investment required for implementation. There is significant interest in understanding AI's role in diagnosing complex faults, extending component lifespans through smarter maintenance, and integrating seamlessly with existing infrastructure. Users expect AI to bring unprecedented levels of precision and foresight to repair operations, moving from reactive fixes to proactive asset management, thereby revolutionizing traditional repair paradigms. They seek clarity on the return on investment for AI technologies and the skill sets required for technicians in an AI-augmented environment.

- AI-powered predictive maintenance algorithms analyze sensor data from railcars to forecast potential component failures, enabling proactive repairs and minimizing unexpected downtime.

- Automated visual inspection systems, leveraging computer vision and machine learning, can rapidly detect minute defects on wheels, tracks, and car bodies, significantly improving inspection speed and accuracy.

- Optimized scheduling and resource allocation for repair workshops are enhanced by AI, balancing workload, technician availability, and spare parts inventory to maximize efficiency.

- AI-driven diagnostics assist technicians in quickly identifying root causes of complex malfunctions, reducing troubleshooting time and improving first-time fix rates.

- Robotics and AI collaborate in tasks such as welding, painting, and component handling, enhancing precision, safety, and speed in repetitive or hazardous repair processes.

DRO & Impact Forces Of Railcar Repair Market

The Railcar Repair Market is profoundly influenced by a complex interplay of drivers, restraints, opportunities, and broader impact forces that shape its growth trajectory and operational landscape. Key drivers propelling the market include the vast aging global railcar fleet, which consistently demands extensive maintenance, repair, and refurbishment services to remain operational and compliant with safety standards. The sustained growth in freight volumes worldwide, driven by e-commerce expansion and industrial production, necessitates higher utilization of existing railcar fleets, consequently increasing wear and tear and the need for frequent repairs. Stringent regulatory mandates imposed by national and international railway authorities for operational safety, environmental protection, and maintenance schedules compel operators to invest continuously in robust repair programs. Furthermore, technological advancements in railcar design and repair methodologies, such as modular components, advanced materials, and digital diagnostic tools, also drive demand for specialized repair services. Conversely, the market faces significant restraints, including the substantial capital investment required for modern repair facilities, specialized equipment, and advanced diagnostic technologies. A persistent shortage of skilled labor, particularly technicians with expertise in modern railcar systems and digital technologies, poses a considerable challenge, leading to higher labor costs and potential service delays. Economic downturns or geopolitical instability can adversely impact freight and passenger volumes, subsequently reducing demand for repair services as operators defer maintenance to cut costs. Opportunities abound within this dynamic market, primarily through the adoption of predictive maintenance solutions leveraging AI and IoT, which promise to revolutionize repair scheduling and reduce unplanned outages. The expanding global rail network, particularly in emerging economies, presents new markets for repair service providers. Furthermore, the increasing focus on sustainability and circular economy principles offers opportunities for advanced refurbishment and modernization services that extend the life of railcars and reduce waste. Impact forces such as rapid technological disruption, particularly in areas like additive manufacturing for spare parts or autonomous inspection systems, continue to reshape service delivery models. Evolving regulatory landscapes, especially concerning emissions and safety standards, demand constant adaptation from repair service providers. Supply chain resilience, highlighted by recent global events, is a critical impact force influencing the availability and cost of spare parts. Finally, environmental sustainability pressures are increasingly influencing investment decisions and driving innovation towards greener repair practices and more energy-efficient railcar maintenance, thereby compelling the industry to adapt and evolve continuously to meet both operational and societal demands.

Segmentation Analysis

The Railcar Repair Market is comprehensively segmented across various dimensions, including type, service, component, and end-user, to provide a granular understanding of its diverse landscape. Each segmentation highlights specific operational needs, technological requirements, and customer profiles, enabling market participants to tailor their offerings and strategies effectively. This multi-faceted approach to segmentation reflects the complexity of the rail industry, where specialized expertise is often required for different types of railcars, repair tasks, and component systems. Understanding these segments is crucial for identifying key growth areas, competitive advantages, and unmet market demands within the broader railcar repair ecosystem, supporting targeted business development and strategic resource allocation.

- By Type:

- Freight Railcar: Covers repairs for various cargo-carrying wagons.

- Passenger Railcar: Includes maintenance and repair for commuter, intercity, and high-speed passenger coaches.

- Tank Car: Specialized repairs for railcars transporting liquids, gases, and chemicals.

- Hopper Car: Services for open-top and covered hopper cars used for bulk commodities.

- Flat Car: Maintenance for flat deck railcars suitable for oversized or heavy loads.

- Gondola Car: Repairs for open-top railcars used for bulk materials like coal and ore.

- By Service:

- Component Repair & Overhaul: Focuses on specific parts like wheels, axles, and brakes.

- Accident Repair: Comprehensive repair services for damages resulting from accidents or derailments.

- Routine Maintenance: Scheduled inspections, lubrication, and minor adjustments.

- Refurbishment & Modernization: Upgrading older railcars with new technology, interiors, or structural improvements.

- Painting & Coating: Surface preparation, painting, and application of protective coatings.

- Inspection & Testing: Non-destructive testing, safety inspections, and performance testing.

- By Component:

- Wheels & Axles: Repair, reconditioning, and replacement of wheelsets.

- Brakes: Maintenance, repair, and overhaul of braking systems including air brakes and hand brakes.

- Couplers: Repair and replacement of coupling mechanisms.

- Undercarriage: Services for bogies, frames, and suspension systems.

- Body & Frame: Structural repairs, welding, and panel replacement.

- Interior Components: Repairs for seats, lighting, and other internal fittings in passenger cars.

- HVAC: Heating, ventilation, and air conditioning system maintenance in passenger cars.

- Electrical Systems: Diagnostics and repair of wiring, control panels, and electronic components.

- Bogies: Comprehensive overhaul and repair of bogie assemblies.

- Doors & Hatches: Repair and maintenance of access doors and loading hatches.

- By End-User:

- Freight Operators: Companies operating freight trains for logistics and cargo transport.

- Passenger Operators: Public and private entities running passenger rail services.

- Leasing Companies: Organizations that lease railcars to operators, responsible for maintenance.

- Industrial Customers: Companies owning private fleets for internal transport of raw materials or finished goods.

- Government & Public Sector: Government-owned railways or public transit authorities.

Value Chain Analysis For Railcar Repair Market

The value chain for the Railcar Repair Market is a sophisticated network of interconnected activities, beginning with the upstream supply of raw materials and specialized components, extending through the actual repair and maintenance processes, and culminating in the downstream distribution and end-use of the repaired railcars. Upstream analysis involves raw material suppliers providing steel, aluminum, composites, and various chemicals essential for fabrication and repair. Component manufacturers constitute a crucial upstream segment, supplying specialized parts such as wheels, axles, bogies, braking systems, couplers, and electronic control units, often requiring high precision and compliance with railway standards. These suppliers often engage in long-term contracts with repair service providers and railcar manufacturers. The midstream of the value chain is dominated by the repair service providers themselves, which include independent repair shops, original equipment manufacturers (OEMs) offering aftermarket services, and in-house maintenance divisions of large railway operators or leasing companies. These entities perform diagnostic, maintenance, overhaul, refurbishment, and accident repair services, employing skilled technicians and specialized equipment. Downstream analysis focuses on the entities that ultimately utilize these repair services and the repaired railcars. This primarily includes freight operators, passenger railway companies, railcar leasing firms, and industrial enterprises that own and operate private fleets. The efficiency and reliability of repair services directly impact the operational uptime and safety of these downstream users. Distribution channels for repair services are primarily direct, with railway operators and leasing companies contracting directly with repair facilities or OEMs. However, indirect channels also exist, particularly for the procurement of specialized spare parts, which might go through distributors or authorized resellers. The relationship between upstream suppliers, repair service providers, and downstream end-users is characterized by close collaboration, long-term agreements, and a strong emphasis on compliance, quality, and safety to ensure the continuous and reliable operation of the global rail network. This intricate chain highlights the interdependence of various stakeholders in maintaining the vital infrastructure of rail transport, emphasizing the importance of efficient logistics, skilled labor, and advanced technology throughout the process.

Railcar Repair Market Potential Customers

The potential customers for the Railcar Repair Market represent a diverse yet interconnected group of entities whose core operations rely heavily on the continuous availability, safety, and operational efficiency of their railcar fleets. At the forefront are Freight Operators, including major Class I railroads, regional freight carriers, and short line operators, which transport vast quantities of commodities ranging from agricultural products and coal to automotive parts and chemicals. These operators require regular maintenance, scheduled overhauls, and emergency repairs to ensure their cargo reaches its destination safely and on time, making them a primary customer segment. Similarly, Passenger Operators, encompassing national railway companies, urban transit authorities, and intercity passenger services, are crucial customers. Their demand for railcar repair is driven by the imperative to ensure passenger safety, comfort, and punctuality, leading to extensive requirements for routine maintenance, interior refurbishment, and complex system repairs for locomotives and passenger coaches. Railcar Leasing Companies form another significant customer base. These firms own substantial fleets of railcars that they lease to various freight and passenger operators, and as asset owners, they are responsible for the ongoing maintenance and repair of their rolling stock to preserve asset value and ensure lease compliance. Their focus is often on cost-effective and long-term maintenance solutions. Industrial Customers, such as large manufacturing plants, mines, refineries, and power generation facilities, often own and operate private railcar fleets for internal logistics, transporting raw materials or finished goods within their premises or to mainline connections. These customers have specific repair needs tailored to their specialized railcar types and operational environments. Finally, Government and Public Sector entities, particularly in countries where railway infrastructure and operations are state-owned or heavily regulated, also represent key potential customers. They often directly manage or contract for the repair of publicly owned rail assets, including both freight and passenger rolling stock, driven by national transportation policies and public service mandates. Each of these customer segments seeks reliability, compliance with safety regulations, cost-efficiency, and minimized downtime from railcar repair service providers, making a nuanced understanding of their specific needs vital for market engagement and growth.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 38.5 Billion |

| Market Forecast in 2033 | USD 53.2 Billion |

| Growth Rate | 4.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | The Greenbrier Companies, Trinity Industries, FreightCar America, American Railcar Industries (ARI), Progress Rail (Caterpillar), Wabtec Corporation, Strato Inc., VTG Aktiengesellschaft, GATX Corporation, The Andersons Inc., National Steel Car Limited, Marmon Holdings Inc. (Berkshire Hathaway), CAF (Construcciones y Auxiliar de Ferrocarriles), Siemens Mobility, CRRC Corporation Limited, Alstom, Stadler Rail AG, Hitachi Rail, Knorr-Bremse AG, United Railcar Repair. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Railcar Repair Market Key Technology Landscape

The Railcar Repair Market is increasingly shaped by a dynamic and evolving technology landscape, with innovations aimed at improving efficiency, safety, diagnostic accuracy, and overall operational reliability. Central to this transformation is the widespread adoption of Predictive Maintenance (PdM) technologies, leveraging Internet of Things (IoT) sensors installed on railcars to collect real-time data on component performance, temperature, vibration, and acoustic signatures. This data is then analyzed by advanced analytics and artificial intelligence (AI) algorithms to predict potential failures before they occur, enabling proactive scheduling of repairs and significantly reducing unscheduled downtime. Non-Destructive Testing (NDT) methods, including ultrasonic testing, eddy current testing, magnetic particle inspection, and radiographic inspection, are fundamental for assessing the structural integrity of railcar components without causing damage, ensuring safety compliance and extending asset life. Additive Manufacturing (3D Printing) is emerging as a disruptive technology, offering the potential to rapidly produce complex or obsolete spare parts on demand, reducing lead times, inventory costs, and reliance on traditional supply chains. Digital Twins, virtual replicas of physical railcars and their components, are being used for simulating performance, testing repair scenarios, and optimizing maintenance strategies in a risk-free environment. Advanced Robotics and Automation are increasingly deployed for repetitive or hazardous tasks such as welding, painting, sandblasting, and component handling, enhancing precision, speed, and worker safety. Augmented Reality (AR) and Virtual Reality (VR) technologies are finding applications in technician training, providing immersive experiences for complex repair procedures, and offering remote assistance where expert guidance can be overlaid onto the physical workspace. Furthermore, sophisticated Enterprise Asset Management (EAM) and Maintenance, Repair, and Overhaul (MRO) software systems are crucial for managing maintenance schedules, inventory, labor, and compliance across large fleets. These systems often integrate with financial and operational platforms to provide a holistic view of asset performance and repair costs. The integration of Big Data Analytics allows for deep insights into fleet performance trends, root cause analysis of failures, and optimization of maintenance strategies across entire networks. The continuous evolution of these technologies underscores the market's shift towards more data-driven, intelligent, and automated repair processes, demanding a highly skilled workforce and significant investment in digital infrastructure to remain competitive.

Regional Highlights

- North America: This region represents a mature and significant market, driven by extensive freight rail networks and stringent regulatory environments. The focus here is heavily on modernizing an aging fleet, implementing predictive maintenance technologies, and ensuring compliance with federal safety standards. Major Class I railroads and large leasing companies are key demand generators.

- Europe: Characterized by dense passenger rail networks, high-speed rail, and strong intermodal freight transport. The market is propelled by significant investments in railway infrastructure upgrades, decarbonization targets, and the integration of advanced digital technologies for maintenance. Germany, France, and the UK are prominent contributors to market demand.

- Asia Pacific (APAC): The fastest-growing region, fueled by massive investments in new railway construction, expansion of high-speed rail, and increasing freight and passenger volumes, particularly in China, India, and Southeast Asian countries. This region presents substantial opportunities for new repair facility development and technology transfer, though local market dynamics vary considerably.

- Latin America: An emerging market with growing investments in freight rail infrastructure, especially for commodity transport. The region seeks cost-effective repair solutions and is gradually adopting modern maintenance practices, though challenges persist in terms of infrastructure development and technological adoption consistency. Brazil, Mexico, and Argentina are key markets.

- Middle East and Africa (MEA): This region is witnessing considerable new railway project development as part of economic diversification strategies, particularly in the GCC countries and parts of Africa. This creates nascent but significant demand for railcar repair services, often relying on international expertise and technology transfer for advanced maintenance capabilities.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Railcar Repair Market.- The Greenbrier Companies

- Trinity Industries

- FreightCar America

- American Railcar Industries (ARI)

- Progress Rail (Caterpillar)

- Wabtec Corporation

- Strato Inc.

- VTG Aktiengesellschaft

- GATX Corporation

- The Andersons Inc.

- National Steel Car Limited

- Marmon Holdings Inc. (Berkshire Hathaway)

- CAF (Construcciones y Auxiliar de Ferrocarriles)

- Siemens Mobility

- CRRC Corporation Limited

- Alstom

- Stadler Rail AG

- Hitachi Rail

- Knorr-Bremse AG

- United Railcar Repair

Frequently Asked Questions

Analyze common user questions about the Railcar Repair market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the current growth outlook for the Railcar Repair Market?

The Railcar Repair Market is projected for robust growth, with an estimated Compound Annual Growth Rate (CAGR) of 4.8% between 2026 and 2033, driven by aging fleets, increasing freight volumes, and regulatory mandates for safety and efficiency. This growth trajectory indicates sustained demand for maintenance, refurbishment, and accident repair services across all railcar types.

How is technology impacting railcar repair services?

Technology is profoundly transforming railcar repair through the adoption of predictive maintenance using IoT and AI, advanced non-destructive testing, automated inspection systems, and digital twins for simulation. These innovations enhance diagnostic accuracy, reduce downtime, optimize repair schedules, and improve overall operational safety and efficiency, moving the industry towards more data-driven and proactive maintenance strategies.

Which regions are key contributors to the Railcar Repair Market?

North America and Europe are significant, mature markets characterized by extensive existing networks and high modernization demands. Asia Pacific, particularly China and India, represents the fastest-growing region due to new infrastructure development and expanding rail traffic. Latin America, the Middle East, and Africa are emerging markets with increasing investment in railway expansion, contributing to nascent but growing demand for repair services.

What are the main challenges faced by the railcar repair industry?

The primary challenges include high capital investment requirements for advanced facilities and technologies, a persistent shortage of skilled technicians with expertise in modern railcar systems, and the impact of economic fluctuations on freight volumes and maintenance budgets. Additionally, maintaining compliance with evolving stringent safety and environmental regulations adds complexity to repair operations.

Who are the primary end-users of railcar repair services?

The main end-users are freight operators (e.g., Class I railroads), passenger operators (e.g., urban transit and intercity railways), railcar leasing companies (responsible for leased asset maintenance), industrial customers (owning private fleets), and government entities or public sector organizations managing public rail assets. Each segment has distinct repair needs based on operational demands and regulatory obligations.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager