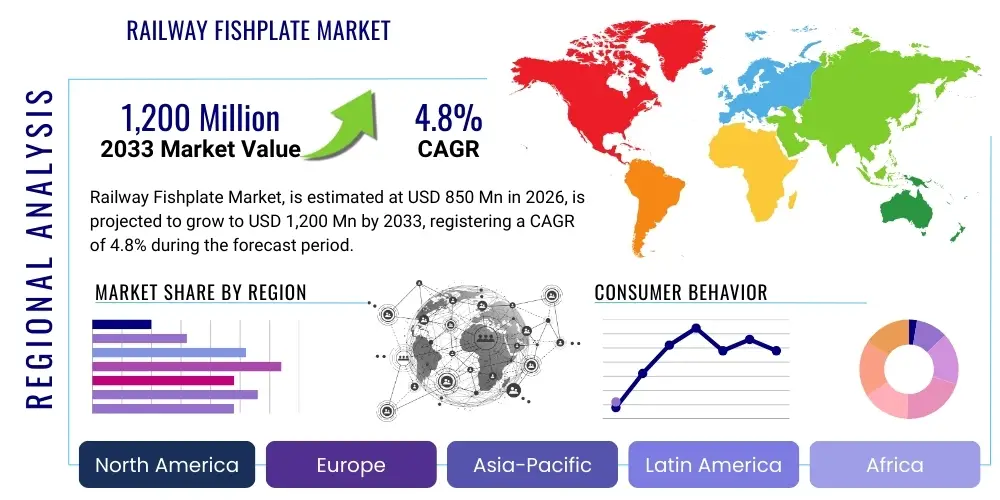

Railway Fishplate Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 438693 | Date : Dec, 2025 | Pages : 243 | Region : Global | Publisher : MRU

Railway Fishplate Market Size

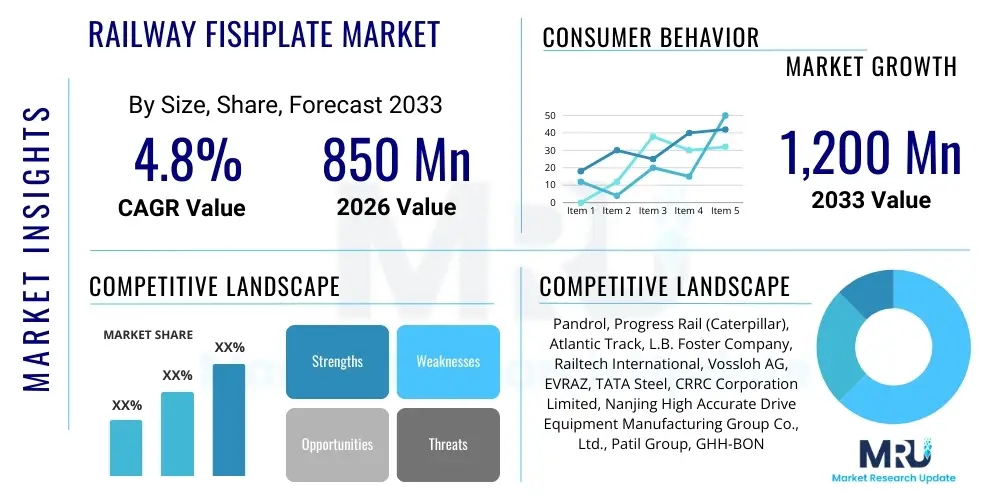

The Railway Fishplate Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.8% between 2026 and 2033. The market is estimated at USD 850 million in 2026 and is projected to reach USD 1,200 million by the end of the forecast period in 2033.

Railway Fishplate Market introduction

The Railway Fishplate Market encompasses the manufacturing, distribution, and utilization of critical components designed to join two rail ends together in railway tracks, ensuring continuity, stability, and safety. A fishplate, also known as a joint bar or splice bar, is essential for maintaining the alignment of rails both horizontally and vertically, minimizing movement under the extreme dynamic loads imposed by passing trains. These components are predominantly fabricated from robust materials such as high-carbon steel or alloy steel, engineered to withstand significant stress, fatigue, and environmental corrosion over decades of service. The reliability of fishplates directly influences track geometry, ride quality, and the prevention of catastrophic rail failures, making them indispensable elements in railway infrastructure globally.

Major applications of railway fishplates span the entire spectrum of railway operations, including high-speed passenger lines, heavy-haul freight corridors, and urban transit systems like metros and trams. In high-speed rail applications, precision-engineered fishplates are crucial, although welded track segments (Continuous Welded Rail - CWR) are preferred; fishplates remain vital for maintenance sections, temporary repairs, and insulated joints required for signaling systems. For conventional and heavy-haul tracks, fishplates bear immense longitudinal forces, necessitating rigorous material specifications and manufacturing standards to ensure prolonged operational life and minimized maintenance downtime. Their primary benefit lies in providing a cost-effective, durable, and relatively easy-to-install mechanical connection that facilitates track expansion and contraction due to temperature fluctuations.

Driving factors propelling the expansion of this market include massive global investments in railway infrastructure modernization, particularly in developing economies in Asia Pacific and Africa, where new rail networks are being established or upgraded. Furthermore, the increasing adoption of heavy-haul freight operations globally necessitates stronger, more durable fishplates capable of handling higher axle loads and greater tonnage. Strict regulatory requirements concerning rail safety and track integrity, compelling railway operators to regularly inspect and replace worn components, also contribute significantly to steady demand. The transition toward high-strength, lightweight alloy fishplates and the demand for specialized insulated joints for advanced signaling systems represent key market growth vectors.

Railway Fishplate Market Executive Summary

The Railway Fishplate Market is characterized by stable demand driven fundamentally by the non-negotiable need for rail safety and continuous global infrastructure development. Business trends show a strong shift towards specialized, high-performance fishplates, particularly compromise fishplates designed to join rails of different profiles or sizes, driven by the complexity of modern network upgrades. There is an emerging trend focusing on material innovation, utilizing advanced metallurgy like micro-alloyed steels and potentially composite inserts to enhance fatigue resistance and reduce maintenance frequency. Key players are investing in automated manufacturing processes to achieve tighter dimensional tolerances, essential for minimizing wear and tear in high-traffic sections. Pricing remains competitive, though specialized insulated and combination fishplates command a premium due to their technical complexity and integration requirements with signaling technology.

Regional trends indicate that the Asia Pacific region, led by China and India, dominates the market growth trajectory due to large-scale government investments in expanding both freight and high-speed passenger rail networks. North America and Europe, while possessing mature networks, present significant demand for maintenance and replacement parts, focusing heavily on specialized components like insulated fishplates and compromise joints required for interlocking zones and sidings. Regulatory environments in these mature markets impose high standards for material quality and traceability, favoring established manufacturers with robust certification processes. Infrastructure spending related to Belt and Road Initiative (BRI) projects also heavily influences demand dynamics across Central Asia and Africa, creating new avenues for manufacturers.

Segment trends reveal that the High Carbon Steel segment maintains the largest market share owing to its cost-effectiveness and proven durability in standard applications. However, the Alloy Steel segment is anticipated to witness the fastest growth rate, fueled by the rising adoption in heavy-haul and high-wear areas where superior mechanical properties are required. Application-wise, the heavy-haul segment exhibits the most rigorous specifications and highest component replacement frequency due to extreme stress environments. Urban Transit systems, while lower in volume, increasingly demand insulated fishplates for track circuit separation, aligning with the expansion of modern metro systems globally. The market structure remains moderately consolidated, with a few global giants dominating the production of standard plates, while specialized joint bars are often supplied by niche engineering firms.

AI Impact Analysis on Railway Fishplate Market

User inquiries regarding the impact of Artificial Intelligence (AI) on the Railway Fishplate Market primarily center on predictive maintenance, quality control during manufacturing, and optimized logistics for replacement schedules. Users frequently ask if AI can predict fishplate failures before traditional inspection methods identify them, how AI-driven vision systems can ensure zero-defect manufacturing, and whether machine learning algorithms can streamline the complex supply chain for rail components across diverse geographical locations. The key themes revolve around enhancing safety, reducing unexpected component failure rates, and optimizing the life cycle costs associated with track maintenance. Users express expectations that AI will transition fishplate management from a scheduled replacement model to a condition-based predictive model, significantly boosting operational efficiency and minimizing network downtime associated with manual inspections and emergency repairs.

- AI-powered predictive maintenance models analyze sensor data (vibration, strain, temperature) near fishplates to forecast fatigue cracking and potential failure points, enabling proactive replacement.

- Machine vision systems integrated into the manufacturing process utilize AI algorithms for automated, high-speed dimensional inspection, crack detection, and quality assurance of finished fishplates, minimizing product defects.

- Optimization of inventory and logistics relies on AI to predict regional demand based on rail traffic volume, climate data, and historical failure rates, ensuring timely supply of specific fishplate types.

- Digital twins of critical track sections use AI to simulate stress accumulation on fishplates under varying load conditions, guiding material selection and structural design improvements.

- AI-assisted drone or rail-mounted inspection systems automate visual examination of bolted joints, identifying loose bolts or surface corrosion far more efficiently than human inspectors.

- Natural Language Processing (NLP) is used to analyze vast archives of maintenance reports and accident data, extracting patterns related to fishplate performance failure mechanisms.

DRO & Impact Forces Of Railway Fishplate Market

The Railway Fishplate Market is shaped by a critical balance of infrastructure investment (Drivers), material longevity expectations (Restraints), modernization projects (Opportunities), and the stringent regulatory environment (Impact Forces). Major drivers include the necessity for constant maintenance and replacement in aging rail networks, coupled with ambitious global expansion projects, especially in emerging economies focused on high-capacity freight lines and metropolitan rapid transit systems. Restraints are primarily rooted in the long life cycle of fishplates, which limits repetitive sales, and the intense competition from Continuous Welded Rail (CWR) technology, which significantly reduces the need for standard fishplates except in specific maintenance sections or insulated joints. Opportunities arise from technological advancements, such as the development of lightweight, high-performance alloys and integrated monitoring systems that can be embedded into the joints. The impact forces are overwhelmingly driven by safety regulations and industry standards established by bodies like the Association of American Railroads (AAR) and national railway organizations, dictating stringent material testing and certification, thus raising the entry barrier for new manufacturers.

Key drivers center on addressing the global backlog of maintenance requirements for legacy tracks, particularly in North America and Europe, where environmental factors accelerate wear and tear. Furthermore, the global push towards heavier freight loads and faster passenger trains demands continuous upgrading to stronger materials, providing a sustained replacement market. Conversely, the market faces constraints due to the complexity and high cost associated with producing specialized fishplates (e.g., insulated joints), which require precision manufacturing and specialized non-conductive materials. Additionally, procurement processes in the railway sector are often lengthy and bureaucratic, presenting logistical hurdles for rapid market entry or product introduction.

Strategic opportunities are abundant in emerging markets where new tracks often involve joining different rail standards inherited from various international suppliers, driving demand for complex compromise fishplates. Furthermore, the integration of condition monitoring sensors directly into fishplates or associated fasteners opens up lucrative opportunities for specialized suppliers of smart components, moving beyond simple mechanical supply. Impact forces derived from geopolitical factors, such as trade wars affecting steel supply and fluctuating raw material costs, necessitate robust supply chain management. Ultimately, the dominant impact force remains the zero-tolerance policy for rail accidents globally, ensuring consistent regulatory pressure for quality enhancement and component durability, thereby stabilizing demand regardless of immediate economic volatility.

Segmentation Analysis

The Railway Fishplate Market is extensively segmented based on material composition, the type of joint configuration, and the specific application within the rail network. Segmentation by material is crucial as it dictates the mechanical properties, load-bearing capacity, and longevity of the product, with High Carbon Steel dominating volumetric sales due to its balance of strength and cost, while Alloy Steel addresses high-stress applications. Configuration segmentation differentiates between standard joints used for traditional tracks, compromise joints necessary for joining rails of varying sizes, and critical insulated joints required for signal integrity. Application segmentation provides insights into end-user demands, differentiating between the rigorous, high-axle-load requirements of heavy-haul freight and the high-frequency, precision needs of urban transit systems.

- By Type:

- Standard Fishplates (Used for joining rails of the same section)

- Compromise Fishplates (Used for connecting rails of different weights or profiles)

- Combination Fishplates (Often incorporating additional features or specific geometries)

- Insulated Fishplates (Crucial for maintaining electrical separation for signaling circuits)

- By Material:

- High Carbon Steel

- Alloy Steel (Manganese Steel, Chromium Steel)

- Composite Materials (Emerging segment for specialized applications)

- By Application:

- Heavy Haul Rail

- Passenger Rail (Standard and High-Speed)

- Urban Transit (Metro, Tram, Light Rail)

- Industrial Sidings and Mining Railways

- By Rail Weight/Size:

- Light Rail (e.g., up to 40 kg/m)

- Medium Rail (e.g., 40 kg/m to 60 kg/m)

- Heavy Rail (e.g., 60 kg/m and above)

Value Chain Analysis For Railway Fishplate Market

The value chain for the Railway Fishplate Market starts with upstream activities involving the sourcing and processing of raw steel, primarily high-grade carbon and alloy steels, which must adhere to stringent metallurgical specifications. Key upstream suppliers include major global steel producers who provide billets and profiles suitable for hot rolling or forging. The manufacturing stage is capital-intensive, involving precision forging, machining, drilling, and heat treatment to achieve the required hardness and fatigue resistance. Quality control is paramount at this stage, focusing on dimensional accuracy and material integrity, often requiring third-party verification to meet national railway standards. Specialized processes are required for insulated fishplates, involving the integration of non-conductive materials like epoxy or specialized plastics, adding complexity and cost.

The downstream component of the value chain is characterized by established, often long-term, relationships between manufacturers and railway operators, government procurement agencies, or large maintenance contractors. Distribution channels are predominantly direct, especially for large volume contracts or highly customized products like compromise joints, ensuring traceability and adherence to specific technical specifications. Indirect distribution, involving authorized dealers or specialized railway component distributors, serves smaller operators, industrial sidings, and emergency replacement needs. Logistics are critical due to the weight and size of the components, requiring efficient global supply chains capable of delivering large quantities of standardized parts or bespoke products quickly to remote track sites.

The distribution network relies heavily on certified engineering partners who not only supply the fishplates but often provide technical consultation on installation and maintenance best practices. Direct procurement ensures the manufacturer retains control over pricing and specifications, fostering collaborative development of new products suitable for advanced rail geometries or materials. Indirect channels, while offering speed and local inventory, must maintain strict quality controls to ensure authenticity and compliance. The overall structure emphasizes quality over cost, given the safety-critical nature of the component, cementing the position of manufacturers with strong track records and robust certification portfolios within the highly regulated railway ecosystem.

Railway Fishplate Market Potential Customers

Potential customers and end-users of railway fishplates are primarily large organizations responsible for the construction, maintenance, and operation of railway networks globally. The largest volume consumers are national railway authorities or state-owned enterprises (e.g., Indian Railways, China State Railway Group, Deutsche Bahn, SNCF), which manage extensive national grids requiring continuous component replacement due as part of routine track renewals and major repair works. Private heavy-haul operators, such as those in mining regions (e.g., Australia, Brazil) or bulk commodity transport sectors, constitute another critical customer segment, demanding ultra-durable, high-specification fishplates capable of enduring extremely high axle loads and frequent passage.

Urban transit authorities (metro and light rail operators) are significant buyers, with a specific focus on insulated fishplates for separating electrical track circuits necessary for signaling and safety systems in densely packed networks. Industrial companies with extensive private sidings, such as large ports, steel mills, and petrochemical complexes, also form a consistent, albeit smaller, customer base, typically procuring standard or lighter-weight plates. Furthermore, independent railway maintenance contractors and large engineering procurement and construction (EPC) firms involved in building new rail lines or modernizing existing ones serve as important intermediate buyers, integrating these components into broader infrastructure projects before handover to the operating entity.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 850 million |

| Market Forecast in 2033 | USD 1,200 million |

| Growth Rate | CAGR 4.8% |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Pandrol, Progress Rail (Caterpillar), Atlantic Track, L.B. Foster Company, Railtech International, Vossloh AG, EVRAZ, TATA Steel, CRRC Corporation Limited, Nanjing High Accurate Drive Equipment Manufacturing Group Co., Ltd., Patil Group, GHH-BONATRANS Group, Harsco Corporation, Amsted Rail, Saira Industrial |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Railway Fishplate Market Key Technology Landscape

The technology landscape in the Railway Fishplate Market is characterized less by revolutionary change and more by evolutionary improvements in material science, manufacturing precision, and integration capabilities. The fundamental manufacturing technology relies on hot rolling and precision forging processes, which are optimized for high-volume production while ensuring exceptional grain structure and mechanical homogeneity in the steel components. Advanced metallurgy, particularly the use of quenched and tempered alloy steels (such as high manganese or chromium alloys), is crucial for manufacturing fishplates that exhibit superior tensile strength, hardness, and resistance to impact and fatigue cracking, especially in heavy-haul environments where stress cycles are severe.

A significant technological advancement involves the development of insulated fishplates, which utilize high-strength fiber-reinforced polymers or specialized insulating epoxy materials inserted between the steel plates and the rail web. This technology is crucial for modern signaling systems that rely on track circuits for train detection and control. The primary technological challenge here is ensuring the insulating material maintains its dielectric strength and mechanical integrity under extreme dynamic loads, temperature fluctuations, and environmental exposure. Non-destructive testing techniques, including ultrasonic testing and magnetic particle inspection, are standard technological requirements to guarantee internal material quality and detect microscopic flaws before deployment.

Emerging technology centers on the integration of condition monitoring capabilities, leading to the concept of "Smart Fishplates." This involves embedding low-power sensors (e.g., strain gauges or accelerometers) directly into the rail joint assembly. These sensors collect data related to bolt tension, joint movement, and vibration patterns, transmitting this information wirelessly for real-time remote monitoring. This technology provides railway operators with predictive maintenance capabilities, moving away from time-based inspection schedules to condition-based assessments, significantly enhancing safety and operational uptime by identifying potential failures before they manifest externally. Furthermore, robotic welding techniques used for compromise joints (where applicable) ensure metallurgical compatibility and reduced thermal distortion.

Regional Highlights

- Asia Pacific (APAC): APAC is the dominant growth engine for the railway fishplate market, driven by extensive investment in high-speed rail networks (China, Japan) and massive modernization and expansion of conventional networks (India, Southeast Asia). Countries like China and India have immense domestic manufacturing capabilities but also represent the largest consumption markets globally due to rapidly increasing passenger and freight volumes. The focus is on establishing standardized rail connections and enhancing safety across newly built infrastructure.

- North America: This region is characterized by a mature, heavily freight-centric rail network, particularly focused on heavy-haul operations. Demand is primarily replacement-driven, with high specifications required for durability under extreme axle loads. The market often favors compromise fishplates due to the legacy presence of multiple different rail standards and high consumption of insulated fishplates for signaling system integration. Strict AAR standards govern material sourcing and component lifespan.

- Europe: European demand is sustained by frequent track maintenance and the extensive complexity of cross-border connections. There is a strong emphasis on precision-engineered components, particularly for high-speed lines, though fishplates are largely used for insulated joints and specific maintenance access points, as CWR is widespread. The region focuses heavily on technological advancements such as smart monitoring integration and adherence to European Union rail safety directives.

- Latin America (LATAM): Market growth is moderate but significant, centered around mining railways (e.g., Chile, Brazil) requiring robust, heavy-duty fishplates for iron ore and mineral transport. Investment is often tied to commodity prices. The region exhibits high variability in rail standards, driving demand for compromise fishplates and often relying on imported components from established global suppliers.

- Middle East and Africa (MEA): This is an emerging high-growth region, particularly the Middle East with massive new desert rail projects connecting ports and industrial centers (e.g., Saudi Arabia, UAE). Africa is seeing substantial infrastructural investment, often funded by international development banks or Chinese firms, leading to a strong initial demand for standard and heavy-duty fishplates for new track laying, prioritizing durability under harsh climate conditions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Railway Fishplate Market.- Pandrol

- Progress Rail (Caterpillar)

- Atlantic Track

- L.B. Foster Company

- Railtech International

- Vossloh AG

- EVRAZ

- TATA Steel

- CRRC Corporation Limited

- Nanjing High Accurate Drive Equipment Manufacturing Group Co., Ltd.

- Patil Group

- GHH-BONATRANS Group

- Harsco Corporation

- Amsted Rail

- Saira Industrial

- CRM Co. Ltd. (China Railway Materials)

- Hanson Group (The UK)

- Robel Bahnbaumaschinen GmbH

- Austrak Pty Ltd.

- Kawasaki Heavy Industries, Ltd.

Frequently Asked Questions

Analyze common user questions about the Railway Fishplate market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary function of a railway fishplate?

The primary function of a railway fishplate, or joint bar, is to mechanically join two ends of running rails, maintaining precise vertical and horizontal alignment while allowing for thermal expansion and contraction, which is critical for track stability and safe operation.

How does Continuous Welded Rail (CWR) technology impact the demand for fishplates?

CWR significantly reduces the overall demand for standard fishplates by replacing numerous bolted joints with continuous welds. However, demand persists for fishplates in essential applications like insulated joints for signaling systems, maintenance sections, and specialized compromise joints.

Which material is most commonly used for manufacturing standard railway fishplates?

High Carbon Steel (typically conforming to standards like AREMA or EN specifications) is the most commonly used material for standard fishplates due to its excellent tensile strength, durability, and cost-effectiveness for general-purpose rail joint applications.

What are 'Smart Fishplates' and how do they benefit railway operators?

Smart Fishplates integrate sensors (e.g., strain gauges) to monitor real-time parameters such as bolt tension and joint stress. They benefit operators by enabling predictive maintenance, reducing unexpected failures, minimizing track downtime, and improving overall operational safety and efficiency.

Why are insulated fishplates critical in modern railway infrastructure?

Insulated fishplates are critical because they use non-conductive materials to electrically separate adjacent rail sections. This separation is essential for track circuits, which are a fundamental component of automatic signaling and train detection systems, ensuring the safe movement and distance control of rolling stock.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager