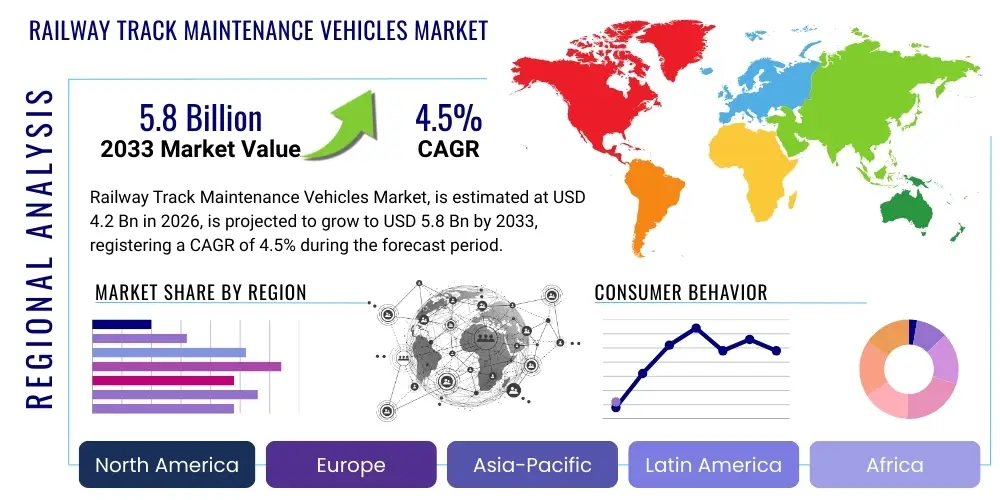

Railway Track Maintenance Vehicles Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 438737 | Date : Dec, 2025 | Pages : 249 | Region : Global | Publisher : MRU

Railway Track Maintenance Vehicles Market Size

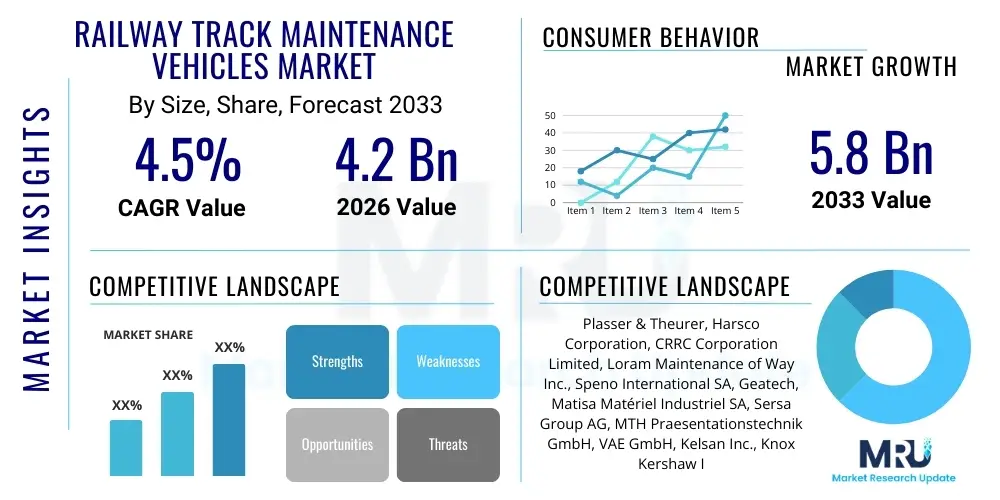

The Railway Track Maintenance Vehicles Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.5% between 2026 and 2033. The market is estimated at USD 4.2 Billion in 2026 and is projected to reach USD 5.8 Billion by the end of the forecast period in 2033.

Railway Track Maintenance Vehicles Market introduction

The Railway Track Maintenance Vehicles Market encompasses specialized machinery designed for the inspection, upkeep, repair, and renewal of railway infrastructure, ensuring safe and efficient rail operations globally. These vehicles are critical components in maintaining the structural integrity of tracks, ballast, sleepers, and overhead electrification systems. Products range from heavy-duty equipment like ballast tampers, track stabilizers, and rail grinding machines to lighter, multifunctional inspection trolleys and diagnostic vehicles. The primary applications span routine maintenance (e.g., tamping and leveling), preventative maintenance (e.g., ultrasonic testing), and large-scale reconstruction projects. The fundamental benefit of utilizing these specialized vehicles is the significant reduction in track possession time, enhancing operational efficiency, minimizing labor costs, and crucially, improving safety standards by automating hazardous tasks associated with manual track repair. Furthermore, the longevity of railway assets is directly linked to timely and effective maintenance facilitated by this specialized equipment.

Driving factors for this market are intrinsically tied to global infrastructure development and the increasing reliance on rail transport for both freight and passenger movement. Government mandates regarding rail safety and performance standards necessitate continuous investment in sophisticated maintenance fleets. The expansion of high-speed rail networks, particularly in Asia Pacific and Europe, demands precision maintenance technologies that conventional methods cannot provide. Additionally, the growing pressure on railway operators to reduce operational disruptions and maintenance-related slow orders fuels the demand for high-capacity, automated, and digitally integrated maintenance vehicles capable of rapid deployment and execution. The lifecycle cost reduction achieved through preventative maintenance regimes further accelerates market adoption.

Railway Track Maintenance Vehicles Market Executive Summary

The Railway Track Maintenance Vehicles Market is currently characterized by robust investment driven by governmental focus on infrastructure resilience and the proliferation of high-speed rail projects. Business trends indicate a strong shift towards automation, digitalization, and the development of multi-functional machines that can perform diverse tasks, thereby optimizing fleet utilization and reducing capital expenditure volatility. Key manufacturers are focusing heavily on developing vehicles compliant with stringent environmental standards, integrating hybrid or electric power systems to reduce carbon footprints, aligning with global sustainable transportation goals. This push for advanced, sustainable solutions is redefining competitive differentiation within the industry.

Segment trends reveal that the Tamping and Stabilizing segment dominates the market due to the constant need for ballast maintenance to ensure track stability under increasing axle loads and speeds. However, the diagnostic and inspection vehicle segment is projected to exhibit the fastest growth, propelled by the integration of advanced sensor technologies, LiDAR, and machine vision systems necessary for predictive maintenance strategies. Regional trends highlight the Asia Pacific (APAC) region as the primary growth engine, fueled by extensive new railway construction and modernization programs in India and China. Europe maintains a mature but steady market, focusing on replacement cycles and the adoption of high-precision measurement technologies, whereas North America emphasizes efficiency gains and larger, higher-output machines suited for long-distance heavy haul operations. The overall market trajectory indicates continued resilience against economic fluctuations due to the non-discretionary nature of rail safety maintenance.

AI Impact Analysis on Railway Track Maintenance Vehicles Market

User queries regarding the impact of Artificial Intelligence (AI) on the railway maintenance sector primarily revolve around how AI can enhance efficiency, reduce costs, and improve safety. Common themes include the feasibility of fully autonomous track maintenance operations, the reliability of AI-driven predictive failure detection systems, and the necessary cybersecurity measures required for digitally integrated maintenance fleets. Users are keenly interested in understanding how machine learning algorithms analyze complex sensor data (e.g., ground-penetrating radar, ultrasonic testing results) gathered by inspection vehicles to determine the optimal timing and location for repairs, moving the industry decisively from scheduled maintenance to condition-based, predictive maintenance models. Concerns often surface regarding the initial investment cost, data handling complexity, and the reskilling requirements for maintenance personnel.

AI's role transcends simple automation; it acts as a central decision-making layer. AI systems, coupled with high-fidelity sensors and Internet of Things (IoT) infrastructure integrated into maintenance vehicles, analyze massive datasets related to vehicle performance, track geometry deviations, rail wear, and historical failure patterns. This advanced analytics capability allows rail operators to prioritize maintenance tasks based on actual risk assessment rather than fixed time schedules, significantly extending the lifespan of track assets and minimizing operational disruptions. The integration of AI also drives the development of next-generation robotic maintenance vehicles capable of localized, precise intervention, further reducing human exposure to hazardous track environments.

- AI-driven Predictive Maintenance: Utilizing machine learning to forecast component failures and track degradation based on real-time sensor data, optimizing maintenance schedules.

- Autonomous Navigation and Operation: Enabling semi-autonomous or fully autonomous track maintenance vehicles, reducing reliance on human operators and increasing operational windows.

- Optimized Fleet Management: AI algorithms determine the most efficient deployment routes and resource allocation for maintenance fleets, reducing fuel consumption and operational delays.

- Enhanced Quality Control: Machine vision and deep learning systems analyze tamping quality, weld integrity, and rail profile measurements instantly, ensuring higher standards of repair work.

- Sensor Fusion and Data Processing: AI handles the integration and complex analysis of diverse data streams (LiDAR, ultrasonic, thermal imaging) collected by specialized inspection vehicles, identifying anomalies imperceptible to human eyes.

DRO & Impact Forces Of Railway Track Maintenance Vehicles Market

The Railway Track Maintenance Vehicles Market is significantly influenced by powerful internal and external forces. The primary drivers include massive government investment in modernizing aging rail infrastructure globally, particularly in developed economies, alongside the relentless expansion of new networks in rapidly industrializing nations. Restraints encompass the high initial capital expenditure required for purchasing and maintaining these highly specialized vehicles, coupled with the extended procurement cycles inherent in government and large rail operator purchasing processes. Opportunities are largely concentrated in the realms of digitalization, particularly in developing autonomous and multi-functional vehicles, and providing robust lifecycle maintenance services (MRO) to rail operators. These factors collectively determine the market's growth trajectory and adoption speed across various geographic regions.

Impact forces stemming from global regulation and technology mandate the direction of research and development. Regulatory pressure, especially concerning safety certifications and emissions standards (e.g., EU Stage V), compels manufacturers to innovate continuously, often increasing R&D costs but ultimately resulting in safer and greener equipment. The impact of digitalization is profound, transforming maintenance from a heavy engineering task into an integrated data management challenge. This shift elevates technology adoption as a major impact force, requiring substantial investment in software development, connectivity, and sensor technology, forcing traditional machinery manufacturers to evolve into holistic solution providers offering integrated hardware and software platforms.

Another crucial impact force relates to labor availability. As skilled labor shortages become prevalent in many regions, the pressure on rail operators to adopt highly automated and remotely operable vehicles intensifies. This necessity converts a potential restraint (high equipment cost) into a driver (labor cost avoidance and increased efficiency). Ultimately, the market dynamism is governed by the interplay between non-negotiable safety standards, the need for efficiency gains, and the capital intensity required for adopting advanced maintenance fleets.

Segmentation Analysis

The Railway Track Maintenance Vehicles Market is comprehensively segmented based on the type of equipment, the specific technology utilized for operation and control, and the critical application or function performed on the track structure. Understanding these segments is vital for manufacturers to tailor product development and for rail operators to optimize their fleet acquisitions. Segmentation by Type distinguishes between heavy-duty machines used for deep track renewal (e.g., ballast cleaners and rail cranes) and lighter equipment focused on routine inspection and minor repair (e.g., rail carts and geometry measuring vehicles). The functional segmentation reflects the core necessity of maintaining specific track components, such as ballast maintenance, rail grinding, or overhead equipment inspection, each requiring highly specialized machinery designed for precision and output efficiency. The technological segmentation focuses on the level of automation and power source, reflecting the industry's evolution toward sustainability and smart operations.

- By Type:

- Ballast Tampers

- Ballast Regulators/Profile Machines

- Rail Grinders

- Track Stabilizers/Dynamic Track Stabilizers (DTS)

- Sleeper/Tie Replacement Machines

- Rail Inspection Vehicles (e.g., Ultrasonic, Eddy Current)

- Special Purpose Vehicles (e.g., Welding Vehicles, Catenary Maintenance Vehicles)

- Cranes and Excavators (Rail-mounted)

- By Application/Function:

- Track Geometry Measurement and Inspection

- Ballast Cleaning and Maintenance

- Rail Head Renewal and Grinding

- Track Laying and Renewal

- Overhead Equipment (OHE) and Catenary Maintenance

- Vegetation Control

- By Technology/Power Source:

- Diesel Powered

- Electric/Hybrid Powered

- Autonomous/Semi-Autonomous Systems

- Conventional Track-Bound Systems

- Road-Rail Vehicles (RRVs)

Value Chain Analysis For Railway Track Maintenance Vehicles Market

The value chain for Railway Track Maintenance Vehicles is complex, beginning with highly specialized upstream suppliers and concluding with essential downstream maintenance services. Upstream analysis involves raw material suppliers (high-strength steel, specialized hydraulics, and electronic components) and key sub-system manufacturers (engines, transmission systems, advanced sensor packages, and specialized railway bogies). The performance and reliability of the final maintenance vehicle are heavily dependent on the quality and precision of these specialized inputs. OEMs often maintain long-term relationships with a select few critical component suppliers, ensuring technological synchronization and optimized supply chain management, particularly for proprietary software and control systems crucial for modern precision maintenance.

The midstream focuses on the Original Equipment Manufacturers (OEMs) responsible for design, engineering, assembly, and rigorous testing of the vehicles. This stage is capital-intensive and requires deep expertise in mechanical, electrical, and control engineering, adhering strictly to global rail safety and interoperability standards. Following manufacturing, the distribution channel is critical. Direct distribution predominates for large, specialized equipment, involving direct contracts between the OEM and major national railway operators (e.g., network rail infrastructure owners, national freight operators). This direct approach ensures specialized consultation, customized features, and comprehensive after-sales support, including operator training and spare parts logistics.

Indirect distribution plays a minor role, often limited to regional distributors or leasing companies that cater to smaller private track owners or industrial railway systems. Downstream activities involve fleet deployment, utilization monitoring (increasingly managed by OEM software platforms), and maintenance, repair, and overhaul (MRO) services. The provision of high-quality MRO, including spare parts availability and skilled technicians, is a significant profit center for OEMs and essential for maximizing the operational uptime of these costly assets, ensuring the continuous functionality of the global rail network.

Railway Track Maintenance Vehicles Market Potential Customers

The primary consumers and end-users of Railway Track Maintenance Vehicles are governmental entities, national rail infrastructure managers, and large private rail operators who possess and maintain extensive track networks. These customers require highly reliable, specialized equipment to manage the mandatory safety and operational standards dictated by national regulatory bodies. National railway companies, such as Deutsche Bahn (Germany), China Railway (China), Indian Railways (India), and Amtrak (USA), represent the largest segment of potential customers due to the sheer scale of their infrastructure maintenance needs and long-term investment cycles. Their purchasing decisions are often influenced by geopolitical priorities, national infrastructure budgets, and public safety mandates.

A growing segment of potential customers includes urban and metropolitan transit authorities, particularly those operating high-density subway, light rail, and tram networks. Although these networks are typically shorter, the maintenance requirements are frequent and precision-driven due to tighter operational windows and complex track geometries. These buyers often favor smaller, multi-functional Road-Rail Vehicles (RRVs) and advanced diagnostic equipment capable of operating efficiently in constrained urban environments. Furthermore, large industrial conglomerates and mining companies that operate extensive private railway systems for bulk commodity transport (e.g., iron ore, coal) represent a significant, though specialized, customer base, prioritizing heavy-haul capability and robust, durable equipment designed for extreme operating conditions.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 4.2 Billion |

| Market Forecast in 2033 | USD 5.8 Billion |

| Growth Rate | 4.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Plasser & Theurer, Harsco Corporation, CRRC Corporation Limited, Loram Maintenance of Way Inc., Speno International SA, Geatech, Matisa Matériel Industriel SA, Sersa Group AG, MTH Praesentationstechnik GmbH, VAE GmbH, Kelsan Inc., Knox Kershaw Inc., Nencki AG, Gemac Engineering, GOS Group, Zwiehoff GmbH, Nordco Inc., ROBEL Bahnbaumaschinen GmbH, SRS Rail System GmbH, Colmar Technik SpA |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Railway Track Maintenance Vehicles Market Key Technology Landscape

The technology landscape in the Railway Track Maintenance Vehicles market is rapidly evolving, driven by the need for higher precision, increased speed, and reduced environmental impact. Central to this evolution is the widespread adoption of high-accuracy measurement and diagnostic systems. These include advanced ultrasonic flaw detectors integrated into inspection vehicles to detect internal rail defects, sophisticated LiDAR and photogrammetry systems for precise track geometry mapping, and Ground Penetrating Radar (GPR) used to assess ballast condition and formation layer stability without requiring physical excavation. These technologies transition maintenance decisions from reactive to predictive, forming the foundation of smart rail maintenance systems. Manufacturers are leveraging these data collection capabilities to feed complex data models for automated analysis and repair planning.

Furthermore, there is a significant technological focus on automation and vehicle drive systems. Automation extends beyond control systems to include robotics for specialized tasks like rail welding and fastener tightening, improving consistency and reducing labor intensity. The shift toward sustainable rail operations is driving the development of electric and hybrid maintenance vehicles, particularly in urban areas and tunnels, addressing noise reduction and local air quality concerns. Road-Rail Vehicles (RRVs), equipped with specialized guidance systems, are also gaining traction, offering flexible deployment capabilities that significantly reduce response times for emergency repairs and maintenance activities in geographically diverse regions.

The future technology trajectory is defined by system integration and connectivity. Advanced Telematics and IoT platforms enable real-time communication between the maintenance fleet, central control centers, and cloud-based analytical software. This interconnected environment facilitates remote diagnostics, performance monitoring, and over-the-air software updates, dramatically enhancing the efficiency of the maintenance logistics chain. The use of robust, field-hardened computing platforms capable of handling real-time data processing is paramount, ensuring that complex algorithms for track analysis can be executed reliably even in challenging operational environments, paving the way for eventual fully autonomous track monitoring and maintenance corridors.

Regional Highlights

The global market for Railway Track Maintenance Vehicles demonstrates varied growth profiles and maturity levels across different regions, influenced by infrastructure investment cycles, technological adoption rates, and regulatory frameworks.

- Asia Pacific (APAC): APAC represents the fastest-growing region, primarily driven by massive government-led initiatives in China, India, and Southeast Asia focused on expanding high-speed rail networks and metro systems. The demand here is centered on acquiring large fleets of new, high-capacity machinery, often emphasizing localized manufacturing partnerships and technology transfer agreements. India's extensive railway modernization program, focused on improving safety and increasing line capacity, is a critical growth catalyst, driving demand for specialized ballast cleaning and track monitoring equipment.

- Europe: Europe holds a mature market characterized by stringent safety regulations and high technological standards. Growth is moderate, focusing mainly on replacement cycles, integrating advanced diagnostic technologies (AIVs), and transitioning towards environmentally friendly (electric/hybrid) vehicles to meet EU environmental directives. Countries like Germany, France, and the UK are leaders in adopting sophisticated predictive maintenance solutions and interoperable equipment designed for seamless cross-border operation.

- North America: The North American market, dominated by Class I freight railroads, prioritizes heavy-duty, high-output equipment designed for long-distance, heavy-haul lines. The emphasis is on maximizing track availability, leading to demand for fast, efficient rail grinding, tamping, and tie replacement machinery. Investment is tied closely to commodity demand and the need for infrastructure resilience against severe weather events. Technological adoption focuses on maximizing data analytics for preventative maintenance strategies.

- Latin America (LATAM): The market in LATAM is driven by localized projects, often involving commodity transport (mining, agriculture) and urban metro expansion. Demand is steady but sensitive to economic stability and infrastructure financing. Brazil and Mexico are key markets, requiring versatile equipment, including RRVs, to manage diverse geographical and track conditions.

- Middle East and Africa (MEA): This region is characterized by significant, often multi-billion-dollar, rail development projects (e.g., GCC rail network, modernization in South Africa). The market demands state-of-the-art, robust equipment capable of handling challenging environmental conditions (e.g., high heat and sand exposure), often relying on turnkey solutions provided by European and Asian OEMs.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Railway Track Maintenance Vehicles Market.- Plasser & Theurer

- Harsco Corporation

- CRRC Corporation Limited

- Loram Maintenance of Way Inc.

- Matisa Matériel Industriel SA

- Speno International SA

- ROBEL Bahnbaumaschinen GmbH

- Nordco Inc.

- Kelsan Inc.

- Knox Kershaw Inc.

- Vossloh AG (Rail Services division)

- Geatech

- GOS Group

- VAE GmbH

- Nencki AG

- Gemac Engineering

- SRS Rail System GmbH

- Zwiehoff GmbH

- Colmar Technik SpA

- MTH Praesentationstechnik GmbH

Frequently Asked Questions

Analyze common user questions about the Railway Track Maintenance Vehicles market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary factors driving the growth of the Railway Track Maintenance Vehicles Market?

Market growth is primarily driven by escalating global investment in railway infrastructure modernization, the expansion of high-speed rail networks demanding high-precision maintenance, and increasing governmental mandates for rail safety and operational efficiency, necessitating the adoption of specialized, automated maintenance fleets.

How does predictive maintenance technology impact the demand for maintenance vehicles?

Predictive maintenance systems, powered by AI and sophisticated sensors, increase demand for advanced diagnostic and inspection vehicles. While potentially reducing the frequency of heavy intervention, these systems simultaneously increase the necessity for high-precision, localized repair vehicles capable of executing targeted, condition-based maintenance identified by the AI platform, ultimately enhancing fleet efficiency.

Which segment of track maintenance vehicles is expected to witness the fastest technological adoption?

The Rail Inspection and Diagnostic Vehicles segment is expected to see the fastest technological adoption. This is due to the integration of advanced non-contact measurement technologies such as LiDAR, ultrasonic testing, and machine vision, coupled with real-time data processing capabilities required for effective condition monitoring and AI-driven analysis.

What is the current trend regarding the power source for new railway maintenance vehicle fleets?

There is a strong industry trend towards sustainable power sources, specifically electric and hybrid propulsion systems. This shift is driven by strict environmental regulations (e.g., emission controls) and the operational requirement for reduced noise and zero emissions, particularly when working within tunnels or densely populated urban areas.

Why is the Asia Pacific region dominating the market for Railway Track Maintenance Vehicles?

The Asia Pacific region dominates due to the unprecedented scale of new track laying and network expansion, especially high-speed rail projects in China and India, coupled with significant governmental budgetary allocations dedicated to modernizing existing, heavily utilized rail corridors and ensuring their long-term operational integrity.

The detailed analysis within this report underscores the robust future of the Railway Track Maintenance Vehicles Market, driven primarily by technological innovation and geopolitical investment in sustainable transit infrastructure. The shift towards autonomous and digitally integrated machinery is not merely an evolutionary step but a foundational restructuring of how rail networks are managed globally. This strategic transition ensures higher operational uptime, significant cost efficiencies, and, most importantly, unparalleled safety standards, positioning the market for sustained expansion throughout the forecast period. Manufacturers who invest heavily in data analytics and sensor fusion technologies will be best positioned to capture market share, particularly in rapidly developing regions like APAC and highly regulated markets in Europe. The non-negotiable nature of track safety ensures continuous demand, making this sector resilient to broader economic fluctuations, provided supply chain stability can be maintained for specialized components.

Future development is intrinsically linked to overcoming the restraints posed by high initial capital investment and the lengthy certification processes required by national rail operators. OEMs are responding by offering more flexible financing and leasing options, as well as integrated maintenance packages that guarantee specific performance outcomes. Furthermore, the convergence of AI, IoT, and heavy machinery necessitates substantial investment in cybersecurity measures to protect critical infrastructure data and operational control systems from potential external threats. This security layer is becoming an essential component of the product offering, differentiating advanced vendors from traditional machinery providers. The long-term success of rail operators globally hinges on their ability to efficiently deploy and utilize these sophisticated maintenance assets.

The ongoing push for standardization and interoperability across international rail networks, particularly within the EU, also influences vehicle design and technology adoption. Maintenance fleets must be capable of working efficiently across diverse signaling and track gauging systems, increasing the complexity of engineering requirements. This global trend favors large, international manufacturers with extensive research and development capabilities and established relationships with infrastructure managers worldwide. The ultimate market landscape will be characterized by highly specialized sub-segments, where technological superiority in diagnostics and robotic repair capabilities will define leadership, propelling the market toward increasingly sophisticated and data-driven maintenance regimes, fundamentally minimizing disruption and maximizing the lifespan of global rail assets.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager