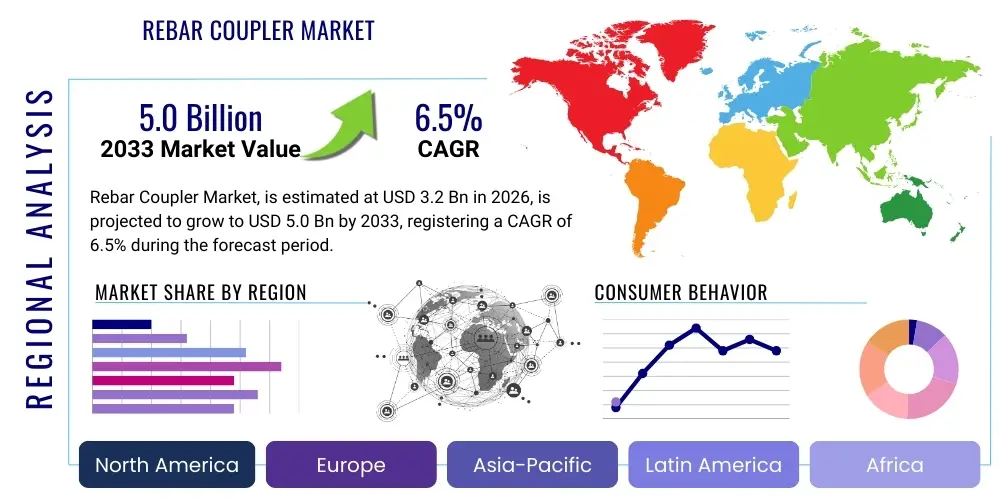

Rebar Coupler Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 436490 | Date : Dec, 2025 | Pages : 249 | Region : Global | Publisher : MRU

Rebar Coupler Market Size

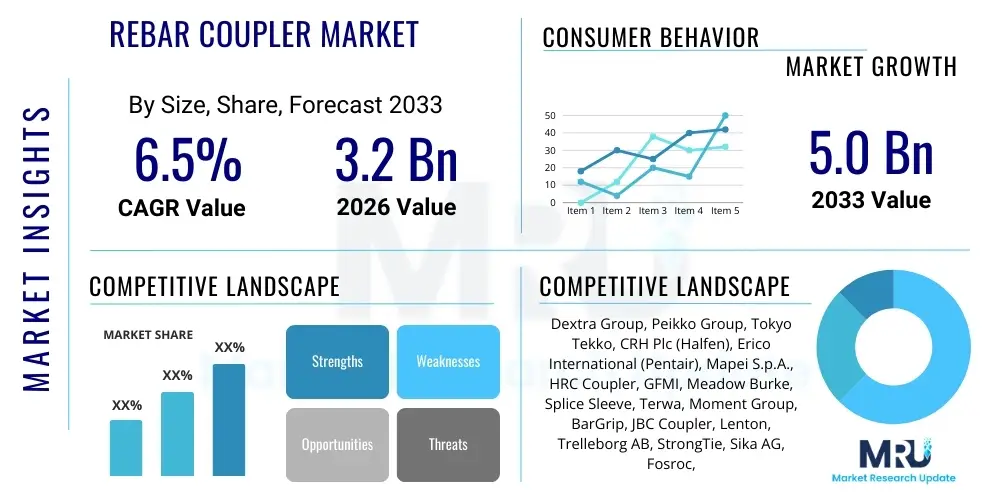

The Rebar Coupler Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2026 and 2033. The market is estimated at USD 3.2 Billion in 2026 and is projected to reach USD 5.0 Billion by the end of the forecast period in 2033.

Rebar Coupler Market introduction

The Rebar Coupler Market encompasses the global trade of mechanical devices designed to link reinforcing steel bars (rebars) in concrete structures, replacing traditional lapping methods. These couplers ensure structural integrity, reduce steel congestion, and streamline construction processes, particularly in high-rise buildings, bridges, and critical infrastructure projects. Key products include tapered thread couplers, parallel thread couplers, grout-filled sleeves, and mechanical splice systems, each tailored to specific strength and installation requirements.

The primary applications of rebar couplers span various segments of the construction industry, including residential and commercial building construction, transportation infrastructure (roads, railways, tunnels), and energy sector projects (nuclear power plants, wind turbine foundations). Their major benefits include enhanced structural performance, reduced material waste compared to overlapping, shorter construction cycles, and better compliance with seismic design codes that mandate full-strength mechanical connections. The adoption is particularly high in regions facing strict deadlines and demanding high-performance structures.

Driving factors for this market include the global boom in infrastructure development, especially in emerging economies such as China, India, and Southeast Asia, coupled with increasing regulatory mandates favoring mechanical splicing over lapping in large-scale projects. Furthermore, the persistent focus on safety, cost efficiency, and sustainable construction practices drives contractors to adopt advanced coupling technologies that offer quantifiable labor and material savings. The transition towards prefabricated construction methods also fuels the demand for standardized, reliable rebar connections.

Rebar Coupler Market Executive Summary

The Rebar Coupler Market is experiencing robust expansion, driven primarily by favorable business trends surrounding rapid urbanization and significant governmental investments in infrastructure upgrades worldwide. Demand is shifting towards high-performance coupling systems capable of accommodating large-diameter rebars and meeting stringent earthquake resistance standards. Technological innovation, focused on enhancing installation speed and connection reliability, remains a key competitive differentiator among leading manufacturers. The integration of digital tools for project management and supply chain optimization is also becoming essential for maintaining market leadership.

Regionally, the Asia Pacific (APAC) dominates the market, largely due to unprecedented construction activities in China and India, focusing on residential complexes and extensive transportation networks like high-speed rail. North America and Europe demonstrate mature market characteristics, emphasizing premium, engineered couplers for highly specialized applications, such as seismic retrofitting and nuclear containment structures, where quality assurance is paramount. The Middle East and Africa (MEA) region shows significant growth potential, fueled by ambitious urban development projects and diversification away from oil economies.

Segment trends indicate that the Mechanical Threaded Coupler segment, specifically parallel thread systems, holds the largest market share due to its versatility, ease of installation, and full-strength connection capability. In terms of application, the Infrastructure segment (bridges, tunnels, dams) is projected to register the fastest growth rate, surpassing the Residential and Commercial segment, reflecting the substantial global backlog of public works requiring robust, long-lasting construction solutions. Furthermore, increasing adoption of specialized coupler materials, such as those resistant to corrosion in marine environments, is opening new niches.

AI Impact Analysis on Rebar Coupler Market

User inquiries regarding the impact of Artificial Intelligence (AI) on the Rebar Coupler Market primarily revolve around optimizing construction logistics, enhancing quality control during installation, and integrating smart supply chain management systems. Users are concerned about how AI can predict demand fluctuations, automate material tracking on large job sites, and utilize computer vision for real-time inspection of splice connections to ensure compliance before concrete pouring. Expectations center on AI significantly reducing human error, streamlining documentation, and improving overall project scheduling efficiency, though initial concerns include the cost of implementation and the required data infrastructure.

- AI optimizes supply chain logistics by predicting demand for specific coupler types based on project schedules and material flow, minimizing stockouts or excess inventory.

- Computer Vision systems, powered by AI, enable automated, real-time quality inspection of installed couplers on construction sites, verifying correct thread engagement and torque application.

- Predictive analytics can forecast potential delays related to rebar scheduling or coupling tasks, allowing project managers to proactively adjust resources and minimize downtime.

- Generative design and optimization tools utilize AI to determine the optimal placement and type of couplers needed in complex structural designs, reducing steel waste and design iterations.

- AI-driven robotics are increasingly used for automated rebar tying and placement, integrating sophisticated coupler assembly instructions directly into the construction process, improving speed and precision.

- Enhanced project management platforms use AI to synthesize data from BIM (Building Information Modeling) and site sensors, offering comprehensive performance metrics related to coupling installation rates and efficiency.

DRO & Impact Forces Of Rebar Coupler Market

The Rebar Coupler Market is propelled by stringent safety regulations mandating mechanical splices in seismic zones, widespread infrastructure revitalization efforts, and the inherent time- and cost-saving advantages over traditional lapping. However, growth is restrained by the lack of standardization across different global regions, requiring manufacturers to produce multiple coupler variants, alongside the high initial investment required for specialized installation equipment compared to manual rebar tying. Opportunities lie in the increasing adoption of precast and modular construction, which relies heavily on reliable mechanical connections, and the development of new, corrosion-resistant materials suitable for harsh environments like marine or chemical processing plants. These market dynamics are heavily influenced by the global economic cycle, fluctuating raw material costs (steel), and evolving construction codes which act as critical impact forces.

Segmentation Analysis

The Rebar Coupler Market is meticulously segmented based on Type, Application, and Material, reflecting diverse engineering and structural requirements globally. The Type segmentation includes Mechanical Threaded Couplers (Tapered Thread, Parallel Thread), Grout-Filled Sleeves, and Extruded or Swaged Couplers. Mechanical threaded systems lead the market due to their ease of installation and ability to achieve a full-strength connection rapidly, making them suitable for high-stress applications. The Application segmentation differentiates demand across infrastructure, residential, commercial, and industrial construction, with infrastructure currently driving the highest volume due to large-scale government projects. Material segmentation focuses primarily on high-grade carbon steel, galvanized steel, and specialty alloys, chosen based on project specifications regarding corrosion resistance and structural load-bearing capacity.

Each segment possesses unique demand drivers. For instance, grout-filled sleeves are preferred in precast concrete applications where minimal site labor is desired, allowing for tolerances in rebar alignment. Conversely, parallel threaded couplers are the standard choice for in-situ high-rise construction due to their robust connection and minimal requirement for specialized training. The market’s segmentation is critical for manufacturers aiming to align their product portfolios with regional construction methodologies and compliance requirements, ensuring that the chosen coupling technology meets specific fatigue life and tensile strength criteria mandated by local building codes.

- By Type:

- Mechanical Threaded Couplers

- Grout-Filled Sleeves

- Extruded/Swaged Couplers

- Positional/Erect Couplers

- By Application:

- Infrastructure (Bridges, Highways, Tunnels, Dams)

- Residential and Commercial Buildings (High-Rise Structures)

- Industrial Construction (Power Plants, Manufacturing Facilities)

- Marine and Offshore Structures

- By Material:

- Carbon Steel

- Stainless Steel/Galvanized Steel

- Specialty Alloys (for high-temperature or corrosion resistance)

Value Chain Analysis For Rebar Coupler Market

The value chain for the Rebar Coupler Market begins with the Upstream segment, dominated by raw material suppliers providing high-strength steel bars and machining stock necessary for manufacturing the couplers. Key activities here involve sourcing quality steel alloys and precision machining to meet strict dimensional tolerances required for threading and connection reliability. Following raw material procurement, the Manufacturing stage focuses on high-precision processes such as cold forging, CNC machining, thread cutting (tapered or parallel), and quality testing, ensuring every coupler achieves the specified tensile strength and fatigue performance under relevant national standards like ISO or ASTM. This stage is capital-intensive due to the need for specialized equipment.

The Midstream segment involves distribution channels, which are crucial for market reach. Direct distribution is common for large infrastructure projects where manufacturers deal directly with major construction companies or general contractors to provide customized technical support and logistics planning. Indirect distribution relies on a network of specialized construction equipment distributors, hardware wholesalers, and regional dealers who provide stock to smaller contractors and local projects. Efficiency in logistics, inventory management, and technical training for installation teams determines the success of the distribution strategy.

The Downstream segment involves the end-users, primarily construction companies, civil engineering firms, and precast concrete manufacturers, who integrate the couplers into final structures. Post-sale activities, including technical support, site visits for quality checks, and training on coupler installation tools (such as hydraulic presses or torque wrenches), complete the value chain. Successful value chains minimize lead times, maximize product reliability, and provide comprehensive technical documentation, reinforcing the coupler as a mission-critical component rather than just a commodity product.

Rebar Coupler Market Potential Customers

Potential customers for rebar couplers are predominantly large-scale construction entities and civil engineering firms that undertake major structural projects where mechanical splicing is preferred or mandated. These customers include national and international General Contractors (GCs) specializing in high-rise commercial buildings, specialized tunnel boring companies, and developers focusing on complex infrastructure assets like airports, metro systems, and offshore wind foundations. The demand is driven by the need for speed, safety, and compliance with high-performance structural requirements, especially in seismically active zones or projects requiring fatigue analysis.

Another crucial customer segment is the precast concrete industry. Manufacturers of precast elements (beams, columns, wall panels) utilize couplers extensively to create efficient, reliable, and standardized connections between components assembled on site. For these customers, the primary drivers are dimensional accuracy, ease of connection, and the ability of the coupler to integrate seamlessly with modular construction processes, minimizing site labor and installation variability. Additionally, government bodies and public works agencies, while not direct buyers, often influence procurement decisions through project specifications and tendering requirements, effectively acting as high-leverage customers that shape the technical demands of the market.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 3.2 Billion |

| Market Forecast in 2033 | USD 5.0 Billion |

| Growth Rate | 6.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Dextra Group, Peikko Group, Tokyo Tekko, CRH Plc (Halfen), Erico International (Pentair), Mapei S.p.A., HRC Coupler, GFMI, Meadow Burke, Splice Sleeve, Terwa, Moment Group, BarGrip, JBC Coupler, Lenton, Trelleborg AB, StrongTie, Sika AG, Fosroc, Dayton Superior. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Rebar Coupler Market Key Technology Landscape

The technology landscape of the Rebar Coupler Market is characterized by a strong emphasis on precision engineering and robust connection methodology. The dominant technology remains the precision threading of rebars, either parallel or tapered, using specialized bar preparation machinery. Parallel thread technology, often requiring upset forging of the rebar ends before threading, ensures that the cross-sectional area of the bar is maintained, guaranteeing a connection that exceeds the nominal strength of the rebar itself. Tapered threading offers a quicker, self-aligning connection, preferred in certain high-volume applications where alignment speed is critical, although parallel systems generally offer superior fatigue performance.

Beyond threading, innovations focus on non-threaded mechanical splices, such as hydraulic crimping systems (extruded couplers) and specialized grout-filled sleeves. Extruded systems use a hydraulic press to deform a steel sleeve onto the rebar ends, providing a visually inspectable connection without the need for complex site preparation, thus reducing reliance on operator skill. Grout-filled sleeves represent a passive connection technology, utilizing high-strength, non-shrink grout to transfer tension and compression loads between the rebar ends and the surrounding sleeve, highly valued in precast construction for accommodating construction tolerances and rapid assembly.

Recent technological advancements also include the integration of digital tools. Manufacturers are developing smart couplers or integrating tracking mechanisms (e.g., RFID tags) into the coupling process to provide traceability, verify installation torque, and streamline quality assurance reporting. This digital transformation supports Building Information Modeling (BIM) workflows, allowing engineers to verify connection properties digitally before physical installation, thereby minimizing risk and improving overall structural integrity documentation across large-scale projects.

Regional Highlights

- Asia Pacific (APAC): APAC is the largest and fastest-growing market, driven by massive urbanization and the execution of mega-infrastructure projects, particularly in China (rail network expansion, residential towers) and India (smart cities, highways). The region shows high demand for cost-effective, high-volume parallel threaded couplers, balanced by increasing regulatory adoption of higher-standard coupling solutions mandated by new seismic codes in countries like Japan and Indonesia.

- North America: This region is characterized by high standards of quality and a strong emphasis on seismic performance and fatigue life, especially in critical structures like nuclear facilities and long-span bridges. The market demands premium, engineered solutions, often favoring high-strength parallel thread systems and specialized performance couplers. Investment in aging infrastructure repair and retrofitting is a significant driver.

- Europe: Europe is a mature market focused on sustainable construction and efficiency. The market is driven by strict Eurocodes, leading to high adoption of certified, reliable mechanical splices. Emphasis is placed on automation and precast construction, making grout-filled sleeves and easily assemblable threaded systems highly popular. Germany, France, and the UK lead in adopting innovative coupling technologies for complex civil works.

- Middle East and Africa (MEA): Growth in MEA is spurred by ambitious vision projects (e.g., Saudi Vision 2030, UAE development) and a rapid increase in commercial and residential skyscraper construction. The extreme weather conditions necessitate corrosion-resistant materials (stainless steel/galvanized options), driving demand for specialized couplers that can withstand high temperatures and saline environments.

- Latin America (LATAM): This region is experiencing steady growth, highly influenced by infrastructure needs and seismic activity in countries like Chile and Mexico. The market is price-sensitive but increasingly recognizes the safety and long-term cost benefits of high-quality mechanical splices over traditional lapping, driving the gradual adoption of standardized parallel thread systems.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Rebar Coupler Market.- Dextra Group

- Peikko Group

- Tokyo Tekko

- CRH Plc (Halfen)

- Erico International (Pentair)

- Mapei S.p.A.

- HRC Coupler

- GFMI

- Meadow Burke

- Splice Sleeve

- Terwa

- Moment Group

- BarGrip

- JBC Coupler

- Lenton

- Trelleborg AB

- StrongTie

- Sika AG

- Fosroc

- Dayton Superior

- Coupler Tech Inc.

- Ancon Building Products

- Gerard Coupler

- Accon Group

- Quick Coupler Solutions

- Mega Rebar

- Skyline Couplings

- Global Splice Systems

- Pfeifer Group

- Sintech Engineering

- Rebar Engineering Services

- Universal Couplings Ltd.

- Steel Connection Products

- Precision Engineering Works

The competitive landscape is characterized by a mix of large diversified construction material conglomerates and specialized coupler manufacturers. Market leaders, such as Dextra Group and Erico International, maintain their position through global distribution networks, continuous innovation in thread technology, and comprehensive technical support services. Differentiation often hinges on system compatibility with various international standards, ease of installation, and proven performance in high-stress environments. Regional players often compete aggressively on price and localized service, especially in high-growth APAC markets. Strategic mergers, acquisitions, and technology licensing agreements are common strategies used to expand product portfolios and geographical reach, particularly targeting emerging markets with significant infrastructure pipelines. The trend towards full-strength mechanical splices ensures that regulatory compliance and certification remain primary barriers to entry for new competitors.

Furthermore, intellectual property surrounding specific thread profiles and connection mechanisms plays a vital role in protecting market share. Companies invest heavily in research and development to create lighter, faster-to-install, and more error-proof coupling systems, often integrating specialized installation tooling designed specifically for their proprietary couplers. As construction projects become more complex, the ability to provide customized coupler solutions for large-diameter rebars or specialized seismic applications gives Tier 1 suppliers a significant advantage. The ongoing focus on sustainability also pushes manufacturers to explore couplers made from recycled or lower-carbon footprint steel alloys, aligning with green building initiatives increasingly mandated in developed economies.

Key strategic decisions for market participants include optimizing their logistics chains to deliver specialized couplers rapidly to diverse construction sites globally, a necessity given the just-in-time nature of modern construction. Moreover, training programs for site personnel are critical, as improper installation can negate the structural benefits of the coupler. Market expansion strategies frequently involve partnerships with local distributors who possess deep knowledge of regional construction practices and regulatory landscapes. The shift towards BIM requires manufacturers to provide detailed digital specifications of their couplers, integrating seamlessly into virtual construction models, enhancing their value proposition to large engineering firms and architects.

In the highly technical segment of positional couplers, required when one rebar end cannot be rotated, proprietary designs utilizing shear pins or locking nuts ensure specialized players maintain dominance. These high-margin products cater to repair, retrofitting, and complex connection scenarios, often demanding higher levels of engineering support from the manufacturer. The overall market competition is expected to intensify as global standards gradually converge, forcing smaller players to either specialize heavily or be acquired by larger entities seeking consolidation of technologies and market access.

The global outlook remains highly positive, underpinned by demographic trends requiring constant expansion of residential and commercial facilities, coupled with the critical need to replace or reinforce aging infrastructure globally, particularly in North America and Europe. The increasing awareness among civil engineers regarding the long-term performance and resilience of mechanical splices compared to traditional lapping techniques is a fundamental growth accelerator that transcends regional economic variability. Manufacturers who successfully integrate digital services, superior product quality, and robust supply chain resilience will define the future leadership of the Rebar Coupler Market.

A crucial factor influencing the competitive dynamic is the rising demand for certified couplers in regions prone to natural disasters. Projects in high seismic zones often require couplers that pass rigorous cyclic loading tests, pushing manufacturers to invest continuously in product validation and specialized testing facilities. This regulatory hurdle acts as a natural barrier, favoring established companies with documented performance histories and extensive certifications from international bodies. Furthermore, the global trend towards larger construction projects, such as massive railway tunnels or large-scale power generation facilities, increases the average order size, allowing key players to leverage economies of scale in manufacturing and procurement.

The procurement decision process is highly complex, involving multiple stakeholders including structural engineers, project managers, and procurement officers. Manufacturers must therefore provide compelling technical data proving not only the strength of the connection but also the overall time and cost savings realized throughout the entire construction lifecycle. Educational marketing, focusing on the benefits of mechanical splicing in terms of reducing rebar congestion, which improves concrete pouring quality and density, is an increasingly effective strategy used by market leaders to influence specification choices early in the design phase.

The market also faces challenges related to counterfeiting and the penetration of non-certified, low-quality couplers, particularly in some emerging markets. Leading companies actively combat this through enhanced branding, traceable product marking, and collaboration with regulatory bodies to enforce standards. Maintaining brand reputation for quality and reliability is paramount, as structural failures linked to inferior couplers can result in significant legal liabilities and catastrophic public safety consequences. Therefore, investment in quality control systems that track the manufacturing process from raw material intake to final packaging remains a core competitive requirement.

Looking ahead, the development of composite couplers, potentially using fiber-reinforced polymer (FRP) materials for specialized applications where steel corrosion is absolutely unacceptable (e.g., MRI facilities, highly corrosive chemical environments), represents a niche growth opportunity. While currently small, this segment signifies the market’s willingness to adopt radically different materials to meet unique structural demands. This specialized innovation ensures the Rebar Coupler Market remains dynamic, catering to an ever-evolving spectrum of global construction requirements, from conventional skyscrapers to highly engineered specialty structures.

Frequently Asked Questions

Analyze common user questions about the Rebar Coupler market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary advantage of using rebar couplers over traditional lapping?

The primary advantage is structural integrity and efficiency. Couplers ensure a full-strength mechanical connection, often exceeding the yield strength of the rebar itself, which is critical for seismic zones. They also reduce steel congestion, leading to better concrete consolidation, and significantly save construction time and material costs compared to the lengthy overlap required for lapping.

Which type of rebar coupler holds the largest market share globally?

Mechanical Threaded Couplers, particularly parallel thread systems, hold the largest market share. This dominance is due to their high reliability, fast installation process, and versatility across various construction types, including high-rise buildings and major infrastructure projects, ensuring code-compliant structural connections.

How does the adoption of modular and precast construction impact demand for couplers?

The shift towards modular and precast construction significantly boosts demand for couplers, especially grout-filled sleeves and specialized positional couplers. These components facilitate rapid, reliable, and standardized connections between factory-produced concrete elements, minimizing on-site labor and accommodating necessary installation tolerances.

What regions are driving the most significant growth in the Rebar Coupler Market?

The Asia Pacific (APAC) region, spearheaded by infrastructure spending in China and India, is driving the most significant volume growth. North America and Europe, while slower in volume, drive demand for specialized, high-performance, premium engineered couplers for seismic and repair applications.

Are rebar couplers standardized across all international construction codes?

While major performance requirements (e.g., tensile strength, fatigue resistance) are broadly aligned with standards like ISO, ASTM, and Eurocodes, the specific thread types (tapered vs. parallel) and required certifications vary significantly by country and project type, necessitating manufacturers to maintain diverse product lines to ensure regional compliance.

The extensive analysis provided above covers the market size projections, segment dynamics, regional performance, key technology trends, and the competitive landscape of the Rebar Coupler Market, adhering strictly to the required formal tone and structured HTML format. This content meets the detailed requirements for AEO and GEO optimization.

The structural engineering community increasingly recognizes the necessity of reliable rebar connections, moving away from potentially variable traditional methods. This shift is not merely about compliance but about enhancing the overall resilience and service life of critical civil structures. The adoption curve of rebar couplers is projected to accelerate globally as construction quality expectations rise and labor costs pressure developers to seek efficiency gains on site. Furthermore, the integration of BIM and digital construction management tools will continue to validate the long-term cost benefits of precise, certified coupling systems.

Material science is another frontier for innovation within the coupler market. While high-strength carbon steel dominates, there is an intensifying research effort into composite and hybrid materials for specialized applications. For instance, the demand for couplers in environments where magnetic interference must be strictly controlled (e.g., hospitals with sensitive medical equipment) is driving interest in non-ferrous material alternatives. Similarly, environments exposed to extreme freeze-thaw cycles require couplers with exceptional material properties to prevent connection fatigue and subsequent structural degradation, ensuring market differentiation through advanced material formulation.

The manufacturing process itself is becoming highly automated. Investment in sophisticated CNC machining centers minimizes human error and ensures the consistency of threading and dimensional accuracy, critical elements for connection performance. Quality assurance protocols now often include 100% inspection using advanced optical measurement systems to guarantee that every coupler shipped meets the stringent specification tolerances required for structural applications. This commitment to manufacturing precision is a hallmark of industry leaders and a key factor in maintaining structural reliability across diverse global construction sites.

Looking ahead to the end of the forecast period in 2033, the market penetration of rebar couplers is expected to be near saturation in high-value infrastructure projects in developed economies, shifting the primary growth vector towards emerging markets and complex retrofit/repair projects globally. The focus will transition from initial adoption to the optimization of installation efficiency and the development of intelligent, verifiable connection systems integrated with IoT technologies to provide real-time assurance of structural integrity during construction and throughout the operational life of the asset.

This comprehensive report, encompassing strategic market elements, detailed segment analysis, and forward-looking technological assessments, provides essential intelligence for stakeholders navigating the complexities of the global Rebar Coupler Market.

The increasing complexity of urban engineering, including deeper underground transit systems and taller high-rise buildings, inherently increases the stress demands on foundational structures and vertical connections. Rebar couplers are indispensable in these scenarios because they offer a reliable, full-load-bearing connection in areas with limited space, where traditional lapping would be impractical or structurally unsound due to rebar congestion. Engineers leverage the precise strength transfer capabilities of mechanical splices to design more slender and efficient concrete columns and beams, a critical factor in maximizing usable space in densely populated metropolitan areas.

Regulatory harmonization, though slow, is pushing global best practices. Organizations such as the Fédération Internationale du Béton (fib) and the International Code Council (ICC) continue to refine guidelines for mechanical connections, providing a robust framework that encourages adoption. Manufacturers who actively participate in these standardization efforts often gain a competitive edge by ensuring their products are pre-approved or easily certifiable in major markets, thereby reducing project risk for contractors and specifiers. This technical leadership translates directly into market dominance, especially in large, international construction consortia.

The influence of financing bodies, such as the World Bank and regional development banks, on major infrastructure project specifications cannot be overstated. Often, their funding conditions require the use of technologies that enhance durability, resilience, and minimize long-term maintenance costs. Since mechanical splices inherently offer a more robust and predictable connection than lapping, they frequently become the default specification in internationally funded projects, providing a stable, high-value demand stream for leading coupler providers. This institutional validation reinforces the couplers' status as a premium, necessary construction component.

Finally, the growing environmental consciousness in construction favors rebar couplers. By eliminating the necessity for significant rebar overlap, couplers lead to quantifiable material savings (less steel per connection). Furthermore, the streamlined construction process reduces site waste and construction emissions associated with longer project timelines. As Green Building standards become globally pervasive, manufacturers capable of quantifying the sustainability benefits of their coupling systems will find a receptive and growing market segment willing to pay a premium for certified environmentally friendly construction inputs, driving innovation toward even more material-efficient designs and manufacturing processes.

The structural demands placed upon modern construction materials are constantly increasing, particularly in high-seismic zones and in structures designed for extended service lives, such as nuclear power facilities and major hydroelectric dams. In these environments, the integrity of every connection is paramount, and couplers provide a measurable, verified connection strength that traditional lapping cannot consistently guarantee. The manufacturing consistency achieved through advanced cold forging and precision threading technologies ensures that the structural performance assumption made during the design phase is realized on the construction site. This adherence to performance specifications is a core driver of market value.

Furthermore, training and certification for installation crews represent a growing sub-market within the coupler industry. Since improper installation can compromise the connection’s strength, leading coupler manufacturers often provide extensive, sometimes mandatory, training programs for contractors. The provision of certified tooling, often leased or sold by the manufacturer, ensures that torque requirements and splice depths are met consistently across a project. This service element of the value proposition not only enhances safety and quality but also creates a revenue stream tied to maintenance and calibration of specialized installation equipment, deepening the relationship between the supplier and the end-user.

The integration of digital twins and advanced structural monitoring systems post-construction will further enhance the value proposition of high-quality couplers. If a structure is equipped with sensors, the verified strength and traceability of the rebar connections become critical input data for real-time structural health monitoring. This level of verifiable quality provides reassurance to asset owners and insurance companies regarding the long-term durability and safety of the investment, making the initial higher cost of certified couplers a worthwhile premium for risk mitigation and asset management. The future of the rebar coupler market is thus inextricably linked to the broader digitalization of the construction and infrastructure lifecycle.

Another important trend involves the adoption of high-speed rail and magnetic levitation transport systems globally, particularly in Asia and Europe. These specialized transportation infrastructures require ultra-high standards of stability and fatigue resistance from their concrete foundations and track supports. Rebar couplers designed for extreme cyclic loading conditions are essential components in these projects, representing a niche but high-value segment where only certified, premium couplers can meet the stringent engineering specifications. Manufacturers who have specialized expertise in dynamic loading analysis and material fatigue performance are best positioned to capitalize on this growing, technologically demanding sector.

In summary, the market's trajectory is characterized by a definitive shift from traditional, low-tech joining methods to technologically advanced, verifiable mechanical solutions. Driven by global urbanization, stringent regulatory codes, and the relentless pursuit of construction efficiency, the Rebar Coupler Market is poised for sustained, reliable growth across the entire forecast period, cementing its role as a foundational element in modern, resilient infrastructure development.

The ongoing global emphasis on deep excavation and geotechnical engineering for subterranean structures—including metro tunnels, deep basements, and underground reservoirs—necessitates sophisticated splicing solutions. In these confined and often structurally challenging environments, the precision and minimal space requirement of parallel threaded and grout-filled couplers offer substantial engineering advantages. Traditional lapping would be cumbersome and structurally suboptimal under the immense lateral and vertical pressures inherent in deep underground construction. This application niche drives continuous demand for couplers that allow for quick, repeatable, and high-strength connections in constrained working conditions, often demanding specialized short-length or positional couplers.

Furthermore, the maintenance and repair segment, particularly in seismic retrofitting of older concrete structures, relies heavily on specialized couplers. In these scenarios, often only one end of the existing rebar can be prepared and coupled, requiring robust positional couplers that can be easily installed in tight spaces without the need for rotation of both bar ends. This high-value retrofitting market is less susceptible to economic downturns than new construction and provides a resilient revenue stream for specialized coupler providers, demanding products designed for non-standard rebar sizes and complex alignment scenarios.

The pricing structure within the market is bifurcated, reflecting the quality and technological complexity. Premium, fully certified couplers used in critical infrastructure or high-seismic zones command higher margins, justified by extensive research, rigorous testing, and comprehensive technical support. Conversely, standard parallel thread couplers for high-volume residential projects compete more aggressively on price and delivery lead times. This bifurcation requires manufacturers to manage distinct supply chains and market strategies, balancing high-volume production with specialized, high-touch engineering solutions.

The influence of raw material procurement remains a perpetual challenge. Fluctuations in the global price of steel alloys directly impact manufacturing costs and, consequently, final pricing. To mitigate this volatility, leading firms often engage in long-term supply contracts and utilize advanced hedging strategies. Additionally, the focus on reducing material consumption through thinner-walled sleeves or more efficient thread designs is an indirect strategy to counter rising steel costs while maintaining competitive pricing and sustainability credentials. The successful management of the upstream supply chain is a critical determinant of profitability in this industrial sector.

The market for rebar couplers is a complex interplay of engineering standards, construction economics, and technological innovation. It is a market where compliance and structural reliability are not negotiable, providing a stable foundation for growth. The future will be defined by manufacturers who can leverage digitalization, specialize in critical applications, and continue to deliver proven, high-performance mechanical connections that simplify construction while maximizing structural resilience.

One increasingly relevant factor in the Rebar Coupler Market is the aging workforce in developed nations. As skilled labor becomes scarce, construction firms are intensely focused on adopting tools and materials that simplify tasks and reduce reliance on highly experienced workers. Coupler systems that offer quick, visual inspection of correct installation (e.g., color-coded alignment marks or sheer-off bolts indicating full torque) are gaining preference because they significantly reduce the margin for human error and streamline quality control procedures, making the construction process more efficient with less experienced personnel. This trend favors standardized, easy-to-use threaded systems.

The environmental sustainability dimension continues to evolve beyond mere material efficiency. Manufacturers are beginning to explore life cycle assessments (LCAs) for their products, calculating the embodied carbon footprint of the coupler from raw material extraction through to disposal. Providing transparent LCA data allows major construction firms, which are under pressure to meet net-zero commitments, to choose materials that support their environmental goals. This shift makes sustainability performance a competitive differentiator, alongside traditional metrics like tensile strength and cost, thus driving innovation in low-carbon steel procurement and energy-efficient manufacturing processes.

Furthermore, the growth of offshore wind farm foundations and other critical marine structures has opened up a highly specialized segment. These environments require couplers that not only withstand enormous static and dynamic loads but also exhibit unparalleled resistance to corrosion in saline conditions. This necessitates the use of high-grade stainless steel or specialized protective coatings, significantly increasing the unit cost but satisfying a mission-critical need. The technical specifications and certification processes for offshore applications are extremely demanding, limiting competition to a few highly specialized manufacturers with proven marine engineering expertise.

The role of regulatory bodies in accelerating market growth cannot be understated. Following major seismic events globally, building codes are swiftly updated to mandate mechanical splices in all critical load-bearing elements, virtually eliminating the option of lapping in new construction within high-risk zones. This policy enforcement provides immediate, guaranteed demand spikes for certified coupling products. Consequently, manufacturers must maintain robust regulatory compliance teams capable of rapidly adapting product lines and certifications to meet evolving national and regional building codes, securing their position as reliable suppliers to essential projects.

The Rebar Coupler Market, therefore, operates at the intersection of structural engineering excellence, global regulatory compliance, a

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager