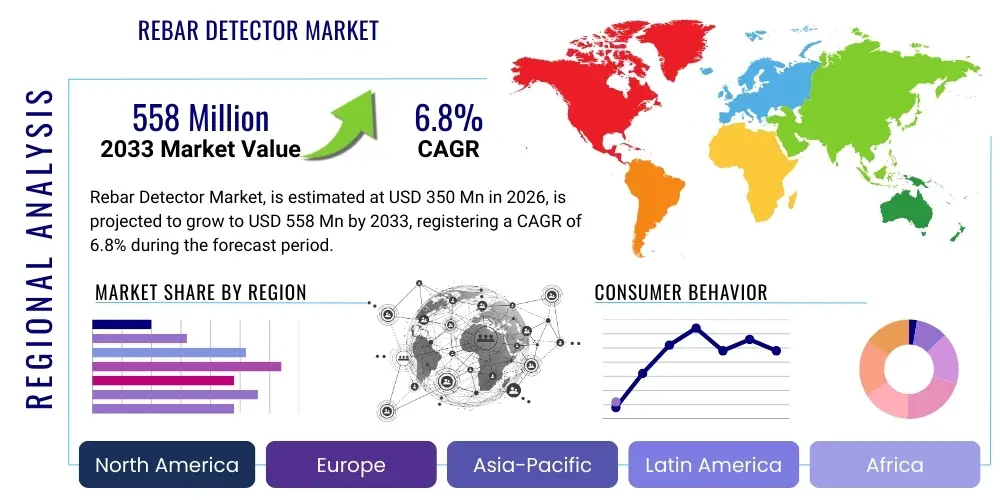

Rebar Detector Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 438308 | Date : Dec, 2025 | Pages : 242 | Region : Global | Publisher : MRU

Rebar Detector Market Size

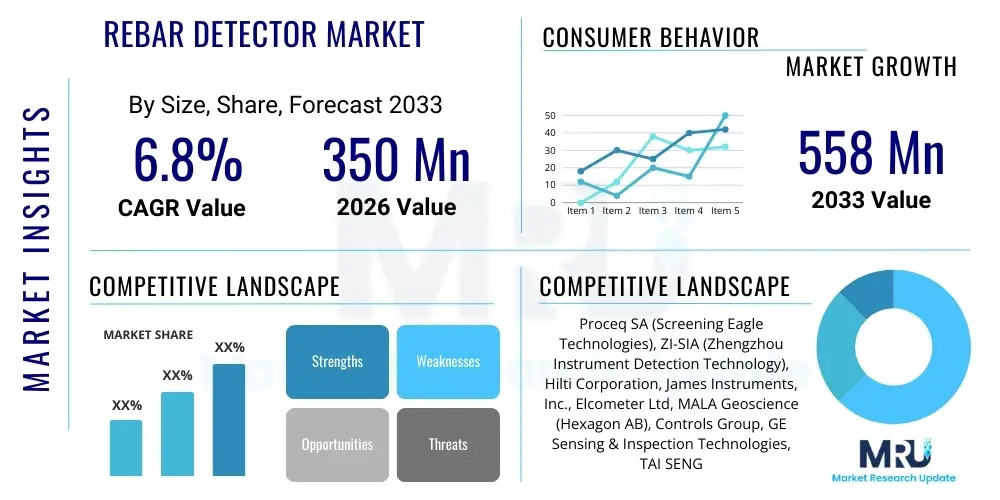

The Rebar Detector Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 350 Million in 2026 and is projected to reach USD 558 Million by the end of the forecast period in 2033. This robust growth trajectory is primarily fueled by increasing global infrastructure development, stringent construction safety regulations mandating non-destructive testing (NDT), and the necessity for accurate structural assessment of aging buildings and bridges.

The valuation reflects the expanding application scope of rebar detectors beyond simple depth measurement to complex structural imaging, offering precise information regarding rebar diameter, location, and corrosion mapping. Developed economies are driving demand through maintenance and rehabilitation projects, while emerging markets contribute significantly due to large-scale new construction initiatives, including massive transportation and housing projects. The integration of advanced signal processing and data logging capabilities into portable devices is making rebar detection an indispensable tool for civil engineers and construction quality control specialists.

Rebar Detector Market introduction

The Rebar Detector Market encompasses instruments designed for the non-destructive testing (NDT) of concrete structures, specifically identifying the location, orientation, depth of cover, and diameter of reinforcing steel bars (rebar), as well as detecting internal anomalies like voids or conduits. These devices operate primarily using principles of electromagnetic induction or ground penetrating radar (GPR), providing crucial data essential for quality assurance during construction, structural analysis during renovation, and corrosion assessment of existing infrastructure. The increasing global focus on the longevity and safety of civil structures, coupled with the need to prevent damage during drilling or cutting operations in reinforced concrete, underpins the market's fundamental utility.

The key products in this domain range from simple magnetic cover meters to sophisticated multi-channel GPR systems capable of generating 3D visualizations of subsurface elements. Major applications include assessing conformity to building codes, determining structural integrity before heavy loading or modification, and mapping potential corrosion zones by measuring concrete resistivity. Driving factors include escalating global investment in infrastructure, heightened governmental emphasis on public safety standards, and the technological evolution offering higher accuracy and integrated data analysis capabilities directly at the job site, thus minimizing delays and improving the efficiency of inspection processes.

Rebar Detector Market Executive Summary

The Rebar Detector Market is characterized by a significant shift towards digitalization and integration of sensing technologies, moving from basic electromagnetic induction tools to advanced Ground Penetrating Radar (GPR) systems that provide comprehensive structural health monitoring data. Business trends highlight strategic mergers and acquisitions focused on consolidating technological expertise, particularly in developing software platforms that translate raw detection data into actionable, easy-to-interpret reports suitable for building information modeling (BIM) workflows. Manufacturers are emphasizing lightweight, ergonomic designs coupled with enhanced battery life to cater to demanding field environments, alongside robust data management systems accessible via cloud infrastructure.

Regionally, Asia Pacific (APAC) stands out as the primary growth engine, driven by massive urbanization and state-funded infrastructure projects in China, India, and Southeast Asia, requiring rigorous quality control for new constructions. North America and Europe maintain high market shares due to the necessity for continuous structural assessment and rehabilitation of aging infrastructure, spurred by rigorous regulatory compliance. Segment trends reveal a rapid adoption of GPR technology over conventional electromagnetic methods for high-accuracy and deep penetration requirements, especially in large-scale bridge and tunnel inspections, while handheld magnetic induction devices dominate routine quality checks on smaller residential and commercial projects.

AI Impact Analysis on Rebar Detector Market

Common user questions regarding the impact of Artificial Intelligence (AI) on the Rebar Detector Market center on how AI can enhance data interpretation, automate defect detection, and integrate findings into larger structural analysis models, such as BIM. Users frequently ask if AI algorithms can differentiate between rebar, post-tensioning tendons, and non-metallic conduits more reliably than traditional methods, and whether AI can predict potential corrosion hotspots based on historical scan data and environmental factors. Furthermore, there is significant interest in AI's role in streamlining the voluminous data generated by GPR scans, transforming complex raw signals into intuitive 3D maps and automated condition reports, thereby reducing reliance on highly specialized human interpretation and improving overall inspection efficiency and speed.

The integration of AI, particularly machine learning (ML) algorithms, is revolutionizing the post-processing phase of rebar detection. AI models trained on vast datasets of healthy and compromised concrete structures are significantly reducing the time required for data analysis and enhancing the precision of anomaly identification. This transition empowers site engineers to make faster, data-driven decisions regarding structural integrity. AI-powered software minimizes false positives and provides automated classification of structural elements, directly contributing to more accurate structural assessment reports and paving the way for predictive maintenance strategies in infrastructure management.

- AI enables automated interpretation of complex Ground Penetrating Radar (GPR) data, distinguishing rebar patterns from noise and other embedded objects.

- Machine learning algorithms enhance the accuracy of depth and diameter measurements by compensating for variations in concrete composition and moisture content.

- Predictive analytics powered by AI allows for early identification and mapping of potential corrosion risks and structural weaknesses.

- AI facilitates seamless integration of structural scan data into Building Information Modeling (BIM) platforms, automating condition reporting.

- Automated quality control checks using image recognition ensure adherence to construction specifications with minimal human intervention.

- AI optimizes calibration procedures and sensor fusion, improving the overall reliability and operational efficiency of multi-sensor rebar detection systems.

DRO & Impact Forces Of Rebar Detector Market

The Rebar Detector Market is significantly influenced by key drivers, restraints, opportunities, and consequential impact forces shaping its trajectory over the forecast period. Primary drivers include increasingly strict government regulations globally regarding infrastructure safety and longevity, coupled with rapid urbanization that necessitates continuous quality control in new construction and ongoing maintenance of aging assets like bridges, dams, and highways. Technological advancements, such as improved penetration depth and higher resolution imaging in NDT equipment, further propel market adoption, as organizations seek precise, non-invasive methods to assess structural integrity without compromising service life.

Conversely, the market faces restraints such as the relatively high initial capital expenditure required for sophisticated GPR and multi-channel systems, presenting an adoption barrier for smaller construction firms or independent inspectors, particularly in price-sensitive developing markets. Additionally, the requirement for highly skilled personnel to operate and accurately interpret the complex data generated by advanced detectors acts as a bottleneck. Opportunities, however, abound in the realm of IoT integration, where connected detectors can upload real-time data to cloud platforms for immediate analysis and collaborative reporting, fostering a centralized approach to structural health monitoring. The expansion of public-private partnerships (PPPs) in infrastructure development globally also presents significant avenues for market penetration.

The key impact forces are centered around regulatory mandates for structural preservation and the escalating costs associated with structural failure, making preventative NDT inspection a highly prioritized expense. The rapid evolution of competing NDT technologies, such as ultrasonic pulse velocity and specialized thermal imaging, pressures rebar detector manufacturers to continuously innovate and integrate multi-sensor capabilities to maintain relevance and competitive advantage. Furthermore, the global trend towards sustainable construction practices places emphasis on material preservation and reduced waste, directly supporting the adoption of non-destructive testing methodologies like rebar detection.

Segmentation Analysis

The Rebar Detector Market is comprehensively segmented based on technology employed, the type of product deployed, and the specific application areas within the construction and civil engineering sectors. Understanding these segments is crucial for manufacturers to tailor product development and for end-users to select the most appropriate NDT tool for their specific operational requirements, whether for routine shallow inspection or complex deep-structural assessment. The primary segmentation criterion, technology, distinguishes devices based on the physical principle utilized, directly influencing accuracy, maximum detection depth, and ease of use in diverse environments, thereby dictating price points and target market specialization.

Product types categorize devices primarily by portability and complexity, ranging from basic, cost-effective handheld meters optimized for speed and ease of use on smaller sites, to robust, cart-based or mounted systems designed for large-scale infrastructure projects requiring extensive area coverage and high-resolution mapping capabilities. The application segmentation clarifies the diverse end-user needs, encompassing critical activities such as quality control checks during new construction phases to ensure rebar placement adherence, comprehensive structural assessment and maintenance planning for existing infrastructure, and preventative maintenance to monitor corrosion and potential degradation over time, particularly in harsh environments like coastal or seismic zones.

- By Product Type

- Handheld Rebar Detectors (Portable & Lightweight)

- Cart-Based Systems (High-resolution GPR)

- Integrated/Mounted Systems (For automation and large-scale scanning)

- By Technology

- Magnetic Pulse Induction (Electromagnetic Cover Meters)

- Ground Penetrating Radar (GPR)

- Hybrid/Multi-Sensor Technology

- By Application

- Quality Control and Assurance (New Construction)

- Structural Assessment and Inspection (Existing Infrastructure)

- Corrosion Mapping and Durability Assessment

- Pre-Drilling/Cutting Safety Checks

- By End-Use Industry

- Construction and Civil Engineering

- Inspection and Consulting Services

- Government and Public Works

Value Chain Analysis For Rebar Detector Market

The value chain for the Rebar Detector Market begins with upstream activities focused on the sourcing of critical electronic components, high-precision sensors (e.g., magnetic coils, radar antennae), and specialized housing materials designed to withstand harsh construction environments. The complexity in the upstream stage lies in maintaining a stable supply of advanced microprocessors and software development expertise necessary for signal processing and data visualization algorithms. Manufacturing is concentrated among a few global NDT technology leaders who possess the necessary intellectual property and calibration facilities to produce devices meeting stringent accuracy standards. This stage involves sophisticated assembly and rigorous quality assurance testing to ensure reliability in the field.

Midstream activities involve sophisticated software integration and post-production customization, often adapting universal hardware platforms to regional regulatory specifications or language requirements. Distribution channels are pivotal; they typically encompass a mix of direct sales teams for major governmental or large enterprise clients, alongside a broad network of specialized NDT equipment distributors and authorized resellers. These distributors provide localized technical support, calibration services, and training, which are critical elements influencing the final adoption rate and user satisfaction across diverse geographical markets. The indirect distribution model is highly prevalent due to the specialized nature of the equipment requiring expert technical consultation.

Downstream activities center on the end-user application and post-sales support. For major infrastructure projects, the devices are sold directly or through exclusive distributors to large civil engineering firms and inspection agencies. Post-sales service, including routine recalibration, software updates, and maintenance contracts, forms a significant revenue stream for manufacturers and distributors, emphasizing the importance of long-term customer relationships. The effectiveness of the value chain is increasingly measured by the ability to provide rapid data analysis and seamless integration of scan results into broader construction management software, linking the field measurements directly to office-based structural engineers.

Rebar Detector Market Potential Customers

The primary customers and end-users of rebar detector technology are professional entities heavily involved in the planning, construction, maintenance, and forensic analysis of reinforced concrete structures. These customers demand highly reliable, accurate, and durable equipment to ensure compliance with stringent safety and structural integrity standards. Key buyer groups include construction contracting companies, ranging from large multinational builders involved in high-rise and complex infrastructure projects to smaller, specialized renovation firms requiring precision for localized repair work. Their need is driven by quality assurance mandates and the necessity to avoid hitting rebar or tension cables during drilling or core sample extraction, which can result in catastrophic structural damage or project delays.

A second crucial customer segment comprises independent structural inspection agencies and specialized non-destructive testing (NDT) consultancies. These entities are often contracted by property owners, government bodies, or insurance firms to conduct structural health assessments, corrosion mapping, and pre-purchase building inspections. Their purchasing decisions are heavily influenced by the detector’s capability to provide detailed, quantifiable data and its ease of integration into standardized reporting protocols. Government agencies, particularly those managing public works, transportation (e.g., DOTs), and defense infrastructure, also represent a substantial direct customer base, prioritizing ruggedness, standardization, and interoperability across different geographical jurisdictions.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 350 Million |

| Market Forecast in 2033 | USD 558 Million |

| Growth Rate | CAGR 6.8% |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Proceq SA (Screening Eagle Technologies), ZI-SIA (Zhengzhou Instrument Detection Technology), Hilti Corporation, James Instruments, Inc., Elcometer Ltd, MALA Geoscience (Hexagon AB), Controls Group, GE Sensing & Inspection Technologies, TAI SENG Industrial Co., GSSI (Geophysical Survey Systems Inc.), VJ Tech, DeFelsko Corporation, NOVOTEST, Sensors & Software Inc., K.D. Engineering, Canect, Matest, Testo SE & Co. KGaA, Baker Hughes, Infrastructure Preservation Corporation (IPC) |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Rebar Detector Market Key Technology Landscape

The core technology landscape of the Rebar Detector Market is dominated by two primary non-destructive methods: Magnetic Pulse Induction (MPI) and Ground Penetrating Radar (GPR), often utilized either separately or in hybrid systems. MPI, utilized in traditional cover meters, relies on generating a magnetic field that interacts with the ferromagnetic properties of rebar. This technique is highly effective for shallow detection and precise cover thickness measurements but is limited in depth penetration and struggles to differentiate between closely spaced rebar or determine bar diameter with high certainty, especially in areas of steel congestion. Recent technological progress in MPI focuses on enhanced signal processing to mitigate the influence of magnetic interference and improve visualization through color mapping.

Ground Penetrating Radar (GPR) represents the advanced end of the market, offering superior capabilities for deep penetration and comprehensive imaging. GPR emits electromagnetic pulses into the concrete; reflections from subsurface interfaces, including rebar, conduits, and voids, are captured and analyzed. Modern GPR systems incorporate high-frequency antennas (up to 3 GHz) to achieve sub-centimeter resolution, enabling the creation of detailed 2D and 3D cross-sectional images of complex rebar layouts. Technological evolution in GPR is heavily focused on multi-channel arrays, which significantly accelerate data acquisition, and advanced software for automated data inversion and interpretation, often leveraging AI and machine learning to rapidly generate accurate structural models from raw radargrams.

Further technological advancements include the integration of supplementary sensor technologies, such as eddy current testing for precise corrosion analysis, and ultrasonic methods to complement GPR data by providing information on concrete quality and void detection. Connectivity features, particularly wireless data transfer (Wi-Fi and Bluetooth) and cloud-based data storage, are now standard, facilitating real-time collaboration between site inspectors and structural engineers. The continuous development of user interfaces, transitioning from simple digital readouts to augmented reality (AR) overlays where the rebar image is projected onto the concrete surface in real-time, significantly enhances usability and accuracy in field operations, driving demand for premium, technologically sophisticated devices.

Regional Highlights

- North America: This region is characterized by high adoption rates driven by strict federal and state regulations concerning the maintenance and inspection of aging infrastructure, particularly bridges, dams, and major roadways. The market here demands high-end, sophisticated NDT equipment, primarily GPR and hybrid systems, capable of complex structural mapping and corrosion monitoring. Significant investment in asset management programs and the readiness to adopt software-integrated solutions, like BIM compatibility and cloud reporting, underpin its dominance in terms of technological sophistication.

- Europe: The European market is highly mature, influenced by comprehensive EU directives on construction quality and occupational safety. Germany, the UK, and France are major contributors, focusing heavily on urban renewal projects and the restoration of historical concrete structures. Demand is balanced between advanced GPR for large-scale structural assessments and precise, user-friendly magnetic induction cover meters for localized quality control in new residential and commercial construction.

- Asia Pacific (APAC): APAC is the fastest-growing region, fueled by unprecedented infrastructure expansion, massive urbanization projects, and high-volume construction in countries like China, India, and Southeast Asian nations. While price sensitivity remains a factor, driving strong demand for reliable, cost-effective magnetic cover meters, the rising scale of complex projects (e.g., high-speed rail, massive dam construction) is increasing the uptake of advanced GPR systems for ensuring long-term structural integrity and compliance with nascent quality standards.

- Latin America (LATAM): The LATAM market is nascent but rapidly developing, driven by necessary public investments in repairing and expanding public utilities and transportation networks. Market growth is sporadic but shows high potential, focusing initially on essential NDT equipment for basic compliance and safety checks. Brazil and Mexico lead the region, exhibiting growing demand for reliable, durable, mid-range equipment supported by localized technical training.

- Middle East and Africa (MEA): The MEA region, particularly the Gulf Cooperation Council (GCC) countries, is characterized by large-scale, high-value infrastructure mega-projects, demanding the latest NDT technology. Extreme environmental conditions (high heat, high salinity) accelerate concrete degradation, necessitating frequent and highly accurate corrosion mapping and rebar assessment, making high-resolution GPR systems essential for ensuring the longevity of structures built in challenging coastal environments.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Rebar Detector Market.- Proceq SA (Screening Eagle Technologies)

- ZI-SIA (Zhengzhou Instrument Detection Technology)

- Hilti Corporation

- James Instruments, Inc.

- Elcometer Ltd

- MALA Geoscience (Hexagon AB)

- Controls Group

- GE Sensing & Inspection Technologies

- TAI SENG Industrial Co.

- GSSI (Geophysical Survey Systems Inc.)

- VJ Tech

- DeFelsko Corporation

- NOVOTEST

- Sensors & Software Inc.

- K.D. Engineering

- Canect

- Matest

- Testo SE & Co. KGaA

- Baker Hughes

- Infrastructure Preservation Corporation (IPC)

Frequently Asked Questions

Analyze common user questions about the Rebar Detector market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary technological difference between Magnetic Pulse Induction (MPI) and Ground Penetrating Radar (GPR) rebar detection systems?

MPI devices, or cover meters, use electromagnetic fields to detect ferromagnetic material, excelling at accurate, shallow cover depth measurement and rebar diameter estimation. GPR systems transmit high-frequency radar waves, providing superior penetration depth and generating high-resolution 2D/3D images, making them ideal for complex, deep structural mapping and void detection, though they are generally more complex and costly.

How do current rebar detectors support Building Information Modeling (BIM) workflows and digital construction management?

Modern rebar detectors, particularly GPR units, feature integrated software and wireless connectivity that allow collected structural data—including rebar location, depth, and material properties—to be exported directly in compatible formats (e.g., IFC, DXF). This seamless integration enables engineers to overlay NDT results onto digital twin models of the structure, facilitating efficient structural assessment, renovation planning, and long-term asset management within the BIM environment.

What are the key limitations or factors that reduce the accuracy of rebar detection equipment in the field?

Accuracy can be significantly impaired by several factors, including high rebar congestion (especially overlapping layers), high moisture content or heterogeneity in the concrete composition, and the presence of external magnetic interference (for MPI systems). GPR performance is also sensitive to concrete conductivity; highly conductive materials or high salt content can limit signal penetration depth and resolution, requiring advanced signal processing to mitigate these effects.

What is the market outlook for specialized rebar detection systems focused on corrosion mapping and durability assessment?

The outlook is exceptionally positive, driven by the global imperative to manage aging infrastructure and prevent catastrophic failures. Specialized systems now integrate rebar detection with corrosion monitoring techniques, such as half-cell potential mapping and concrete resistivity measurements. This multi-sensor approach provides holistic data for proactive maintenance, making these combined durability assessment tools a premium, high-growth segment, particularly in coastal and seismically active regions.

Which geographical region exhibits the highest growth potential for the adoption of sophisticated rebar detection technology?

The Asia Pacific (APAC) region, led by China and India, holds the highest growth potential due to exponential increases in infrastructure investment, massive urban development projects, and a rapid shift towards adopting international quality control and NDT standards. While North America and Europe lead in current technology sophistication, APAC’s sheer volume of new construction requiring quality assurance checks guarantees the fastest expansion in adoption rates for both basic and advanced rebar detection equipment.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager