Rebar Grout Sleeve Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 435339 | Date : Dec, 2025 | Pages : 248 | Region : Global | Publisher : MRU

Rebar Grout Sleeve Market Size

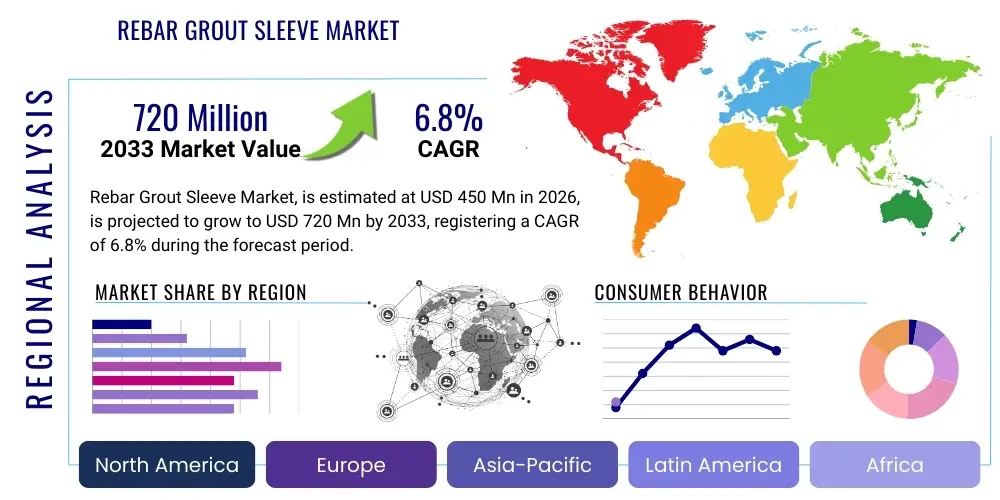

The Rebar Grout Sleeve Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 450 Million in 2026 and is projected to reach USD 720 Million by the end of the forecast period in 2033.

Rebar Grout Sleeve Market introduction

The Rebar Grout Sleeve Market encompasses specialized mechanical coupling systems designed for connecting reinforcing bars (rebar) in precast and cast-in-situ concrete construction. These sleeves, typically made from high-strength steel or ductile iron, utilize high-performance, non-shrink grout to achieve structural continuity equivalent to or exceeding traditional monolithic construction methods. Grout sleeves are foundational components in the rapidly expanding industrialized construction sector, facilitating faster erection times, superior quality control achieved in factory environments, and reduced reliance on specialized on-site welding or labor-intensive lapping techniques. Their primary function is to transfer tensile and compressive forces seamlessly between connecting reinforcement members, ensuring the integrity and seismic resilience of the overall structure, particularly crucial in high-seismicity zones and large-scale infrastructure projects such as high-speed rail bridges, data centers, and high-rise commercial towers.

The product’s description centers on its robust mechanical properties, ease of installation, and ability to handle varying degrees of construction misalignment while maintaining structural performance. Major applications span across critical infrastructure development, including highway construction, modular housing projects, commercial complex development, and essential utility infrastructure. The adoption of rebar grout sleeves is intrinsically linked to global trends favoring off-site manufacturing and modular construction methodologies, which mandate precise, repeatable, and high-strength connections. The inherent benefits of using these sleeves include significant time savings on project schedules, enhanced safety records due to less on-site handling of heavy reinforcement cages, and a marked improvement in the overall durability and longevity of the concrete structure, driving substantial interest from both private developers and governmental infrastructure agencies worldwide.

Driving factors for this market are multifaceted, stemming primarily from stringent building codes requiring enhanced seismic performance and the global push towards efficiency and sustainability in construction. The increasing complexity of modern architectural designs often necessitates innovative connection solutions that traditional methods cannot reliably provide. Furthermore, the persistent shortage of skilled construction labor globally compels the industry to adopt prefabricated components, where grout sleeves are indispensable connectors. The market dynamics are also heavily influenced by continuous innovation in proprietary high-strength, fast-setting grout formulations that reduce curing times and allow for quicker progression to the next construction phase. These technological advancements, combined with the rising investment in public infrastructure renewal programs across Asia Pacific and North America, solidify the market's trajectory towards sustained expansion over the forecast period.

Rebar Grout Sleeve Market Executive Summary

The Rebar Grout Sleeve Market is poised for significant growth, underpinned by fundamental shifts in global construction practices favoring industrialized building methods and modularization. Key business trends indicate a movement towards specialized high-strength mechanical sleeves capable of accommodating larger rebar diameters and providing certified performance in extreme environments, particularly those susceptible to high-stress fatigue or seismic events. The competitive landscape is characterized by intellectual property differentiation regarding sleeve materials (e.g., cast iron vs. specialized steel alloys) and proprietary grout compositions designed for rapid strength gain. Strategic alliances between sleeve manufacturers and leading precast concrete fabricators are becoming essential for securing large-volume infrastructure contracts. Investment in advanced manufacturing techniques, such as automated casting and precision machining, is crucial for companies aiming to meet the rising demand for standardized, zero-defect connector components globally.

Regionally, the Asia Pacific (APAC) stands out as the primary growth engine, driven by massive urbanization, rapid infrastructure expansion in China and India, and governmental mandates promoting prefabrication techniques to address housing shortages efficiently. North America and Europe demonstrate mature market characteristics, focusing intensely on quality standards, code compliance (especially relating to ACI and Eurocode specifications), and the retrofit of aging infrastructure utilizing advanced coupling solutions. The Middle East and Africa (MEA) region is exhibiting robust demand, propelled by mega-projects in the UAE and Saudi Arabia, which prioritize fast-track construction schedules and require highly reliable structural connections. These regional trends highlight the market's sensitivity to local regulatory environments and levels of investment in public works, creating differentiated opportunities across developed and emerging economies.

Segmentation trends reveal that the 'Standard Mechanical Grout Sleeve' segment dominates in volume due to its versatility and established use in conventional precast applications, while the 'Specialized Seismic Sleeve' segment is rapidly increasing its market share, driven by enhanced regulatory requirements and high-value infrastructure projects demanding exceptional ductility and performance under cyclic loading. Application-wise, the infrastructure sector (bridges, tunnels, rail systems) remains the largest consumer, valuing the robust connections provided by grout sleeves for long-span structures. However, the commercial and residential building segments, particularly those adopting modular and high-rise construction, are expected to register the fastest growth rates, signaling a widespread acceptance of industrialized construction methodology across the built environment. Manufacturers are strategically diversifying their product offerings to cater to both standard high-volume needs and specialized, high-specification performance requirements.

AI Impact Analysis on Rebar Grout Sleeve Market

Common user questions regarding AI's impact on the Rebar Grout Sleeve Market frequently revolve around optimization of construction supply chains, enhancement of structural design safety margins, and predictive maintenance capabilities. Users are keen to understand how AI and Machine Learning (ML) can be integrated into the complex logistics of delivering specialized components to high-volume construction sites, minimizing delays and waste. Furthermore, significant inquiries focus on leveraging AI to analyze seismic performance data from simulations and real-world events, thereby optimizing the material composition and design parameters of the sleeves themselves for superior performance. Users also express interest in AI-driven quality assurance processes, specifically asking how computer vision and ML algorithms can autonomously detect defects in sleeve manufacturing or improper grout application on-site, ensuring 100% compliance with stringent structural integrity requirements.

The core theme emerging from this analysis is the expectation that AI will transform the grout sleeve ecosystem from a purely physical product supply into a digitally integrated solution. AI applications are anticipated to radically improve the precision and reliability associated with precast connections. For instance, ML algorithms can process vast datasets related to concrete curing environments, temperature fluctuations, and grout properties to predict optimal curing times and prevent connection failures. This predictive capability translates directly into reduced project risk and improved quality assurance, which is critical for structural components. Moreover, AI is expected to revolutionize structural design optimization by quickly testing thousands of coupling configurations against various load conditions, leading to lighter, more efficient, and cost-effective sleeve designs, minimizing material usage without compromising safety standards, thereby aligning with sustainability goals.

Integration of AI and digital twins into the construction process will fundamentally change how grout sleeves are specified and installed. BIM (Building Information Modeling) platforms, enhanced by AI, can automatically verify the precise positioning and orientation of rebar sleeves in complex structural models, flag potential clashes or misalignment issues before they occur on the factory floor or construction site. This level of digital scrutiny, powered by sophisticated algorithms, significantly reduces the margin for human error, a long-standing challenge in traditional construction. Consequently, while AI does not directly manufacture the sleeve, it acts as a pervasive intelligence layer optimizing the entire lifecycle—from design simulation and material procurement to logistical delivery and final installation verification—ensuring the reliability and efficiency of this vital structural component in modern industrialized construction projects.

- AI-powered predictive logistics optimization for just-in-time delivery of sleeves and specialized grout.

- Machine Learning integration into structural analysis software to optimize sleeve design for seismic resilience and material efficiency.

- Computer vision systems utilizing AI for automated, real-time quality control inspection during sleeve manufacturing and on-site grout filling.

- Implementation of Digital Twin technology using ML to monitor the performance and structural health of connected elements post-installation.

- Data analytics driven by AI to correlate curing conditions (temperature, humidity) with grout performance, ensuring optimal connection strength.

DRO & Impact Forces Of Rebar Grout Sleeve Market

The dynamics of the Rebar Grout Sleeve Market are shaped by a strong interplay between significant drivers rooted in construction modernization, inherent restraints related to cost and standardization, and compelling opportunities derived from emerging construction techniques and regulatory changes. The primary driver is the global acceleration of industrialized construction (IC) and the adoption of precast and modular methods, which intrinsically rely on robust mechanical connectors like grout sleeves to maintain continuity between prefabricated elements. However, widespread adoption is somewhat restrained by the initial higher component cost compared to traditional rebar lapping and the critical need for meticulous installation procedures; any deviation from manufacturer specifications can compromise structural integrity. Opportunities are concentrated in emerging fields such as high-performance concrete structures, nuclear facility construction, and the development of specialized sleeves for ultra-high-strength steel reinforcement, suggesting substantial long-term market expansion potential. These forces create a competitive environment where innovation in material science and installation efficiency is paramount for sustained growth and market leadership.

Drivers: The market benefits enormously from the increasing global commitment to infrastructure spending, particularly in rapidly urbanizing regions, where speed of construction is a critical factor. Mandates for enhanced structural safety, especially in regions prone to earthquakes (e.g., Japan, California, Turkey), necessitate the use of high-performance coupling systems that exceed the performance of simple lap splices under cyclic loading. The persistent challenge of labor shortages on construction sites also pushes contractors toward factory-fabricated precast elements, where grout sleeves simplify and accelerate the assembly process. Furthermore, the push for construction sustainability favors prefabrication, as it reduces material waste and allows for more efficient resource utilization, further bolstering the demand for reliable coupling solutions.

Restraints: Despite the benefits, the market faces key limitations. The higher initial component cost of a specialized grout sleeve system compared to conventional rebar connections can deter cost-sensitive projects, particularly in developing economies. Lack of global standardization regarding testing protocols and product specifications across different regulatory bodies (e.g., ACI, Eurocode, various national standards) creates market friction and complexity for international manufacturers. Crucially, the performance of the system is highly dependent on the quality of the non-shrink grout and the precision of the on-site installation, including proper cleaning and filling. Misapplication or inadequate quality control during installation poses a risk, acting as a constraint on universal acceptance until fully automated or fail-safe installation procedures become commonplace.

Opportunities: Significant future growth resides in the expansion of modular and volumetric construction techniques beyond standard residential applications into complex commercial and industrial structures. The development of advanced, specialized sleeves capable of connecting next-generation materials, such as fiber-reinforced polymer (FRP) rebar or ultra-high-performance concrete (UHPC) structures, opens high-value niche markets. Furthermore, the retrofit and renovation segment represents a considerable opportunity; rebar grout sleeves offer efficient solutions for connecting new structural elements to existing concrete frameworks without complex and destructive interventions. Continuous Research and Development focused on faster-curing, less temperature-sensitive grout formulations that improve cold-weather performance will unlock further untapped potential in diverse geographical markets.

Segmentation Analysis

The Rebar Grout Sleeve Market is segmented primarily by the Type of Sleeve, the Diameter of Rebar Accommodated, the Material used for the sleeve, and the End-use Application. Segmentation by Type distinguishes between standard mechanical sleeves, which rely predominantly on the tensile strength achieved by the specialized grout and the sleeve housing, and specialized mechanical splice systems, which may incorporate additional locking features or proprietary thread forms for enhanced performance under extreme dynamic loading. The primary differentiation often lies in the force transfer mechanism and the corresponding certification levels required for high-seismic or fatigue-sensitive applications. Understanding these segments is crucial for manufacturers to tailor their production capabilities and marketing strategies to specific regulatory and performance requirements mandated by local construction codes.

The segmentation based on End-use Application is vital for determining market volume and value distribution. The infrastructure segment typically commands the largest share by volume due to the high rebar density in projects like bridges, tunnels, and mass transit systems, where structural longevity is paramount. Conversely, the commercial and high-rise residential sectors are rapidly increasing their market contribution, driven by the need for quick turnaround times and the efficiency benefits derived from using prefabricated floor slabs and shear walls. Material segmentation (e.g., cast iron, steel, proprietary polymers) reflects the trade-offs between cost, weight, and maximum tensile strength capability, influencing adoption across various project types. The trend is moving towards high-performance materials that offer improved ductility and lighter weight without compromising load-bearing capacity.

Geographically, market segmentation reflects disparities in construction maturity and regulatory enforcement. Developed markets in North America and Europe prioritize certified seismic sleeves, driving up the average unit price and focusing on compliance with strict performance specifications. Emerging markets in APAC and Latin America, while growing rapidly, often seek a balance between cost-effectiveness and performance, stimulating demand for standard, high-volume sleeves. This complex market structure necessitates a multi-faceted approach to product development, ensuring a portfolio that addresses both the high-specification demands of structural engineers in developed economies and the volume-driven needs of general contractors in emerging economies, thereby optimizing market penetration across all key segments and achieving robust global growth.

- By Type:

- Standard Grout Sleeves (Non-Seismic Applications)

- Seismic/High-Performance Grout Sleeves (High-Cyclic Loading)

- Mechanical Splices (Threaded and Non-Threaded Variants)

- By Rebar Diameter:

- Small Diameter (Up to 20mm)

- Medium Diameter (20mm to 32mm)

- Large Diameter (Above 32mm)

- By Application:

- Infrastructure (Bridges, Tunnels, Rail Systems, Utilities)

- Commercial Construction (High-Rise Buildings, Offices, Data Centers)

- Residential Construction (Modular Housing, Multi-Family Units)

- Industrial Construction (Power Plants, Manufacturing Facilities)

- By Material:

- Cast Iron

- Steel Alloy

- Ductile Iron

Value Chain Analysis For Rebar Grout Sleeve Market

The value chain for the Rebar Grout Sleeve Market begins with the sourcing and processing of specialized raw materials, primarily high-grade steel or ductile iron used for the sleeve housing, and proprietary chemical constituents required for the high-performance non-shrink grout. Upstream analysis involves rigorous quality control over metallurgy to ensure the sleeve body meets necessary strength and ductility standards, particularly important for certified seismic applications. Key upstream activities also include the highly technical formulation and manufacturing of the non-shrink grout, where consistency and rapid strength gain are critical performance indicators. Manufacturers often maintain integrated or closely audited supply chains for these materials to ensure minimal variance and consistent product quality, protecting the structural integrity of the final application. Cost fluctuations in global steel and energy markets significantly influence the profitability at this stage, necessitating sophisticated risk mitigation strategies.

The midstream segment involves the core manufacturing process, including casting, precision machining, and finishing of the sleeve bodies, followed by the rigorous testing and certification of the combined sleeve and grout system. Distribution channels are complex, involving both direct sales and specialized indirect channels. Direct sales are often utilized for large, high-profile infrastructure projects where technical consultation and on-site support are essential, allowing the manufacturer to work closely with engineering procurement and construction (EPC) firms and precast concrete fabricators. Indirect channels rely heavily on established networks of construction material distributors and specialized rebar suppliers who maintain stock and provide localized logistics to small-to-mid-sized construction contractors. The choice of channel is dictated by project size, geographic location, and the necessity for immediate technical guidance on complex installations.

Downstream analysis focuses on the end-users: the precast concrete manufacturers, general contractors, and specialized installation crews responsible for the final assembly of the structure. The success of the grout sleeve system relies heavily on proper training and adherence to installation specifications, making technical support a vital component of the downstream value proposition. Manufacturers increasingly invest in digital tools and on-site support to ensure correct grout mixing, sleeve alignment, and curing processes, thereby mitigating liability and ensuring the structure performs as designed. The circular economy aspect is also gaining relevance, exploring options for end-of-life material recovery, although the high integration of the sleeves into concrete structures presents significant logistical challenges for large-scale recycling efforts, maintaining a focus predominantly on maximizing initial product longevity and performance.

Rebar Grout Sleeve Market Potential Customers

The primary consumers and buyers of rebar grout sleeves fall into several distinct categories within the construction ecosystem, all linked by their involvement in projects utilizing industrialized or precast concrete construction methodologies. Leading the demand are specialized Precast Concrete Manufacturers (PCM) who integrate these sleeves directly into their factory-produced structural elements, such as wall panels, beams, and columns, to ensure structural continuity when assembled on-site. These PCMs value the sleeves for facilitating high-speed production, achieving superior dimensional accuracy, and providing a certified connection system that meets stringent factory quality control standards. For them, grout sleeves are an essential enabling technology for efficient, large-scale precast fabrication, making them high-volume, repeat purchasers focused intensely on cost, supply reliability, and ease of installation.

Another crucial segment comprises large Engineering Procurement and Construction (EPC) firms and general contractors specializing in high-rise commercial, complex industrial, and public infrastructure projects. These entities specify and purchase grout sleeves for both precast elements sourced externally and for critical cast-in-situ joints where mechanical splices offer performance advantages over traditional lapping. For EPC firms, the primary motivation is minimizing construction timelines, reducing the complexity of on-site rebar placement, and guaranteeing the performance of critical joints under the high loads characteristic of infrastructure projects like long-span bridges or high-speed rail lines. They require comprehensive technical documentation, detailed installation guides, and verifiable product certification to comply with project specifications and regulatory audits, placing high value on manufacturer reputation and technical support capabilities.

The third significant customer segment includes governmental agencies and infrastructure owners, who, while not direct purchasers, heavily influence market demand through the establishment of strict building codes and the selection of preferred construction methods for publicly funded projects. Organizations managing seismic resilience programs, transportation departments, and urban development authorities dictate the performance criteria that mandate the use of high-performance coupling systems. Furthermore, specialized structural repair and retrofit contractors represent a growing customer base, utilizing grout sleeves for strengthening or extending the lifespan of existing concrete structures, particularly those requiring localized reinforcement upgrades without disrupting the entire framework. These diverse customers all prioritize the sleeves' capacity to deliver verifiable, high-strength, code-compliant, and time-efficient structural connections.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450 Million |

| Market Forecast in 2033 | USD 720 Million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Dextra Group, Peikko Group Corporation, CRH Plc (Hulamin), Erico (Pentair), Ancon Building Products, Sika AG, Fosroc International, Moment, Trelleborg AB, Lenton, Nippon Steel Corporation, Grout Systems, Dayton Superior, Tokyo Rope Mfg. Co., Ltd., BASF SE, Master Builders Solutions (MBCC Group), Max Frank GmbH & Co. KG, JORDAHL GmbH, CSC Construction Group, and Halfen (CRH company). |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Rebar Grout Sleeve Market Key Technology Landscape

The Rebar Grout Sleeve Market is characterized by continuous technological evolution focused on three main pillars: material science innovation for both the sleeve and the grout, advancements in sleeve design geometry, and integration with digital construction methodologies. In material science, the focus is shifting towards developing lighter, yet stronger, sleeve materials, such as specialized ductile iron alloys or engineered steel compositions that offer superior fracture toughness and impact resistance, essential for surviving transport and on-site handling. Crucially, the non-shrink grout technology is seeing significant investment in proprietary formulations that achieve ultra-high compressive and bond strength rapidly, often within 24 to 48 hours, regardless of ambient temperature variations. This quick-curing capability directly addresses the construction industry's demand for accelerated project schedules, providing a competitive advantage to manufacturers who can reliably deliver high-performance grout systems that minimize downtime before subsequent construction phases can begin.

Sleeve design advancements are driven by the necessity to simplify the connection process while accommodating increasing structural demands, especially the requirements for 'ductile' connections mandated by modern seismic codes. Innovations include tapered sleeve designs for improved grout flow and self-centering capabilities, and the development of hybrid systems that combine the simplicity of grout filling with secondary mechanical locking features (such as threads or bolts) to ensure immediate connection security before the grout achieves full strength. Furthermore, manufacturers are increasingly engineering sleeves to manage wider tolerance ranges regarding rebar alignment and penetration depth. This adaptability is vital on large construction sites where absolute precision is often logistically challenging, thereby making the installation process more forgiving and reliable, reducing the incidence of non-conformance and costly rework associated with misaligned reinforcement bars.

Digital integration represents the future trajectory of the technology landscape. The key technological shift involves ensuring seamless compatibility of rebar grout sleeve dimensions and specifications within Building Information Modeling (BIM) platforms. Manufacturers are providing detailed BIM objects and technical specifications that allow structural engineers and precast detailers to accurately model the coupling system, verify clearances, and automate quantity take-offs. Furthermore, the use of specialized pumping and mixing equipment, often integrated with Internet of Things (IoT) sensors, is becoming standard practice to monitor and record critical installation parameters, such as grout volume, pressure, and temperature. This digital logging provides an auditable trail of connection quality, satisfying the stringent quality assurance (QA) requirements of high-value infrastructure projects and providing engineers with verifiable proof of compliance, elevating the standard for structural connection reliability in industrialized construction.

Regional Highlights

- Asia Pacific (APAC): APAC represents the largest and fastest-growing market for rebar grout sleeves globally. This immense growth is fueled by massive government investments in new infrastructure, particularly high-speed rail networks, smart city developments, and large-scale affordable housing projects in key economies like China, India, and Southeast Asia. Regulatory environments in these countries are increasingly promoting industrialized building systems (IBS) and precast technology to meet rapid urbanization demands efficiently. China, in particular, maintains strong demand due to its volume-driven construction market and the national emphasis on adopting modern, quality-controlled construction techniques, making it a critical hub for both manufacturing and consumption of grout sleeve technology.

- North America: The North American market is characterized by a strong focus on high-specification, seismic-certified sleeves, driven by strict building codes in regions like California (ASCE 7 standards) and ongoing infrastructure renewal programs, notably the US Infrastructure Investment and Jobs Act. The market here places a premium on product certification, testing against ASTM and ACI standards, and proven performance under fatigue and seismic loading. While volume growth may be slower than in APAC, the market value remains high due to the demand for technologically advanced, premium-priced mechanical coupling solutions essential for high-rise commercial structures and seismic retrofits.

- Europe: The European market demonstrates steady growth, driven by environmental sustainability mandates and the widespread adoption of modular and prefabricated construction techniques, especially in countries like Germany, the UK, and the Nordic region. European demand is heavily influenced by Eurocode standards (specifically Eurocode 2 for concrete structures), which require robust connections for precast elements. Manufacturers focus on sleeves that facilitate high thermal insulation properties and rapid assembly, catering to projects prioritizing energy efficiency and minimal construction disturbance in dense urban environments.

- Middle East and Africa (MEA): This region is experiencing high demand linked to mega-projects in the Gulf Cooperation Council (GCC) nations, particularly Saudi Arabia (NEOM, Red Sea Project) and the UAE. Construction timelines are exceptionally aggressive in the MEA, making speed and quality control critical. Grout sleeves provide the necessary acceleration and reliability. Challenges in this market include extreme temperature fluctuations, necessitating specialized grout formulations that can perform reliably in high heat and arid conditions, leading to demand for customized, high-performance product lines.

- Latin America (LATAM): Growth in LATAM is variable but shows upward trajectory, primarily driven by urbanization and the need for seismic-resistant construction techniques in countries along the Pacific Ring of Fire (e.g., Chile, Mexico). Market growth is stimulated by public housing initiatives and infrastructure modernization, though adoption is sometimes constrained by economic volatility and reliance on highly localized construction standards and supply chains, necessitating adaptive market entry strategies focusing on cost-effective, durable solutions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Rebar Grout Sleeve Market.- Dextra Group

- Peikko Group Corporation

- CRH Plc (Hulamin)

- Erico (Pentair)

- Ancon Building Products

- Sika AG

- Fosroc International

- Moment

- Trelleborg AB

- Lenton

- Nippon Steel Corporation

- Grout Systems

- Dayton Superior

- Tokyo Rope Mfg. Co., Ltd.

- BASF SE

- Master Builders Solutions (MBCC Group)

- Max Frank GmbH & Co. KG

- JORDAHL GmbH

- CSC Construction Group

- Halfen (CRH company)

Frequently Asked Questions

Analyze common user questions about the Rebar Grout Sleeve market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary benefits of using rebar grout sleeves over traditional lap splices?

Rebar grout sleeves offer superior structural performance, particularly under seismic or fatigue loading, ensuring full mechanical continuity (100% rebar strength). They significantly reduce construction time, minimize rebar congestion, and allow for better quality control by facilitating industrialized, off-site precast concrete construction methods, leading to overall faster project completion.

How does the Rebar Grout Sleeve Market contribute to sustainable construction practices?

Grout sleeves support sustainability by enabling the efficient use of resources inherent in precast construction, reducing material waste on site, and improving the longevity and durability of structures. Their use also reduces the need for energy-intensive, on-site welding and minimizes reliance on specialized labor, aligning with green building standards and efficiency goals.

What is the key difference between standard and seismic-certified grout sleeves?

Seismic-certified sleeves are designed and rigorously tested to maintain structural integrity and ductility when subjected to cyclic loading (repeated shaking) characteristic of earthquakes. They typically adhere to stricter performance codes (e.g., ACI 318 Type 2 requirements), whereas standard sleeves primarily meet basic tensile strength requirements for non-seismic or static load conditions.

What role does grout composition play in the performance of the sleeve system?

The specialized, non-shrink, high-performance grout is critical as it provides the force-transfer mechanism, ensuring the rebar bonds tightly within the sleeve body. The grout's properties—specifically its rapid strength gain, non-shrink characteristics, and high compressive strength—are essential for achieving the required structural continuity and minimizing curing delays on the construction schedule.

Which regions are leading the demand for high-performance grout sleeve technology?

Asia Pacific (APAC) is currently leading the global demand due to unprecedented infrastructure and housing construction volume. However, North America and Europe lead in the adoption of high-performance, seismic-certified sleeves, driven by strict regulatory standards and the high complexity of commercial and retrofit construction projects.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager