Redispersible Latex Powder Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439522 | Date : Jan, 2026 | Pages : 246 | Region : Global | Publisher : MRU

Redispersible Latex Powder Market Size

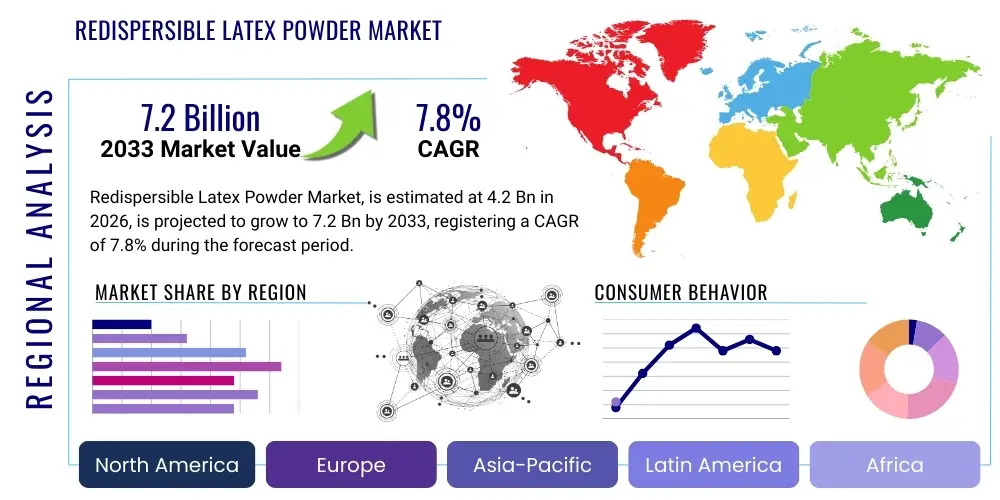

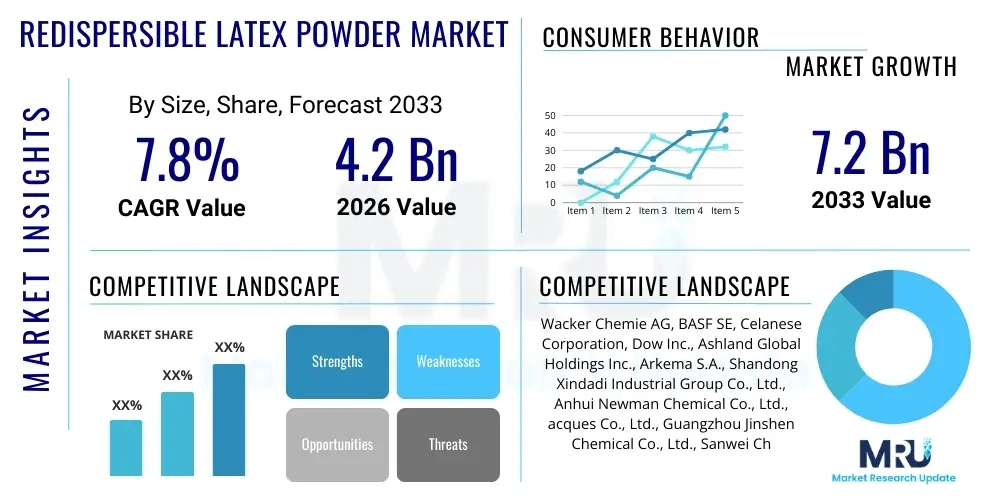

The Redispersible Latex Powder Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2026 and 2033. The market is estimated at USD 4.2 Billion in 2026 and is projected to reach USD 7.2 Billion by the end of the forecast period in 2033. This growth is primarily fueled by the escalating demand from the construction industry, particularly in emerging economies, where infrastructure development and urbanization projects are continuously expanding. The inherent properties of Redispersible Latex Powder (RDP), such as improved adhesion, flexibility, water resistance, and workability in various construction materials, solidify its critical role in modern building practices. Furthermore, the increasing emphasis on sustainable and durable construction solutions globally is driving its adoption across a diverse range of applications, including tile adhesives, grouts, exterior insulation and finish systems (EIFS), and self-leveling compounds. The market's trajectory is also positively influenced by renovation and repair activities in developed regions, necessitating high-performance additives.

Redispersible Latex Powder Market introduction

The Redispersible Latex Powder Market encompasses the production, distribution, and consumption of polymer powders that, when mixed with water, revert to a liquid emulsion state, enhancing the properties of cement-based and gypsum-based dry-mix formulations. These specialized chemical additives are derived primarily from vinyl acetate-ethylene (VAE) copolymers, styrene-butadiene (SB) copolymers, and acrylics, among others, each offering distinct performance characteristics tailored to specific application requirements. The core function of RDP is to improve the flexibility, adhesion strength, water resistance, abrasion resistance, and overall durability of construction materials, making them suitable for a wide array of demanding environments and applications.

Major applications for Redispersible Latex Powder span across the entire construction spectrum. They are critically utilized in tile adhesives and grouts, where they significantly boost bond strength to various substrates, including low-absorption tiles and challenging surfaces. In exterior insulation and finish systems (EIFS), RDPs contribute to superior impact resistance, crack bridging, and weatherproofing, essential for energy-efficient building envelopes. Beyond these, RDPs are integral components in self-leveling compounds, wall putties, repair mortars, masonry mortars, and concrete admixtures, where they impart crucial workability, reduced shrinkage, and enhanced mechanical properties. The versatility of RDPs allows for their incorporation into both new construction projects and renovation efforts, supporting the longevity and structural integrity of built environments.

The benefits derived from incorporating Redispersible Latex Powder are manifold, encompassing both performance and economic advantages. Improved flexibility helps materials accommodate structural movements and thermal stresses, preventing cracking and delamination. Enhanced adhesion ensures long-lasting bonds, particularly in critical applications like tiling and facade systems. Furthermore, RDPs contribute to better water repellency, crucial for exterior applications and wet environments, thereby extending the lifespan of structures and reducing maintenance needs. These performance improvements ultimately lead to higher quality, more durable, and aesthetically pleasing construction outcomes, driving their consistent demand. The market is propelled by factors such as rapid urbanization, governmental investments in infrastructure, the rising trend of green building materials, and technological advancements leading to specialized RDP formulations for niche applications.

Redispersible Latex Powder Market Executive Summary

The Redispersible Latex Powder (RDP) market is characterized by robust business trends driven by the global construction boom, particularly in Asia Pacific, where urbanization and industrialization continue at an unprecedented pace. Manufacturers are focusing on product innovation, developing specialized RDPs for enhanced performance in areas like high-flexibility tile adhesives, waterproof mortars, and low-VOC (Volatile Organic Compound) formulations to meet stringent environmental regulations and green building standards. Strategic collaborations, mergers, and acquisitions are common as companies seek to expand their geographic footprint, diversify product portfolios, and consolidate market share. There is also a discernible shift towards sustainable production methods and the use of bio-based raw materials, responding to increasing consumer and regulatory pressures for eco-friendly construction solutions, which in turn influences investment in research and development.

Regional trends indicate that Asia Pacific dominates the RDP market, largely due to massive investments in residential, commercial, and infrastructure projects in countries like China, India, and Southeast Asian nations. This region is not only a major consumer but also a significant producer of RDP. Europe and North America, while mature markets, are experiencing steady growth fueled by renovation activities, increasing adoption of energy-efficient building solutions like EIFS, and a strong emphasis on high-performance and durable construction materials. Latin America, the Middle East, and Africa are emerging as high-growth regions, driven by nascent construction sectors, growing populations, and significant infrastructure development initiatives. Each region presents unique challenges and opportunities, influencing market entry strategies and product localization efforts by key players.

Segmentation trends reveal that Vinyl Acetate Ethylene (VAE) copolymer-based RDPs continue to hold the largest market share due to their superior performance balance of adhesion, flexibility, and water resistance, making them versatile for a broad range of applications. However, Styrene Butadiene (SB) RDPs are gaining traction in specific high-performance applications requiring exceptional water resistance and flexibility, such as in waterproofing membranes and specialized mortars. Application-wise, tile adhesives and grouts remain the dominant segment, propelled by the global growth in ceramic and porcelain tile installation. Exterior Insulation and Finish Systems (EIFS) and self-leveling compounds are also rapidly expanding segments, driven by energy efficiency mandates and the demand for high-quality floor finishes. The residential end-user segment is expected to maintain its lead, although commercial and industrial applications are showing significant growth due to increasing infrastructure and non-residential construction projects.

AI Impact Analysis on Redispersible Latex Powder Market

User inquiries regarding AI's impact on the Redispersible Latex Powder market often revolve around efficiency gains in manufacturing, optimization of R&D processes for new formulations, predictive analytics for supply chain management, and potential for automated quality control. Key themes include how AI can streamline production, reduce costs, improve product consistency, and accelerate the development of innovative RDP solutions tailored for specific performance requirements or sustainable attributes. Concerns also arise about the initial investment required for AI integration and the potential need for a skilled workforce to manage these advanced systems. Users are keen to understand if AI can make RDP production more responsive to market demands and contribute to more resilient supply chains in the face of fluctuating raw material costs and global disruptions.

- AI can optimize RDP manufacturing processes by enabling predictive maintenance for machinery, reducing downtime, and increasing operational efficiency.

- Leveraging AI in research and development can accelerate the discovery of novel RDP formulations with enhanced properties by simulating material interactions and predicting performance.

- AI-driven supply chain analytics can provide better forecasting of raw material prices and availability, enabling more strategic procurement and inventory management.

- Automated quality control systems powered by AI can detect inconsistencies in RDP production in real-time, ensuring higher product quality and reducing waste.

- AI can facilitate customized RDP solutions by analyzing customer requirements and recommending optimal formulations, thus enhancing customer satisfaction and market responsiveness.

- Predictive modeling with AI can help anticipate market demand for various RDP types across different regions, allowing manufacturers to adjust production proactively.

DRO & Impact Forces Of Redispersible Latex Powder Market

The Redispersible Latex Powder (RDP) market is shaped by a confluence of influential factors, categorized into drivers, restraints, opportunities, and broader impact forces. Key drivers include the relentless expansion of the global construction industry, particularly the rapid pace of urbanization and infrastructure development in emerging economies, which necessitates high-performance additives for durable and sustainable structures. The increasing adoption of green building practices and materials, alongside a rising demand for renovation and repair activities in mature markets, further fuels the market's growth. The inherent benefits of RDPs, such as improved adhesion, flexibility, and water resistance in cementitious applications, solidify their indispensable role in modern construction formulations. Technological advancements leading to specialized RDP variants for niche applications also contribute significantly to market expansion, opening new revenue streams for manufacturers.

However, the market also faces notable restraints. The volatility in raw material prices, particularly for vinyl acetate monomer (VAM) and butadiene, which are critical precursors for VAE and SB RDPs, can significantly impact production costs and profit margins. Stringent environmental regulations in some regions concerning VOC emissions and chemical manufacturing processes pose compliance challenges and may necessitate costly process adjustments. Furthermore, the availability of alternative binders and additives, while often not offering the full spectrum of RDP benefits, can present competitive pressures, especially in price-sensitive segments. The capital-intensive nature of RDP production and the need for specialized technical expertise also act as barriers to entry for new players, leading to market concentration among established manufacturers.

Opportunities within the RDP market are abundant, especially in emerging economies where the construction sector is undergoing rapid transformation and modernization. There is significant potential for market penetration in these regions as building codes evolve and the demand for higher quality construction materials increases. The development of specialized RDPs designed for specific applications like 3D printing in construction, or formulations with enhanced fire resistance and antimicrobial properties, represents untapped growth avenues. Moreover, advancements in sustainable chemistry and bio-based raw materials offer pathways for developing eco-friendly RDPs, aligning with global sustainability initiatives and attracting environmentally conscious consumers. These innovations not only address existing market gaps but also position RDP as a crucial component in future-proof construction solutions. Impact forces such as global economic fluctuations directly influence construction spending, while geopolitical tensions can disrupt supply chains and raw material availability, requiring manufacturers to build resilient operational strategies. Regulatory shifts, particularly those related to environmental standards and construction material specifications, continuously shape product development and market dynamics. Additionally, ongoing technological innovation remains a constant impact force, driving continuous improvement in RDP performance and expanding its application scope, thereby ensuring its long-term relevance and growth within the construction chemicals industry.

Segmentation Analysis

The Redispersible Latex Powder (RDP) market is comprehensively segmented by type, application, and end-user, providing a granular view of market dynamics and growth opportunities. Each segment highlights distinct product characteristics, usage patterns, and consumer demands that collectively shape the market landscape. Understanding these segmentations is crucial for manufacturers to tailor their product offerings, develop targeted marketing strategies, and optimize their supply chains to meet specific industry needs. The versatility of RDP allows for its integration into a wide array of construction materials, reflecting the diverse requirements of the global building and construction sector.

- By Type:

- Vinyl Acetate Ethylene (VAE): Dominant segment due to excellent balance of flexibility, adhesion, and water resistance; widely used in various dry-mix mortars.

- Styrene Butadiene (SB): Known for superior water resistance and high flexibility, making it suitable for waterproofing and crack bridging applications.

- VeoVa (Vinyl Ester of Versatic Acid): Offers good hydrolytic stability and adhesion, particularly in exterior coatings and renders.

- Acrylic: Provides excellent UV stability, weather resistance, and strong adhesion; often used in exterior applications and repair mortars.

- Others: Includes specialized RDP types for niche applications, offering specific performance enhancements.

- By Application:

- Tile Adhesives and Grouts: Largest application, improving bond strength, flexibility, and water resistance for various tile types.

- Exterior Insulation and Finish Systems (EIFS): Enhances impact resistance, crack resistance, and weatherability of insulation boards and renders.

- Self-Leveling Compounds: Improves flowability, adhesion, and compressive strength for smooth floor finishes.

- Wall Putty: Provides better adhesion, crack resistance, and workability for smooth wall surfaces.

- Mortars (Repair Mortars, Masonry Mortars): Increases durability, flexibility, and adhesion in repair and masonry applications.

- Concrete Admixtures: Enhances workability, reduces permeability, and improves durability of concrete.

- Plaster: Improves adhesion, flexibility, and crack resistance in plaster formulations.

- Gypsum Products: Enhances strength, workability, and moisture resistance in gypsum-based materials.

- Others: Includes applications in waterproofing membranes, sealants, joint fillers, and various other construction chemicals.

- By End-User:

- Residential: Driven by new housing construction and renovation activities, requiring RDP in tiling, plastering, and EIFS.

- Commercial: Includes office buildings, retail spaces, and hotels, where aesthetic appeal and durability are critical for flooring, facades, and interior finishes.

- Industrial: Utilized in industrial flooring, specialized repair mortars, and protective coatings for factories and warehouses, demanding high performance and chemical resistance.

- By Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America

- Middle East and Africa (MEA)

Value Chain Analysis For Redispersible Latex Powder Market

The value chain for the Redispersible Latex Powder (RDP) market is a complex network involving several stages, beginning from the procurement of raw materials to the final distribution to end-users. The upstream analysis focuses on the sourcing and processing of critical feedstocks. Key raw materials include vinyl acetate monomer (VAM), ethylene, butadiene, acrylic monomers, and various stabilizers and emulsifiers. These are typically sourced from petrochemical companies. The quality and stable supply of these basic chemicals are paramount, as they directly impact the performance and cost-effectiveness of the final RDP product. Fluctuations in crude oil prices and petrochemical market dynamics significantly influence the upstream segment, creating challenges and opportunities for manufacturers to secure favorable supply agreements and manage input costs.

Midstream activities involve the actual manufacturing process of RDP. This stage includes the polymerization of monomers into latex emulsions, followed by spray drying, which converts the liquid emulsion into a fine, free-flowing powder. This process requires specialized equipment and technical expertise to ensure consistent particle size distribution, redispersibility, and overall product quality. Manufacturers often invest heavily in R&D to optimize these processes, improve product performance, and develop new formulations that cater to evolving market demands, such as enhanced sustainability or specialized application properties. This phase is critical for value addition, transforming basic chemicals into high-performance construction additives with specific functionalities. Companies at this stage strive for operational efficiency, cost reduction through process optimization, and differentiation through product innovation.

Downstream activities encompass the distribution and sales of RDP to various end-users in the construction industry. This segment involves an intricate distribution channel network that can be broadly categorized into direct and indirect channels. Direct channels involve RDP manufacturers selling directly to large dry-mix mortar producers, major construction companies, or specialized formulators who incorporate RDP into their final products. This approach allows for closer client relationships, technical support, and tailored solutions. Indirect channels involve distributors, agents, and wholesalers who serve smaller customers, regional markets, and offer a broader range of construction chemical products. These intermediaries play a crucial role in market penetration, inventory management, and providing localized support. The choice of distribution channel depends on factors such as market size, geographic reach, customer type, and logistical capabilities. Effective management of these channels is vital for timely product delivery, market accessibility, and maintaining competitive pricing, ensuring that the RDP reaches its intended application efficiently and effectively.

Redispersible Latex Powder Market Potential Customers

The primary potential customers for Redispersible Latex Powder (RDP) are diverse entities within the construction and building materials industry, all seeking to enhance the performance and durability of their products. These end-users or buyers typically fall into several categories, each with specific needs and applications for RDP. A significant portion of the demand originates from dry-mix mortar manufacturers. These companies produce a wide range of pre-mixed powders such as tile adhesives, tile grouts, wall putties, self-leveling compounds, and repair mortars, where RDP is a crucial ingredient for improving adhesion, flexibility, water resistance, and workability. For these manufacturers, RDP is not merely an additive but a performance enhancer that allows them to meet stringent building codes and customer expectations for high-quality, long-lasting construction materials. The ability of RDP to impart specific properties enables these manufacturers to develop differentiated products for various applications and market segments, from standard residential projects to high-performance commercial and industrial constructions.

Another major customer segment includes producers of Exterior Insulation and Finish Systems (EIFS) and other facade coating systems. These manufacturers rely on RDP to improve the adhesion of insulation boards to substrates, enhance the flexibility and crack resistance of base coats and finish coats, and contribute to the overall weatherability and durability of the facade system. The demand for EIFS is driven by increasing energy efficiency mandates and the desire for sustainable building solutions, positioning EIFS manufacturers as consistent buyers of specialized RDPs. Furthermore, manufacturers of concrete admixtures and specialized concrete repair products also constitute a significant customer base. RDPs are incorporated into these products to improve the workability of fresh concrete, reduce permeability, enhance bond strength for repair applications, and increase the overall durability and service life of concrete structures. These customers are looking for RDP solutions that can withstand harsh environmental conditions, provide structural integrity, and extend the lifespan of concrete infrastructure projects.

Beyond these primary segments, other potential customers include gypsum board manufacturers, who use RDP to improve the strength and moisture resistance of gypsum-based products; specialized construction chemical formulators creating waterproofing membranes, sealants, and joint fillers; and increasingly, innovative companies exploring RDP for additive manufacturing in construction, such as 3D printing of concrete elements. The residential, commercial, and industrial construction sectors, directly or indirectly, represent the ultimate end-users, with contractors, builders, and property developers influencing the demand for RDP-enhanced materials. The continuous pursuit of higher performance, greater sustainability, and cost-effectiveness in construction materials across all these segments ensures a consistent and evolving demand for Redispersible Latex Powder, making this market resilient and dynamic.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 4.2 Billion |

| Market Forecast in 2033 | USD 7.2 Billion |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Wacker Chemie AG, BASF SE, Celanese Corporation, Dow Inc., Ashland Global Holdings Inc., Arkema S.A., Shandong Xindadi Industrial Group Co., Ltd., Anhui Newman Chemical Co., Ltd., acques Co., Ltd., Guangzhou Jinshen Chemical Co., Ltd., Sanwei Chemical Co., Ltd., Shanxi Sanwei Group Co., Ltd., Vinavil S.p.A., Bosson Union Chemical Corporation, Synthomer plc, Benson Polymer Pvt. Ltd., GEMHOO Chemical, KCC Corporation, SIDLEY Chemical Co., Ltd., Dairen Chemical Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Redispersible Latex Powder Market Key Technology Landscape

The Redispersible Latex Powder (RDP) market is characterized by a dynamic and evolving technology landscape, primarily focused on enhancing product performance, sustainability, and application versatility. Core technologies revolve around the polymerization processes used to create the base latex emulsions, such as emulsion polymerization for vinyl acetate-ethylene (VAE) copolymers, styrene-butadiene (SB) copolymers, and various acrylic polymers. Advancements in polymerization techniques aim to achieve greater control over polymer architecture, particle size distribution, and monomer ratios, leading to RDPs with tailored properties like improved hydrophobicity, stronger adhesion to challenging substrates, or enhanced flexibility at low temperatures. These advancements directly translate into superior performance in dry-mix mortar formulations, allowing for the development of higher-quality and more specialized construction materials.

Beyond polymerization, spray drying technology is a critical aspect of the RDP manufacturing process. Innovations in spray drying equipment and methodologies are crucial for producing free-flowing powders that redisperse easily in water without clumping and maintain their performance characteristics. Technologies are continually being developed to optimize drying parameters, reduce energy consumption, and ensure the consistent quality and stability of the RDP. This includes advancements in nozzle design, drying chamber configurations, and post-processing treatments that prevent agglomeration and improve the shelf life of the powder. The development of encapsulation techniques also plays a role, ensuring that the polymer particles are effectively protected until they are redispersed, thereby preserving their functionality.

Furthermore, the key technology landscape includes formulation science and application engineering. This involves understanding the complex interactions between RDPs and other dry-mix mortar ingredients, such as cement, aggregates, additives, and water. Manufacturers are leveraging advanced analytical techniques and computational modeling to predict how different RDP formulations will perform in specific applications, optimizing the blend for desired properties like open time, sag resistance, bond strength, and water retention. There's a growing focus on developing RDPs with reduced VOC emissions and those derived from bio-based or recycled content, aligning with sustainable construction trends. This involves the exploration of new polymer chemistries and the integration of novel functional additives to achieve eco-friendly yet high-performance solutions, reflecting a commitment to innovation that extends beyond traditional performance metrics to encompass environmental responsibility and broader market demands for green building materials.

Regional Highlights

- Asia Pacific: This region is the undisputed leader in the Redispersible Latex Powder market, driven by massive investments in infrastructure, rapid urbanization, and a booming residential and commercial construction sector, particularly in China, India, and Southeast Asian countries. The presence of numerous manufacturing facilities and a large consumer base contribute to its dominance.

- Europe: A mature market characterized by a strong emphasis on sustainable construction, renovation of existing buildings, and the widespread adoption of energy-efficient systems like EIFS. Western European countries lead in the consumption of high-performance RDPs, driven by stringent building codes and a demand for durable, long-lasting materials.

- North America: Exhibits steady growth fueled by a recovering construction industry, increasing focus on residential and commercial renovations, and a growing preference for advanced building materials that offer enhanced durability and performance. The region also sees significant R&D activities for specialized RDP applications.

- Latin America: An emerging market with considerable growth potential, primarily driven by increasing government spending on public infrastructure projects, rising disposable incomes, and urbanization trends in countries like Brazil and Mexico. The adoption of modern construction practices is gradually boosting RDP demand.

- Middle East and Africa (MEA): This region is witnessing substantial growth due to ambitious construction projects, particularly in the GCC countries (UAE, Saudi Arabia, Qatar) for new cities, hospitality, and commercial developments. Growing populations and economic diversification initiatives further stimulate the demand for RDP in various construction applications.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Redispersible Latex Powder Market.- Wacker Chemie AG

- BASF SE

- Celanese Corporation

- Dow Inc.

- Ashland Global Holdings Inc.

- Arkema S.A.

- Shandong Xindadi Industrial Group Co., Ltd.

- Anhui Newman Chemical Co., Ltd.

- acques Co., Ltd.

- Guangzhou Jinshen Chemical Co., Ltd.

- Sanwei Chemical Co., Ltd.

- Shanxi Sanwei Group Co., Ltd.

- Vinavil S.p.A.

- Bosson Union Chemical Corporation

- Synthomer plc

- Benson Polymer Pvt. Ltd.

- GEMHOO Chemical

- KCC Corporation

- SIDLEY Chemical Co., Ltd.

- Dairen Chemical Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the Redispersible Latex Powder market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is Redispersible Latex Powder (RDP) and how is it used in construction?

Redispersible Latex Powder (RDP) is a polymer powder that, when mixed with water, forms a liquid emulsion. It is used as a chemical additive in dry-mix mortars and other cementitious formulations to improve key properties such as adhesion, flexibility, water resistance, and workability, thereby enhancing the durability and performance of construction materials.

What are the main types of RDP available in the market?

The primary types of RDP include Vinyl Acetate Ethylene (VAE) copolymers, Styrene Butadiene (SB) copolymers, VeoVa (Vinyl Ester of Versatic Acid), and Acrylics. Each type offers distinct performance characteristics, making them suitable for different applications based on desired properties like flexibility, adhesion strength, or water resistance.

Which factors are driving the growth of the RDP market?

The market growth is primarily driven by the expanding global construction industry, rapid urbanization, increasing demand for green building materials, governmental investments in infrastructure projects, and the rising emphasis on renovation and repair activities across various regions, all requiring high-performance additives like RDP.

What are the key applications of RDP in the construction industry?

RDP is extensively used in various applications, including tile adhesives and grouts, exterior insulation and finish systems (EIFS), self-leveling compounds, wall putties, repair and masonry mortars, concrete admixtures, plaster, and gypsum products, among others, where it significantly enhances material properties.

What are the major challenges faced by the Redispersible Latex Powder market?

Key challenges include the volatility of raw material prices (such as VAM and butadiene), which impacts production costs and profit margins. Additionally, stringent environmental regulations in some regions regarding VOC emissions and manufacturing processes pose compliance challenges for RDP producers.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager