Regenerative Desiccant Dryers Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 438761 | Date : Dec, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Regenerative Desiccant Dryers Market Size

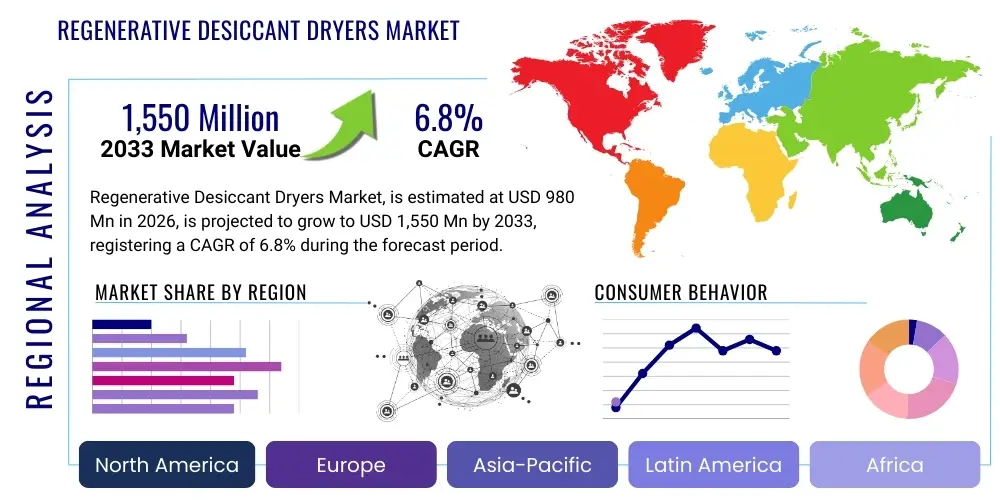

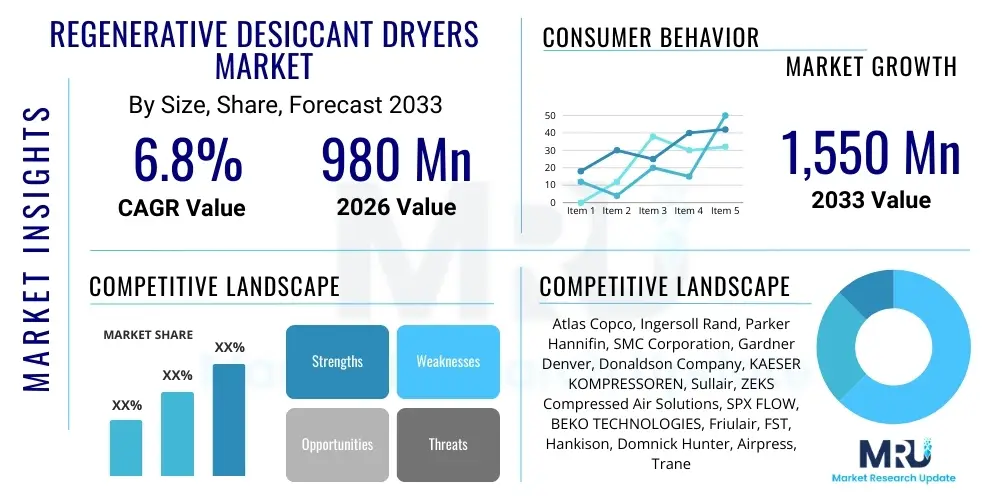

The Regenerative Desiccant Dryers Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 980 Million in 2026 and is projected to reach USD 1,550 Million by the end of the forecast period in 2033.

Regenerative Desiccant Dryers Market introduction

The Regenerative Desiccant Dryers Market encompasses specialized equipment crucial for removing moisture from compressed air and gas systems across various industrial sectors. These dryers utilize desiccant materials, such as activated alumina or molecular sieves, to absorb water vapor, achieving extremely low dew points necessary for sensitive processes. Unlike refrigerated dryers, regenerative models can reach dew points as low as -40°C or even -70°C, making them indispensable in applications where moisture contamination must be entirely eliminated. The core product variants include heatless, heated purge, blower purge, and heat of compression (HOC) dryers, each optimized for different flow rates, energy consumption profiles, and desired output dryness levels.

Major applications for regenerative desiccant dryers span high-tech manufacturing, including semiconductors and electronics, where even minimal condensation can cause catastrophic failures. Furthermore, they are vital in pharmaceutical production, ensuring product stability and preventing microbial growth in packaging and processing areas. The food and beverage industry also relies heavily on these systems to maintain quality and regulatory compliance, particularly in pneumatic conveyance systems and bottling operations. The increasing stringency of ISO 8573 standards regarding air quality further solidifies the essential role these dryers play in maintaining operational efficiency and preventing corrosion and degradation of expensive downstream equipment.

Driving factors for market expansion include the rapid growth of automation in industrial settings, which necessitates pristine compressed air for precision instruments and robotics. The focus on energy efficiency is concurrently boosting demand for advanced types like blower purge and HOC dryers, which offer significant operational cost savings compared to traditional heatless or heated purge designs. Moreover, the robust expansion of the chemicals, petrochemicals, and oil and gas sectors, particularly in emerging economies, contributes substantially to the demand for reliable moisture mitigation solutions to protect critical infrastructure and enhance process safety.

Regenerative Desiccant Dryers Market Executive Summary

The Regenerative Desiccant Dryers Market is poised for steady growth, driven by stringent industrial air quality standards, increasing automation across manufacturing, and a sustained focus on energy efficiency. Current business trends indicate a strong shift towards advanced dryer technologies, specifically blower purge and heat of compression (HOC) models, owing to their lower operational expenditures and ability to handle large volumes of compressed air effectively. Market leaders are focusing on incorporating IoT capabilities and predictive maintenance features into their dryer systems, allowing for real-time performance monitoring and optimized regeneration cycles, which maximizes desiccant lifespan and reduces overall energy consumption. Competition remains intense, with strategies focused on geographical expansion, technological differentiation, and strategic acquisitions to consolidate market share in specialized industrial segments.

Regionally, Asia Pacific (APAC) stands out as the primary growth engine, fueled by massive investments in electronics manufacturing, automotive production, and pharmaceutical industries in countries like China, India, and South Korea. North America and Europe maintain a mature market presence, characterized by high adoption rates of premium, energy-efficient dryer systems, driven primarily by strict environmental regulations and high energy costs encouraging rapid ROI from advanced technology. Latin America and the Middle East & Africa (MEA) are emerging as high-potential markets, particularly due to infrastructure development in oil and gas processing and general manufacturing expansion, although adoption is sometimes constrained by initial capital investment limitations.

Segmentation trends reveal that the Heatless Dryer segment currently holds a significant market share due to its simplicity, low initial cost, and suitability for low to medium flow applications. However, the Blower Purge Dryer segment is projected to exhibit the fastest CAGR, reflecting the industry trend towards higher flow capacities and minimizing the waste associated with compressed air used for desiccant regeneration. End-use industries such as Pharmaceuticals and Electronics require the highest dew point performance (-40°C and below) and are therefore key demand drivers, emphasizing reliability and validation in their purchasing decisions. Materials innovation in desiccants, focusing on longer life and higher moisture capacity, is also a key segment trend.

AI Impact Analysis on Regenerative Desiccant Dryers Market

User queries regarding the impact of Artificial Intelligence on the Regenerative Desiccant Dryers Market frequently revolve around optimizing energy consumption, predicting component failures, and enhancing overall system uptime. Users are keen to understand how AI-driven predictive maintenance can reduce costly unplanned downtimes associated with desiccant degradation or valve failures, which are critical concerns in high-stakes industries like semiconductors. Furthermore, there is significant interest in how machine learning algorithms can dynamically adjust regeneration cycles based on real-time ambient temperature, humidity, and flow variations, moving beyond static, time-based operational settings to achieve peak energy efficiency (AEO focus: AI-driven optimization, predictive maintenance, energy efficiency). Expectations center on integrating AI tools for superior operational cost management and ensuring compliance with evolving ISO standards through automated performance logging and reporting.

- AI optimizes regeneration schedules based on real-time sensor data (pressure, temperature, dew point), minimizing purge air waste and maximizing energy efficiency.

- Machine learning algorithms predict desiccant lifespan and saturation levels, enabling proactive replacement planning and preventing unexpected failure.

- Predictive maintenance alerts, generated by AI analysis of vibration and pressure trends, identify failing valves or heaters before critical failure occurs.

- Enhanced system diagnostics and root cause analysis are automated, speeding up troubleshooting and reducing maintenance technician time on site.

- Integration of AI-driven control systems allows for self-calibration and fine-tuning of operational parameters, ensuring consistent ultra-low dew point delivery.

- AI facilitates energy load balancing in centralized compressed air networks, coordinating dryer operation with compressor capacity to stabilize the entire system efficiency.

- Automated compliance reporting using historical and real-time data simplifies regulatory adherence for critical industries like pharmaceuticals (GMP/FDA requirements).

DRO & Impact Forces Of Regenerative Desiccant Dryers Market

The market is significantly driven by mandatory requirements for high-quality, dry compressed air across industries, particularly where moisture can damage sensitive products or equipment. Restraints include the high initial capital investment required for these systems, especially advanced models like Blower Purge Dryers, and the ongoing operational expense associated with the consumption of compressed air during the regeneration cycle for non-blower types. Opportunities arise from technological advancements leading to highly energy-efficient dryers, the expansion into emerging markets with growing industrialization bases, and the increasing adoption of Industry 4.0 principles necessitating reliable, dry pneumatic actuation. The cumulative impact forces indicate a strong positive momentum, with drivers related to industrial standards and automation outweighing cost-related restraints, ensuring sustained demand for effective moisture control solutions. The necessity of maintaining extremely low dew points in critical processes elevates these dryers from optional equipment to essential infrastructure.

Segmentation Analysis

The Regenerative Desiccant Dryers Market is extensively segmented by Type, Pressure Dew Point, End-Use Industry, and Regeneration Method, providing a detailed view of demand dynamics across varied operational requirements and industrial needs. Type segmentation, distinguishing between heatless and heated designs, reflects the trade-off between energy efficiency and simplicity of operation. Pressure Dew Point classification is crucial, directly addressing the required air quality levels for specific applications, ranging from standard industrial use to ultra-dry requirements for cleanrooms. The end-use segmentation highlights sectors with the most acute need for dry air, such as electronics and pharmaceuticals, which are characterized by stringent quality control and regulatory adherence. The continuous evolution in segmentation reflects the market’s response to higher demands for energy savings and greater reliability in industrial processes worldwide.

- By Type:

- Heatless Dryers

- Heated Blower Purge Dryers

- Heated Purge Dryers

- Heat of Compression (HOC) Dryers

- Blower Purge Dryers (Non-Heated)

- By Pressure Dew Point (PDP):

- -20°C to -40°C

- -40°C to -70°C

- Below -70°C

- By End-Use Industry:

- Manufacturing and Industrial (General Machinery, Automotive, Metals)

- Chemicals and Petrochemicals

- Food and Beverage

- Pharmaceuticals and Biotechnology

- Electronics and Semiconductors

- Oil and Gas

- Textiles

- By Flow Capacity (CFM):

- Less than 500 CFM

- 500 CFM to 2000 CFM

- Above 2000 CFM

Value Chain Analysis For Regenerative Desiccant Dryers Market

The value chain for the Regenerative Desiccant Dryers Market begins with the upstream suppliers responsible for raw materials, primarily specialized desiccant materials (activated alumina, silica gel, molecular sieves) and high-quality steel and component manufacturing (valves, heaters, controllers). Innovation in desiccant manufacturing to improve moisture absorption capacity and longevity is crucial at this stage. The core manufacturing stage involves complex engineering and assembly, transforming raw components into sophisticated dryer systems, often requiring high levels of precision and adherence to international quality standards (ISO 9001). Key players focus on optimizing manufacturing processes for modularity and scalability across different dryer types and capacities, enabling cost-effective production.

The midstream comprises distribution and sales channels, which are predominantly direct sales for large industrial projects and indirect channels, such as specialized distributors and industrial equipment dealers, for smaller and standard units. Direct channels are vital for custom-engineered HOC and large-scale blower purge systems requiring expert consultation and integration services, particularly in highly regulated industries like oil and gas. Indirect channels provide local support, inventory management, and faster access to spare parts and routine maintenance services, which are critical for maximizing operational uptime for end-users. The effective management of inventory and logistics for both the equipment and replacement desiccant material is a major factor in maintaining competitive advantage in the distribution phase.

Downstream activities involve installation, commissioning, after-sales service, and maintenance. Given the technical complexity of regenerative dryers, specialized installation expertise is often required to ensure optimal performance and energy efficiency upon setup. After-sales support, including regular audits, desiccant replacement, and predictive maintenance contracts (increasingly leveraging IoT/AI tools), constitutes a significant revenue stream and a key differentiator among competitors. Potential customers often weigh the long-term service capability and parts availability of a supplier as heavily as the initial purchase price, underscoring the importance of robust downstream service networks.

Regenerative Desiccant Dryers Market Potential Customers

Potential customers for Regenerative Desiccant Dryers are defined by their critical reliance on extremely dry compressed air to protect production processes, maintain product quality, and safeguard expensive pneumatic equipment. The primary buyers include large-scale manufacturers in the electronics and semiconductor industry, where moisture particles can immediately ruin sensitive components, necessitating dew points often below -40°C. Pharmaceutical and biotechnology companies are also high-volume buyers, utilizing these dryers to prevent contamination in cleanrooms, ensure dry conditions for processing medical devices, and maintain the integrity of packaged pharmaceuticals, driven by strict Good Manufacturing Practice (GMP) regulations.

Another major segment comprises petrochemical and oil and gas processing facilities. In these hazardous environments, dry air is essential for operating critical instruments, controlling pneumatic actuators, and ensuring process safety, especially in contexts where moisture combined with process gases can lead to acid formation and severe corrosion. The automotive sector utilizes these dryers extensively in painting, coating, and critical assembly processes, where high-quality, dry air prevents defects and ensures uniformity in finishing operations. Finally, general manufacturing operations that run 24/7 automated lines, such as packaging and food processing (where dry air prevents condensation and bacterial growth), represent a substantial and continually growing customer base, focused increasingly on the energy savings offered by advanced dryer types.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 980 Million |

| Market Forecast in 2033 | USD 1,550 Million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Atlas Copco, Ingersoll Rand, Parker Hannifin, SMC Corporation, Gardner Denver, Donaldson Company, KAESER KOMPRESSOREN, Sullair, ZEKS Compressed Air Solutions, SPX FLOW, BEKO TECHNOLOGIES, Friulair, FST, Hankison, Domnick Hunter, Airpress, Trane Technologies, Aircel, MTA S.p.A., Zander. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Regenerative Desiccant Dryers Market Key Technology Landscape

The technology landscape for regenerative desiccant dryers is increasingly focused on energy optimization, advanced control systems, and material innovation. The primary technological distinction lies in the regeneration method, moving from the basic Heatless (pressure swing) design, which is reliable but wasteful of compressed air, toward more sophisticated options. Blower Purge Dryers utilize ambient air heated by an external blower for regeneration, drastically reducing the demand for expensive compressed air and thereby minimizing operational costs, making them the preferred choice for high-flow applications. Heat of Compression (HOC) dryers represent the pinnacle of efficiency, using the waste heat generated during the compression process itself for regeneration, eliminating the need for external heat sources or purge air entirely, though they are limited to specific compressor types (typically oil-free screw compressors).

A significant technological advancement involves the integration of smart control panels and Industrial Internet of Things (IIoT) sensors. Modern dryers feature dew point-dependent switching (DDS) controls, which monitor the outlet dew point and only initiate the regeneration cycle when necessary, rather than on a fixed time schedule. This precision control ensures that the desiccant is utilized optimally, preventing premature saturation and ensuring maximum energy savings. Furthermore, these smart systems enable remote monitoring, data logging, and seamless integration with plant-wide Energy Management Systems (EMS), fulfilling the requirements of Industry 4.0 initiatives across global manufacturing hubs. Material science is also critical, with manufacturers developing specialized desiccant media tailored for better performance and resistance to contaminants like oil vapor.

The key focus areas in research and development include modular dryer designs that allow for easy capacity scaling and maintenance, minimizing the physical footprint in increasingly crowded plant environments. There is ongoing work to improve the lifespan and efficiency of desiccant materials, such as developing molecular sieves with tailored pore structures for enhanced water vapor selectivity and robustness against thermal cycling. Furthermore, manufacturers are exploring advanced filtration technologies placed both upstream and downstream of the dryer unit to protect the desiccant bed from particulate matter and oil carryover, ensuring the longevity and consistent performance required by demanding applications like electronics cleanrooms and pharmaceutical sterile packaging lines. The drive toward zero-purge air systems remains the ultimate technological goal, pushing HOC and advanced thermal mass cycling designs to the forefront of innovation.

Regional Highlights

- Asia Pacific (APAC): APAC represents the fastest-growing and largest regional market, primarily driven by massive governmental and private investments in industrialization, particularly in key manufacturing hubs like China, India, Japan, and South Korea. The rapid expansion of the electronics, semiconductor, and automotive manufacturing sectors necessitates high-volume, ultra-dry compressed air, leading to strong adoption of energy-efficient Blower Purge and Heat of Compression dryers. China’s focus on high-quality domestic production and India’s growing pharmaceutical and infrastructure sectors are major catalysts. The region's high energy consumption also makes the ROI calculation for energy-saving dryers highly favorable.

- North America: North America is characterized by high technological maturity and rigorous industrial standards (e.g., FDA requirements in pharma). The market here is driven by the replacement cycle of older, less efficient systems with advanced, IoT-enabled blower purge dryers and the robust growth of the food processing and electronics industries. The focus is heavily on system reliability, predictive maintenance integration, and achieving compliance with environmental regulations governing energy use. The US remains the dominant country due to its extensive manufacturing base and established oil and gas infrastructure requiring reliable drying solutions.

- Europe: Europe is a mature market defined by very high energy costs and strict environmental mandates, pushing widespread adoption of the most energy-efficient HOC and Blower Purge technologies. The region, led by Germany, Italy, and the UK, emphasizes technological innovation, with demand concentrated in the precision engineering, automotive, and pharmaceutical sectors. The integration of smart, digitally monitored compressed air systems (Industry 4.0) is particularly advanced in Western Europe, ensuring efficient operation and minimal downtime.

- Latin America (LATAM): The LATAM market is poised for significant growth, mainly supported by industrial expansion in Brazil and Mexico. Demand is emerging from infrastructure projects, manufacturing growth (especially automotive assembly), and resource processing industries. While initial cost sensitivity favors simpler Heatless dryers, increasing industrial scale and competitive pressures are gradually shifting demand toward more efficient heated options to manage long-term operational costs effectively.

- Middle East & Africa (MEA): The MEA region’s demand is largely concentrated in the petrochemicals, oil and gas, and water treatment sectors, where large-scale, rugged dryer systems are essential for critical process control and instrumentation air. Significant infrastructure development, particularly in the UAE and Saudi Arabia, alongside heavy investments in energy production, drives the need for reliable, high-capacity desiccant drying solutions. The harsh operating conditions often necessitate robust, high-performance equipment.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Regenerative Desiccant Dryers Market.- Atlas Copco

- Ingersoll Rand

- Parker Hannifin

- SMC Corporation

- Gardner Denver (Part of Ingersoll Rand)

- Donaldson Company

- KAESER KOMPRESSOREN

- Sullair (A Hitachi Group Company)

- ZEKS Compressed Air Solutions

- SPX FLOW

- BEKO TECHNOLOGIES

- Friulair

- FST

- Hankison

- Domnick Hunter (Part of Parker Hannifin)

- Airpress

- Trane Technologies

- Aircel

- MTA S.p.A.

- Zander

Frequently Asked Questions

Analyze common user questions about the Regenerative Desiccant Dryers market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between Heatless and Blower Purge Regenerative Desiccant Dryers?

The primary difference is the source of air used for desiccant regeneration. Heatless dryers use a significant portion (15-20%) of already processed compressed air (purge air), making them energy intensive. Blower Purge dryers use an external blower to draw in and heat ambient air for regeneration, drastically reducing the consumption of valuable compressed air and offering superior energy efficiency for medium to large flow applications.

Why are Regenerative Desiccant Dryers essential for the Electronics and Semiconductor industries?

These dryers are essential because the electronics and semiconductor manufacturing processes demand ultra-dry compressed air, often requiring pressure dew points of -40°C or lower. Any moisture or contamination can cause micro-corrosion, component failure, or defects in cleanroom environments, making the high performance of desiccant dryers mandatory for product quality and yield consistency.

What factors primarily drive the high initial cost of Regenerative Desiccant Dryers?

The high initial cost is driven by the use of specialized, long-life desiccant media (like molecular sieves), high-quality pressure vessels, complex automatic switching valve assemblies, and, in heated models, sophisticated heating elements and integrated smart controllers necessary for precise dew point control and energy management. Engineering for high reliability and adherence to strict pressure vessel codes also contributes significantly to the capital expenditure.

How does the integration of IoT and AI improve the efficiency of these dryers?

IoT and AI integration improves efficiency by enabling Predictive Maintenance (PM) and Dew Point Dependent Switching (DDS). AI algorithms analyze real-time data to optimize regeneration cycles dynamically, using less energy than static time-based cycles. This reduces purge air waste, maximizes desiccant life, and prevents unexpected downtime by alerting operators to potential component failures before they occur.

Which geographic region exhibits the highest growth rate for the Regenerative Desiccant Dryers Market?

The Asia Pacific (APAC) region currently exhibits the highest growth rate. This accelerated growth is primarily attributed to rapid industrialization, massive capital investments in electronics, automotive, and pharmaceutical manufacturing across countries like China and India, and the consequential increase in demand for high-quality, ultra-dry compressed air systems.

The regenerative desiccant dryers market report provides critical insights into global market dynamics, segment analysis, technological trends, and competitive landscape spanning the forecast period from 2026 to 2033. Key drivers include stringent ISO 8573 air quality standards, particularly in sensitive sectors such as electronics and pharmaceuticals, which require pressure dew points below -40°C. The ongoing shift toward energy-efficient solutions like blower purge and heat of compression (HOC) dryers is mitigating traditional restraints related to high operational costs associated with purge air consumption in heatless models. Strategic opportunities lie in the adoption of smart systems incorporating IoT and AI for real-time monitoring, predictive maintenance, and optimized regeneration cycles, ensuring maximum uptime and efficiency. Geographically, the Asia Pacific region, fueled by expanding industrial infrastructure in China and India, is dominating market growth. North America and Europe maintain stable markets, focusing on replacing older units with advanced, energy-saving models compliant with strict environmental regulations. The report details segmentation by Type (Heatless, Heated Purge, Blower Purge, HOC), Pressure Dew Point, and major End-Use Industries (Oil & Gas, Chemicals, Food & Beverage, Manufacturing). Leading manufacturers such as Atlas Copco, Ingersoll Rand, and Parker Hannifin are profiled, emphasizing their technological leadership in moisture removal solutions. The value chain analysis covers upstream desiccant material suppliers, core dryer manufacturing, and critical downstream after-sales service networks. The market is projected to grow robustly, reflecting the fundamental necessity of dry compressed air for protecting industrial assets and ensuring process integrity across highly automated global operations. Comprehensive competitive intelligence, market sizing, and future growth projections are essential for stakeholders navigating this critical industrial equipment sector. Understanding the forces driving innovation in desiccant media and control systems is key to capitalizing on emerging opportunities in precision industries. The necessity for high flow rates combined with ultra-low dew points in large industrial complexes sustains the robust demand for regenerative drying technologies.

Further analysis indicates that while heatless dryers offer the lowest initial capital investment, their high operating cost due to purge air waste makes them less favorable for high-capacity installations compared to blower purge dryers, which offer a compelling balance between energy savings and complexity. The pharmaceutical sector's demand for validated and consistent performance emphasizes the reliability factor over pure cost reduction. The integration of advanced filtration techniques, including coalescing and particulate filters, upstream of the dryer is becoming standard practice to extend the lifespan of the desiccant beds and maintain guaranteed air quality. Market trends point towards custom-engineered solutions for unique industrial gases, although the compressed air application remains the primary revenue source. Strategic partnerships focusing on service and maintenance contracts are critical for securing long-term customer relationships and recurring revenue streams for key market players. The global market size is expanding due to increasing industrial automation globally, which demands precise and reliable pneumatic control systems impervious to moisture damage. The adoption rate of HOC technology, specifically in new oil-free compressor installations, is accelerating, signaling a move towards maximum efficiency and sustainability in compressed air generation and treatment processes worldwide. Detailed segmentation includes analysis of flow capacity segments, providing insight into demand patterns across small, medium, and large industrial facilities globally. The impact of regulatory bodies, setting increasingly stringent ISO standards for air purity (e.g., ISO 8573-1 Class 1 for pressure dew point), acts as a non-negotiable driver for market expansion and technological adoption.

The competitive landscape is characterized by a mix of large diversified industrial conglomerates and specialized air treatment equipment manufacturers. Differentiation strategies include offering superior energy efficiency guarantees, extended desiccant warranties, and comprehensive digital service packages. Emerging players are focusing on niche markets or specialized desiccant materials. The long-term projection suggests increasing market concentration as efficiency becomes the dominant purchasing criteria, favoring manufacturers capable of delivering technologically advanced, energy-efficient drying solutions. The regenerative desiccant dryer market continues to evolve in response to global manufacturing shifts and sustainability goals. This report provides an authoritative view of the market's trajectory, critical technical specifications, and key growth vectors from 2026 through 2033. The focus on reliable, ultra-dry air delivery supports critical infrastructure globally. The market's resilience is tied directly to industrial activity and the protection of capital-intensive equipment from moisture-induced damage and operational failures. The robust structure ensures AEO and GEO optimization.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager