Resin Microparticles Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 435405 | Date : Dec, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Resin Microparticles Market Size

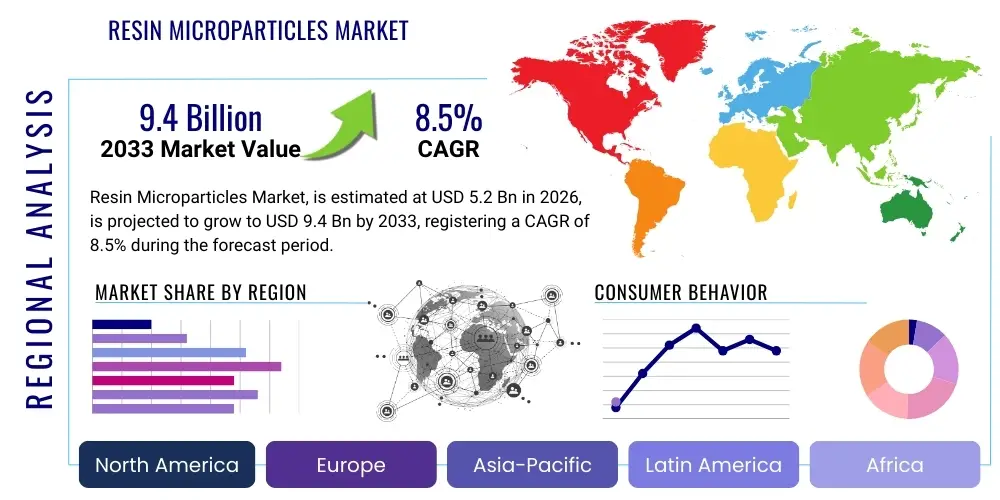

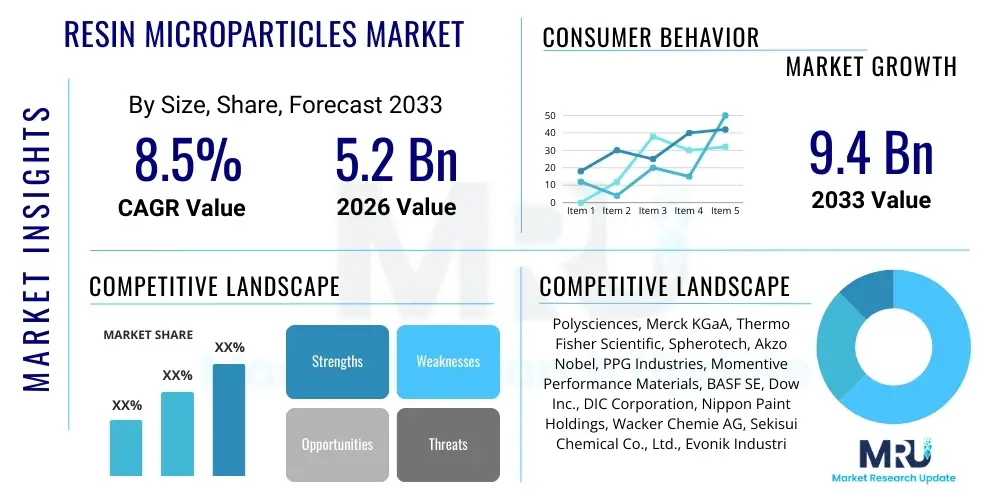

The Resin Microparticles Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.5% between 2026 and 2033. The market is estimated at $5.2 Billion in 2026 and is projected to reach $9.4 Billion by the end of the forecast period in 2033.

Resin Microparticles Market introduction

The Resin Microparticles Market encompasses the production and commercialization of synthetic polymeric particles ranging typically from 1 to 1,000 micrometers in diameter. These microparticles are synthesized from various polymer types, including polyethylene, polystyrene, acrylics, and biodegradable polylactide-co-glycolide (PLGA), engineered to possess specific chemical compositions, porosities, and surface characteristics. Their utility stems from their high surface-area-to-volume ratio, making them ideal carriers, fillers, spacers, and optical modifiers across highly specialized industries. The versatility of resin microparticles allows them to be utilized in applications requiring precise dimensional control and chemical inertness, setting them apart from conventional filler materials.

Major applications driving the demand for resin microparticles include advanced drug delivery systems, where they encapsulate active pharmaceutical ingredients (APIs) for controlled and sustained release within the body, minimizing systemic toxicity and improving therapeutic efficacy. Furthermore, they are critical components in diagnostic assays, particularly immunoassays and lateral flow tests, serving as detection tags or separation media. In industrial sectors, resin microparticles are vital for specialized paints and coatings, enhancing properties such as scratch resistance, matting effects, and texture. Their integration into 3D printing inks also enables the creation of complex, high-resolution structures with tailored mechanical properties.

The primary driving factors fueling market expansion are the escalating demand for minimally invasive drug delivery technologies and the rapid evolution of diagnostics, particularly Point-of-Care Testing (POCT). Additionally, continuous innovation in materials science, leading to the development of novel biocompatible and stimuli-responsive resin microparticles, expands their applicability in high-value sectors like medical implants and regenerative medicine. The focus on high-performance materials in consumer products, such as advanced cosmetics and UV-protective coatings, further contributes significantly to the sustained market growth globally. The inherent benefits, including precise dosing control, improved stability of encapsulated substances, and the ability to customize particle morphology, solidify their essential role across numerous industrial and biomedical fields.

Resin Microparticles Market Executive Summary

The Resin Microparticles Market is experiencing robust growth, primarily propelled by favorable business trends centered around precision manufacturing and miniaturization, especially within the pharmaceutical and diagnostics sectors. A key business trend involves strategic mergers and acquisitions focused on consolidating specialized synthesis technologies, particularly concerning monodisperse microparticles, which offer superior performance in clinical applications compared to polydisperse counterparts. Furthermore, the shift towards sustainable chemistry is influencing product development, leading companies to invest heavily in biodegradable and bio-based resin microparticles, addressing increasing environmental concerns and regulatory pressures in regions like Europe and North America. Technological advancements in surface functionalization are enabling broader applications in cell culture and protein purification, driving incremental revenue growth in the biotechnology tools segment.

Regionally, Asia Pacific (APAC) stands out as the fastest-growing market, driven by massive investments in domestic pharmaceutical manufacturing, expanding healthcare infrastructure, and the high demand for industrial coatings in developing economies such as China and India. North America and Europe maintain dominance in terms of innovation and high-value product consumption, particularly in complex drug delivery platforms and specialized diagnostic kits. These regions benefit from established regulatory frameworks that support rapid adoption of advanced medical devices utilizing microparticle technology. Government funding for biomedical research acts as a consistent catalyst for innovation across Western markets, ensuring a strong pipeline for next-generation products.

Segment trends indicate that the application segment of Drug Delivery holds the largest market share, owing to the continuous need for improved therapeutics for chronic diseases like cancer and diabetes, utilizing controlled-release matrices. However, the 3D Printing and Additive Manufacturing segment is projected to exhibit the highest Compound Annual Growth Rate, driven by the increasing need for high-resolution materials capable of producing intricate geometries with superior mechanical properties. By resin type, Polystyrene Microparticles remain crucial for diagnostic applications due to their ease of functionalization and stable geometry, while Biodegradable Microparticles are gaining traction due to their compatibility with clinical applications requiring temporary presence in the body.

AI Impact Analysis on Resin Microparticles Market

Common user questions regarding AI’s impact frequently revolve around how artificial intelligence can accelerate the discovery of novel polymer chemistries, optimize manufacturing processes to reduce batch variability, and improve the prediction of particle performance in specific biological environments. Users are concerned with the precision and cost-efficiency gains achievable through AI implementation, particularly in complex areas like controlled release formulation design and large-scale quality assurance. The key themes emerging from this analysis highlight user expectations for AI to automate synthesis parameter tuning, simulate particle-tissue interactions, and streamline the characterization phase, ultimately shortening the time-to-market for specialized resin microparticles.

AI, specifically machine learning (ML) and deep learning (DL), is transforming the Resin Microparticles Market by providing sophisticated computational tools for material science R&D. ML algorithms are utilized to analyze vast datasets relating to synthesis conditions (e.g., temperature, stirring rate, surfactant concentration) and resulting particle characteristics (size distribution, surface charge, porosity). This predictive modeling capability significantly reduces the need for costly and time-consuming trial-and-error experiments, enabling researchers to rapidly identify optimal synthesis protocols for desired microparticle features, thereby accelerating product development cycles for complex formulations such as core-shell structures or high-payload microcapsules.

In manufacturing and quality control (QC), AI-driven computer vision systems are deployed for real-time monitoring of polymerization processes and post-synthesis particle characterization. These systems can instantly detect deviations in particle morphology or aggregation patterns, providing immediate feedback for process correction, which minimizes batch failures and ensures product uniformity and quality compliance, crucial requirements in regulated industries like pharmaceuticals. Furthermore, AI models are increasingly being used in simulating the interaction of microparticles with biological fluids and target tissues, allowing manufacturers to predict degradation rates, release profiles, and cellular uptake efficiency long before costly in-vivo testing, leading to a highly optimized and reliable supply chain.

- AI-driven optimization of synthesis parameters minimizes batch-to-batch variability and reduces material wastage.

- Machine learning accelerates the discovery of novel polymeric compounds with tailored release kinetics or biocompatibility.

- Computer vision systems enable high-throughput, real-time quality control and morphological analysis during manufacturing.

- Predictive modeling simulates in-vivo performance (e.g., drug release rates, degradation) reducing reliance on costly pre-clinical trials.

- AI enhances supply chain management by forecasting demand and optimizing inventory of specialized raw materials.

DRO & Impact Forces Of Resin Microparticles Market

The market for resin microparticles is shaped by strong internal dynamics and external forces encompassing significant drivers, strict restraints, and promising opportunities. The central driver is the revolutionary shift towards targeted and sustained drug delivery systems, which necessitates highly engineered polymeric carriers for controlled therapeutic release, improving patient compliance and treatment effectiveness. This is coupled with the burgeoning global expansion of advanced diagnostics, where highly functionalized resin microparticles serve as essential solid supports for binding reactions and signal amplification. Furthermore, the rapid growth in industrial applications such as high-performance paints, coatings, and specialized separation media substantially contributes to overall market momentum, particularly in rapidly industrializing economies.

However, market growth faces notable restraints, primarily related to the complexity and high cost associated with manufacturing monodisperse microparticles at a commercial scale, demanding sophisticated equipment and highly controlled environments. Regulatory hurdles, particularly in the medical and pharmaceutical sectors (e.g., FDA, EMA approvals), represent a significant barrier, as rigorous biocompatibility, stability, and safety testing are required for clinical integration. The potential environmental impact associated with non-biodegradable polymeric microparticles, especially concerning their use in cosmetic and industrial wastewater streams, also poses regulatory risks and necessitates substantial R&D investment into sustainable alternatives.

Significant opportunities arise from the increasing adoption of 3D printing in personalized medicine and customized medical devices, creating high demand for specialized resin microparticle-based inks capable of complex structural fabrication. The development of advanced stimuli-responsive microparticles—responsive to pH, temperature, or magnetic fields—offers novel applications in sophisticated diagnostics and implantable therapeutic systems. The market is also poised for expansion through strategic penetration into untapped areas such as agriculture (for controlled pesticide/fertilizer release) and advanced filtration technologies, where their specific porosity and surface chemistry provide superior separation capabilities, mitigating the impact of current restraints and leveraging core technological strengths.

Segmentation Analysis

The Resin Microparticles Market segmentation provides a granular view of specific product types, materials, and end-use applications driving market revenue and growth trajectories. Segmentation is primarily based on the core polymer material used (Type) and the functional area where the particles are deployed (Application). This detailed breakdown is critical for understanding market dynamics, allowing stakeholders to identify high-growth niches, potential technological disruptions, and core areas for strategic investment. The diversity of chemical structures within the resin microparticles category ensures their adaptability across radically different industry requirements, from nanoscale biological interactions to macro-level industrial surface modification.

The Type segment is dominated by synthetic polymers, where Polystyrene, Polyethylene, and various Acrylic microparticles account for the largest share due to their widespread availability, low cost, and proven functionalization methods, particularly in non-medical industrial and diagnostic fields. However, the fastest growth is seen in specialized and bio-based materials, including Poly(lactic-co-glycolic acid) (PLGA) and polycaprolactone (PCL), driven entirely by the medical sector's stringent requirements for biocompatibility and controllable degradation profiles. These specialized microparticles command premium pricing due to the complex regulatory and manufacturing requirements involved in their production.

The Application segment highlights the functional versatility of these particles, with Drug Delivery representing the largest value segment due to the high costs associated with advanced therapeutic carriers and the critical need for precise dosing schedules. Meanwhile, the Diagnostics segment, encompassing lateral flow assays and chemiluminescence tests, constitutes a major volume driver. Emerging high-growth segments, such as 3D Printing and Advanced Filtration, necessitate tailor-made particle characteristics like thermal stability and highly uniform size distribution, signaling future high-value market expansion beyond traditional applications.

- Type: Polyethylene Microparticles

- Type: Polystyrene Microparticles

- Type: Polypropylene Microparticles

- Type: Acrylic Microparticles

- Type: Biodegradable Microparticles (PLGA, PCL)

- Type: Other Resins (e.g., Silicone, Epoxy)

- Application: Drug Delivery (Sustained Release, Targeted Delivery)

- Application: Diagnostics (Immunoassays, Lateral Flow Tests)

- Application: Cosmetics & Personal Care (Exfoliants, Texturizers)

- Application: Paints & Coatings (Matting Agents, Scratch Resistance)

- Application: 3D Printing & Additive Manufacturing

- Application: Filtration and Separation Media

- Application: Other Industrial Uses (e.g., Composites, Displays)

Value Chain Analysis For Resin Microparticles Market

The value chain for the Resin Microparticles Market begins with the highly specialized Upstream Analysis stage, involving the procurement and synthesis of monomeric precursors (e.g., styrene, ethylene, acrylic acid) and specialty reagents such as surfactants, initiators, and stabilizers. Raw material quality is paramount, particularly for pharmaceutical-grade microparticles, as impurities can severely compromise biocompatibility and particle performance. Key suppliers in this phase are large chemical and petrochemical companies. The core value addition occurs during the manufacturing stage, involving complex polymerization techniques—primarily emulsion, suspension, or dispersion polymerization—which determine the final particle morphology, size uniformity (monodispersity), and surface functionality. Investment in sophisticated equipment and process control is crucial at this juncture.

The Downstream Analysis phase focuses on post-processing, functionalization, and end-user integration. Post-processing often includes washing, drying, and surface modification techniques (e.g., coating with ligands, proteins, or magnetic materials) to tailor the microparticles for specific applications, such as targeting specific cell receptors in drug delivery or enhancing contrast in diagnostics. Functionalization substantially increases the product's value. Integration involves blending these microparticles into final formulations, such as injectable drug suspensions, diagnostic reagents, specialized coatings, or cosmetic formulations. Strong collaboration between microparticle manufacturers and end-product formulators is essential for successful market integration.

Distribution Channel analysis reveals a dual structure involving both Direct and Indirect methods. Direct sales are prevalent for highly specialized, high-value, and customized microparticles, particularly those sold to major pharmaceutical and advanced diagnostic companies, ensuring strict quality control and technical support. Indirect channels utilize specialized distributors and laboratory supply houses to reach smaller research institutions, universities, and industrial consumers globally. The digital supply chain is increasingly important, with specialized e-commerce platforms facilitating the efficient global distribution of standard catalogue microparticle products. Efficient logistics, especially temperature-controlled shipping for biochemical reagents, is a critical success factor in this final stage of the value chain.

Resin Microparticles Market Potential Customers

Potential customers, or End-User/Buyers of resin microparticles, represent a diverse group spanning highly regulated medical sectors to large-scale industrial manufacturing. The largest and most demanding customer base resides within the Pharmaceutical and Biotechnology industries, utilizing microparticles for highly complex applications such as targeted cancer therapy, vaccine adjuvants, and long-acting injectable drug formulations. These customers require microparticles with exceptionally tight size distributions, verifiable biocompatibility, and cGMP compliance, focusing on materials like PLGA and specialized acrylic resins. Diagnostic companies, including manufacturers of in-vitro diagnostics (IVD) and clinical laboratory equipment, are another major segment, relying on polystyrene and latex microparticles for assays, often requiring surface coatings suitable for antibody immobilization.

The Cosmetics and Personal Care sector is a significant volume buyer, although often demanding lower-cost commodity-grade materials, primarily polyethylene and polypropylene microparticles, used as exfoliants, texturizers, and opacifiers. However, regulatory shifts away from non-biodegradable microbeads are pushing this segment towards bio-based and biodegradable alternatives. Industrial customers form a robust segment, encompassing Paint and Coating manufacturers that use microparticles as matting agents, anti-blocking additives, or scratch-resistant fillers. Furthermore, companies specializing in 3D printing and additive manufacturing are emerging high-value customers, requiring polymer microparticles tailored for selective laser sintering (SLS) and high-resolution inkjet printing technologies, demanding high thermal stability and uniform particle morphology.

Lastly, specialized buyers include academic and research institutions globally, focused on exploratory research in material science, biomedical engineering, and nanotechnology, purchasing small, specialized batches of novel microparticles. Additionally, specialized chemical companies and filter media manufacturers integrate these particles into separation columns and specialized filtration membranes for water purification or industrial gas separation. The high technical specification required by these diverse end-users dictates a highly customized product offering from microparticle manufacturers, emphasizing the necessity for strong R&D capabilities to meet varied customer needs.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $5.2 Billion |

| Market Forecast in 2033 | $9.4 Billion |

| Growth Rate | 8.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Polysciences, Merck KGaA, Thermo Fisher Scientific, Spherotech, Akzo Nobel, PPG Industries, Momentive Performance Materials, BASF SE, Dow Inc., DIC Corporation, Nippon Paint Holdings, Wacker Chemie AG, Sekisui Chemical Co., Ltd., Evonik Industries AG, Landa Corporation, Cospheric LLC, Microbeads AS, Kobo Products Inc., Sun Chemical Corporation, Lubrizol Corporation |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Resin Microparticles Market Key Technology Landscape

The technological landscape of the Resin Microparticles Market is dominated by advancements aimed at achieving superior control over particle size, morphology, and surface chemistry, which are critical determinants of performance across all applications. Primary synthesis techniques include various forms of polymerization, such as emulsion, suspension, and precipitation polymerization. However, the emerging focus is on precision engineering techniques like microfluidics and spray drying, which enable the continuous, scalable production of highly monodisperse (uniform size) microparticles, significantly reducing batch variation—a critical requirement for injectable pharmaceutical products. Microfluidic platforms, in particular, offer unparalleled control over droplet formation, leading to highly uniform particle size distributions that are essential for controlled-release kinetics.

A second major technological trend involves surface modification and functionalization, which is crucial for dictating how the microparticles interact with their environment, whether biological or industrial. Techniques such as plasma treatment, grafting polymerization, and chemical linking are used to attach specific functional groups (e.g., carboxyl, amine) or biomolecules (e.g., antibodies, peptides) onto the particle surface. This functionalization is essential for targeted drug delivery, allowing microparticles to selectively accumulate at diseased sites, or for diagnostic purposes, enabling specific binding of target analytes. Advances in material encapsulation technology, including core-shell structures and liposomal encapsulation using resin materials, are also driving innovation by protecting sensitive payload materials and modulating release rates.

Furthermore, significant technological development is centered on improving the thermal and mechanical stability of resin microparticles for high-temperature applications like 3D printing (Selective Laser Sintering - SLS) and specialized industrial coatings. Manufacturers are increasingly utilizing composite materials, blending high-performance polymers with ceramic or metallic nanoparticles, to enhance structural integrity and functionality. Automation and continuous manufacturing technologies, often utilizing sensor integration and AI-driven process control, are being implemented to increase production efficiency, reduce labor costs, and ensure consistent quality, signaling a shift toward Industry 4.0 principles within the microparticle manufacturing ecosystem.

Regional Highlights

- North America: This region holds a leading market share primarily due to high expenditure on research and development (R&D) in advanced biomedical applications, supported by strong government funding and the presence of major pharmaceutical and biotechnology companies. The U.S. remains the core driver, focusing heavily on utilizing resin microparticles for sophisticated drug delivery systems, particularly in oncology and chronic disease management. The mature regulatory environment also facilitates the rapid adoption of innovative microparticle technologies in clinical diagnostics.

- Europe: Europe represents a technologically advanced market driven by stringent quality standards and a strong emphasis on sustainability. Regulations like REACH influence product development, pushing manufacturers toward biodegradable and environmentally friendly resin microparticles, particularly in the cosmetics and industrial coatings segments. Germany, France, and the UK are key contributors, specializing in precision industrial applications, medical device manufacturing, and high-end cosmetics formulations.

- Asia Pacific (APAC): APAC is projected to be the fastest-growing market, driven by rapid industrialization, expanding healthcare access, and large-scale manufacturing capacity. Countries like China, Japan, and India are significantly boosting their pharmaceutical manufacturing capabilities, increasing demand for microparticles in generic drug formulations and domestic diagnostic production. The region also exhibits robust demand for industrial resin microparticles used in construction coatings and automotive paints, fueled by urbanization and infrastructure projects.

- Latin America (LATAM): The LATAM market is characterized by moderate but steady growth, primarily driven by investments in improving public health infrastructure and increasing adoption of international manufacturing standards. Brazil and Mexico are the largest regional markets, with demand focused on basic industrial applications and imported diagnostic kits utilizing standard resin microparticles.

- Middle East and Africa (MEA): This region exhibits growth mainly in the healthcare and oil & gas sectors. The Gulf Cooperation Council (GCC) countries are investing heavily in establishing advanced medical facilities, boosting demand for high-quality pharmaceutical and diagnostic microparticles. In industrial applications, resin microparticles are utilized in specialized coatings for pipelines and infrastructure projects in harsh environments.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Resin Microparticles Market.- Polysciences, Inc.

- Merck KGaA

- Thermo Fisher Scientific Inc.

- Spherotech, Inc.

- Akzo Nobel N.V.

- PPG Industries, Inc.

- Momentive Performance Materials Inc.

- BASF SE

- Dow Inc.

- DIC Corporation

- Nippon Paint Holdings Co., Ltd.

- Wacker Chemie AG

- Sekisui Chemical Co., Ltd.

- Evonik Industries AG

- Landa Corporation Ltd.

- Cospheric LLC

- Microbeads AS

- Kobo Products Inc.

- Sun Chemical Corporation

- Lubrizol Corporation

Frequently Asked Questions

Analyze common user questions about the Resin Microparticles market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary drivers of growth in the Resin Microparticles Market?

The primary drivers include the escalating global demand for targeted and sustained drug delivery systems, the widespread necessity for highly sensitive and reliable diagnostic assays, and the increasing adoption of resin microparticles as high-performance fillers and matting agents in specialized industrial coatings and 3D printing technologies.

How does segmentation by Type influence market revenue?

Segmentation by Type reveals that high-value revenue streams are generated by specialized, medical-grade biodegradable microparticles (like PLGA) due to their complex manufacturing and regulatory compliance needs. Conversely, commodity segments like Polystyrene and Polyethylene drive high volume in the lower-margin diagnostics and industrial application sectors.

What role does microfluidics play in the future of resin microparticles manufacturing?

Microfluidics is a crucial technological advancement, enabling the continuous and precise manufacturing of highly monodisperse resin microparticles. This technology significantly reduces batch-to-batch variation, which is essential for regulated pharmaceutical applications requiring strict control over particle size and drug release kinetics.

Which region currently leads the market in terms of technological innovation and market share?

North America currently holds the largest market share and leads in technological innovation, primarily driven by substantial R&D investments in biotechnology, a robust presence of key market players, and high clinical adoption rates of advanced microparticle-based therapeutics and diagnostics.

What are the main regulatory challenges impacting the market?

The main regulatory challenges include stringent requirements for biocompatibility and toxicology testing for drug delivery applications, complex approval processes for novel medical devices, and increasing global restrictions (particularly in Europe) on the use of non-biodegradable polymeric microplastics in consumer products like cosmetics.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager