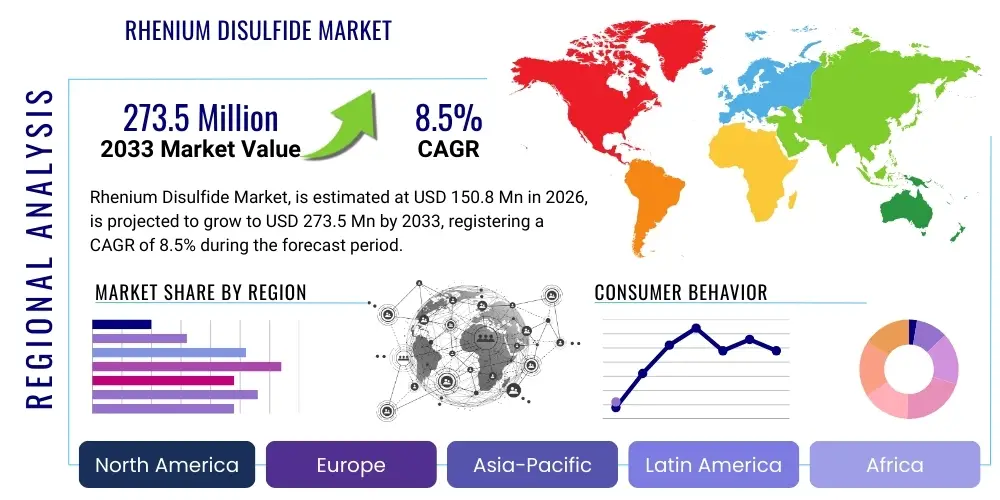

Rhenium Disulfide Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 434570 | Date : Dec, 2025 | Pages : 248 | Region : Global | Publisher : MRU

Rhenium Disulfide Market Size

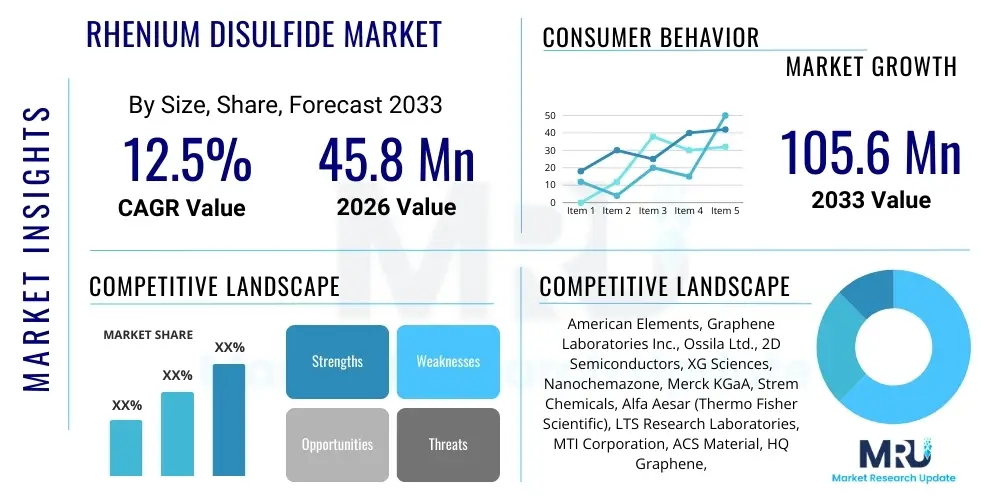

The Rhenium Disulfide Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 12.5% between 2026 and 2033. The market is estimated at USD 45.8 Million in 2026 and is projected to reach USD 105.6 Million by the end of the forecast period in 2033. This substantial growth trajectory is underpinned by the increasing utilization of Rhenium Disulfide (ReS2) in emerging high-technology sectors, particularly advanced electronics, flexible devices, and next-generation catalysis.

The valuation reflects the increasing commercial viability of scalable synthesis methods for high-purity, two-dimensional ReS2, which is critical for achieving superior performance characteristics in semiconductor and energy storage applications. While the market size remains relatively nascent compared to bulk materials, the high price point and exceptional functional attributes of ReS2, such as its direct bandgap structure and anisotropic properties, drive significant revenue generation within specialized, high-value industrial segments. Investment in research and development focusing on novel applications like photovoltaic cells and memory devices further solidifies this market expansion.

Rhenium Disulfide Market introduction

The Rhenium Disulfide Market encompasses the production, distribution, and application of ReS2, a critical material classified as a two-dimensional (2D) Transition Metal Dichalcogenide (TMD). ReS2 is highly valued for its unique electronic and optical properties, notably its direct bandgap across varying layer thicknesses, making it superior to many other TMDs for optoelectronic applications. Major applications include advanced transistors, photodetectors, flexible electronics, high-performance catalysts in hydrodesulfurization processes, and components for lithium-ion batteries and supercapacitors. The primary driving factors fueling market expansion include the global shift towards miniaturization in electronics, the intense demand for high-efficiency catalysts in the petrochemical industry, and breakthroughs in material science enabling cost-effective, high-quality production of monolayer and few-layer ReS2, offering enhanced performance and energy efficiency benefits across industrial and consumer sectors.

Rhenium Disulfide Market Executive Summary

The Rhenium Disulfide Market is characterized by strong business trends centered on material purity improvement and scalability in chemical vapor deposition (CVD) techniques, transitioning ReS2 from laboratory novelty to industrial relevance. Geographically, Asia Pacific, led by China, South Korea, and Japan, dominates consumption and research due to established semiconductor manufacturing hubs and heavy investment in 2D material synthesis. Segment trends show that the Electronics and Optoelectronics sector holds the largest market share, driven by demand for novel transistors and highly efficient sensors, while the Catalyst segment exhibits the fastest growth rate, fueled by strict environmental regulations mandating better fuel desulfurization processes. The market remains competitive, with focus shifting toward strategic partnerships between specialized material producers and established electronic device manufacturers to accelerate commercial integration and adoption of ReS2-based components.

AI Impact Analysis on Rhenium Disulfide Market

User queries regarding AI’s influence on the Rhenium Disulfide market frequently revolve around how artificial intelligence can accelerate material discovery, optimize synthesis processes, and predict material performance in complex device architectures. The core themes center on reducing the laborious experimental phase of 2D material engineering and improving quality control for industrial-scale production. Users express high expectations that AI and machine learning (ML) models will significantly cut production costs and variability, particularly in sophisticated techniques like Molecular Beam Epitaxy (MBE) and Chemical Vapor Deposition (CVD). Furthermore, there is considerable interest in AI-driven modeling for simulating the anisotropic electrical and thermal properties of ReS2, enabling quicker optimization for specific applications, such as flexible displays or high-frequency transistors, thereby accelerating product development cycles and expanding market accessibility.

- AI-driven simulation optimizes the structure and purity of ReS2 during CVD growth, minimizing defects and enhancing electronic performance.

- Machine learning algorithms predict optimal conditions for synthesizing large-area, single-crystal ReS2 films, improving manufacturing yield.

- AI accelerates the discovery of novel ReS2 heterostructures and composite materials for enhanced battery electrodes and photocatalysis applications.

- Data analytics derived from synthesis processes improve quality assurance and regulatory compliance for high-specification electronic grade ReS2.

- Automated analysis of spectroscopic data (Raman, PL) facilitated by AI ensures rapid, real-time material characterization and quality control.

DRO & Impact Forces Of Rhenium Disulfide Market

The Rhenium Disulfide market is primarily driven by the escalating demand for high-performance 2D materials in next-generation electronic devices, capitalizing on ReS2’s intrinsic direct bandgap and anisotropic carrier mobility. However, market expansion is restrained by the high cost and complexity associated with synthesizing ultra-pure, large-area ReS2 films, which currently limits widespread commercial adoption beyond high-end, niche applications. Significant opportunities exist in leveraging ReS2’s unique properties for flexible and transparent electronics, advanced memory solutions (RRAM), and high-efficiency solid-state lighting components. The primary impact forces include stringent intellectual property rights surrounding synthesis techniques, fluctuating prices of raw Rhenium sources, and the intense competitive pressure from other highly researched 2D materials like MoS2 and Tungsten Disulfide (WS2), necessitating continuous innovation in production efficiency and material quality to maintain market relevance.

Segmentation Analysis

The Rhenium Disulfide market is comprehensively segmented across several key dimensions, including form, application, and end-user industry, reflecting the material’s diverse capabilities and technological readiness levels. Segmentation by form differentiates between Powder/Bulk forms, often used in catalytic processes and material composites, and Film/Crystalline forms, which are essential for high-precision electronic and optoelectronic device fabrication. Application segmentation highlights the material's use in Semiconductors, Catalysts, Energy Storage, and Photodetectors, reflecting varying purity and dimensional requirements. Understanding these segments is crucial for manufacturers to target specific high-growth areas, particularly where ReS2 offers a definitive performance advantage over conventional materials or other TMDs.

- By Form:

- Powder/Bulk

- Thin Films/Crystals (Monolayer, Few-layer)

- Suspensions and Dispersions

- By Application:

- Electronics and Semiconductors (Transistors, Memory Devices)

- Catalysis (Hydrodesulfurization, Hydrogen Evolution Reaction (HER))

- Optoelectronics (Photodetectors, Solar Cells)

- Energy Storage (Li-ion Battery Electrodes, Supercapacitors)

- Sensors and Biomedical Devices

- By End-User Industry:

- Semiconductor Industry

- Chemical and Petrochemical Industry

- Aerospace and Defense

- Energy and Power

- Research and Academia

Value Chain Analysis For Rhenium Disulfide Market

The value chain for Rhenium Disulfide is characterized by high technical barriers at the upstream stages and specialized distribution channels tailored for high-purity, low-volume advanced material delivery. The process begins with the extraction and purification of raw Rhenium precursors, which are often highly regulated and expensive, directly impacting the final material cost. Upstream activities involve specialized chemical providers focusing on synthesizing Rhenium tetrachloride or Rhenium oxides necessary for 2D growth techniques. Midstream manufacturing involves complex, controlled environment processing using techniques like CVD, MBE, or micromechanical exfoliation to yield high-quality ReS2 films, where proprietary intellectual property plays a critical role in differentiating producers.

Downstream integration focuses on the application development phase, where electronic device manufacturers and catalytic system providers integrate ReS2 into finished products. Direct distribution channels are predominantly used for customized research-grade materials sold directly to university labs and corporate R&D centers, ensuring technical support and quality traceability. Indirect channels utilize specialized material distributors and regional agents, particularly for bulk powder forms destined for large-scale industrial catalytic use or composite manufacturing. This structure necessitates close collaboration between material producers and end-users to optimize material specifications for precise performance requirements.

The high capital expenditure required for advanced synthesis equipment and the need for skilled expertise in handling and characterizing 2D materials create bottlenecks in the midstream segment. Furthermore, the limited number of companies capable of producing electronic-grade monolayer ReS2 enhances the value captured at this processing stage. Effective value chain management, therefore, hinges on securing stable, cost-effective Rhenium supplies and developing scalable, high-throughput manufacturing processes that meet stringent electronic industry standards, moving ReS2 from a bespoke material to a standardized industrial component.

- Upstream Analysis: Sourcing and purification of raw Rhenium and Sulfur precursors; production of high-purity chemical intermediates.

- Midstream Manufacturing: Specialized synthesis techniques (CVD, MBE, Exfoliation) to produce ReS2 powder, thin films, or single crystals; material characterization and quality control.

- Downstream Integration: Incorporation of ReS2 into functional devices (transistors, sensors, catalysts, battery components); device testing and prototyping.

- Distribution Channel: Direct sales to R&D institutions and large OEM manufacturers; specialized chemical and advanced material distributors for bulk and industrial-grade ReS2 products.

Rhenium Disulfide Market Potential Customers

The primary potential customers for Rhenium Disulfide are institutions and corporations operating at the forefront of advanced material applications, particularly those seeking materials with superior anisotropic electrical properties and high catalytic activity. The semiconductor industry constitutes a major buyer, specifically manufacturers developing next-generation flexible displays, transparent conductive films, and high-mobility field-effect transistors (FETs) that require materials capable of operating efficiently at nanoscale dimensions. Research laboratories, both academic and private industrial R&D centers, are also significant consumers, driving demand for small quantities of ultra-high-purity ReS2 for fundamental materials science studies and proof-of-concept device development.

A rapidly expanding segment of potential customers includes companies in the petrochemical and environmental sectors. These entities utilize ReS2 as a highly efficient and stable catalyst, particularly for hydrodesulfurization (HDS) processes necessary for producing cleaner fuels in compliance with stringent global environmental standards. Furthermore, manufacturers of advanced energy storage devices, including specialized battery makers and supercapacitor companies, are increasingly investigating ReS2 for its potential as a high-capacity, durable electrode material, offering improved cycling stability and energy density compared to conventional materials.

The specialized nature of ReS2 necessitates that potential customers possess sophisticated material handling and integration capabilities. Adoption is often contingent upon the customer's ability to seamlessly integrate the 2D material into their existing fabrication lines, making high-technology original equipment manufacturers (OEMs) and established Tier 1 suppliers crucial targets. Strategic sales efforts focus on demonstrating the material’s quantifiable performance gains in areas like processing speed, energy efficiency, and operational longevity within complex electronic or chemical systems.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 45.8 Million |

| Market Forecast in 2033 | USD 105.6 Million |

| Growth Rate | 12.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | American Elements, Graphene Laboratories Inc., Ossila Ltd., 2D Semiconductors, XG Sciences, Nanochemazone, Merck KGaA, Strem Chemicals, Alfa Aesar (Thermo Fisher Scientific), LTS Research Laboratories, MTI Corporation, ACS Material, HQ Graphene, Re-Materials, Nanografi Nano Technology, Stanford Advanced Materials, 6Carbon Technology, Nanjing XFNANO Materials Tech Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Rhenium Disulfide Market Key Technology Landscape

The Rhenium Disulfide market's technological landscape is dominated by sophisticated synthesis and processing methods necessary to achieve the desired two-dimensional structure and high purity required for functional devices. Chemical Vapor Deposition (CVD) is the most widely adopted and scalable technique, enabling the production of large-area thin films, crucial for industrial semiconductor applications, though challenges remain in controlling the number of layers and minimizing defects. Another significant technology is Mechanical Exfoliation, primarily utilized in academic research for producing pristine, high-quality flakes, serving as the benchmark for material property studies, despite its lack of scalability for mass production.

Molecular Beam Epitaxy (MBE) represents a high-end synthesis route, offering precise control over film thickness, interface quality, and crystallographic orientation, which is essential for developing complex ReS2-based heterostructures and advanced integrated circuits. Beyond synthesis, material characterization technologies, including high-resolution transmission electron microscopy (HRTEM), Raman spectroscopy, and photoluminescence (PL) spectroscopy, are vital. These technologies ensure stringent quality control, verifying layer count, structural integrity, and the direct bandgap presence, thereby confirming the material's suitability for specific optoelectronic or electronic roles.

Recent technological advancements are centered on solution-phase processing and liquid-phase exfoliation, aimed at developing scalable, cost-effective methods for producing ReS2 nanosheets in suspension. This approach is particularly relevant for applications like composites, inks, and large-area printed electronics, offering a path toward low-cost, flexible device fabrication. The integration of advanced computational materials science, leveraging density functional theory (DFT) and machine learning, further defines the landscape, guiding experimental efforts to optimize synthesis parameters and predict the performance of ReS2 in novel device architectures before costly physical prototyping.

Regional Highlights

The Rhenium Disulfide market exhibits significant regional variations in terms of adoption rates, application focus, and production capabilities, strongly correlating with the regional intensity of semiconductor manufacturing and specialized chemical processing. Asia Pacific (APAC) holds the dominant position in the global market, driven by the presence of major electronic manufacturing powerhouses in South Korea, China, and Taiwan, which are heavily investing in 2D material research for advanced transistor and flexible display technologies. Furthermore, the high concentration of petrochemical refining facilities in China and India generates substantial demand for ReS2 as an advanced hydrodesulfurization catalyst, solidifying APAC's market leadership. The regional market growth is supported by government initiatives promoting advanced material research and large-scale industrialization.

North America, particularly the United States, represents a significant market share focused on high-end research, defense, and niche applications within the aerospace sector. Demand here is characterized by the need for ultra-high-purity ReS2 for cutting-edge technologies like quantum computing components, high-frequency communication devices, and military-grade sensors. While the volume of consumption may be lower than in APAC, the value generated per unit is exceptionally high due to stringent quality and performance requirements. Leading academic institutions and federally funded laboratories drive fundamental research and early-stage commercialization in this region.

Europe contributes moderately to the market, concentrating its efforts primarily on sustainable energy applications and advanced catalytic processes. Countries like Germany and the Netherlands show strong adoption of ReS2 in green chemistry and energy storage research, utilizing its potential for enhancing hydrogen production (HER) efficiency and developing safer battery technologies. The European market emphasizes collaborative industrial projects and cross-border research initiatives aimed at overcoming the scalability challenges of ReS2 production, focusing on developing environmentally responsible synthesis methods to meet the region's strong regulatory environment favoring sustainability.

- Asia Pacific (APAC): Dominant market share fueled by robust semiconductor manufacturing base (South Korea, China) and high demand for catalytic materials in the petrochemical industry.

- North America: Focuses on high-value, niche applications in defense, aerospace, and advanced R&D; characterized by high per-unit material costs and stringent quality standards.

- Europe: Strong uptake in sustainable technology research, including green catalysis and advanced energy storage solutions; growth driven by strict environmental mandates.

- Latin America (LAMEA): Nascent market, primarily focused on limited academic research and minor industrial catalytic applications related to regional petrochemical operations.

- Middle East and Africa (MEA): Growth driven by investment in high-purity catalytic materials for the vast regional oil and gas sector, with minimal current electronics application.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Rhenium Disulfide Market.- American Elements

- Graphene Laboratories Inc.

- Ossila Ltd.

- 2D Semiconductors

- XG Sciences

- Nanochemazone

- Merck KGaA

- Strem Chemicals

- Alfa Aesar (Thermo Fisher Scientific)

- LTS Research Laboratories

- MTI Corporation

- ACS Material

- HQ Graphene

- Re-Materials

- Nanografi Nano Technology

- Stanford Advanced Materials

- 6Carbon Technology

- Nanjing XFNANO Materials Tech Co., Ltd.

- Specific Materials (UK) Ltd.

- Goodfellow Cambridge Ltd.

- Materion Corporation

- Ereztech LLC

Frequently Asked Questions

Analyze common user questions about the Rhenium Disulfide market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary advantages of Rhenium Disulfide (ReS2) over conventional semiconductor materials?

ReS2 possesses a direct bandgap independent of layer thickness (unlike MoS2), excellent anisotropic electrical properties, and high carrier mobility, making it highly advantageous for developing high-performance, miniaturized transistors and highly sensitive photodetectors, especially in flexible device architectures.

How scalable is the production of electronic-grade Rhenium Disulfide thin films?

Scalability remains a primary challenge. While Chemical Vapor Deposition (CVD) offers the highest potential for large-area industrial production, achieving consistent layer control, high purity, and low defect density across large substrates for electronic applications is complex and costly, requiring specialized high-vacuum processing equipment.

What role does Rhenium Disulfide play in the energy storage sector?

ReS2 is actively researched for its potential as a high-performance electrode material in lithium-ion and sodium-ion batteries, exhibiting high theoretical capacity and stability. Its layered structure allows for efficient intercalation of ions, aiming to improve energy density and cycle life compared to traditional graphite and oxide cathodes.

Which industry segment accounts for the largest demand for Rhenium Disulfide globally?

The Electronics and Semiconductors segment currently holds the largest market share in terms of value. This dominance is driven by high-value applications requiring ultra-high-purity, thin-film ReS2 for advanced FETs, optoelectronic sensors, and prototypes of flexible integrated circuits, particularly in Asia Pacific manufacturing hubs.

What are the key drivers mitigating the high production cost of ReS2?

The high initial cost is being mitigated by advancements in large-scale synthesis technologies, primarily optimized CVD and solution-based processing methods. Furthermore, the superior performance gains ReS2 offers in final products often justify the premium material cost in niche, high-performance applications where no cheaper material can deliver comparable results.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager