Rheological Additives Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 436651 | Date : Dec, 2025 | Pages : 251 | Region : Global | Publisher : MRU

Rheological Additives Market Size

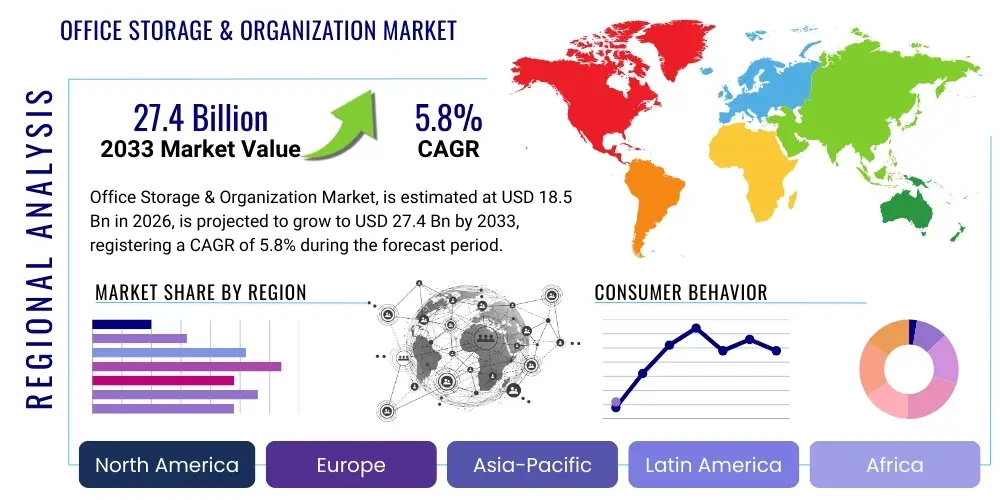

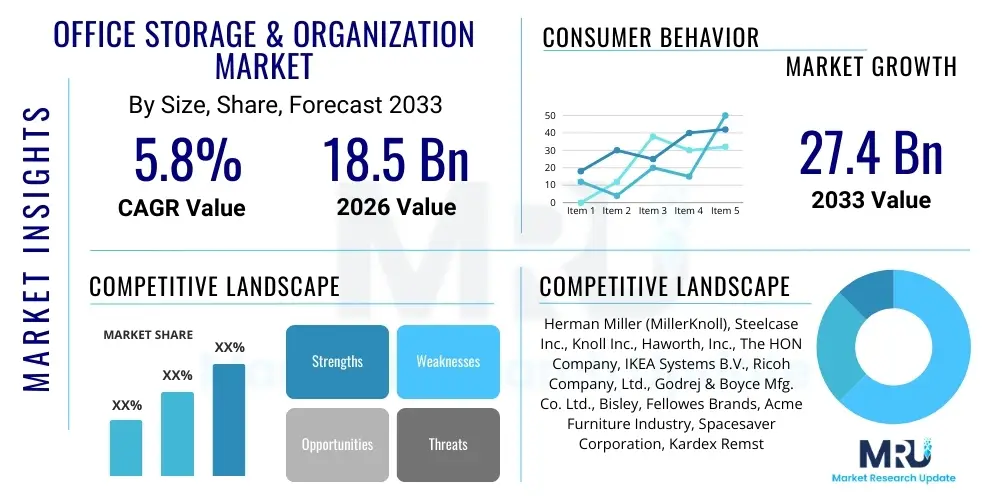

The Rheological Additives Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 4.5 Billion in 2026 and is projected to reach USD 6.7 Billion by the end of the forecast period in 2033.

Rheological Additives Market introduction

Rheological additives are specialized chemical compounds incorporated into liquid systems to control and modify flow characteristics, including viscosity, thixotropy, sag resistance, and anti-settling properties. These essential performance enhancers are critical in formulations such as paints, coatings, inks, adhesives, sealants, and drilling fluids, where precise control over material behavior during processing, application, and storage is paramount. The primary function of these additives is to establish a desired internal structure within the liquid, preventing sedimentation of pigments or solids under static conditions while allowing for smooth flow and easy application under shear stress.

The product description spans a diverse range of chemical entities, including inorganic compounds like fumed silica and organoclays, and organic polymers such as polyurethanes, polyacrylics, and cellulose derivatives. Their selection depends entirely on the application matrix—whether solvent-borne, water-borne, or powder systems—and the specific rheological profile required. For instance, in high-performance automotive coatings, additives ensure uniform film thickness and prevent sagging, whereas in oilfield drilling muds, they maintain viscosity and stabilize cuttings transport deep underground. Major applications are concentrated in construction, automotive, industrial coatings, and the oil & gas industry.

The market is primarily driven by the expanding construction sector, particularly in emerging economies, alongside rigorous demand for high-solid and water-borne coatings which necessitate effective rheology control for superior environmental performance and application aesthetics. Benefits of using these additives include enhanced product stability, improved quality control, reduced waste, and the ability to formulate multi-functional products. Furthermore, the push towards sustainable and environmentally friendly products is fueling innovation in bio-based and solvent-free rheological modifiers, contributing significantly to market growth.

Rheological Additives Market Executive Summary

The Rheological Additives Market is experiencing robust expansion driven by increasing industrialization, stringent environmental regulations favoring water-based formulations, and escalating infrastructure development globally. Key business trends indicate a strong focus on research and development aimed at developing high-efficiency, multi-purpose rheology modifiers that offer excellent performance across a wider range of temperatures and pH levels, thereby consolidating product lines and reducing formulation complexity for end-users. Strategic alliances and mergers between specialized additive manufacturers and large chemical conglomerates are also defining the competitive landscape, aiming to broaden geographical reach and technology portfolios, especially concerning nano-material based additives.

Segment trends highlight the dominance of inorganic additives, such as organoclays and fumed silica, owing to their versatility and cost-effectiveness, although organic additives, particularly associative thickeners used in waterborne coatings, are exhibiting the fastest growth due to their superior performance in environmentally compliant systems. The coatings segment remains the largest consumer, reflecting sustained demand from the automotive, architectural, and protective coatings industries. Furthermore, the oil and gas sector remains a significant, albeit volatile, driver, relying heavily on specialized rheology modifiers for advanced drilling and completion fluids.

Regionally, Asia Pacific (APAC) stands out as the primary engine of market growth, attributed to rapid urbanization, massive infrastructure investment, and the migration of manufacturing facilities to countries like China, India, and Southeast Asia. North America and Europe, while mature, are characterized by high demand for specialized, high-performance, and sustainable rheological solutions, particularly those adhering to stringent volatile organic compound (VOC) limits. These mature markets focus heavily on innovation in synthetic polymer thickeners and sustainable rheology control agents derived from renewable sources, maintaining their influence on technology standardization and premium product pricing.

AI Impact Analysis on Rheological Additives Market

Common user questions surrounding AI in the Rheological Additives Market often center on how predictive modeling can optimize formulation stability, reduce trial-and-error in R&D, and enhance manufacturing efficiency. Users are keenly interested in leveraging machine learning algorithms to predict the rheological behavior of complex systems based on input parameters (temperature, solvent type, concentration) faster than traditional experimental methods. Key themes include concerns about data standardization for training robust AI models, the computational cost of simulating complex fluid dynamics, and the expectation that AI will lead to the rapid discovery and synthesis of novel, high-performance rheology modifiers with targeted properties, thereby dramatically accelerating product development cycles and ensuring precise quality control across large batches. AI is expected to transform the additive selection process from empirical testing to predictive design, significantly cutting time-to-market and enhancing material performance predictability in diverse application matrices. This predictive capability reduces material consumption during testing and helps in tailoring viscosity profiles exactly to the required application conditions, such as high-shear spraying or low-shear leveling.

- AI optimizes additive formulation by predicting viscosity profiles based on composition inputs, drastically reducing empirical testing time.

- Machine learning models enhance quality control by identifying anomalies in batch consistency and predicting potential shelf-life instability.

- Computational Fluid Dynamics (CFD) integrated with AI assists in simulating material behavior under various application conditions (e.g., spray coating, brushing).

- AI accelerates the discovery and synthesis of novel, sustainable rheology modifiers by analyzing vast chemical databases and structural properties.

- Predictive maintenance for manufacturing equipment used in additive production is improved, ensuring optimal particle size distribution and chemical purity.

- Supply chain optimization using AI ensures just-in-time delivery of specialized rheological additives, minimizing inventory holding costs for formulators.

DRO & Impact Forces Of Rheological Additives Market

The Rheological Additives Market dynamic is shaped by a confluence of influential factors: robust market drivers, significant operational restraints, compelling growth opportunities, and impactful external forces. The primary drivers include the global expansion of the construction and infrastructure sectors, especially in developing economies, which rely heavily on high-performance paints, coatings, and specialized construction chemicals. Furthermore, the global shift towards water-borne and high-solid coatings, mandated by stricter environmental protection regulations aiming to reduce Volatile Organic Compounds (VOCs), consistently boosts demand for specialized associative thickeners and synthetic polymer additives that perform optimally in aqueous systems.

Conversely, the market faces restraints such as volatility in raw material prices, particularly petrochemical-derived precursors and specialized minerals, which impacts production costs and profit margins across the value chain. Additionally, the technical complexity involved in selecting the appropriate rheological additive for specific formulations presents a major challenge; failure to correctly match the additive to the system can result in product failure, requiring high levels of technical expertise and often hindering standardization. The maturity of the market in developed regions also limits exponential growth, relying instead on incremental technological improvements and regulatory compliance for expansion.

Significant opportunities lie in the development of bio-based and sustainable rheological additives, responding to consumer and regulatory preference for green chemistry, opening new revenue streams. Moreover, the burgeoning demand from specialized applications, such as 3D printing inks, advanced ceramics, and electric vehicle battery components, requires entirely new classes of rheology modifiers capable of handling extreme processing conditions and high solid loadings. The combined impact forces, including rapid technological advancements in additive synthesis and intense regulatory pressure on solvent use, necessitate continuous innovation and collaboration between academic institutions and industrial players to maintain market relevance and competitive edge.

Segmentation Analysis

The Rheological Additives Market is comprehensively segmented based on product type, application, and end-use industry, reflecting the diverse and specialized requirements of global industrial formulations. This granular segmentation allows manufacturers to tailor their product offerings, focusing on the specific performance metrics demanded by sectors ranging from high-performance automotive finishes to essential household consumer goods. Analyzing these segments is critical for understanding market dynamics, investment trends, and future growth pockets, particularly the rapid growth observed in the organic segment driven by stringent environmental compliance requirements.

- Product Type:

- Inorganic Rheological Additives (Fumed Silica, Organoclays/Bentonite, Attapulgite)

- Organic Rheological Additives (Cellulose-based, Synthetic Polymers/Associative Thickeners, Castor Oil Derivatives, Polyurea/Polyurethane)

- Application:

- Coatings (Architectural, Industrial, Automotive, Protective)

- Adhesives and Sealants

- Inks

- Personal Care and Pharmaceuticals

- Construction Chemicals

- Oil & Gas (Drilling Fluids, Cement Slurries)

- Others (Ceramics, Textiles, Detergents)

- End-Use Industry:

- Automotive

- Construction

- Chemical Processing

- Cosmetics

- Oil & Gas

- Pharmaceuticals

Value Chain Analysis For Rheological Additives Market

The rheological additives value chain is complex and highly structured, commencing with the sourcing and purification of specialized raw materials, followed by advanced chemical processing, and culminating in global distribution to highly technical end-use sectors. Upstream activities are dominated by the extraction of specialized minerals like bentonite and fumed silica, alongside the production of synthetic chemical precursors such as petroleum derivatives for organic polymers and specialty alcohols. Quality control at the raw material stage is paramount, as minute variations in particle size or chemical purity can drastically impact the final rheological performance. Key decisions at this stage revolve around sustainable sourcing practices and maintaining long-term supply agreements to mitigate price volatility.

The midstream focuses on the manufacturing process, involving sophisticated techniques like chemical modification, surface treatment, and polymerization to convert raw materials into functional rheological agents. This segment demands substantial R&D investment to enhance additive efficiency, improve compatibility with modern solvent systems (especially water-based ones), and ensure thermal stability. Distribution channels are specialized, balancing direct sales to major multinational chemical formulators with indirect distribution through dedicated specialty chemical distributors who provide localized technical support and manage inventories for smaller, regional customers. The effectiveness of the supply chain relies heavily on robust logistics networks capable of handling both bulk shipments of mineral additives and precisely packaged, highly concentrated polymer solutions.

Downstream analysis highlights the critical role of formulators who integrate these additives into final products. End-users, spanning construction, coatings, and personal care, require additives tailored to meet rigorous performance specifications—such as optimal brush loading for architectural paints or controlled slump resistance for high-rise concrete. Technical service and collaborative innovation between the additive producer and the end-user are crucial for successful product development. The highest value addition often occurs at this downstream stage, where specialized knowledge transforms a commodity chemical into a high-performance functional component, driving differentiation and competitive advantage in the final consumer or industrial product.

Rheological Additives Market Potential Customers

The potential customer base for rheological additives is vast and multidisciplinary, fundamentally comprising industries where the control of fluid flow, suspension stability, and material application properties is essential to product quality and manufacturing efficiency. The most significant buyers are manufacturers within the coatings sector—including major producers of architectural, marine, and automotive paints—who require additives to ensure pigment suspension, prevent sagging on vertical surfaces, and guarantee a smooth finish after application. Similarly, the construction chemicals industry, focusing on mortar, cement, and concrete admixtures, relies on rheology modifiers to improve pumpability, workability, and anti-settling characteristics of their high-solid systems.

Beyond traditional sectors, high-growth potential customers include manufacturers in the personal care and pharmaceutical sectors. Cosmetic producers utilize thickeners to achieve desirable textures and mouthfeel in creams, lotions, and gels, ensuring product stability and consumer acceptability. Pharmaceutical companies employ these additives in oral suspensions and topical preparations to control dosage delivery consistency and enhance patient compliance. These regulated industries demand extremely high purity and consistent batch performance, making them premium customers for specialized organic and synthetic thickeners.

The oil and gas industry represents another vital segment, purchasing large volumes of rheological additives, predominantly mineral-based organoclays and synthetic polymers, for use in drilling fluids and cement slurries. These additives maintain the integrity of the borewell by controlling fluid viscosity under high temperature and pressure, ensuring efficient transport of rock cuttings and preventing fluid loss. Consequently, potential customers are highly diversified, ranging from multinational chemical giants requiring bulk supply to highly specialized medical formulators needing customized, low-volume, high-value specialty products, all united by the need for precise control over fluid dynamics.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 4.5 Billion |

| Market Forecast in 2033 | USD 6.7 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Elementis plc, Evonik Industries AG, The Lubrizol Corporation, Clariant AG, Ashland Global Holdings Inc., BASF SE, Croda International Plc, Dow Inc., Byk Additives & Instruments (Altana Group), Momentive Performance Materials Inc., Wacker Chemie AG, Arkema S.A., Eastman Chemical Company, KAO Corporation, Nouryon, Cargill, Inc., Air Products and Chemicals, Inc., PPG Industries, Imerys S.A., Qingdao Kingway New Material Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Rheological Additives Market Key Technology Landscape

The technological landscape of the Rheological Additives Market is characterized by continuous innovation aimed at improving efficiency, ensuring compatibility with water-borne systems, and reducing environmental impact. A key area of focus involves advanced synthesis techniques for synthetic associative thickeners, such as Hydrophobically modified Ethoxylated Urethanes (HEUR) and Hydrophobically modified Alkali-Swellable Emulsions (HASE). These technologies allow formulators to achieve superior flow and leveling characteristics in high-solid, low-VOC coatings by establishing a temporary, controllable network structure through association with binder particles, offering significant performance advantages over traditional cellulosics.

Another dominant technological trend involves the development and surface modification of inorganic additives, particularly fumed silica and nano-clays. Manufacturers are increasingly utilizing advanced surface treatment chemistries to enhance the dispersibility of these fine powders in organic and aqueous systems, preventing flocculation and maximizing their thickening and thixotropic efficiency. This modification is critical for maintaining long-term stability in high-performance coatings and industrial lubricants. Furthermore, nanotechnology is enabling the creation of specialized nano-additives that provide exceptional performance at lower incorporation levels, optimizing cost-in-use for end-users while improving overall formulation efficacy and anti-settling properties.

The future technology trajectory points toward integrating bio-based polymers and natural thickeners, such as modified starches, cellulose ethers derived from sustainable sources, and polysaccharide derivatives. Research is intensively focused on chemically modifying these natural materials to achieve the robustness and temperature stability currently offered by synthetic alternatives, meeting the growing market demand for ecological and renewable chemical solutions. Additionally, the adoption of high-throughput screening and computational chemistry is accelerating the pace of new additive discovery, enabling the precise engineering of molecular structures that yield specific, targeted rheological profiles for highly specialized applications like advanced battery slurries and high-resolution 3D printing resins.

Regional Highlights

- Asia Pacific (APAC): This region is the largest and fastest-growing market, driven by massive investments in residential and commercial infrastructure, booming automotive production, and expanding manufacturing sectors in countries like China, India, and Indonesia. High demand for industrial coatings, especially protective coatings for rapidly expanding industrial zones and marine applications, fuels consumption of both inorganic and synthetic organic rheology modifiers.

- North America: Characterized by stringent environmental regulations (especially concerning VOC emissions) and advanced technology adoption. The market here is mature but focuses heavily on high-performance, specialized additives for the oil & gas industry, advanced protective coatings, and premium personal care products. Innovation in green chemistry and sustainable additives is a major regional driver.

- Europe: Similar to North America, Europe is highly regulated, necessitating a strong shift toward water-borne and solvent-free formulations. Key growth is observed in Central and Eastern Europe's construction market, while Western Europe drives demand for highly specialized and technically advanced polymer additives used in automotive refinishing, printing inks, and pharmaceutical gels.

- Latin America (LATAM): Market growth is moderate but steady, largely dependent on construction activities in Brazil, Mexico, and Argentina. The region serves as a growing hub for coatings and adhesives manufacturing, with increasing adoption of globally standardized formulations, leading to higher consumption of cost-effective, high-volume rheological additives.

- Middle East and Africa (MEA): Growth is primarily linked to large-scale infrastructure projects (especially in the GCC nations) and significant demand from the regional oil and gas sector. Specialized high-temperature and high-pressure rheology modifiers are critical for maintaining the efficiency of deep drilling operations and pipeline coatings in harsh environments.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Rheological Additives Market.- Elementis plc

- Evonik Industries AG

- The Lubrizol Corporation

- Clariant AG

- Ashland Global Holdings Inc.

- BASF SE

- Croda International Plc

- Dow Inc.

- Byk Additives & Instruments (Altana Group)

- Momentive Performance Materials Inc.

- Wacker Chemie AG

- Arkema S.A.

- Eastman Chemical Company

- KAO Corporation

- Nouryon

- Cargill, Inc.

- Air Products and Chemicals, Inc.

- PPG Industries (Additives Division)

- Imerys S.A.

- Qingdao Kingway New Material Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the Rheological Additives market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary functions of rheological additives in coatings?

Rheological additives serve to control the flow behavior of liquid coatings, ensuring anti-settling of pigments during storage, preventing sagging or dripping on vertical surfaces after application, and maintaining stable viscosity under different shear rates, crucial for a smooth, uniform film build and high-quality finish.

How do environmental regulations impact the demand for specific rheological additive types?

Stringent environmental regulations, particularly those limiting Volatile Organic Compounds (VOCs), significantly increase the demand for water-borne and high-solid formulations. This directly favors the growth of specialized organic additives like synthetic associative thickeners (HEUR, HASE) and high-performance cellulose derivatives that function effectively in aqueous systems.

Which product segment holds the largest share in the Rheological Additives Market?

The inorganic rheological additives segment, including fumed silica and organoclays (bentonite), currently holds the largest market share due to their widespread use, versatility across various solvent and aqueous systems, and cost-effectiveness in high-volume applications like construction chemicals and protective coatings.

What is the main driver of market growth in the Asia Pacific region?

The primary driver in the Asia Pacific region is the unprecedented growth in the construction and infrastructure sectors, coupled with rapid urbanization and industrialization, leading to massive consumption of paints, sealants, and construction materials that rely heavily on rheology modification for optimal performance.

What are the key technical challenges in formulating rheological additives for modern applications?

Key technical challenges include achieving consistent performance across extreme temperatures and varied pH levels, ensuring compatibility with complex multi-component systems (like zero-VOC coatings), and developing additives that maintain high viscosity stability over extended shelf-life without impacting final product color or clarity.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Rheological Additives Market Statistics 2025 Analysis By Application (Water Treatment, Paper Industry, Paints & Coatings, Cosmetics Industry, Rubber Industry, Others), By Type (Aqueous Phase Additives, Non Aqueous Phase Additives), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Paint Rheological Additives Market Statistics 2025 Analysis By Application (Architectural, Industrial, Wood and Furniture, Automotive, Other), By Type (Inorganic Type, Organic Type), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Rheological Additives Market Size By Regional (Europe, North America, South America, Asia Pacific, Middle East And Africa), Industry Growth Opportunity, Price Trends, Competitive Shares, Market Statistics and Forecasts 2025 - 2032

- Rheological Additives Market Size, Share, Trends, & Covid-19 Impact Analysis By Type (Aqueous Phase Additives, Non Aqueous Phase Additives), By Application (Water Treatment, Paper Industry, Paints & Coatings, Cosmetics Industry, Rubber Industry, Others), By Region - North America, Latin America, Europe, Asia Pacific, Middle East, and Africa | In-depth Analysis of all factors and Forecast 2023-2030

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager