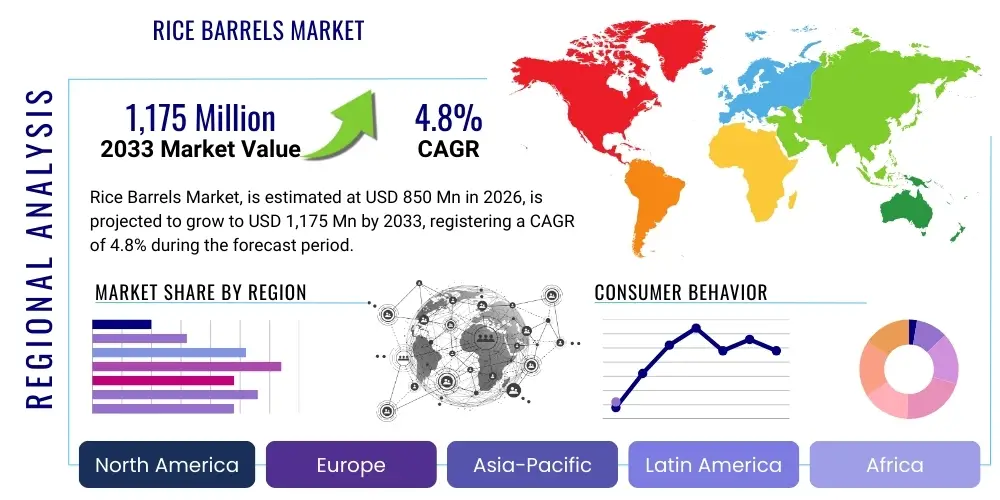

Rice Barrels Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 435794 | Date : Dec, 2025 | Pages : 253 | Region : Global | Publisher : MRU

Rice Barrels Market Size

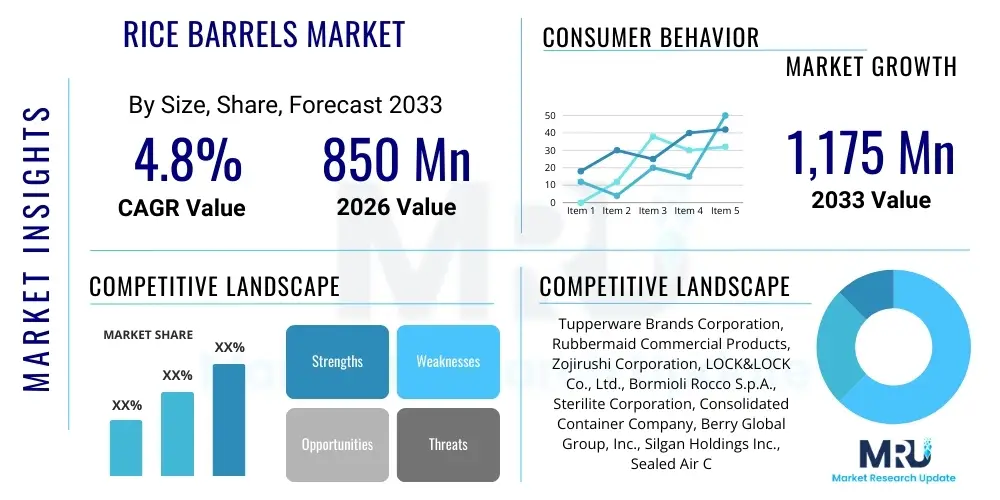

The Rice Barrels Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.8% between 2026 and 2033. The market is estimated at USD 850 Million in 2026 and is projected to reach USD 1,175 Million by the end of the forecast period in 2033.

Rice Barrels Market introduction

The Rice Barrels Market encompasses the manufacturing, distribution, and sale of specialized storage containers designed primarily for the long-term preservation and safe handling of bulk rice. These containers, historically made of wood, have evolved significantly, now frequently utilizing advanced polymers, galvanized metals, and food-grade plastics to ensure optimal preservation characteristics. Modern rice barrels, often termed storage bins or specialized silos depending on capacity, focus heavily on pest resistance, moisture control, and airtight sealing capabilities, which are critical for maintaining the nutritional value and preventing spoilage of one of the world's most vital staple foods.

Major applications of these barrels span across household consumer storage, ensuring freshness in residential settings, and extensive commercial use within restaurant supply chains, institutional catering, and large-scale grain processing facilities. Key benefits derived from utilizing specialized rice barrels include enhanced longevity of the stored grain, superior protection against common pests such as weevils and rodents, and simplified inventory management, particularly with the introduction of transparent or semi-transparent materials and modular stacking designs. The growing global population, coupled with increasing concerns regarding food security and mandated governmental quality control standards for grain storage, are the primary driving factors fueling the expansion of this market globally.

Furthermore, the demand for aesthetically pleasing and kitchen-integrated storage solutions in developed economies is influencing product design, leading manufacturers to incorporate features like integrated measurement tools, ergonomic handles, and diverse color options. The market is increasingly segmented based on material durability and capacity, with high-end segments focusing on smart technology integration for real-time monitoring of temperature and humidity. These advancements move rice barrels beyond simple containers into sophisticated tools for modern food preservation management, further solidifying their indispensable role in the global food supply chain.

Rice Barrels Market Executive Summary

The Rice Barrels Market is poised for stable expansion, underpinned by evolving global food safety regulations and a pronounced shift toward durable, multi-functional storage units. Business Trends indicate a strong inclination towards premiumization, where consumers and commercial entities prioritize long-term cost savings through investment in high-quality, pest-resistant materials like durable polypropylene and galvanized steel, moving away from cheaper, less secure alternatives. Manufacturers are rapidly integrating features such as airtight locking mechanisms and moisture absorption packets to appeal to quality-conscious buyers. Simultaneously, the market is experiencing consolidation as larger packaging and storage solution providers acquire specialized rice barrel manufacturers to capture niche segments.

Regional Trends emphatically highlight the Asia Pacific (APAC) region as the undisputed market leader, driven by its massive consumption base and the necessity for robust agricultural and household grain storage solutions across populous countries such as China, India, and Indonesia. However, rapid urbanization in Latin America and the Middle East & Africa (MEA) is accelerating demand for smaller, stackable, and visually appealing household units suitable for modern apartment living. Developed regions like North America and Europe show steady demand primarily for specialized, high-capacity industrial storage used in food service and ethnic grocery distribution, often requiring compliance with stringent western food hygiene standards.

Segments trends reveal that the Material segment is witnessing a pronounced shift towards food-grade plastic (specifically high-density polyethylene, HDPE), favored for its cost-effectiveness, lightweight nature, and excellent resistance to moisture and chemical leaching. While traditional wooden barrels maintain a heritage niche, particularly in certain specialized artisanal storage applications, the fastest growth is observed in the capacity segment focusing on 20kg to 50kg units, which balances household bulk purchasing habits with manageable physical handling. Distribution Channel analysis indicates a robust migration towards organized retail and e-commerce platforms, offering consumers greater access to diverse international brands and specialized storage options, particularly in metropolitan areas.

AI Impact Analysis on Rice Barrels Market

Analysis of common user questions concerning the influence of Artificial Intelligence on the Rice Barrels Market reveals a core curiosity centered on logistical optimization, predictive inventory management, and enhancing quality control within commercial storage environments. Users frequently inquire about how AI can prevent massive spoilage events, how machine learning algorithms can predict optimal storage conditions based on regional climate data, and the feasibility and cost-effectiveness of integrating smart sensors for automation. Key themes indicate that the expectation is for AI to transform rice barrel usage from a passive storage role into an active, data-driven preservation system. Users are specifically concerned with minimizing waste, improving supply chain traceability, and achieving ‘just-in-time’ inventory levels by leveraging predictive analytics that monitor consumption patterns and storage status in real-time, thereby maximizing efficiency and food safety compliance across large-scale storage facilities that utilize thousands of barrels or bins.

- AI optimizes supply chain logistics by predicting demand fluctuations, ensuring appropriate barrel capacity is available at agricultural hubs.

- Machine learning (ML) models analyze sensor data (temperature, humidity, oxygen levels) within IoT-enabled barrels to predict the probability of spoilage or pest infestation proactively.

- AI-driven inventory systems minimize human error in stock rotation (First-In, First-Out or FIFO), managing rice stored across numerous barrels in commercial warehouses.

- Predictive maintenance algorithms use historical data to determine when specialized barrel components, such as airtight seals or dispensing mechanisms, require replacement, reducing unexpected failures.

- Computer vision, integrated into automated packing and inspection lines, ensures that only barrels meeting rigorous quality standards (e.g., integrity, cleanliness) are used for storage.

- Natural Language Processing (NLP) helps streamline compliance reporting and documentation related to governmental food storage regulations across diverse jurisdictions.

DRO & Impact Forces Of Rice Barrels Market

The market dynamics for rice barrels are primarily driven by the imperative of global food security and the increasing complexity of international food safety standards, which necessitate superior preservation solutions capable of protecting vast quantities of grain from environmental degradation and pests. Drivers include the steady rise in global rice consumption, particularly in developing economies, coupled with heightened consumer awareness regarding the health implications of spoiled or contaminated grain, pushing demand toward certified, food-grade storage materials. Conversely, the market faces significant Restraints, notably the high initial capital expenditure required for premium, durable, and smart storage barrels, which deters adoption in budget-constrained smaller farming operations or lower-income households. Furthermore, intense competition from generic, low-cost storage alternatives, such as large plastic bins or flexible intermediate bulk containers (FIBCs), continuously pressures the pricing strategies of specialized barrel manufacturers.

However, substantial Opportunities exist within the innovation landscape, specifically through the development and mass production of biodegradable and environmentally sustainable storage materials, addressing the growing global mandate for reducing plastic waste. Integrating advanced tracking and monitoring technologies (e.g., RFID, IoT sensors) into barrels offers manufacturers a pathway to command premium pricing and expand commercial utility by providing real-time quality assurance data to logistics managers and food safety inspectors. The market is also heavily influenced by critical Impact Forces related to stringent governmental regulations targeting grain quality and mandatory pest control standards. Regulatory bodies globally are increasingly mandating specific airtight and tamper-proof features for large-volume food storage, directly influencing the design and material choice for industrial-grade rice barrels.

These regulatory pressures, combined with the rising volatility in agricultural yields due to climate change, elevate the importance of reliable, high-performance storage solutions. Manufacturers must constantly innovate to provide materials that can withstand diverse climatic conditions—from high humidity tropics to arid regions—without compromising the integrity of the rice. The socio-economic shift toward bulk buying among consumers, driven by cost-efficiency and supply chain uncertainty, also acts as a powerful demand force, necessitating larger capacity household barrels that are both ergonomic and highly effective at preservation. Consequently, success in this market is intrinsically linked to a manufacturer’s ability to balance compliance, durability, sustainability, and technological integration efficiently.

Segmentation Analysis

The Rice Barrels Market segmentation offers a granular view of demand patterns, differentiating consumer and commercial needs based on material science, volumetric capacity, specific application settings, and preferred distribution channels. The overall segmentation reveals a clear dichotomy between the established, traditional segment (characterized by basic wooden or metal containers used primarily in rural agricultural settings) and the rapidly growing modern segment, which demands highly engineered, food-grade plastic barrels featuring integrated seals, measurement indicators, and often, technological enhancements for advanced preservation. This modern segment drives significant revenue growth, appealing directly to urban households and high-volume commercial users prioritizing hygiene and efficiency. Manufacturers are strategically targeting specific segments, for instance, by developing modular, colorful, small-capacity plastic barrels for space-constrained urban kitchens, while simultaneously scaling up durable metal or composite barrels for large processing plants and government reserves.

The segmentation by capacity is perhaps the most dynamic, reflecting varied purchasing behaviors globally. Smaller capacity barrels (up to 10 kg) cater to niche markets focused on specialty rice varieties or small nuclear families in high-frequency purchasing environments. Conversely, the middle capacity range (10 kg to 50 kg) dominates the household market across Asia Pacific, acting as the standard storage solution for weekly or monthly consumption needs. The largest capacity barrels (over 50 kg, often referred to as bins or drums) are almost exclusively utilized by commercial entities, including wholesalers, restaurants, and institutional buyers, where durability and volume throughput are the primary considerations, often justifying a higher initial investment in robust, long-lasting materials like heavy-gauge stainless steel or thick-walled HDPE.

Distribution segmentation underscores the changing consumer landscape. While traditional channels such as agricultural supply stores and local wholesalers remain critical for bulk transactions, the swift expansion of e-commerce platforms and modern retail outlets (hypermarkets and supermarkets) has provided unprecedented visibility and reach for branded, higher-quality rice barrels. This shift facilitates easier consumer comparison of features, pricing, and warranties, propelling greater market penetration for innovative products. Understanding these segmented demands is crucial for market stakeholders, allowing them to tailor marketing strategies and product specifications to address the precise functional requirements and budgetary constraints of diverse end-users, ensuring product relevance across the entire consumer spectrum, from traditional farm storage to high-tech, smart kitchen solutions.

- By Material:

- Plastic (HDPE, PP)

- Wood

- Metal (Galvanized Steel, Stainless Steel)

- Ceramic/Clay (Niche/Traditional)

- Composite Materials

- By Capacity:

- Small (Up to 10 kg)

- Medium (10 kg – 50 kg)

- Large (Above 50 kg)

- By Application:

- Household Storage

- Commercial Food Service (Restaurants, Catering)

- Industrial/Agricultural (Wholesalers, Mills, Government Reserves)

- By Distribution Channel:

- Online Retail (E-commerce)

- Offline Retail (Supermarkets, Hypermarkets, Department Stores)

- Direct Sales (B2B Supply, Agricultural Distributors)

Value Chain Analysis For Rice Barrels Market

The value chain for the Rice Barrels Market begins with Upstream Analysis, focusing intensely on the sourcing of high-quality raw materials. For plastic barrels, this involves petrochemical suppliers providing specialized food-grade polymers (HDPE, PP) that must meet strict toxicity and durability standards. For metal barrels, sourcing high-gauge, corrosion-resistant steel or aluminum is essential. Quality control at this stage dictates the longevity and safety of the final product, directly influencing manufacturing costs and downstream compliance. Manufacturing processes involve injection molding for plastic variants, sheet metal fabrication for metal barrels, and traditional crafting/sealing for wooden types. Efficiency in manufacturing, particularly reducing material waste and optimizing mold design for stackability, is a critical cost differentiator in this highly competitive market segment.

The Midstream component centers on the complex Distribution Channel network. This includes both Direct and Indirect pathways. Direct distribution involves large-volume B2B sales primarily aimed at industrial customers, grain mills, and government agencies, where contracts often specify customized volumes and strict quality assurances. Indirect distribution channels encompass wholesale aggregators, specialized agricultural equipment dealers, and, increasingly, modern retail channels and e-commerce platforms. E-commerce is rapidly gaining prominence for household and small commercial units, leveraging global logistics networks to reach remote consumers who lack access to specialized local stores, demanding robust secondary packaging to ensure the product arrives undamaged and ready for immediate use.

Downstream analysis focuses on the end-user interaction and post-sale service. The final buyers, whether households or commercial kitchens, evaluate the product based on functional attributes such as airtightness, ease of cleaning, dispensing mechanism reliability, and durability. The effectiveness of the value chain is measured by its ability to deliver a product that minimizes rice spoilage throughout its entire life cycle. Furthermore, the increasing focus on sustainability necessitates manufacturers to consider end-of-life management for barrels, encouraging the use of recyclable plastics and offering trade-in or recycling programs, thereby closing the loop and adding value through corporate responsibility initiatives that appeal directly to environmentally conscious consumers.

Rice Barrels Market Potential Customers

The primary End-Users/Buyers of rice barrels are highly diverse, spanning the entire food consumption spectrum from individual households focused on preservation and pantry organization to multi-national food corporations requiring massive, specialized storage infrastructure. Households form a substantial customer base, particularly in rice-consuming nations, seeking containers that offer convenient dispensing, maintain hygiene, and integrate seamlessly into kitchen aesthetics. Demographic shifts, such as the increase in middle-class disposable income, drive demand for premium, smart household barrels featuring advanced sealing technology and visual indicators for monitoring content levels.

On the commercial front, potential customers include the extensive network of restaurants, catering businesses, and institutional kitchens (schools, hospitals, military bases) that rely on predictable, high-volume access to rice, necessitating durable barrels capable of frequent handling and sterilization. These buyers prioritize industrial-grade materials like stainless steel for longevity and compliance with strict commercial hygiene standards. Furthermore, large-scale agricultural processors, rice mills, wholesale distributors, and government food security reserves represent the highest capacity users, requiring barrels designed for long-term, static bulk storage often involving controlled environment features such as temperature and humidity regulation, making them key targets for high-value B2B contracts.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 850 Million |

| Market Forecast in 2033 | USD 1,175 Million |

| Growth Rate | 4.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Tupperware Brands Corporation, Rubbermaid Commercial Products, Zojirushi Corporation, LOCK&LOCK Co., Ltd., Bormioli Rocco S.p.A., Sterilite Corporation, Consolidated Container Company, Berry Global Group, Inc., Silgan Holdings Inc., Sealed Air Corporation, Winco Foods, Pactiv Evergreen Inc., Curver (Keter Group), Cuisinart, Pioneer Plastics, Inc., TCC Packaging Solutions, Guangzhou Huale Industrial Co., Ltd., Shaanxi Top Metal Co., Ltd., KIS Group, and King Pack Industrial Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Rice Barrels Market Key Technology Landscape

The technological evolution within the Rice Barrels Market is moving away from basic containment towards integrated preservation and management systems, reflecting broader trends in smart kitchens and efficient logistics. A core technological focus involves advanced sealing mechanisms, utilizing features such as dual-gasket technology and vacuum-sealing capabilities, ensuring an almost oxygen-free environment crucial for inhibiting the growth of mold and pests over extended storage periods. The refinement of food-grade plastic compounds, specifically utilizing antimicrobial additives embedded directly into the polymer matrix, represents a key material science innovation aimed at enhancing hygiene and extending the lifespan of the stored grain without relying solely on chemical treatments.

Furthermore, the integration of Internet of Things (IoT) sensors is rapidly emerging, particularly in commercial and industrial rice barrels. These smart features allow for real-time monitoring of internal environmental parameters, including temperature, relative humidity, and residual oxygen levels. Data captured by these sensors is transmitted wirelessly, enabling predictive maintenance alerts and automated adjustments in controlled storage facilities. This technological leap transforms passive containers into active management tools, significantly reducing inventory losses due to environmental fluctuations or pest breaches, thereby adding considerable value to commercial buyers who manage substantial reserves.

Design innovation also plays a crucial role, focusing on modularity and user experience. Manufacturers are employing CAD and simulation technologies to develop stackable, ergonomic barrel designs that maximize storage density in constrained spaces (e.g., apartment pantries or small warehouse footprints) while maintaining structural integrity under heavy loads. The development of integrated mechanical dispensing systems, which provide precise, measured portions of rice (e.g., per cup or gram), minimizes the need to repeatedly open the main container, further enhancing preservation by limiting air exposure, reflecting a confluence of advanced mechanical engineering and user-centric design principles aimed at optimizing daily use.

Regional Highlights

- Asia Pacific (APAC): APAC is the dominant market leader, accounting for the largest volume consumption and production of rice barrels globally. The necessity for reliable, high-capacity storage is driven by billions of consumers for whom rice is the primary dietary staple. The market here is characterized by a strong presence of both traditional (wooden/ceramic) and modern (plastic/metal) barrels, with robust demand originating from agricultural regions, rice mills, and rapidly expanding urban populations. Government initiatives aimed at ensuring national food security and reducing post-harvest losses are major investments driving the adoption of large, specialized storage bins and barrels, particularly in countries like India, China, and Vietnam.

- North America: This region represents a highly mature market, where demand is largely concentrated in the commercial segment, focused on supplying the extensive food service industry (restaurants, catering) and ethnic grocery stores. Household demand tends toward premium, aesthetic, small-to-medium capacity barrels that fit modern kitchen designs, prioritizing airtightness, branding, and superior material quality. Innovation adoption, especially IoT-enabled storage solutions, is higher here due to better infrastructure and willingness to pay premium prices for advanced inventory management and food safety features, mandated by strict federal health regulations.

- Europe: The European market demonstrates steady growth, driven by stringent EU food hygiene and safety standards, favoring high-quality, non-toxic, and often metallic or high-grade plastic containers. Demand is focused on industrial use in processing facilities, logistical warehousing, and specialized imported goods distribution. The household segment, while smaller than APAC, shows a strong preference for sustainably produced or recyclable storage solutions, reflecting high environmental awareness among consumers and providing a niche opportunity for manufacturers specializing in eco-friendly materials.

- Latin America (LATAM): This region is characterized by emerging demand, fueled by rapid urbanization and the formalization of food retail. As populations shift from rural to urban centers, the need for safe, durable household storage that protects rice from pests and humidity in dense environments increases significantly. The market is price-sensitive, with a strong preference for cost-effective, durable plastic barrels, but shows potential for high growth in the commercial sector as agricultural distribution chains modernize and require standardized bulk storage containers.

- Middle East and Africa (MEA): The MEA market is heavily influenced by factors such as climate extremes (high heat, low humidity), requiring specialized materials that can maintain rice integrity, and substantial reliance on imported rice. Demand is high for robust industrial barrels used by large importers and governmental food reserve agencies. Household adoption is accelerating, driven by population growth and increased disposable income in oil-rich economies, leading to a rising interest in medium-capacity, airtight plastic solutions that address high heat and dust challenges inherent to the region.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Rice Barrels Market.- Tupperware Brands Corporation

- Rubbermaid Commercial Products

- Zojirushi Corporation

- LOCK&LOCK Co., Ltd.

- Bormioli Rocco S.p.A.

- Sterilite Corporation

- Consolidated Container Company

- Berry Global Group, Inc.

- Silgan Holdings Inc.

- Sealed Air Corporation

- Winco Foods

- Pactiv Evergreen Inc.

- Curver (Keter Group)

- Cuisinart

- Pioneer Plastics, Inc.

- TCC Packaging Solutions

- Guangzhou Huale Industrial Co., Ltd.

- Shaanxi Top Metal Co., Ltd.

- KIS Group

- King Pack Industrial Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the Rice Barrels market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving growth in the Rice Barrels Market?

The key driver is the increasing global emphasis on food security and the necessity for superior, pest-resistant grain storage solutions mandated by escalating governmental food safety regulations worldwide, coupled with sustained growth in global rice consumption.

Which material segment is expected to see the fastest growth rate?

The food-grade Plastic segment, particularly high-density polyethylene (HDPE), is projected for the fastest growth due to its cost-effectiveness, lightweight properties, excellent moisture barrier characteristics, and suitability for mass production of airtight household and commercial containers.

How is AI impacting commercial rice barrel management?

AI impacts commercial management by enabling predictive inventory systems and quality control through IoT sensor data analysis, minimizing spoilage risks, optimizing supply chain logistics, and ensuring proactive maintenance of storage environments.

What are the main capacity segments addressed by the market?

The market primarily addresses three capacity segments: Small (up to 10 kg) for specialty or short-term household use, Medium (10 kg – 50 kg) for standard bulk household buying, and Large (above 50 kg) for industrial, agricultural, and commercial food service applications.

Why is the Asia Pacific region dominant in the Rice Barrels Market?

APAC dominates the market due to its overwhelming position as the largest global producer and consumer of rice, necessitating vast quantities of specialized storage containers for both agricultural protection and household preservation across its highly populous nations.

What differentiates premium rice barrels from standard storage containers?

Premium rice barrels are differentiated by advanced features such as multi-layered airtight sealing, antimicrobial material composites, integrated mechanical dispensing systems, superior durability for long-term use, and often, the inclusion of smart monitoring technology (IoT sensors) for active preservation management.

What restraint challenges market penetration in developing regions?

A significant restraint is the high initial investment cost required for purchasing durable, specialized, and quality-certified rice barrels, which often poses a financial barrier for smaller farming operations and low-income households compared to cheaper, generic storage alternatives.

Are biodegradable materials an opportunity in this market?

Yes, the development and adoption of biodegradable and sustainable composite materials present a key opportunity, aligning with global environmental mandates and catering to the increasing consumer demand for eco-friendly packaging and storage solutions, particularly in developed markets.

How do climate factors influence barrel design?

Climate factors necessitate specific design considerations; for high-humidity regions, barrels must have superior moisture barriers, while in arid or high-heat environments, materials must be highly UV-resistant and thermally stable to prevent material degradation and grain damage over time.

What role does e-commerce play in distribution?

E-commerce plays a vital role by expanding market reach, allowing manufacturers to sell specialized, branded household barrels directly to consumers globally, providing convenience, greater product transparency, and supporting the growth of premium segments in urban areas.

Which application segment uses the largest capacity barrels?

The Industrial/Agricultural application segment, which includes grain mills, wholesalers, and government food reserves, utilizes the largest capacity rice barrels, often above 50 kg, focusing on bulk static storage and long-term grain preservation.

What is AEO optimization in the context of rice barrels marketing?

AEO (Answer Engine Optimization) involves structuring product content and market analysis reports with direct, concise answers to common user questions (like these FAQs) using clear, semantic language, ensuring search engines can extract accurate information quickly for direct display in search snippets and generative outputs.

What are the major challenges related to pest control in rice barrel storage?

Pest control challenges require robust solutions, including flawless airtight seals, non-toxic materials, and sometimes chemical-resistant surfaces, as common pests like rice weevils and rodents can quickly compromise grain quality if the barrel design is structurally weak or poorly sealed.

What is the significance of the "Impact Forces" category in market analysis?

The Impact Forces category identifies macro-environmental and regulatory factors, such as climate change volatility, stringent government mandates, and shifting consumer preferences (e.g., sustainability demands), which exert profound, non-cyclical pressures directly shaping product innovation and market viability for rice barrels.

How is the value chain managing raw material volatility?

The value chain addresses raw material volatility by fostering strategic, long-term sourcing partnerships with certified petrochemical and metal suppliers, and through material substitution, such as exploring high-performance composites when standard plastic polymer costs spike, maintaining production stability.

What technological feature is crucial for preventing spoilage?

The most crucial technological feature for spoilage prevention is the implementation of advanced airtight sealing mechanisms, often utilizing dual silicone or rubber gaskets and high-pressure locking systems, minimizing oxygen ingress and maintaining stable internal humidity levels necessary for grain integrity.

How does urbanization affect household rice barrel demand?

Urbanization shifts household demand towards smaller, stackable, and aesthetically pleasing rice barrels, as consumers in city apartments require space-efficient, durable storage solutions that integrate well with modern kitchen designs, driving the growth of the premium and medium-capacity segments.

What is the projected Compound Annual Growth Rate (CAGR) for the market?

The Rice Barrels Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.8% between the forecast period of 2026 and 2033, indicating stable and sustainable growth driven by both commercial expansion and household quality upgrades.

Why do commercial buyers prefer stainless steel barrels?

Commercial buyers, especially in food service and processing, prefer stainless steel due to its superior durability, inherent resistance to rust and corrosion, ease of sterilization, and compliance with rigorous commercial food hygiene and sanitation standards that demand non-reactive storage materials.

What competitive advantage do modular barrel designs offer?

Modular barrel designs offer a competitive advantage by allowing users to maximize storage density through efficient stacking and organization, appealing primarily to commercial warehouses and urban households constrained by space, while often incorporating standardized components for easier repair and inventory management.

How is the market addressing sustainability concerns?

The market is addressing sustainability concerns by researching and implementing recycled and biodegradable plastics, designing barrels for maximum material longevity to reduce replacement frequency, and establishing end-of-life recycling programs for non-biodegradable components, targeting environmentally conscious consumers.

What is the main concern users have about AI integration in rice barrels?

The main concern users express is often the cost-effectiveness and complexity of integrating AI and IoT sensors into traditional storage solutions, questioning whether the added expense justifies the gains in quality control and inventory management, especially for smaller scale operations.

What defines the 'Base Year' and 'Forecast Year' in this report?

The Base Year for this market analysis is 2025, serving as the benchmark for market valuation, while the Forecast Year spans from 2026 through 2033, defining the period for which market growth projections and trend analyses are provided.

What is the difference between Upstream and Downstream analysis in the value chain?

Upstream analysis focuses on the input factors, specifically the sourcing and procurement of raw materials (polymers, metals). Downstream analysis focuses on the output factors, including distribution channels, end-user purchase behavior, and post-sale product performance and feedback.

How do customized barrels benefit government reserves?

Customized barrels benefit government reserves by meeting precise specifications for volume, structural load capacity, and specialized preservation features required for long-term strategic grain storage, often including enhanced security and tracking mechanisms crucial for national food security mandates.

What is the role of technical documentation in rice barrel marketing?

Technical documentation, including material certifications, airtightness test results, and compliance statements regarding food safety standards (like FDA or EU regulations), is crucial for marketing, particularly when targeting commercial and industrial buyers who require strict quality assurance before purchase.

What is a primary restraint in the Latin America and MEA regions?

In Latin America and MEA, a primary restraint is often volatility in local currency coupled with higher import duties on specialized storage materials, which increases the retail price of high-quality, imported rice barrels, limiting market accessibility for budget-conscious buyers.

How are aesthetic considerations influencing household barrel design?

Aesthetic considerations drive demand for barrels that are visually appealing, featuring diverse colors, sleek designs, and ergonomic shapes that seamlessly blend with modern kitchen decor, moving away from purely utilitarian industrial looks and supporting premium pricing strategies.

What is the key benefit of integrated dispensing systems in barrels?

The key benefit of integrated dispensing systems is enhanced preservation, as they allow users to measure and extract rice without fully opening the main container, minimizing the rice's exposure to ambient air, moisture, and potential contaminants, thereby extending shelf life.

Which distribution channel is most critical for bulk industrial purchases?

Direct Sales and B2B Supply channels are most critical for bulk industrial purchases, as they facilitate specialized contract agreements, volume discounts, customized product specifications, and direct logistical support between the manufacturer and the large commercial end-user.

How does IoT integration enhance rice barrel utility?

IoT integration enhances utility by transforming barrels into smart storage units capable of monitoring internal environmental conditions (temperature, humidity) and providing real-time data alerts to managers, enabling proactive intervention to prevent quality degradation or pest outbreaks.

What capacity range is considered dominant in the APAC household market?

The Medium capacity range (10 kg – 50 kg) is considered dominant in the APAC household market, reflecting typical family consumption patterns and bulk purchasing habits where rice is bought and stored for multi-week consumption cycles.

What is the historical year range covered in the report?

The historical year range covered in this comprehensive market report analysis is from 2019 to 2024, providing a foundation for understanding past market performance and trajectory leading up to the base year.

What distinguishes traditional wooden barrels in today's market?

Traditional wooden rice barrels maintain a niche presence, often favored for specialized or artisanal rice storage where aesthetics or historical methods are valued, though they generally lack the airtight sealing and modern pest resistance offered by plastic or metal counterparts.

What is the main challenge related to using recycled plastics in rice barrels?

The main challenge related to using recycled plastics is ensuring that the material still meets stringent food-grade safety standards and does not leach contaminants, which requires highly advanced processing techniques to certify its safety for long-term food contact, increasing production complexity.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager