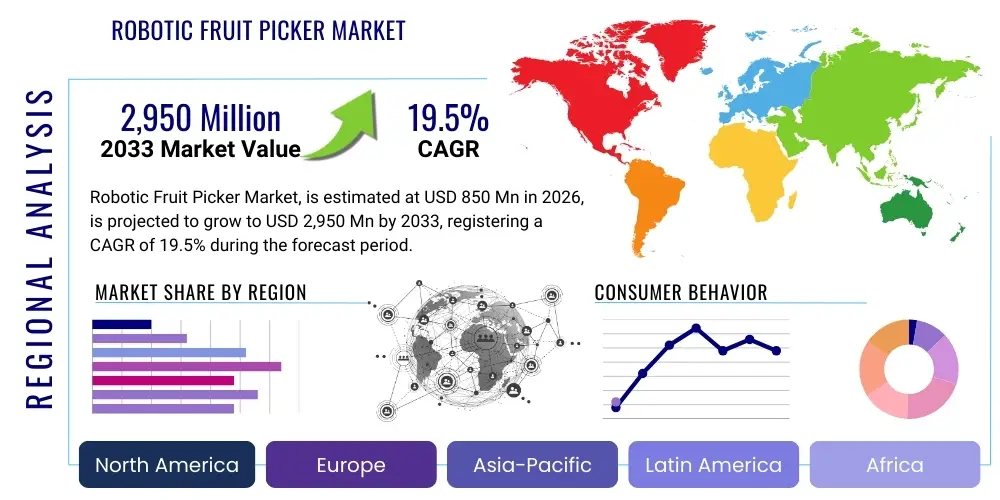

Robotic Fruit Picker Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 438679 | Date : Dec, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Robotic Fruit Picker Market Size

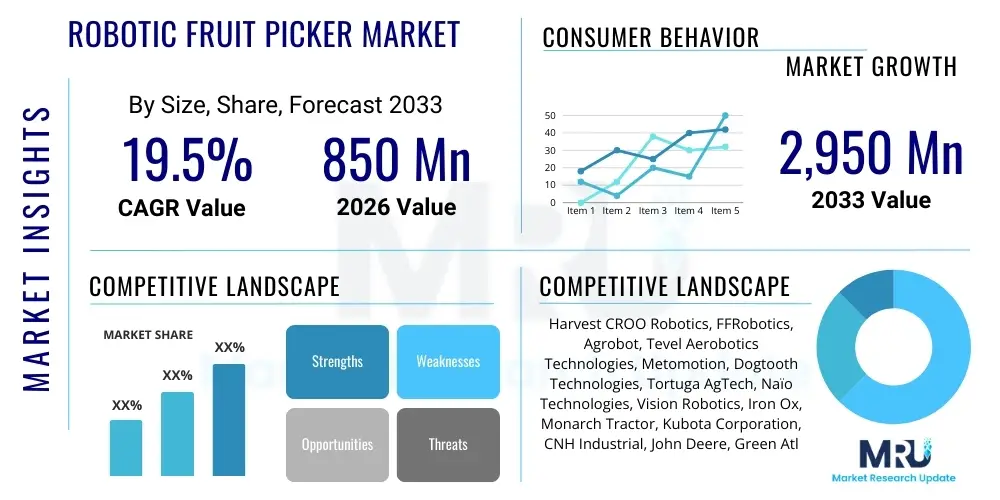

The Robotic Fruit Picker Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 19.5% between 2026 and 2033. The market is estimated at $850 Million in 2026 and is projected to reach $2,950 Million by the end of the forecast period in 2033.

Robotic Fruit Picker Market introduction

The Robotic Fruit Picker Market encompasses the development, manufacturing, and deployment of autonomous and semi-autonomous systems designed to harvest delicate and high-value fruit crops. These advanced machines utilize complex sensor arrays, sophisticated computer vision (CV) algorithms, and specialized end-effectors to identify, assess ripeness, and carefully detach fruit from plants or trees, thereby addressing critical labor shortages plaguing the global agricultural sector. The core product involves mobile robotic platforms equipped with articulated arms and highly precise gripping mechanisms, often leveraging AI for real-time decision-making regarding fruit quality and optimal picking strategy, ensuring minimal damage and maximum yield efficiency for growers worldwide.

Major applications of robotic fruit pickers span various high-density orchards and fields, notably strawberries, apples, citrus fruits, and soft berries, where manual labor is historically intensive and highly variable in quality. The primary benefits include substantial reductions in operational costs, improved consistency and speed of harvesting operations, and the ability to operate continuously, irrespective of climate or availability of human labor. Furthermore, these systems contribute significantly to precision agriculture by gathering high-resolution data on yield prediction, plant health, and localized ripening patterns, transforming traditional farming practices into data-driven operations.

The market growth is fundamentally driven by intensifying global agricultural labor shortages, coupled with increasing consumer demand for consistent quality fresh produce, which mandates highly efficient harvesting methods. Moreover, government subsidies and investments in agricultural technology (AgriTech) across North America and Europe, aimed at enhancing food security and domestic production capacity, act as powerful accelerators. Technological advancements, particularly in machine learning, sensor technology, and battery life, are continuously lowering the barriers to adoption, enabling robust performance even in challenging field environments, thereby solidifying the market's strong trajectory through the forecast period.

Robotic Fruit Picker Market Executive Summary

The Robotic Fruit Picker Market is undergoing rapid technological maturation, transitioning from experimental prototypes to commercially viable solutions driven by urgent operational needs within the agricultural sector. Current business trends indicate a strong focus on modular designs and platform flexibility, allowing single robotic units to be adapted for different fruit types or farm layouts, thereby improving the return on investment (ROI) for farmers. Strategic alliances between technology developers and large farm equipment manufacturers are becoming commonplace, facilitating scalable production and integrating advanced robotics into existing agricultural machinery ecosystems. Venture capital investment remains robust, primarily targeting startups specializing in advanced vision systems and soft robotics (compliant end-effectors) crucial for handling sensitive produce like raspberries and tomatoes, signaling market confidence in long-term automation solutions.

Regionally, North America and Europe lead the market adoption curve, propelled by severely constrained labor markets, high minimum wages, and substantial governmental emphasis on sustainable, technology-driven agriculture. Asia Pacific (APAC), particularly China and Japan, is emerging as a critical growth engine, driven by significant government-led investments in modernization and the increasing retirement rates of the aging farming populations. In contrast, emerging economies in Latin America and MEA are beginning to explore pilot programs, often focusing on high-value export crops, but face hurdles related to infrastructure and initial capital expenditure, yet these regions represent substantial long-term market opportunities.

In terms of segmentation, the Fully Autonomous operation mode dominates market revenue, reflecting the industry's desire for 'lights-out' harvesting capabilities that minimize human intervention. The Application segment is currently skewed toward high-volume, high-value crops like strawberries and apples, which offer clear economic justifications for high upfront costs, although rapid technological advancements are expanding applicability to more complex crops like grapes and delicate soft berries. Furthermore, segmentation by End-Effector Type shows an increasing preference for vacuum or suction-based systems in specific fruit categories (e.g., citrus) due to their simplicity and speed, while sophisticated mechanical grippers, often incorporating compliant materials, are essential for delicate fruit like peaches and raspberries.

AI Impact Analysis on Robotic Fruit Picker Market

User queries regarding AI's impact on robotic fruit picking frequently center on reliability, accuracy, and the ability of machines to replicate human judgment, particularly concerning ripeness assessment and defect detection. Common themes revolve around questions such as: "How accurately can AI differentiate between ripe and unripe fruit under varying light conditions?" "Can machine learning algorithms adapt quickly to new fruit varieties or seasonal changes?" and "Will AI reduce the necessity for extensive human supervision?" The prevailing expectation is that AI, specifically deep learning and convolutional neural networks (CNNs), will be the key differentiator, solving the 'perception problem' which has historically limited robotic harvesting success. Users are highly concerned with the speed of data processing and the ability of AI to optimize picking paths in real-time, thereby maximizing operational efficiency and minimizing wasted motion, making highly accurate visual perception and predictive maintenance the most desired AI capabilities.

The integration of Artificial Intelligence (AI) and Machine Learning (ML) is fundamentally transforming the capabilities and economic viability of robotic fruit pickers. AI powers the core computer vision systems, enabling robots to process complex visual data, accurately segment fruit from foliage, and determine precise 3D localization necessary for successful gripping. This cognitive layer allows robots to learn from massive datasets of images and environmental parameters, significantly enhancing accuracy beyond simple color differentiation to assess subtle ripeness cues, bruise detection, and overall market quality, making the harvested yield more predictable and valuable.

Beyond perception, AI optimizes the entire harvesting workflow. Reinforcement learning is utilized to refine robotic arm motion planning, ensuring the fastest, least damaging path is taken for each pick, adapting dynamically to different tree architectures and density levels. Furthermore, predictive analytics driven by AI models are now integrated into fleet management systems, forecasting equipment maintenance needs, optimizing battery charging schedules, and strategically deploying machines across large fields based on real-time ripening maps derived from robot-collected data. This holistic integration of AI moves the technology beyond mere automation to intelligent, scalable agricultural management systems, substantially boosting the overall productivity per hectare.

- Enhanced Ripeness and Quality Assessment: Deep learning models precisely classify fruit stages, maximizing the harvest of optimum quality produce.

- Real-Time Obstacle Avoidance and Path Planning: AI algorithms optimize arm movement, minimizing collision risk and accelerating picking cycles.

- Adaptive Harvesting Strategies: Machine learning allows robots to adjust picking parameters (force, speed, angle) based on fruit variety and environment instantly.

- Predictive Maintenance: AI monitors sensor data to predict component failure, reducing unexpected downtime and enhancing operational reliability.

- Data-Driven Yield Mapping: Robots generate highly detailed geospatial data, enabling precise yield forecasting and localized farm management decisions.

DRO & Impact Forces Of Robotic Fruit Picker Market

The dynamics of the Robotic Fruit Picker Market are shaped by a powerful confluence of drivers pushing adoption and restraints hindering widespread deployment, framed by transformative opportunities that dictate future growth trajectories. The primary driving force is the acute, persistent scarcity of seasonal agricultural labor across developed economies, which makes reliance on manual harvesting economically unsustainable and highly volatile. Coupled with this, ongoing technological breakthroughs in sensing, AI, and battery technology have lowered the functional threshold for commercial viability. Conversely, the market is restrained by the high initial capital investment required for these sophisticated machines, which creates a significant barrier to entry for smaller farming operations, alongside the complexity of maintaining and repairing these high-tech systems in demanding field environments. Opportunities lie in expanding technological capabilities to soft fruits and addressing the standardization gap across the industry, facilitating easier integration.

Key drivers include the global push towards precision agriculture, which demands the high level of data accuracy and non-destructive harvesting only robots can provide, coupled with increasing governmental support and subsidies aimed at promoting agricultural mechanization to secure domestic food supply chains. The stringent quality requirements imposed by major retailers also favor robotic harvesting due to its consistency in minimizing fruit damage. Impact forces heavily favor drivers, reflecting a structural shift in agricultural production; high labor costs represent a permanent and escalating force, while technological advancement provides a consistently decreasing counter-force to the cost restraints. The impact forces are intensifying, pressuring farms of all sizes to automate to remain competitive globally.

Restraints are slowly being mitigated by evolving business models, such as Robotics-as-a-Service (RaaS), which lowers the upfront cost burden, making the technology accessible to a wider pool of growers. Furthermore, while the complexity of maintenance remains a concern, the increasing modularity and remote diagnostic capabilities built into newer generations of robotic pickers are improving uptime and serviceability. Opportunities are vast, particularly in refining soft robotics for extremely delicate crops (e.g., raspberries, avocados), developing fully autonomous charging and navigation solutions, and integrating robotic harvesting data seamlessly with broader farm management software platforms, unlocking unprecedented efficiency gains across the entire agricultural value chain.

Segmentation Analysis

The Robotic Fruit Picker Market segmentation provides a clear framework for understanding market dynamics based on the technology deployed, the specific crop application, the level of autonomy in operation, and the economic capacity of the end-user. Analyzing these segments helps stakeholders identify key investment areas, target customer groups, and develop specialized product features that address unique agricultural requirements. For instance, the choice of end-effector technology is directly dependent on the fruit's texture and delicacy, dictating the design constraints and cost structure of the resulting robotic system, while the application segment highlights areas where the economic urgency for automation is highest, such as in high-labor-intensive strawberry harvesting.

The segmentation by Operation mode—Fully Autonomous versus Semi-Autonomous—reflects the differing levels of farm technological readiness and regulatory environment. Fully Autonomous systems represent the aspirational end-state, offering maximum labor displacement and continuous operation, while Semi-Autonomous systems, which might require human supervision or assistance in navigation, serve as an important transitional technology, particularly for farms in early stages of digitalization or those managing irregularly structured fields. Geographic segmentation further differentiates market demand, with advanced agricultural regions prioritizing high-throughput, fully automated solutions, whereas emerging markets often seek lower-cost, scalable semi-automated options that can be gradually integrated into existing operations.

Understanding the segmentation by Farm Size (Large, Medium, Small) is crucial for commercialization strategies. Large corporate farms typically demand high-capacity, multi-arm robotic platforms integrated with existing machinery (e.g., tractors), justifying significant investment through sheer volume and operational scale. Conversely, smaller farms represent a viable segment addressable through Robotics-as-a-Service models or by specialized, lighter-weight, lower-cost robotic platforms designed for smaller plot management and faster mobilization, ensuring that the benefits of automation are accessible across the entire agricultural spectrum, preventing a technological divide within the industry.

- By Type:

- End-Effector Type: Suction/Vacuum Grippers, Mechanical Claws/Grippers (Hard, Compliant), Cutting Mechanisms.

- Robotic Arm Type: Multi-Arm Systems, Single-Arm Systems.

- By Application (Fruit Type):

- Strawberry

- Apple

- Citrus (Oranges, Lemons)

- Grape/Vineyard

- Soft Fruits (Raspberries, Blueberries)

- Stone Fruits (Cherries, Peaches)

- By Operation:

- Fully Autonomous

- Semi-Autonomous (Requires human monitoring/intervention)

- By Farm Size:

- Large Farms (250+ Acres)

- Medium Farms (50-250 Acres)

- Small Farms (Less than 50 Acres)

Value Chain Analysis For Robotic Fruit Picker Market

The value chain for the Robotic Fruit Picker Market is characterized by high technological specialization, starting with core component manufacturing and culminating in on-farm deployment and long-term maintenance services. The upstream activities involve the specialized supply of critical components, including high-resolution sensors (LiDAR, RGB-D cameras), advanced microprocessors for AI processing, complex mechanical actuators, and specialized materials for soft end-effectors, where suppliers of industrial automation components and vision technology hold significant leverage. The midstream is dominated by system integrators and robotics manufacturers who assemble these components, develop proprietary AI algorithms, and conduct rigorous field testing to ensure reliability under diverse agricultural conditions, requiring intensive R&D investment.

Downstream activities focus on market entry, distribution, and critical after-sales support. Distribution channels are typically bifurcated: Direct sales are common for large, specialized corporate farms that require customized solutions and direct contractual relationships, ensuring detailed knowledge transfer. Indirect channels involve partnerships with established agricultural equipment dealers and machinery distributors (e.g., John Deere, Kubota networks), who leverage their existing sales infrastructure and service networks to reach a broader base of medium and small farmers. The effectiveness of the downstream segment is highly dependent on the quality of technical training and the availability of responsive, localized maintenance services to maximize robot uptime during critical harvesting seasons.

The value generated is shifting increasingly toward data monetization and service provision rather than merely hardware sales. Direct and indirect distribution channels also play a pivotal role in feeding back crucial performance data from the field to R&D teams, creating a continuous improvement loop essential for refining AI models and mechanical durability. The "Robotics-as-a-Service" (RaaS) model is reshaping the downstream segment, blurring the line between sales and service, offering comprehensive solutions that include hardware deployment, software updates, maintenance, and performance guarantees for a fixed fee or revenue share, effectively derisking adoption for farmers and establishing long-term revenue streams for manufacturers.

Robotic Fruit Picker Market Potential Customers

The primary customers for robotic fruit pickers are commercial agricultural enterprises that manage high-value fruit crops, facing consistent pressures from increasing labor costs and variability in human harvesting quality. These end-users range from large-scale corporate orchards and vineyard holdings, particularly those focused on export-quality production, to medium-sized family farms struggling to maintain seasonal labor forces. Initial adopters are typically characterized by high operational volume, early technological readiness, and a strong financial capacity to absorb high upfront capital expenditures, viewing automation as a strategic imperative for long-term sustainability and efficiency gains. These customers prioritize metrics such as picking throughput, percentage of fruit damaged, and the consistency of ripeness selection provided by the robotic systems, demanding proven ROI within a relatively short timeframe.

Secondary customer segments include food processing companies and cooperatives that require large, standardized volumes of raw fruit for products like juices, preserves, or frozen goods. While their quality tolerances might be slightly wider than the fresh market, they require immense, predictable supply volumes that robotic harvesting is ideally suited to provide consistently, minimizing supply chain disruption. Furthermore, agricultural research institutions and universities are potential customers, utilizing these advanced robots for field experiments, data collection, and developing new, high-density orchard designs optimized for automated harvesting, thus influencing future technology adoption trends and breeding programs.

An emerging, yet strategically crucial, segment involves greenhouse and vertical farming operations. These controlled environment agriculture (CEA) setups, particularly those growing strawberries, tomatoes, and other soft berries year-round, offer highly structured, predictable environments that are perfectly suited for robotic automation. These customers prioritize continuous operation, integration with existing climate control systems, and data-rich operational reporting, often favoring smaller, highly specialized robotic units designed for indoor movement rather than large field platforms, driving demand for compact and highly sophisticated autonomous pickers.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $850 Million |

| Market Forecast in 2033 | $2,950 Million |

| Growth Rate | 19.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Harvest CROO Robotics, FFRobotics, Agrobot, Tevel Aerobotics Technologies, Metomotion, Dogtooth Technologies, Tortuga AgTech, Naïo Technologies, Vision Robotics, Iron Ox, Monarch Tractor, Kubota Corporation, CNH Industrial, John Deere, Green Atlas, Yamaha Motor Co., Ltd., Panasonic Corporation, VARTA AG, AppHarvest (Root AI assets), Advanced Farm Technologies. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Robotic Fruit Picker Market Key Technology Landscape

The technological landscape of robotic fruit picking is defined by the convergence of advanced sensor technology, sophisticated AI-driven software, and specialized mechanical engineering designed to interact delicately with biological material. Central to this landscape are high-resolution 3D vision systems, often utilizing a combination of RGB cameras, near-infrared (NIR) sensors, and LiDAR, which provide the robots with the depth perception and spectral analysis needed to accurately identify fruit location and determine ripeness across varying light conditions. The computational power required for real-time image processing and AI execution necessitates high-performance embedded systems, driving demand for specialized processing units optimized for edge computing directly on the field robot, ensuring rapid decision-making without reliance on cloud connectivity.

End-effector technology represents another critical area of innovation, moving away from rigid, potentially damaging grippers toward soft robotics and compliant materials. Innovations in pneumatic or vacuum-based suction cups and specialized mechanical fingers lined with soft, food-grade materials are crucial for handling delicate crops like peaches, raspberries, and tomatoes without bruising. Furthermore, the autonomy of the system relies heavily on advanced navigation and locomotion technology, incorporating Real-Time Kinematic (RTK) GPS for centimeter-level positioning accuracy, coupled with inertial measurement units (IMUs) and SLAM (Simultaneous Localization and Mapping) algorithms to navigate uneven terrain and dense foliage effectively, ensuring efficient coverage of the farming area.

Energy management systems, including high-density lithium-ion batteries and efficient power distribution, are essential for ensuring long operational periods, often demanding the ability to operate for a full 10-12 hour shift or longer without refueling or recharging. Data integration and connectivity are also foundational, with robots generating vast amounts of data on fruit health, yield mapping, and operational performance. Standardized communication protocols and seamless integration with existing Farm Management Information Systems (FMIS) are necessary prerequisites for widespread commercial success, allowing growers to leverage robotic data for strategic agronomic decisions beyond just harvesting efficiency.

Regional Highlights

- North America: This region is characterized by exceptionally high labor costs and stringent worker protection regulations, making robotic automation an economic necessity rather than an option. The U.S. and Canada lead in investment and adoption, particularly for apple, strawberry, and citrus harvesting. The market is supported by robust venture capital funding directed at robotics startups and large-scale farming enterprises willing to serve as early adopters. Strong academic research institutions focused on agricultural engineering further accelerate technological deployment, positioning North America as the primary revenue generator and innovation hub in the near term. The focus here is on achieving high throughput and full autonomy to mitigate severe seasonal labor scarcity, driving demand for sophisticated, multi-arm robotic platforms capable of rapid deployment across vast acreage.

- Europe: Driven by the EU's Farm to Fork strategy and significant governmental subsidies promoting sustainable farming and technological modernization, Europe represents a highly mature market segment. Countries like the Netherlands, Spain, and Italy, major producers of greenhouse crops, grapes, and stone fruits, show high demand. Regulations are generally supportive of technological integration, though varied agricultural practices require flexible robotic solutions. The European market sees a strong focus on Robotics-as-a-Service (RaaS) models, driven by the desire of smaller and medium-sized farms to access high-cost technology without prohibitive capital outlay, encouraging manufacturers to offer usage-based subscription services that emphasize maintenance and operational guarantees.

- Asia Pacific (APAC): APAC is projected to exhibit the highest growth rate during the forecast period due to large-scale government initiatives promoting agricultural modernization, particularly in China and Japan, where rural populations are aging rapidly, leading to significant labor shortages. China's push for advanced domestic technology manufacturing and subsidized adoption programs creates a massive potential market. Japan focuses on precision horticulture and high-quality fruit production (e.g., specialty strawberries), favoring highly accurate, if slower, robots optimized for controlled environments. India and Southeast Asia are emerging, driven by high-value export crops, but require rugged, cost-effective solutions tailored for challenging infrastructure and diverse climate zones.

- Latin America: This region presents a strong opportunity, especially in countries like Chile, Brazil, and Mexico, which are massive exporters of high-value fruits (e.g., table grapes, avocados, berries). Adoption is currently limited by economic volatility and higher financing costs but is accelerating in large corporate holdings focused on vertical integration and export quality control. The key driver here is ensuring consistent, export-grade quality to meet demanding international market standards, where robotic precision significantly reduces rejected fruit rates. Demand is primarily centered on semi-autonomous and robust systems designed for large-scale, open-field operations.

- Middle East and Africa (MEA): While currently the smallest market share, MEA shows potential, particularly in regions investing heavily in food security and advanced desert agriculture (e.g., UAE, Israel, Saudi Arabia). Israel remains a leader in AgriTech innovation, developing niche robotic solutions for specific local fruit types and challenging environments. The market growth depends heavily on government infrastructure projects and large-scale sovereign investments in farming technology to enhance local production capacity and reduce reliance on unstable foreign labor pools, demanding systems that are resilient to extreme heat and dust.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Robotic Fruit Picker Market.- Harvest CROO Robotics

- FFRobotics

- Agrobot

- Tevel Aerobotics Technologies

- Metomotion

- Dogtooth Technologies

- Tortuga AgTech

- Naïo Technologies

- Vision Robotics

- Iron Ox

- Monarch Tractor

- Kubota Corporation

- CNH Industrial

- John Deere

- Green Atlas

- Yamaha Motor Co., Ltd.

- Panasonic Corporation

- VARTA AG

- AppHarvest (Root AI assets)

- Advanced Farm Technologies

Frequently Asked Questions

Analyze common user questions about the Robotic Fruit Picker market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving the adoption of robotic fruit pickers?

The most significant driver is the critical and escalating scarcity of reliable manual agricultural labor globally, coupled with rising minimum wage requirements, making robotic automation an essential economic solution for maintaining profitable farm operations.

Are robotic fruit pickers capable of accurately assessing fruit ripeness?

Yes, modern robotic systems utilize advanced AI and deep learning algorithms integrated with multispectral vision sensors to accurately assess ripeness, detect blemishes, and determine quality, often achieving higher consistency than human laborers.

What is the typical Return on Investment (ROI) period for robotic harvesting technology?

The ROI period varies significantly based on farm size, fruit type, and local labor costs, but large-scale commercial operations frequently report achieving ROI within three to five years, primarily through labor cost savings and increased yield quality.

Which fruit crops are currently the most feasible for robotic harvesting?

High-value crops with predictable structures, such as strawberries (field and protected culture), apples (especially high-density dwarf orchards), and certain citrus fruits, currently have the most commercially viable robotic solutions.

How is Robotics-as-a-Service (RaaS) impacting the market?

RaaS is lowering the financial barrier to entry, allowing small and medium-sized farms to access expensive technology via subscription or usage fees, accelerating market penetration and shifting the risk of maintenance and technological obsolescence from the farmer to the provider.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager