Robotic Laser Cleaning Machines Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440176 | Date : Jan, 2026 | Pages : 255 | Region : Global | Publisher : MRU

Robotic Laser Cleaning Machines Market Size

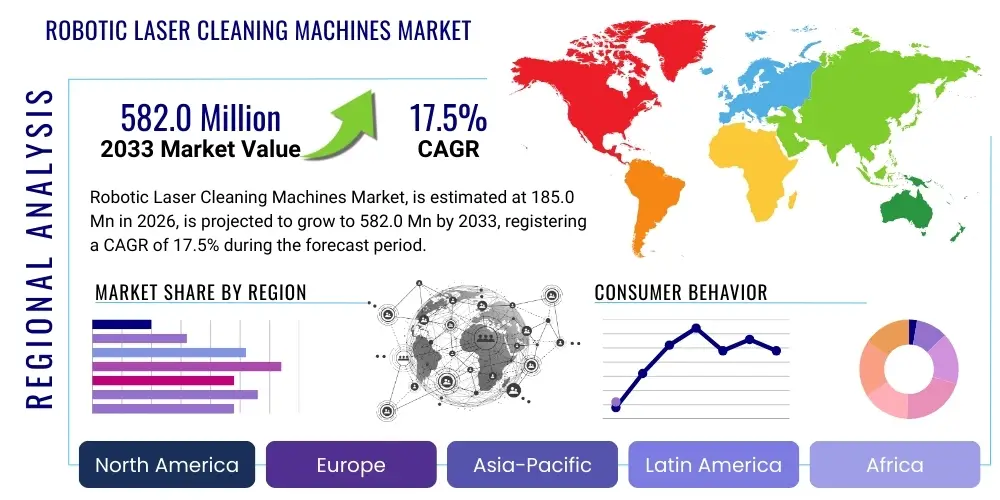

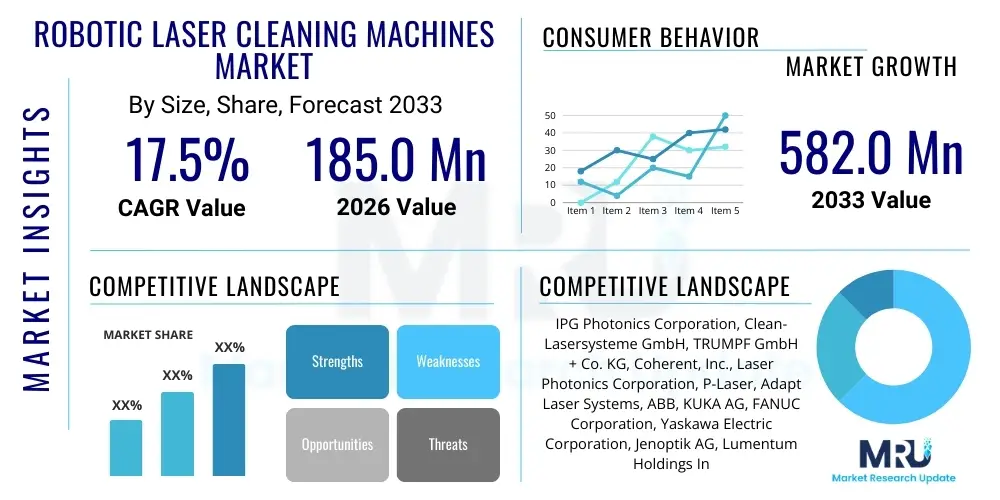

The Robotic Laser Cleaning Machines Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 17.5% between 2026 and 2033. The market is estimated at USD 185.0 Million in 2026 and is projected to reach USD 582.0 Million by the end of the forecast period in 2033.

Robotic Laser Cleaning Machines Market introduction

The Robotic Laser Cleaning Machines Market encompasses advanced industrial solutions that integrate robotic automation with high-precision laser technology for surface treatment and cleaning applications. These systems offer a non-contact, abrasive-free, and environmentally sound alternative to traditional cleaning methods such as sandblasting, chemical cleaning, or manual scrubbing. The core product involves a robotic arm or automated system precisely directing a laser beam onto a surface to remove contaminants, rust, paint, oxides, or other unwanted layers without damaging the underlying substrate. This technology is gaining significant traction across diverse industries due to its efficacy, efficiency, and minimal environmental footprint.

Major applications of robotic laser cleaning machines span critical sectors including automotive for paint stripping and welding preparation, aerospace and defense for precise coating removal and surface maintenance, and general manufacturing for mold cleaning, rust removal, and pre-treatment processes. The versatility of these systems extends to electronics, art restoration, and energy sectors, where delicate or precise cleaning is paramount. The inherent benefits include superior cleaning quality, reduced operational costs through automation, elimination of consumables (like abrasive media or chemicals), minimal waste generation, enhanced worker safety by avoiding hazardous environments, and improved production throughput due to faster and more consistent results.

Driving factors for the adoption of robotic laser cleaning machines are multifaceted. Growing industrial automation trends, particularly within the context of Industry 4.0, are fueling demand for sophisticated robotic solutions that can perform repetitive and intricate tasks with high accuracy. Additionally, increasingly stringent environmental regulations worldwide are pushing industries to adopt greener manufacturing processes, making laser cleaning an attractive alternative to chemical-intensive or waste-producing methods. The continuous technological advancements in laser sources, robotics, and integrated vision systems further enhance the performance, reliability, and cost-effectiveness of these machines, solidifying their position as a transformative technology in industrial cleaning.

Robotic Laser Cleaning Machines Market Executive Summary

The Robotic Laser Cleaning Machines Market is experiencing robust growth, driven by an escalating demand for automated, environmentally friendly, and precise surface treatment solutions across global industries. Key business trends indicate a strong focus on integration with existing manufacturing lines, the development of more compact and user-friendly systems, and a shift towards customizable solutions that can address specific industrial cleaning challenges. Companies are increasingly investing in research and development to enhance laser power, improve robotic precision, and incorporate advanced software for process optimization and data analytics. The market is also witnessing strategic collaborations and partnerships between robotics manufacturers and laser technology providers to offer comprehensive, integrated cleaning solutions.

From a regional perspective, the market's growth is predominantly led by the Asia Pacific region, particularly countries like China, Japan, and South Korea, which are major manufacturing hubs and early adopters of advanced automation technologies. North America and Europe also exhibit significant market shares, characterized by strong automotive, aerospace, and general manufacturing sectors that are rapidly industrializing and prioritizing sustainable practices. Emerging economies in Latin America, the Middle East, and Africa are showing nascent but accelerating adoption, primarily driven by investments in manufacturing infrastructure and a growing awareness of the benefits of laser cleaning over traditional methods. Each region presents unique market dynamics influenced by local industrial policies, labor costs, and environmental regulations.

Segmentation trends highlight the increasing prominence of high-power laser cleaning systems for heavy-duty industrial applications, alongside a growing interest in collaborative robotic (cobot) systems for flexible and safe human-robot interaction in various settings. Application-wise, rust and oxide removal, paint stripping, and pre-welding surface preparation remain dominant, but new applications are emerging in areas such as mold cleaning, cultural heritage restoration, and medical device manufacturing, demonstrating the technology's expanding versatility. End-user industries like automotive and aerospace continue to be major revenue generators, yet electronics, general manufacturing, and energy sectors are rapidly expanding their adoption, signaling a diversified market landscape and broad applicability of robotic laser cleaning solutions.

AI Impact Analysis on Robotic Laser Cleaning Machines Market

User inquiries regarding the impact of Artificial Intelligence on the Robotic Laser Cleaning Machines Market frequently revolve around how AI can enhance automation, precision, and efficiency, as well as its role in predictive maintenance and seamless integration within Industry 4.0 frameworks. Common questions explore AI's capability to optimize cleaning parameters for different materials and contaminants, adapt to complex geometries, and improve real-time decision-making during the cleaning process. Users are keen to understand how AI can reduce operational costs, minimize human intervention, and ultimately lead to a more intelligent and autonomous cleaning workflow, while also addressing concerns about data privacy and the complexity of AI system implementation.

- AI-driven vision systems enable real-time surface analysis, identifying contaminants and optimizing laser parameters (power, pulse duration, frequency) for specific materials and cleaning requirements, ensuring precise and efficient removal without substrate damage.

- Predictive maintenance capabilities, powered by AI algorithms analyzing operational data from robotic arms and laser sources, anticipate potential component failures, minimize downtime, and extend the lifespan of the cleaning machines.

- Machine learning algorithms allow robotic laser cleaning systems to learn from past cleaning operations, adapt to new surface conditions, and automatically adjust trajectories and power settings, thereby improving performance and consistency over time.

- AI facilitates enhanced path planning and collision avoidance for robotic arms, especially in complex or confined spaces, ensuring safe and efficient operation while protecting both the equipment and the work environment.

- Integration of AI with manufacturing execution systems (MES) and enterprise resource planning (ERP) systems supports smarter production scheduling, resource allocation, and quality control, making robotic laser cleaning a seamless part of smart factory operations.

- AI enhances operator interfaces through intelligent dashboards, voice commands, and augmented reality (AR) support, simplifying programming, monitoring, and troubleshooting tasks for technicians.

- Data analytics capabilities provided by AI offer profound insights into cleaning performance, energy consumption, and process optimization, empowering manufacturers to make informed decisions for continuous improvement.

DRO & Impact Forces Of Robotic Laser Cleaning Machines Market

The Robotic Laser Cleaning Machines Market is significantly influenced by a confluence of driving forces, prominent among which is the escalating global demand for automated and highly precise industrial cleaning solutions that prioritize environmental sustainability. Stringent regulations pertaining to industrial emissions and waste disposal are increasingly compelling manufacturers to seek cleaner alternatives to traditional methods, thereby amplifying the appeal of laser cleaning. Furthermore, continuous technological advancements in laser source efficiency, robotic precision, and integrated sensor technologies are making these systems more capable, reliable, and economically viable, expanding their applicability across a wider range of industries and accelerating adoption rates. The push for Industry 4.0 and smart manufacturing also fuels the integration of robotic laser cleaning into automated production lines.

Despite these robust drivers, the market faces several restraining factors that could impede its growth trajectory. The most significant barrier remains the high initial capital investment required for robotic laser cleaning machines, which can be a substantial hurdle for small and medium-sized enterprises (SMEs) with limited budgets. The complexity involved in integrating these advanced robotic systems into existing production infrastructures, coupled with the need for specialized technical expertise for operation and maintenance, also presents challenges. Additionally, safety concerns associated with high-power industrial lasers, including potential risks of eye damage or skin exposure if proper precautions are not followed, necessitate rigorous safety protocols and training, which can add to operational overheads and slow down adoption in some cautious sectors.

Opportunities for market expansion are abundant and diverse, pointing towards a promising future for robotic laser cleaning. There is significant potential for market penetration into new and niche applications, such as the restoration of historical artifacts, specialized cleaning in the medical device manufacturing sector, and maintenance, repair, and overhaul (MRO) operations in the aerospace industry. The development of more compact, modular, and cost-effective laser cleaning systems, including collaborative robots (cobots) designed for smaller workspaces and safer human interaction, could unlock broader market segments and reduce the entry barrier for smaller businesses. Furthermore, the continuous evolution of AI and machine learning integration promises to enhance system intelligence, predictive capabilities, and overall operational efficiency, creating intelligent cleaning solutions that can adapt to dynamic manufacturing environments and boost productivity.

Segmentation Analysis

The Robotic Laser Cleaning Machines Market is comprehensively segmented to provide a detailed understanding of its diverse applications, technological variations, and end-user demands. This segmentation allows for a granular analysis of market trends, identifying high-growth areas and specific product-market fits. The primary segmentation criteria revolve around the fundamental components that constitute these systems, the power output of the laser, the specific applications they address, the end-user industries benefiting from the technology, and the inherent types of robotic systems deployed. Such a multi-dimensional approach ensures that market dynamics are captured across the entire value chain, from component suppliers to integrated system providers and end consumers.

- By Component

- Laser Source

- Robotic System (Arms, Gantries, AGVs/AMRs)

- Optical System (Scanning Heads, Beam Delivery)

- Control & Software

- Safety Features & Enclosures

- By Power

- Low Power (<100W)

- Medium Power (100W-500W)

- High Power (>500W)

- By Application

- Rust & Oxide Removal

- Paint & Coating Removal

- Surface Preparation (Pre-welding/Bonding)

- Degreasing & Oil Removal

- Mold Cleaning

- Deburring & Contaminant Removal

- By End-User Industry

- Automotive

- Aerospace & Defense

- Electronics & Semiconductor

- General Manufacturing

- Energy & Utilities

- Restoration & Conservation

- Marine

- Medical

- By Type

- Fixed Robotic Laser Cleaning Systems

- Mobile & Autonomous Robotic Laser Cleaning Systems

- Collaborative Robotic Laser Cleaning Systems (Cobots)

Value Chain Analysis For Robotic Laser Cleaning Machines Market

The value chain for the Robotic Laser Cleaning Machines Market is intricate, involving multiple stages from raw material sourcing to end-user deployment and after-sales services. Upstream analysis highlights the critical role of specialized component manufacturers, including suppliers of high-quality laser sources (such as fiber lasers, CO2 lasers, and pulsed lasers), precision robotic arms and manipulators, advanced optical scanning systems, and sophisticated control software and hardware. These suppliers form the foundational layer, providing the core technologies that enable the functionality of the final cleaning systems. Innovation and quality in these upstream segments directly influence the performance and competitiveness of the overall market, as manufacturers of complete systems rely heavily on robust and cutting-edge components to differentiate their offerings.

Midstream activities involve the integration and assembly of these various components into complete robotic laser cleaning systems. This stage is dominated by system integrators, robotics companies, and specialized laser cleaning machine manufacturers who design, develop, and customize solutions for specific industrial applications. These players add significant value through engineering expertise, software development for process control, safety system integration, and rigorous testing. They often work closely with end-users to understand their unique cleaning requirements and tailor the systems accordingly. The ability to offer turn-key solutions, including installation, commissioning, and operator training, is a key competitive differentiator in this phase, emphasizing solution-oriented approaches over mere component sales.

Downstream analysis focuses on the distribution channels and the ultimate deployment to end-users across various industries. Distribution typically involves both direct sales channels, where manufacturers or integrators sell directly to large industrial clients, and indirect channels, which may include regional distributors, value-added resellers (VARs), and system integrators specializing in particular geographic markets or industry verticals. Post-sale services, encompassing maintenance, repairs, spare parts supply, software updates, and technical support, are crucial for customer satisfaction and long-term relationships. These services ensure optimal performance and longevity of the robotic laser cleaning machines, often representing a significant revenue stream and a vital link in the value chain by extending the product lifecycle and ensuring operational continuity for the end-users.

Robotic Laser Cleaning Machines Market Potential Customers

The potential customer base for Robotic Laser Cleaning Machines is broad and diverse, primarily encompassing industries that require high-precision, efficient, and environmentally friendly surface treatment or cleaning processes. End-users span across heavy industries, advanced manufacturing, and specialized sectors where traditional cleaning methods are either insufficient, too costly, or environmentally undesirable. Key target customers include large-scale automotive manufacturers needing automated solutions for paint stripping, welding line preparation, and mold cleaning, as well as aerospace and defense companies requiring precise coating removal for component refurbishment and maintenance, repair, and overhaul (MRO) operations. These industries prioritize reliability, accuracy, and adherence to stringent quality standards, making laser cleaning an ideal solution.

Beyond these major sectors, the market also targets the general manufacturing industry, where robotic laser cleaning can be applied for rust removal from metal parts, degreasing, surface preparation for bonding or painting, and cleaning of production tooling and molds. The electronics and semiconductor industry represents another significant customer segment, particularly for delicate cleaning tasks that require non-abrasive methods to avoid damage to sensitive components. Energy sector companies, including those in oil and gas, nuclear, and renewable energy, are also increasingly adopting these machines for maintenance of critical infrastructure, such as turbine blades, pipelines, and power generation equipment, where precision and minimal waste generation are paramount.

Furthermore, emerging customer segments include cultural heritage preservation and art restoration, where the non-contact and highly controllable nature of laser cleaning is invaluable for delicate removal of dirt, corrosion, and old coatings from artifacts without causing damage. The marine industry can utilize these systems for ship hull cleaning and maintenance, while the medical device manufacturing sector benefits from sterile, precise cleaning of instruments and implants. As the technology becomes more accessible and versatile, its adoption is expected to broaden further into smaller workshops and specialized service providers who seek to enhance their cleaning capabilities while reducing operational costs and environmental impact, thereby expanding the overall market reach.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 185.0 Million |

| Market Forecast in 2033 | USD 582.0 Million |

| Growth Rate | 17.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces | >|

| Segments Covered | >|

| Key Companies Covered | IPG Photonics Corporation, Clean-Lasersysteme GmbH, TRUMPF GmbH + Co. KG, Coherent, Inc., Laser Photonics Corporation, P-Laser, Adapt Laser Systems, ABB, KUKA AG, FANUC Corporation, Yaskawa Electric Corporation, Jenoptik AG, Lumentum Holdings Inc., Rofin-Sinar Technologies, nLIGHT, Inc., Raycus Laser, Maxphotonics, Precitec Group, Scansonic MI GmbH, Laser Cleaning Technologies, Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Robotic Laser Cleaning Machines Market Key Technology Landscape

The Robotic Laser Cleaning Machines Market is underpinned by a sophisticated array of interconnected technologies that collectively enhance its precision, efficiency, and versatility. Central to these systems are advanced laser sources, predominantly pulsed fiber lasers, which offer superior control over pulse energy, duration, and repetition rate. This precise control is crucial for selective material ablation, allowing the removal of coatings or contaminants without damaging the underlying substrate. The continuous evolution of these laser technologies, including increases in power output, improved beam quality, and enhanced energy efficiency, directly contributes to faster cleaning speeds and broader application capabilities. Solid-state lasers and CO2 lasers are also utilized for specific applications, but fiber lasers are becoming increasingly dominant due to their robustness and compact size.

Equally critical are the advanced robotic systems that provide the motion and positioning accuracy required for laser cleaning. This includes multi-axis industrial robotic arms, collaborative robots (cobots), and increasingly, autonomous mobile robots (AMRs) or automated guided vehicles (AGVs) integrated with robotic arms for greater flexibility and reach in large-scale environments. These robots are equipped with high-precision encoders and feedback systems to ensure repeatability and accuracy in complex cleaning paths. The development of lighter, faster, and more dextrous robotic manipulators, coupled with intuitive programming interfaces, further streamlines the integration and operation of these cleaning machines, reducing setup times and allowing for quick adaptation to varying production requirements.

The integration of sophisticated vision systems and smart software forms another cornerstone of the technological landscape. High-resolution cameras, often combined with 3D scanners and spectral analysis tools, provide real-time feedback on surface conditions, contaminant identification, and cleaning progress. This data feeds into intelligent control software, often incorporating artificial intelligence and machine learning algorithms, which can dynamically adjust laser parameters and robotic trajectories for optimal cleaning results. Furthermore, robust safety systems, including laser safety enclosures, interlocks, and fume extraction units, are essential to ensure operator safety and compliance with industrial regulations. These integrated technologies collectively enable the high levels of automation, precision, and safety that define modern robotic laser cleaning solutions, continuously pushing the boundaries of what is achievable in industrial surface treatment.

Regional Highlights

- North America: This region is a significant market for robotic laser cleaning, driven by strong manufacturing sectors (automotive, aerospace, general industrial) and a high adoption rate of automation. Strict environmental regulations encourage the shift from traditional, chemical-intensive cleaning methods to eco-friendly laser solutions. The U.S. and Canada are leading adopters, with continuous investments in R&D and advanced manufacturing.

- Europe: Europe holds a substantial market share, fueled by its robust automotive, machinery manufacturing, and cultural heritage preservation industries. Countries like Germany, France, and Italy are at the forefront, emphasizing sustainable production processes and advanced robotic integration. The region benefits from strong regulatory support for green technologies and a skilled labor force in automation.

- Asia Pacific (APAC): APAC is projected to be the fastest-growing market, primarily due to the rapid industrialization, expansion of manufacturing bases, and increasing adoption of Industry 4.0 technologies in countries such as China, Japan, South Korea, and India. The region's large automotive and electronics industries, coupled with competitive labor costs and government initiatives supporting automation, drive significant demand.

- Latin America: The market in Latin America is in an emerging phase, with increasing investments in industrial infrastructure and manufacturing capabilities, particularly in countries like Brazil and Mexico. The growing awareness of advanced cleaning technologies and a push towards modernizing industrial processes are key drivers for adoption, albeit from a smaller base.

- Middle East and Africa (MEA): This region shows nascent growth, with demand primarily stemming from the oil & gas, automotive assembly, and construction sectors in the UAE, Saudi Arabia, and South Africa. Investments in diversifying economies and developing local manufacturing capabilities are gradually creating opportunities for robotic laser cleaning solutions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Robotic Laser Cleaning Machines Market.- IPG Photonics Corporation

- Clean-Lasersysteme GmbH

- TRUMPF GmbH + Co. KG

- Coherent, Inc.

- Laser Photonics Corporation

- P-Laser

- Adapt Laser Systems

- ABB

- KUKA AG

- FANUC Corporation

- Yaskawa Electric Corporation

- Jenoptik AG

- Lumentum Holdings Inc.

- Rofin-Sinar Technologies (now Coherent)

- nLIGHT, Inc.

- Raycus Laser

- Maxphotonics

- Precitec Group

- Scansonic MI GmbH

- Laser Cleaning Technologies, Inc.

Frequently Asked Questions

Analyze common user questions about the Robotic Laser Cleaning Machines market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary benefits of using robotic laser cleaning machines?

Robotic laser cleaning offers numerous benefits including superior cleaning quality, non-contact and non-abrasive operation, elimination of consumables (chemicals, media), minimal waste generation, enhanced worker safety, higher precision, faster processing speeds, and reduced operational costs compared to traditional methods.

How does AI impact the performance and efficiency of robotic laser cleaning systems?

AI significantly enhances performance by enabling real-time surface analysis, dynamic adjustment of laser parameters and robotic paths, predictive maintenance, and optimized process control. This leads to increased precision, efficiency, adaptability to varied surfaces, and reduced downtime, making the cleaning process more intelligent and autonomous.

What industries are the main adopters of robotic laser cleaning technology?

The main adopters include the automotive, aerospace & defense, general manufacturing, electronics & semiconductor, and energy sectors. These industries leverage robotic laser cleaning for applications such as paint removal, rust and oxide cleaning, pre-welding preparation, and mold cleaning due to its precision and efficiency.

What are the major challenges associated with implementing robotic laser cleaning?

Key challenges include the high initial capital investment, the complexity of integrating these advanced systems into existing production lines, the need for specialized technical expertise for operation and maintenance, and ensuring stringent laser safety protocols for personnel and the work environment.

What are the future growth opportunities for the Robotic Laser Cleaning Machines Market?

Future growth opportunities lie in expanding into new applications like cultural heritage restoration and medical device cleaning, developing more compact and cost-effective systems including collaborative robots, and further integrating with Industry 4.0 technologies like advanced AI and IoT for intelligent and interconnected manufacturing ecosystems.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager