Robotic Piece Picking Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439889 | Date : Jan, 2026 | Pages : 249 | Region : Global | Publisher : MRU

Robotic Piece Picking Market Size

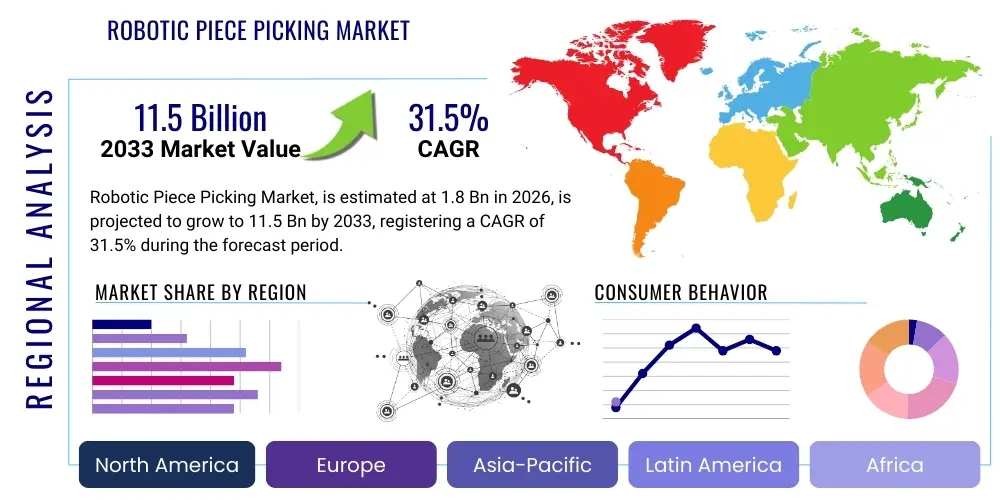

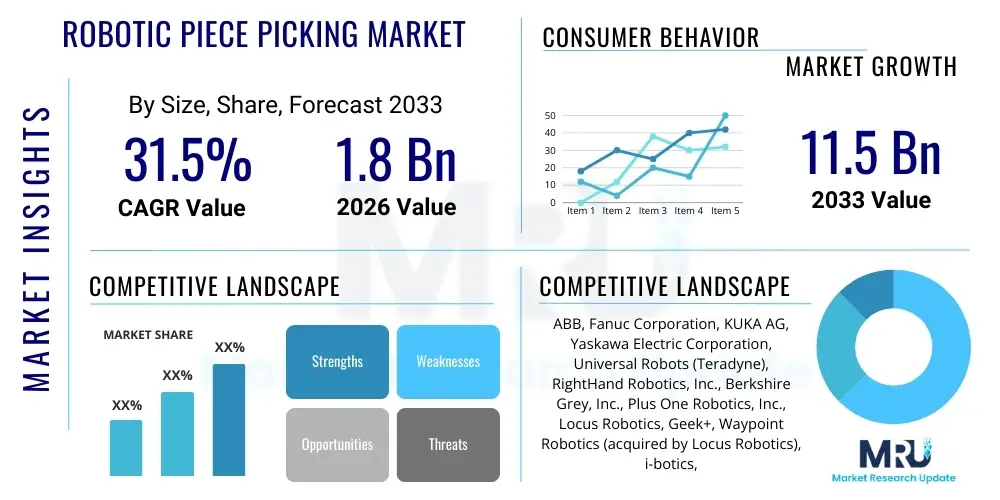

The Robotic Piece Picking Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 31.5% between 2026 and 2033. The market is estimated at USD 1.8 Billion in 2026 and is projected to reach USD 11.5 Billion by the end of the forecast period in 2033. This substantial growth trajectory is fundamentally underpinned by the escalating demands of the global e-commerce sector, which necessitates unprecedented levels of speed and accuracy in order fulfillment. The persistent and widespread labor shortages plaguing critical sectors such as logistics, warehousing, and manufacturing globally further amplify the imperative for automation. Businesses are increasingly recognizing the pivotal role of robotic piece picking in achieving enhanced operational efficiencies, significantly reducing manual handling costs, and mitigating the risks associated with human error, all of which are crucial for maintaining competitive advantage in a rapidly evolving economic landscape. The continuous evolution and increasing sophistication of robotic technologies, particularly in areas like artificial intelligence, machine learning, advanced sensor fusion, and adaptive gripping mechanisms, are key enablers for this rapid expansion, allowing robots to competently and reliably handle an ever-broader array of objects with greater precision, speed, and reduced susceptibility to damage.

The market's robust expansion is further fueled by a growing understanding among businesses of the tangible return on investment (ROI) that robotic piece picking systems offer, extending far beyond the mere automation of repetitive tasks. These advanced systems provide unparalleled levels of consistency and accuracy, dramatically reducing human error rates in complex order compilation and kitting processes, and are capable of operating continuously without fatigue or breaks, leading to significantly higher throughput and accelerated delivery times. Strategic and substantial investments in state-of-the-art automation infrastructure by leading global logistics providers, major retail giants, and progressive manufacturing enterprises are actively cultivating a fertile ground for the widespread adoption of these sophisticated robotic solutions. Moreover, the modularity and increasing ease of integration of modern robotic piece picking systems into existing warehouse management systems (WMS) and enterprise resource planning (ERP) platforms are lowering the barriers to entry for many organizations, positioning this technology as a critical and indispensable component in the future of supply chain optimization, agile manufacturing processes, and the pursuit of resilient, efficient, and scalable operational frameworks.

Robotic Piece Picking Market introduction

Robotic piece picking represents a cutting-edge application of advanced industrial and collaborative robotics where sophisticated robotic systems, inherently equipped with highly developed vision, gripping, and artificial intelligence capabilities, are autonomously deployed to identify, select, and meticulously manipulate individual items from a mixed bin, a cluttered shelf, or a fast-moving conveyor belt. This groundbreaking technology is ingeniously designed to replicate, and often surpass, the intricate dexterity, nuanced judgment, and adaptive intelligence typically associated with a human worker in handling an extremely diverse range of physical objects—a task historically considered exceedingly challenging and complex for traditional automation solutions. The primary objective driving its development and widespread adoption is to fundamentally enhance throughput, dramatically improve accuracy, and significantly boost overall operational efficiency in environments that demand the precise and careful handling of discrete items. This revolutionizes the way goods are processed, sorted, and moved through the entire supply chain, from manufacturing plants to end-consumer delivery points. The intricate combination of high-precision robotic arms, highly specialized end-effectors (grippers), sophisticated 3D vision systems, and intelligent, self-learning software algorithms collectively enables these robots to seamlessly adapt to varying item sizes, irregular shapes, diverse textures, and arbitrary orientations, thereby making them an indispensable cornerstone in modern logistics, e-commerce fulfillment, and advanced manufacturing operations.

The major applications for robotic piece picking systems are remarkably broad and span a wide array of industrial sectors, predominantly including the burgeoning e-commerce and retail industries for rapid order fulfillment, efficient returns processing, and meticulous inventory management. Within the logistics and warehousing domain, these systems are critical for high-speed sorting, precise kitting of components, and streamlined cross-docking operations. In manufacturing, they play a vital role in assembly line feeding, machine tending, and quality inspection, significantly improving process consistency and reducing manual intervention. Specifically, in e-commerce, these systems tackle the monumental logistical challenge of rapidly picking millions of unique stock-keeping units (SKUs) to fulfill highly individualized customer orders, often under stringent time constraints. In manufacturing settings, they streamline the feeding of delicate or heavy components for intricate assembly processes, thereby enhancing precision, reducing ergonomic strain on human workers, and minimizing production errors. The multifaceted benefits derived from the implementation of robotic piece picking are substantial and far-reaching: these include profound reductions in operational costs attributed to decreased dependency on manual labor, a significant increase in the speed and accuracy of picking operations, an elevated standard of workplace safety by intelligently taking over monotonous, repetitive, and ergonomically challenging or hazardous tasks, and a dramatically improved capacity for scalability to effectively meet highly fluctuating demand patterns without the often-prohibitive need to continuously hire, train, and manage large numbers of additional personnel. This comprehensive suite of advantages empowers businesses to achieve unprecedented levels of consistency, predictability, and agility in their operations, which is absolutely crucial for maintaining a robust competitive edge in today's exceptionally fast-paced and globalized market landscape.

The driving factors propelling the accelerated growth and widespread adoption of this market are deeply intertwined with profound global economic, technological, and demographic shifts. The explosive growth of e-commerce, particularly amplified and accelerated by recent global public health crises and evolving consumer behaviors, has created an unprecedented and sustained demand for highly efficient, scalable, and resilient order fulfillment solutions capable of processing an ever-increasing volume and variety of goods. Simultaneously, persistent and chronic labor shortages in critical warehousing, logistics, and manufacturing sectors across nearly all developed economies are increasingly forcing businesses to urgently seek sophisticated automated alternatives to sustain their operational continuity and growth. Furthermore, the inexorable rise in labor costs, coupled with the increasing complexity of global supply chains driven by heightened consumer expectations for faster, cheaper, and more reliable delivery services, makes robotic piece picking an increasingly economically compelling and strategically indispensable solution. Continuous and groundbreaking technological advancements in core robotics, artificial intelligence (AI), machine learning (ML), and sophisticated sensor technologies are making these systems progressively more capable, significantly more affordable, and substantially easier to integrate into existing operational frameworks. These advancements are steadily expanding their applicability across new industries and use cases, thereby accelerating their widespread adoption. The confluence of these powerful factors collectively positions robotic piece picking as not merely an incremental improvement, but as a foundational cornerstone technology poised to redefine the future of industrial automation, logistics, and retail fulfillment.

Robotic Piece Picking Market Executive Summary

The global Robotic Piece Picking Market is experiencing a period of exceptionally robust and transformative growth, primarily fueled by the exponential expansion of the e-commerce sector, pervasive chronic labor shortages across the logistics and manufacturing industries, and an unwavering global imperative for enhanced operational efficiency and substantial cost reduction. Current business trends indicate a significant surge in strategic investments from a diverse range of stakeholders, including pioneering venture capitalists, established automation solution providers, and major industrial conglomerates, leading to rapid and profound innovation across gripper technology, advanced vision systems, and sophisticated AI-driven control software platforms. Leading market players are strategically focusing their research and development efforts on engineering and deploying increasingly versatile, highly adaptable, and truly collaborative robotic solutions that are capable of seamlessly integrating into existing, often complex, warehouse management systems (WMS) and enterprise resource planning (ERP) platforms. A pronounced emphasis is being placed on developing modular and scalable designs, which provides businesses with the crucial flexibility to incrementally adopt automation at their own pace and subsequently scale their operations efficiently in response to fluctuating market demands or business growth. Furthermore, the market is witnessing an increasing number of strategic partnerships and collaborative ventures between core robot manufacturers, specialized system integrators, and innovative software developers, collectively fostering a comprehensive and synergistic ecosystem dedicated to delivering advanced, end-to-end automated solutions that address the multifaceted challenges of modern supply chains.

Analysis of regional trends highlights distinct yet dynamic patterns of adoption and growth across different geographies. North America and Europe continue to represent historically significant and robust markets, characterized by their high labor costs, advanced technological infrastructures, a deep-seated culture of industrial automation, and highly mature e-commerce landscapes. These regions are currently witnessing widespread and accelerated deployment of robotic piece picking solutions in state-of-the-art fulfillment centers, intricate sortation hubs, and highly advanced manufacturing facilities, particularly in sectors like automotive and electronics. In contrast, the Asia Pacific (APAC) region is projected to emerge as the fastest-growing market segment, propelled by its rapidly burgeoning e-commerce markets in populous nations like China, India, and Southeast Asian countries. This growth is further amplified by substantial government investments in smart logistics infrastructure, aggressive industrial modernization programs, and strong policy support promoting the widespread adoption of industrial automation and robotics. Emerging markets in Latin America and the Middle East & Africa (MEA) are also showing considerable and increasing interest, coupled with growing investments in robotic automation, as they actively strive to modernize their nascent supply chain capabilities and effectively address the rising domestic consumer demands, albeit from a relatively lower adoption base. These diverse regional dynamics collectively underscore a pervasive global shift towards automation, with differing paces and distinct drivers that are meticulously tailored to specific local economic conditions, industrial imperatives, and policy environments.

Segmentation trends within the market reveal that advanced gripper technologies, particularly innovative soft and suction grippers capable of gently yet securely handling a vast array of delicate, irregularly shaped, or highly variable items, are proving to be absolutely critical components driving significant market expansion and opening up new application possibilities. Concurrently, vision systems, particularly those leveraging cutting-edge 3D vision and sophisticated AI-powered object recognition algorithms, are undergoing continuous and remarkable advancements, enabling robots to perform exceedingly complex picking tasks with unparalleled accuracy, speed, and reliability in unstructured environments. From an end-user perspective, the e-commerce and retail sector continues to dominate as the largest segment, accounting for the lion's share of robotic piece picking deployments due to the sheer volume, velocity, and immense diversity of items that need to be processed daily. However, other specialized sectors such as food & beverage, pharmaceuticals, and electronics manufacturing are also rapidly escalating their adoption of these systems. This is driven by an imperative to improve stringent hygiene standards, enhance precision in handling sensitive products, optimize production efficiency, and ensure product integrity. A prominent and accelerating trend observed across the market is the seamless integration of robotic piece picking systems with other advanced automated guided vehicles (AGVs) and autonomous mobile robots (AMRs), leading to the creation of holistic, end-to-end intra-logistics solutions. This integration is forging increasingly flexible, intelligent, and highly optimized automation environments that can dynamically respond to real-time operational demands and unforeseen supply chain disruptions.

AI Impact Analysis on Robotic Piece Picking Market

Common user questions regarding the profound impact of Artificial Intelligence (AI) on the Robotic Piece Picking Market frequently revolve around how this transformative technology fundamentally enhances robot capabilities, whether it truly makes these complex systems more adaptable, precise, and efficient in real-world scenarios, and what the far-reaching future implications are for both human labor dynamics and overall operational efficiency within warehouses and factories. Users are particularly keen to inquire about AI's specific role in advanced object recognition, sophisticated grasp pose generation, optimal path planning within dynamic environments, and robust error recovery mechanisms, seeking to deeply understand if AI can genuinely bridge the remaining gap between the intricate dexterity and cognitive judgment of a human worker and the current capabilities of robotic automation. There is also substantial and growing interest in AI's inherent ability to 'learn' from new and often unstructured environments, adapt to previously unseen or unknown items, and its expansive potential to optimize entire warehouse or fulfillment center operations well beyond the singular task of just piece picking. Key themes consistently emerging from these user inquiries include a profound curiosity about AI-driven improvements in robotic perception (how robots 'see' and 'understand'), decision-making autonomy, and the overall intelligence and self-sufficiency of the system, alongside legitimate concerns regarding the practicalities of integration complexity, cybersecurity risks, and the quantifiable return on investment (ROI) that advanced AI-enhanced solutions can realistically deliver in diverse operational contexts.

- AI significantly enhances object recognition and classification through sophisticated deep learning algorithms, enabling robots to accurately identify and differentiate a vast array of items regardless of their arbitrary orientation, variable packaging, occlusions, or challenging lighting conditions.

- Predictive analytics, powered by advanced machine learning and reinforcement learning paradigms, empower robots to dynamically optimize picking strategies, proactively minimize collision risks, and dramatically improve grasp success rates, thereby allowing for real-time adaptation to novel items and unexpected operational scenarios.

- AI-powered 3D vision systems provide superior spatial perception, enabling robots to precisely locate and accurately measure objects even in highly cluttered bins or disarrayed stacks, effectively overcoming previous limitations inherent in traditional 2D vision systems.

- Machine learning models enable robotic systems to continuously learn from failed picking attempts, assimilate data from new item introductions, and iteratively refine their performance, thereby substantially reducing the need for extensive and time-consuming manual programming.

- AI facilitates deeper and more intelligent integration with overarching warehouse management systems (WMS), enterprise resource planning (ERP) platforms, and other operational software, enabling more intelligent task allocation, dynamic workflow optimization, and proactive predictive maintenance protocols.

- Real-time data processing and advanced analytics, intrinsically driven by AI, provide actionable insights into potential operational bottlenecks, system performance metrics, and inventory flows, leading to continuous and data-driven improvements in overall picking efficiency and throughput rates.

- AI contributes profoundly to the development of more adaptive and compliant grippers, where the robotic system can intelligently adjust its grasping force, finger configuration, and approach trajectory based on the perceived fragility, precise geometry, and surface properties of the item being handled.

- Enhanced decision-making capabilities, a hallmark of AI integration, allow AI-driven robots to autonomously prioritize picks based on predefined criteria, intelligently navigate dynamic and changing environments, and autonomously recover from minor operational errors or anomalies, significantly reducing the necessity for constant human intervention.

DRO & Impact Forces Of Robotic Piece Picking Market

The Robotic Piece Picking Market is profoundly influenced by a complex and dynamic interplay of interconnected Drivers, Restraints, and Opportunities, which collectively constitute the formidable Impact Forces shaping its developmental trajectory and market penetration. A primary driver is the unprecedented and continuous exponential growth of the global e-commerce sector, which inherently necessitates exceptionally rapid, highly accurate, and extremely scalable fulfillment of millions of individual customer orders, often involving a vast and diverse array of products. Complementing this is the escalating and persistent global labor shortages experienced across critical logistics, warehousing, and manufacturing sectors, which exerts immense pressure on industries to seek sophisticated automation solutions to maintain operational continuity and growth. Furthermore, the relentless and universal pressure on businesses to significantly reduce operational costs, substantially enhance overall supply chain efficiency, and demonstrably improve workplace safety through the systematic elimination of monotonous, ergonomically challenging, or hazardous manual tasks acts as an incredibly powerful catalyst. Finally, continuous and groundbreaking technological advancements in core artificial intelligence (AI), advanced machine learning (ML) algorithms, sophisticated sensor fusion, and adaptive robotics are steadily making these complex robotic systems more capable, increasingly versatile, and progressively more economically viable, thereby accelerating their widespread adoption across an ever-expanding array of end-user industries. These compelling drivers collectively create a strategic imperative for businesses to invest aggressively in advanced automation solutions to secure and maintain a robust competitive advantage in dynamic global markets.

Despite these powerful tailwinds, the market also faces a set of considerable and persistent restraints that temper its growth. The inherently high initial capital investment required for procuring and implementing sophisticated robotic piece picking systems remains a significant and often prohibitive barrier for many small and medium-sized enterprises (SMEs), despite the promise of long-term operational savings. Furthermore, the inherent technical complexities associated with seamlessly integrating these advanced, intelligent robotic systems into often legacy or disparate existing infrastructure, particularly older warehouse management systems (WMS) or enterprise resource planning (ERP) systems, pose substantial challenges in terms of data exchange, system compatibility, and operational synchronization. Current limitations in terms of maximum payload capacity, overall picking speed for certain very high-volume scenarios, and the dexterity required for handling extremely delicate or highly irregular items can also restrict the broader applicability and widespread adoption of these solutions in specific niche applications. Moreover, the critical need for a new cadre of highly skilled personnel to effectively operate, meticulously maintain, and proficiently troubleshoot these advanced robotic systems, coupled with potential resistance and apprehension from the existing workforce due often to valid concerns about job displacement, presents significant socio-economic and organizational hurdles that demand careful planning, thoughtful communication, and robust reskilling initiatives for successful and ethical deployment.

Notwithstanding these formidable restraints, substantial and exciting opportunities exist for significant market expansion and continued innovation. The ongoing research and development in more versatile, adaptive, and cost-effective gripping technologies, including revolutionary soft robotics, bio-inspired grippers, and highly modular, easily interchangeable end-effectors, is rapidly opening doors for handling an even wider and more complex range of products, from highly fragile goods to awkwardly shaped or compressible items. The increasing and urgent demand for flexible automation solutions that can dynamically adapt to highly fluctuating order volumes, sudden shifts in product mixes, and seasonal peaks presents a highly fertile ground for the accelerated development and deployment of collaborative robots (cobots) in various piece picking applications, enabling safe and efficient human-robot teaming. Furthermore, the largely untapped potential in emerging markets across Latin America, the Middle East, and Africa, coupled with the pervasive and accelerating global trend of digital transformation and Industry 4.0 initiatives across virtually all industrial sectors, provides compelling new avenues for market penetration and sustained growth. Strategic partnerships and the cultivation of robust ecosystem development among core technology providers, expert system integrators, and diverse end-users will be absolutely crucial in effectively capitalizing on these burgeoning opportunities, driving continuous innovation, and systematically overcoming existing barriers to achieve truly widespread and transformative adoption of robotic piece picking technology.

Segmentation Analysis

The Robotic Piece Picking Market is meticulously segmented across a multitude of crucial parameters to provide a truly granular, in-depth understanding of its diverse components, an expansive range of applications, and the various end-user industries that are driving its adoption. This comprehensive and multi-dimensional segmentation approach allows for a highly detailed and nuanced analysis of intricate market dynamics, identifies the most influential growth drivers, and highlights specific challenges that exist within distinct market niches and sub-segments. By systematically categorizing the market based on fundamental components (such as robotic arms, grippers, and vision systems), distinct types of picking systems (stationary versus mobile), the innovative gripper technologies employed (e.g., vacuum, mechanical, soft), varying payload capacities, the specific applications being addressed, and the diverse end-user industries served, we can more effectively identify and track emerging trends, pinpoint lucrative investment hotspots, and ascertain areas ripe for accelerated technological innovation and strategic disruption. Understanding these intricate segments is not merely analytical; it is absolutely crucial for all stakeholders within the market to develop highly targeted and effective strategies, optimize their product development roadmaps, and precisely address the unique and evolving needs of different market verticals, thereby ensuring a more effective, efficient, and impactful deployment of cutting-edge robotic piece picking solutions across the global industrial landscape.

- By Component:

- Robotic Arms (e.g., Articulated, SCARA, Delta, Collaborative)

- Grippers (End-Effectors) (e.g., Suction Cups, Mechanical Claws, Soft Grippers, Magnetic Grippers)

- Vision Systems (e.g., 3D Cameras, 2D Cameras, AI-powered Object Recognition Software, Stereo Vision)

- Software (e.g., Picking Algorithms, Machine Learning Modules, Control Software, Simulation Software, Integrations with WMS/ERP)

- Controllers (e.g., Robot Controllers, PLC Integration, Edge Computing Units)

- Sensors (e.g., Force Sensors, Proximity Sensors, LiDAR, Encoders)

- Conveyors & Sorting Systems (e.g., Belt Conveyors, Roller Conveyors, Sorters)

- Safety Systems (e.g., Safety Scanners, Light Curtains, Fencing)

- By Type:

- Stationary Robotic Piece Picking Systems (Fixed-base manipulators for high-volume, repetitive tasks)

- Mobile Robotic Piece Picking Systems (Mobile Manipulators, AMR-based Picking for flexible, dynamic environments)

- By Gripper Type:

- Vacuum/Suction Grippers (For smooth, non-porous items, widely used in e-commerce)

- Mechanical/Claw Grippers (For rigid items, often heavier payloads, specific geometries)

- Soft Grippers (Pneumatic, Compliant, Bio-inspired for delicate, irregularly shaped, or fragile goods)

- Magnetic Grippers (Specialized for ferrous materials, common in manufacturing)

- Custom/Specialized Grippers (Tailored for unique product characteristics or applications)

- By Payload Capacity:

- Light-Duty (Up to 5 kg, typical for small consumer goods, electronics)

- Medium-Duty (5 kg - 20 kg, suitable for larger packages, automotive parts)

- Heavy-Duty (Above 20 kg, for industrial components, bulk items)

- By Application:

- Order Fulfillment & E-commerce (Single item picks, multi-item order aggregation)

- Kitting & Assembly (Grouping components for manufacturing or order preparation)

- Machine Tending (Loading/unloading parts for CNC machines, injection molding)

- Sorting & Palletizing (Automated item categorization and stacking on pallets)

- Packaging & Depalletizing (Placing items into packaging, unstacking from pallets)

- Returns Processing (Inspecting, sorting, and relocating returned merchandise)

- Material Handling (General movement of goods within a facility)

- By End-User Industry:

- E-commerce & Retail (Fashion, General Merchandise, Groceries, Home Goods)

- Logistics & Warehousing (3PLs, Distribution Centers, Freight Forwarders)

- Automotive (Components kitting, assembly, quality control)

- Food & Beverage (Food processing, packaging, fresh produce handling, cold chain logistics)

- Pharmaceuticals & Healthcare (Drug compounding, sterile handling, order collation)

- Electronics & Electrical (Circuit board handling, small component assembly, testing)

- General Manufacturing (Industrial components, consumer goods production)

- Others (Aerospace & Defense, Textiles, Chemical Industry)

Value Chain Analysis For Robotic Piece Picking Market

The value chain for the Robotic Piece Picking Market encompasses a highly complex and interconnected network of diverse stakeholders, ranging systematically from upstream raw material and component suppliers to sophisticated downstream end-users and essential service providers. At the foundational upstream level, the value chain commences with the sourcing of raw materials and the manufacturing of core robotic components, which include precision-engineered robotic arms, innovative gripping mechanisms, advanced vision sensors, high-resolution cameras, sophisticated control electronics, and industrial-grade computing hardware. These foundational elements are absolutely crucial as they directly dictate the fundamental capabilities, performance parameters, and overall reliability of the entire robotic system. Continuous innovation at this initial stage, particularly in developing advanced materials for more durable and dexterous grippers, designing higher-resolution 3D vision sensors with enhanced depth perception, and integrating cutting-edge edge computing capabilities for faster data processing, directly and significantly impacts the ultimate efficiency, versatility, and adaptability of the final robotic piece picking solution. Specialized software developers also play an increasingly critical upstream role, creating the intricate AI/ML algorithms, robotic operating system (ROS) functionalities, and advanced control software that collectively enable intelligent decision-making, precise object manipulation, and seamless system integration.

Robotic Piece Picking Market Potential Customers

The primary potential customers and ideal end-users for robotic piece picking solutions are diverse industrial sectors that are inherently grappling with exceptionally high volumes of individual item handling, labor-intensive operational processes, and a non-negotiable imperative for both unparalleled speed and meticulous accuracy in their daily operations. At the forefront of this customer landscape are e-commerce and online retail companies, encompassing not only major global market players but also rapidly emerging direct-to-consumer (D2C) brands, whose fundamental business models are entirely predicated on the efficient and accurate fulfillment of vast numbers of highly unique customer orders, often involving an immense and ever-changing variety of Stock Keeping Units (SKUs). These enterprises require robust, scalable, and adaptable automation to effectively manage highly fluctuating demand, process customer returns with unparalleled efficiency, and significantly accelerate order dispatch timelines, thereby making robotic piece picking a mission-critical investment for achieving sustained scalability, operational resilience, and a decisive competitive advantage in the intensely competitive online marketplace. The intrinsic ability of these robotic systems to handle an exceptionally wide range of products, spanning from delicate apparel to complex electronics and general merchandise, renders them indispensable assets in modern fulfillment centers that are relentlessly striving to meet increasingly ambitious next-day or even same-day delivery promises.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.8 Billion |

| Market Forecast in 2033 | USD 11.5 Billion |

| Growth Rate | 31.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | ABB, Fanuc Corporation, KUKA AG, Yaskawa Electric Corporation, Universal Robots (Teradyne), RightHand Robotics, Inc., Berkshire Grey, Inc., Plus One Robotics, Inc., Locus Robotics, Geek+, Waypoint Robotics (acquired by Locus Robotics), i-botics, Photoneo, Cognex Corporation, SICK AG, Intel Corporation, NVIDIA Corporation, Amazon Robotics, Mujin Inc., Pick-it (Robotics), PSSI Robotics, Kawasaki Heavy Industries, Omron Corporation. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Robotic Piece Picking Market Key Technology Landscape

The technological landscape of the Robotic Piece Picking Market is characterized by relentless and rapid innovation across several critical and inter-dependent areas, collectively forming the sophisticated backbone of these advanced automation systems. At the core of this innovation are highly sophisticated vision systems, which are progressively transitioning from rudimentary 2D cameras to immensely powerful and perception-rich 3D vision technologies. These include advanced stereo cameras, precision-engineered structured light sensors, and high-speed time-of-flight (ToF) cameras. These cutting-edge systems are almost universally augmented with state-of-the-art Artificial Intelligence (AI) and machine learning (ML) algorithms, which together empower robots to accurately perceive objects in extremely complex, unstructured, and often cluttered environments. This allows them to precisely identify their myriad shapes, varying sizes, arbitrary orientations, and even estimate their physical properties such as surface texture, material composition, and inherent fragility. This profoundly enhanced perception capability is absolutely vital for consistently successful piece picking, as it enables robots to adeptly tackle previously insurmountable tasks with a human-like discernment and unparalleled precision, dramatically reducing errors and significantly increasing their adaptability to an ever-expanding diversity of product mixes found in modern logistics and manufacturing.

Regional Highlights

-

North America: This region stands as a vanguard in the adoption and deployment of robotic piece picking solutions, fundamentally driven by persistently high labor costs, an exceptionally mature and expansive e-commerce market, and a strategic, overarching focus on supply chain automation, resilience, and efficiency. The United States and Canada are at the absolute forefront of this technological embrace, characterized by significant and continuous investments from major global retailers, prominent e-commerce giants, and leading third-party logistics (3PL) providers into highly automated and intelligent fulfillment centers. Strong governmental initiatives actively supporting advanced manufacturing automation, coupled with the dense presence of numerous pioneering robotics innovators and technology startups, further bolster and accelerate market growth across the region. North America particularly emphasizes the development and deployment of sophisticated AI-driven solutions, designed to significantly enhance operational efficiency, mitigate the impact of labor shortages, and markedly reduce dependency on manual labor in high-volume, high-variability picking operations, pushing the boundaries of what is achievable in autonomous material handling.

-

Europe: Europe represents another exceptionally key and influential market for robotic piece picking, characterized by its advanced manufacturing capabilities, stringent and evolving safety regulations, and a profound, growing emphasis on the principles of Industry 4.0 and smart factory initiatives. Prominent economic powerhouses like Germany, the United Kingdom, France, and the Nordics are actively investing heavily in robotic piece picking technologies for a dual purpose: both in high-volume e-commerce fulfillment operations and in diverse industrial applications, including complex automotive assembly lines and intricate electronics manufacturing. The region benefits significantly from a robust and highly integrated ecosystem of world-class robot manufacturers, specialized system integrators, and leading research institutions. This is further complemented by a concerted and strategic effort to improve worker safety, address the demographic challenges of an aging workforce through intelligent automation, and enhance overall industrial competitiveness within the global market. European businesses often prioritize precision, reliability, and human-robot collaboration in their automation strategies.

-

Asia Pacific (APAC): The APAC region is unequivocally poised for the most rapid and expansive growth within the robotic piece picking market during the forecast period. This explosive growth is robustly fueled by its burgeoning and dynamic e-commerce sector, particularly in economic giants like China, India, Japan, South Korea, and the rapidly developing economies of Southeast Asia. Concurrently, the region is witnessing massive and ongoing investments in state-of-the-art logistics infrastructure, aggressive industrialization, and strong, supportive government initiatives actively promoting industrial automation and robotics as strategic national priorities. These initiatives aim to fundamentally enhance manufacturing competitiveness, boost export capabilities, and efficiently meet the demands of a rapidly expanding and increasingly affluent consumer base. The sheer volume and velocity of goods processed across vast supply chains, coupled with an unwavering drive for unparalleled operational efficiency and cost-effectiveness, collectively position APAC as the undisputed critical growth engine for the global robotic piece picking market, fostering a highly competitive and innovative landscape.

-

Latin America: This region constitutes an emerging yet increasingly promising market for robotic piece picking, exhibiting steadily rising adoption rates, particularly within the larger economies of Brazil and Mexico. The nascent but accelerating growth is primarily underpinned by the rapid expansion of e-commerce platforms, the critical need for modernization across logistics operations to keep pace with global standards, and a strategic imperative to significantly improve competitiveness within intricate global supply chains. While starting from a comparatively lower base of automation adoption, investments in advanced robotics and automation solutions are gradually but consistently increasing as regional businesses actively seek to overcome persistent infrastructural challenges, address growing domestic labor constraints, and enhance overall operational capabilities. Government support for industrial upgrading and increasing foreign direct investment in manufacturing and logistics are also contributing to this positive trend, signaling a maturation of the market.

-

Middle East & Africa (MEA): The MEA region is also an emerging and strategically important market, characterized by significant and growing investments in state-of-the-art logistics and warehousing infrastructure, particularly concentrated in economic hubs like the UAE, Saudi Arabia, and other Gulf Cooperation Council (GCC) countries. These nations are actively pursuing ambitious economic diversification efforts away from traditional oil-dependent economies, coupled with substantial government spending on developing smart cities, advanced industrial capabilities, and modern trade corridors. These strategic initiatives are collectively creating new and substantial opportunities for the adoption of robotic piece picking solutions. The primary focus here is on establishing and operating highly efficient, cutting-edge facilities that can effectively and economically serve both burgeoning domestic and rapidly expanding regional trade volumes, thereby building resilient and competitive supply chains to support long-term economic growth and diversification goals. As the region continues its modernization drive, the demand for intelligent automation will only intensify.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Robotic Piece Picking Market.- ABB

- Fanuc Corporation

- KUKA AG

- Yaskawa Electric Corporation

- Universal Robots (Teradyne)

- RightHand Robotics, Inc.

- Berkshire Grey, Inc.

- Plus One Robotics, Inc.

- Locus Robotics

- Geek+

- Waypoint Robotics (acquired by Locus Robotics)

- i-botics

- Photoneo

- Cognex Corporation

- SICK AG

- Intel Corporation

- NVIDIA Corporation

- Amazon Robotics

- Mujin Inc.

- Pick-it (Robotics)

- PSSI Robotics

- Kawasaki Heavy Industries

- Omron Corporation

- ROEQ (Robot Equipment)

- OnRobot

Frequently Asked Questions

What is robotic piece picking?

Robotic piece picking is an advanced automation technology where intelligent robots utilize sophisticated vision systems, adaptable grippers, and artificial intelligence to autonomously identify, meticulously select, and precisely handle individual items from unstructured environments such as bins, shelves, or fast-moving conveyors. It is a crucial solution for tasks requiring agile manipulation of diverse products in complex logistics, e-commerce fulfillment, and advanced manufacturing operations.

What are the main benefits of implementing robotic piece picking?

Key benefits include significantly increased operational efficiency and higher throughput rates, enhanced picking accuracy with a dramatic reduction in human errors, substantial labor cost savings, improved workplace safety by automating repetitive and ergonomically challenging tasks, and greater scalability and flexibility to dynamically adapt to fluctuating demand without extensive workforce adjustments or retraining.

Which industries are the primary users of robotic piece picking solutions?

The leading industries actively adopting robotic piece picking are the e-commerce and retail sectors for high-volume order fulfillment and returns processing, third-party logistics (3PL) providers and warehousing companies for sorting, kitting, and distribution, and various manufacturing industries such as automotive, food & beverage, and pharmaceuticals for assembly, packaging, and material handling processes.

How does Artificial Intelligence (AI) enhance robotic piece picking capabilities?

AI profoundly enhances piece picking by powering advanced 3D vision systems for superior object recognition and precise localization, enabling robots to adapt to novel and unknown items through continuous machine learning, optimizing complex grasp strategies and path planning, and facilitating robust autonomous error recovery, ultimately making these robotic systems more versatile, intelligent, and highly efficient in dynamic environments.

What are the primary challenges in adopting robotic piece picking technology?

Major challenges include the inherently high initial capital investment required for these sophisticated systems, significant technical complexities in seamlessly integrating robots with existing, often legacy, warehouse management systems, certain limitations in handling extremely fragile or very high-volume specific items at maximum speed, and the ongoing critical need for a new cadre of skilled personnel for effective system operation, meticulous maintenance, and proficient troubleshooting.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager