Rock and Concrete Splitter Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 434011 | Date : Dec, 2025 | Pages : 242 | Region : Global | Publisher : MRU

Rock and Concrete Splitter Market Size

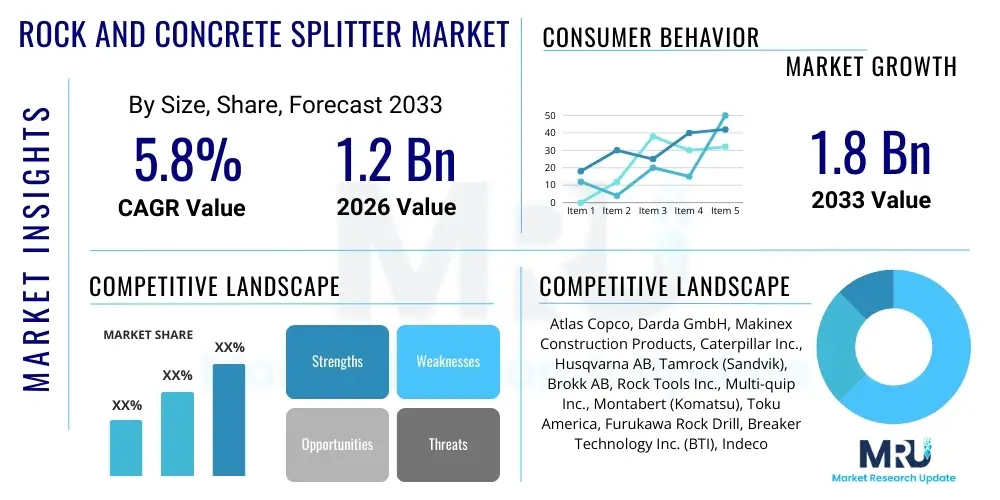

The Rock and Concrete Splitter Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 1.2 Billion in 2026 and is projected to reach USD 1.8 Billion by the end of the forecast period in 2033.

Rock and Concrete Splitter Market introduction

The Rock and Concrete Splitter Market encompasses tools and equipment designed for the controlled fracturing and demolition of hard materials, such as rock, concrete, and heavily reinforced structures, without relying on traditional explosive methods. These devices function by generating immense outward hydraulic or mechanical force within a pre-drilled hole, causing the material to split predictably along the line of least resistance. The fundamental advantage of rock and concrete splitters lies in their ability to perform controlled demolition in noise-sensitive, vibration-sensitive, or confined environments where conventional blasting is prohibited or impractical, making them crucial tools in dense urban infrastructure projects and delicate renovation work. Key product offerings range from small, handheld hydraulic wedge splitters used for intricate structural modifications to large, machine-mounted systems employed in high-volume quarrying and mining operations.

The product portfolio generally includes hydraulic, pneumatic, and mechanical splitters, with hydraulic variants dominating the market due to their high power-to-weight ratio and precise control over the splitting force. Major applications span structural demolition, trenching, foundation removal, mining overburden reduction, and tunneling. The primary driving factors for market expansion include the global increase in infrastructure development and urban renovation projects, coupled with stringent environmental regulations that restrict noise pollution and ground vibration associated with conventional blasting techniques. Furthermore, enhanced safety standards on construction sites favor the use of non-explosive, controlled demolition methods, thereby propelling the adoption of rock and concrete splitting equipment across various sectors.

Benefits derived from using these specialized tools are significant, including minimal dust generation, improved operational safety, elimination of specialized blasting licenses, and the ability to work in close proximity to existing structures without causing collateral damage. The consistent demand from the civil engineering and utility sectors, particularly for pipeline installation and utility tunnel construction in populated areas, reinforces the market's trajectory. As construction firms increasingly prioritize precision, safety, and compliance with urban regulations, the role of advanced rock and concrete splitting technology becomes indispensable, driving innovation in portability, power efficiency, and remote operation capabilities within the industry.

Rock and Concrete Splitter Market Executive Summary

The Rock and Concrete Splitter Market is exhibiting robust growth, fundamentally driven by global urbanization and the resultant need for controlled, low-impact demolition methods necessary for modern infrastructure upgrades and renovation projects. Business trends indicate a strong shift toward highly portable, battery-powered hydraulic units, catering to smaller construction sites and specialized interior demolition tasks, alongside continued investment in heavy-duty, machine-mounted splitters essential for large-scale quarrying and tunneling. Key manufacturers are focusing on integrating advanced materials to reduce equipment weight while maximizing splitting power, addressing the dual user requirements of mobility and efficiency. The rental market is also witnessing significant growth, offering flexibility to small and medium-sized contractors who seek access to high-cost equipment without the burden of capital expenditure, thereby broadening market penetration.

Regionally, the Asia Pacific (APAC) market is poised for the fastest expansion, fueled by massive government investments in new public infrastructure, including high-speed rail, highways, and residential complexes in rapidly developing economies like China and India. North America and Europe, characterized by sophisticated regulatory frameworks, show stable growth primarily stemming from renovation, utility maintenance, and complex urban demolition where environmental and safety compliance is paramount. Segmentation trends highlight the enduring dominance of the Hydraulic Splitters segment due to superior force delivery, while the Demolition application segment maintains the largest market share, reflecting the widespread utility of these tools in breaking down obsolete concrete structures and foundations within constrained urban settings.

In summary, the market's trajectory is positive, supported by the confluence of strict safety regulations, high density urban development, and technological advancements that enhance equipment efficiency and user safety. Strategic initiatives by key players involve geographical expansion into emerging markets and the development of integrated digital solutions for monitoring equipment performance and optimizing operational workflows. The long-term outlook remains strong, suggesting sustained investment in controlled, non-explosive rock and concrete breakdown solutions as global construction practices trend toward greater precision and environmental responsibility.

AI Impact Analysis on Rock and Concrete Splitter Market

Users frequently inquire about how AI and machine learning (ML) can improve the operational efficiency, safety, and predictive maintenance of rock and concrete splitting equipment. Common questions center on optimizing the drilling location and angle for maximum splitting force, predicting equipment failure before downtime occurs, and implementing automated safety checks using vision systems. Based on this analysis, the key theme is the shift from reactive maintenance and manual operation planning to proactive, data-driven workflow optimization. Users expect AI to reduce operational costs, extend the lifespan of high-value splitting components like wedges and cylinders, and minimize human error, thereby enhancing the overall return on investment for specialized demolition equipment in demanding construction and mining environments.

- AI-powered predictive maintenance algorithms analyze vibration, pressure, and temperature data from hydraulic systems to anticipate wear on cylinders and wedges, drastically reducing unplanned downtime.

- Machine learning models optimize splitting patterns by analyzing rock/concrete density and structural reinforcement data collected via sensors or drones, recommending optimal hole depth and splitter placement for maximum efficiency and material yield.

- Computer vision systems integrated with splitting equipment enhance site safety by continuously monitoring the exclusion zone, automatically halting operation if personnel or unauthorized objects enter the immediate vicinity.

- AI assists in dynamic resource allocation and fleet management, optimizing the deployment of specialized splitting equipment across multiple construction sites based on real-time project schedules and material breakdown requirements.

- Automated reporting and compliance tracking utilize AI to log operational parameters, pressure exerted, and splitting results, simplifying regulatory adherence and providing comprehensive performance metrics for contractors.

DRO & Impact Forces Of Rock and Concrete Splitter Market

The dynamics of the Rock and Concrete Splitter Market are heavily influenced by a compelling balance of regulatory drivers and operational constraints, alongside significant technological opportunities. Key drivers include the overwhelming need for silent and non-vibratory demolition methods in densely populated areas, spurred by tightening governmental regulations regarding noise and ground disturbance, particularly in Europe and North America. The rapid expansion of infrastructure renewal projects globally, such as bridge replacement and tunnel modifications, further accelerates demand, as splitters offer the precision required to safely dismantle structures adjacent to critical operational assets. Furthermore, the inherent safety advantages over conventional explosives, eliminating the risks associated with transporting and handling hazardous materials, provide a significant impetus for adoption, especially within sensitive public domains.

Conversely, significant restraints hinder market growth. The high initial capital investment required for high-capacity hydraulic power units and specialized splitting tools often poses a barrier to entry, especially for small and regional contractors who prefer renting or using less precise but cheaper alternatives like jackhammers. Additionally, the requirement for specialized training to operate and maintain high-pressure hydraulic equipment efficiently acts as a limiting factor, requiring continuous investment in workforce skills development. The weight and bulkiness of some high-force hydraulic systems, particularly when used in remote or difficult-to-access locations, also present logistical and operational challenges that must be overcome through innovative design and material usage.

Opportunities for market expansion are substantial, primarily driven by the increasing demand for rental services, which democratizes access to expensive technology for a wider range of users. Technological advancements focusing on lighter, more powerful battery-operated systems promise to address portability restraints, opening up new niches in interior demolition and smaller construction tasks. Furthermore, the adoption of splitting technology in niche applications such as secondary breaking in quarrying and reducing oversized boulders in mining operations presents a strong avenue for growth. The core impact forces shaping the market are the regulatory push toward quiet demolition, the technological push toward lighter and smarter equipment, and the economic requirement for precise, risk-mitigated construction and demolition methodologies.

Segmentation Analysis

The Rock and Concrete Splitter Market is comprehensively segmented based on the power source mechanism, the physical form factor of the equipment, and the primary application in which the tools are utilized. This structure helps in understanding the varying demands across different end-user industries and geographical regions, allowing manufacturers to tailor their product offerings effectively. The primary segmentation by type includes Hydraulic Splitters, which utilize fluid pressure to generate immense force, Mechanical Splitters (often screw-based or utilizing lever action), and Pneumatic Splitters, which are less common but used in specific environments. The hydraulic segment dominates due to its superior power, efficiency, and force consistency, crucial for breaking heavily reinforced concrete.

Further analysis of segmentation reveals key distinctions in operational deployment, classified into Handheld Splitters and Machine-Mounted Splitters. Handheld units are essential for detailed work, interior demolition, and locations with restricted access, valuing portability and ease of use. Machine-mounted systems, conversely, are utilized in heavy-duty applications like mass demolition or quarrying, where they are integrated with excavators or other heavy machinery to deliver significantly higher and sustained splitting power over long operational cycles. Application-wise, the market is broadly divided into Demolition & Renovation, Mining & Quarrying, and Civil Engineering & Utility Works, with the Demolition sector generating the highest revenue due to the constant need for safe and precise removal of urban structures.

Understanding these segments is vital for strategic market planning. For instance, the demand for battery-powered handheld hydraulic splitters is rapidly growing within the renovation segment in developed economies, driven by noise limitations and worker mobility needs. Meanwhile, the demand in developing regions often focuses on rugged, high-output, machine-mounted hydraulic systems optimized for large-scale infrastructure projects such as highway construction or dam removal. This diversified demand profile necessitates innovation across all segments, ensuring that manufacturers provide tools optimized for both precision urban work and high-volume industrial breakdown tasks.

- By Type:

- Hydraulic Splitters

- Mechanical Splitters

- Pneumatic Splitters

- By Application:

- Demolition and Renovation

- Mining and Quarrying

- Civil Engineering and Utility Works (e.g., Trenching, Tunneling)

- By Operation Mode:

- Handheld Systems

- Machine-Mounted Systems (Excavator Attachments)

- By End-User:

- Construction Contractors

- Mining Companies

- Infrastructure Developers

- Specialized Demolition Firms

- Rental Equipment Companies

Value Chain Analysis For Rock and Concrete Splitter Market

The value chain for the Rock and Concrete Splitter Market begins with upstream activities focused on the sourcing and processing of specialized raw materials, primarily high-strength steel alloys for wedges and cylinders, high-pressure seals, and durable hydraulic components (pumps, hoses). Manufacturing involves precision machining of components to withstand extreme internal pressures and external forces, followed by rigorous quality assurance and assembly of the power units and splitting heads. Upstream innovation focuses heavily on material science to develop lighter, yet stronger, alloys that can reduce the overall weight of handheld units without compromising the immense splitting force required for heavy-duty applications. Suppliers specializing in customized hydraulic circuits and compact, high-efficiency electric motors play a critical role in the initial stages of the value chain.

Midstream activities revolve around the final assembly, testing, and branding of the equipment. Distribution channels are complex, involving both direct and indirect routes to reach the diverse global customer base. Direct sales are often preferred for high-value, machine-mounted systems where specialized consultation, integration, and training are required, typically targeting large mining companies or major infrastructure developers. Indirect channels, which form the bulk of the market, rely heavily on established networks of specialized construction equipment dealers, authorized regional distributors, and, critically, heavy equipment rental companies. Rental firms act as essential intermediaries, providing short-term access to expensive equipment for small and medium contractors (SMEs) and lowering the financial entry barrier for using advanced splitting technology.

Downstream analysis focuses on after-sales service, maintenance, and technical support, which are crucial given the high-stress nature of the equipment's operation. End-users require reliable parts supply and expert maintenance services to minimize operational downtime. The most significant value addition downstream comes from specialized demolition consultants and training providers who educate operators on best practices for achieving maximum splitting efficiency and maintaining site safety standards. The rise of digitalization within the construction industry means that the distribution channel is increasingly leveraged for delivering software updates, performance diagnostics, and remote technical support, thereby connecting manufacturers more closely with the end-user experience and generating recurring revenue streams through service agreements.

Rock and Concrete Splitter Market Potential Customers

The primary customers and end-users of rock and concrete splitting equipment are found within the infrastructure, construction, mining, and utility maintenance sectors, all seeking controlled, vibration-free methods for material breakdown. Major buyers include general construction contractors engaged in urban redevelopment and foundation removal projects, who value the precision and low-noise characteristics of hydraulic splitters for working within tight property lines or adjacent to occupied buildings. Specialized demolition firms constitute another significant customer base, often requiring high-powered, machine-mounted splitters for dismantling large structures like bridges, overpasses, and cooling towers where explosive use is strictly regulated or undesirable due to environmental factors.

The mining and quarrying industry, particularly those focused on dimension stone quarrying or secondary breaking of oversized material at the mine face, rely on robust splitting equipment to reduce large rocks into manageable sizes without damaging the structural integrity of the surrounding rock mass or generating hazardous blast fumes. Civil engineering firms and utility companies involved in trenching, tunneling, and installing subterranean infrastructure (water pipes, communication cables, sewage systems) in urban environments are heavy consumers. These projects often necessitate breaking concrete or rock layers directly beneath existing roads or sensitive utility lines, making the controlled, fracture-based approach of splitting equipment ideal for minimizing disruption and ensuring structural safety.

Furthermore, equipment rental companies represent a critical group of customers. They purchase high volumes of splitters, especially the popular handheld hydraulic models, to maintain a flexible inventory that meets the fluctuating demands of SMEs and specialized trade contractors who cannot justify the large capital investment for direct ownership. These rental outlets not only provide equipment but also often serve as crucial training and technical support hubs. In essence, the customer profile is defined by those who prioritize operational safety, noise and vibration mitigation, and precision demolition over speed and brute force, particularly in highly regulated or sensitive project environments.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.2 Billion |

| Market Forecast in 2033 | USD 1.8 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Atlas Copco, Darda GmbH, Makinex Construction Products, Caterpillar Inc., Husqvarna AB, Tamrock (Sandvik), Brokk AB, Rock Tools Inc., Multi-quip Inc., Montabert (Komatsu), Toku America, Furukawa Rock Drill, Breaker Technology Inc. (BTI), Indeco North America, Chicago Pneumatic. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Rock and Concrete Splitter Market Key Technology Landscape

The technology landscape of the Rock and Concrete Splitter Market is characterized by continuous refinement aimed at increasing operational efficiency, reducing weight, and enhancing safety features. The foundational technology remains high-pressure hydraulics, but innovation is centered on maximizing the force generated by smaller, more efficient power packs. A significant trend involves the transition from traditional diesel or tethered electric power units to advanced lithium-ion battery technology, particularly for handheld splitters. These battery-powered systems offer unprecedented mobility, eliminate the logistical burden of hydraulic hoses and cables, and meet strict emission standards in confined spaces, fundamentally changing how specialized interior demolition tasks are executed. The development of ultra-lightweight, high-tensile strength materials (like specialized steel alloys) for wedge and counter-wedge fabrication is also crucial, ensuring durability under pressures exceeding 40,000 psi while minimizing material failure and maintenance needs.

Furthermore, digital integration is becoming a key differentiator. Modern hydraulic power units are equipped with sophisticated sensor systems that monitor internal fluid pressure, temperature, flow rates, and vibration patterns in real-time. This data facilitates predictive maintenance, allowing operators and fleet managers to identify potential component wear (such as seal degradation or pump inefficiency) long before catastrophic failure occurs, thereby maximizing uptime and reducing life-cycle costs. Telematics and IoT connectivity are integrating these monitoring systems, enabling remote diagnostics and performance tracking, which is particularly valuable for large contractors managing extensive fleets of machine-mounted splitters across multiple, geographically dispersed sites. This connectivity provides manufacturers with essential usage data to inform future design improvements.

Another emerging technological focus is the integration of advanced control systems for optimizing the splitting process. Microprocessor-controlled pressure regulation ensures that force is applied consistently and precisely, improving the predictability of the fracture and minimizing risk to surrounding structures. Research and development efforts are also focused on multi-directional splitting heads and customized wedge designs tailored for specific material compositions, such as heavily rebar-reinforced concrete or igneous rock formations. Noise reduction technologies, both in the power unit and the operational mechanism, are constantly being refined to exceed increasingly strict urban environmental regulations, cementing the market’s position as the preferred solution for quiet, controlled material breakdown.

Regional Highlights

- Asia Pacific (APAC): APAC represents the fastest-growing region in the Rock and Concrete Splitter Market, driven by unprecedented investment in national infrastructure projects, urbanization, and large-scale industrial expansion across China, India, and Southeast Asian countries. The demand is particularly high for high-capacity, machine-mounted splitters used in tunneling, metro construction, and quarrying operations. Regulatory frameworks are rapidly evolving to prioritize non-explosive methods in dense urban centers, further stimulating market uptake.

- North America: North America holds a substantial and mature market share, characterized by high adoption rates of advanced, technologically integrated splitting equipment. Growth here is primarily fueled by maintenance, rehabilitation, and replacement of aging infrastructure (bridges, dams, utility systems) where controlled, vibration-free demolition is mandated. The robust construction and equipment rental sectors ensure consistent demand, with a growing emphasis on battery-powered and highly portable hydraulic units for specialized interior work.

- Europe: The European market is highly regulated and innovation-driven, with extremely strict standards regarding noise pollution (Directive 2000/14/EC) and ground vibration. This regulatory environment mandates the use of precision tools like rock and concrete splitters over traditional blasting, particularly in countries like Germany, the UK, and France. Demand centers around renovation, utility upgrades, and historical preservation projects, favoring compact, environmentally compliant, high-performance hydraulic systems.

- Latin America (LATAM): This region is experiencing moderate growth, linked to mining expansion (especially copper and iron ore) and fragmented urbanization projects. Market adoption is often constrained by budget limitations, leading to a focus on cost-effective, durable equipment. However, increased investment in regional highway and energy infrastructure is creating pockets of high demand for specialized demolition and earthmoving attachments.

- Middle East and Africa (MEA): Growth in the MEA region is sporadic but significant, concentrated in the Gulf Cooperation Council (GCC) countries due to megaprojects (e.g., NEOM, various smart cities). These projects demand rapid construction and require controlled demolition for specialized architecture and foundation work. In Africa, demand is primarily driven by mining activities, where rock splitting is utilized for controlled extraction and secondary breaking in remote locations.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Rock and Concrete Splitter Market.- Atlas Copco

- Darda GmbH

- Makinex Construction Products

- Caterpillar Inc. (via hydraulic attachments)

- Husqvarna AB

- Sandvik Group (Tamrock)

- Brokk AB

- Rock Tools Inc.

- Multi-quip Inc.

- Montabert (Komatsu)

- Toku America Inc.

- Furukawa Rock Drill

- Breaker Technology Inc. (BTI)

- Indeco North America

- Chicago Pneumatic

- Power Team (SPX Flow)

- Holmatro Industrial & Rescue

- Hydra-Tech Pumps Inc.

Frequently Asked Questions

Analyze common user questions about the Rock and Concrete Splitter market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary advantages of using rock and concrete splitters over traditional blasting methods?

The primary advantages are the execution of controlled demolition with minimal noise, zero ground vibration, and low dust generation. This makes splitting essential for urban areas, sensitive environments, and sites adjacent to existing structures, improving safety and regulatory compliance.

How is the adoption of battery technology affecting the Rock and Concrete Splitter Market?

Battery technology is driving significant growth in the handheld segment by enhancing portability and eliminating the need for hydraulic hoses or external power sources. This allows for increased operational flexibility and mobility, particularly for interior and smaller-scale renovation projects in noise-sensitive zones.

Which segment, Hydraulic or Mechanical Splitters, holds the largest market share, and why?

Hydraulic Splitters hold the largest market share due to their ability to generate immense, consistent splitting force (often exceeding 400 tons) in a compact design. Their power-to-weight ratio and effectiveness against heavily reinforced concrete structures make them the preferred choice across heavy-duty demolition and mining applications.

What major factors are restraining the overall growth of the market?

The primary restraints include the high initial purchase cost of specialized high-pressure hydraulic power units and cylinders, which can deter smaller contractors. Additionally, the requirement for specialized operator training and ongoing maintenance of precision hydraulic components presents an operational barrier.

In which geographical region is the demand for rock and concrete splitters growing the fastest?

The Asia Pacific (APAC) region is currently experiencing the fastest growth in demand, driven by massive governmental investments in large-scale infrastructure and civil engineering projects, alongside rapid urbanization that necessitates controlled, low-impact demolition techniques.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager