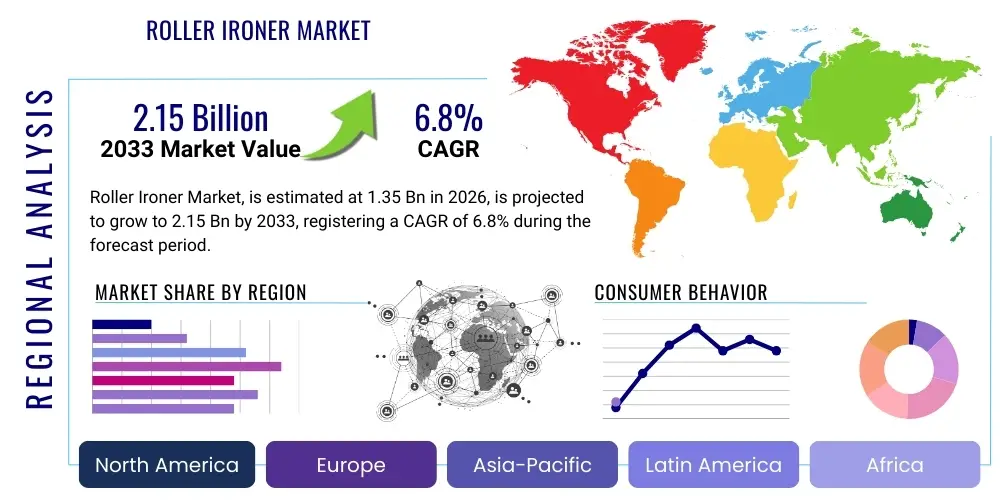

Roller Ironer Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440258 | Date : Jan, 2026 | Pages : 245 | Region : Global | Publisher : MRU

Roller Ironer Market Size

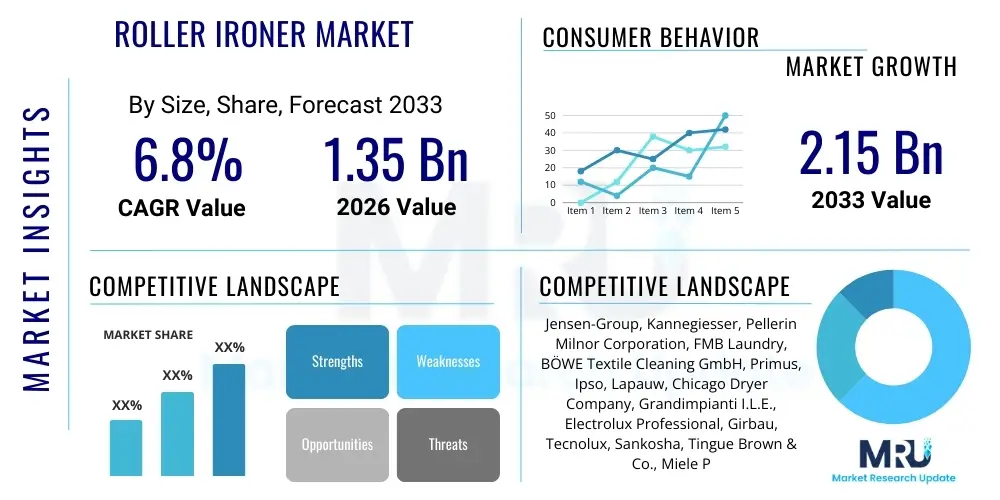

The Roller Ironer Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 1.35 billion in 2026 and is projected to reach USD 2.15 billion by the end of the forecast period in 2033. This growth signifies a robust expansion driven by increasing demand from various commercial and industrial sectors globally, alongside continuous advancements in ironing technology and efficiency solutions.

Roller Ironer Market introduction

The Roller Ironer Market encompasses the manufacturing, distribution, and sales of machinery designed for efficiently ironing large quantities of flat linen items such as sheets, tablecloths, and towels. These machines, often referred to as flatwork ironers or rotary ironers, are integral to the operational efficiency of commercial laundries, hotels, hospitals, and other institutions requiring high-volume laundry processing. They utilize heated rollers or chests to press and dry fabrics simultaneously, significantly reducing labor and time compared to traditional ironing methods. The primary product variations include chest-heated ironers and roller-heated ironers, each offering distinct advantages in terms of heat transfer, speed, and suitability for specific fabric types and volumes.

Major applications for roller ironers span a wide array of industries. In the hospitality sector, they are indispensable for maintaining pristine bedding and table linens in hotels, resorts, and cruise ships, directly impacting guest satisfaction. Healthcare facilities rely on them for sanitizing and pressing patient gowns, bed linens, and surgical drapes, where stringent hygiene standards are paramount. Commercial laundries, which serve diverse clients from restaurants to sports clubs, leverage these machines for their sheer capacity and speed. Beyond these, industrial uniform rental companies, correctional facilities, and large-scale catering operations also constitute significant end-users. The versatility and efficiency of roller ironers make them a critical investment for any entity with substantial flatwork laundry requirements.

The benefits derived from adopting roller ironers are multifaceted, extending beyond mere productivity. They ensure a consistent, high-quality finish, enhancing the professional appearance of linens and contributing to brand image, particularly in hospitality settings. Operating roller ironers leads to substantial labor cost savings by automating a labor-intensive process, freeing staff for other tasks. Furthermore, modern roller ironers are increasingly designed with energy efficiency in mind, incorporating features like heat recovery systems and optimized heating elements to reduce operational expenses. Key driving factors propelling market growth include the burgeoning global tourism and hospitality industry, rising awareness of hygiene standards, particularly post-pandemic, the increasing trend towards outsourcing laundry services, and the continuous push for automation to combat rising labor costs and shortages across various economies.

Roller Ironer Market Executive Summary

The Roller Ironer Market is experiencing dynamic shifts, characterized by several key business, regional, and segment trends. From a business perspective, the market is witnessing a strong impetus towards automation and integration of smart technologies, aiming to enhance operational efficiency and reduce manual intervention in commercial laundry settings. Manufacturers are focusing on developing eco-friendly models with improved energy consumption profiles and reduced water usage, aligning with global sustainability initiatives and stricter environmental regulations. Additionally, there is a growing demand for customized solutions that cater to specific end-user requirements, such as varied capacities, specialized heating systems, and ergonomic designs. Strategic collaborations and mergers among key players are also prevalent, driven by the desire to expand geographic reach, diversify product portfolios, and leverage combined technological expertise to capture a larger market share.

Regional trends reveal varied growth trajectories and market maturity levels across different geographies. Asia Pacific is emerging as a significant growth engine, fueled by rapid urbanization, an expanding hospitality sector, increasing healthcare infrastructure development, and a burgeoning middle-class consumer base driving demand for high-quality services. Countries like China and India are at the forefront of this growth, supported by government investments in tourism and healthcare. Europe, a mature market, continues to innovate, with a strong focus on advanced, energy-efficient, and highly automated systems, driven by high labor costs and stringent environmental standards. North America also exhibits steady growth, with significant adoption in large-scale commercial laundries and institutional settings, emphasizing durability and high-capacity solutions. Emerging economies in Latin America and the Middle East & Africa are gradually increasing their adoption of roller ironers as their commercial and institutional sectors expand, albeit from a smaller base.

Segmentation trends indicate a clear preference for certain product types and applications. By type, roller-heated ironers, especially those with multiple rollers, are often favored for their high throughput and efficiency in large commercial laundries. Chest-heated ironers, known for their superior heat transfer and ability to handle heavier fabrics, also maintain a strong market presence, particularly for specialized applications. In terms of application, the hospitality sector continues to be the dominant end-user, followed closely by commercial laundries and healthcare. The demand for industrial and heavy-duty roller ironers is on the rise, reflecting the increasing scale of laundry operations. Furthermore, there is a noticeable trend towards modular designs and systems that can be easily integrated into existing laundry setups, offering scalability and flexibility to operators. This granular understanding of segment performance is crucial for market participants to tailor their offerings and penetrate high-growth niches effectively.

AI Impact Analysis on Roller Ironer Market

Common user questions regarding the impact of AI on the Roller Ironer Market frequently revolve around how artificial intelligence can revolutionize efficiency, predictive maintenance, quality control, and operational costs. Users are keen to understand if AI can enable more autonomous operations, optimize energy consumption, and integrate seamlessly with broader laundry management systems. Key themes include the potential for AI to preemptively identify mechanical failures, reduce downtime, dynamically adjust ironing parameters based on fabric type and load, and provide actionable insights for process optimization. Concerns often touch upon the initial investment required for AI integration, data security, the need for skilled personnel to manage AI-driven systems, and the fear of job displacement. Expectations are high for AI to deliver significant improvements in operational intelligence, sustainability, and overall productivity, making roller ironers smarter, more reliable, and ultimately more cost-effective.

- AI-powered predictive maintenance reduces downtime by identifying potential mechanical failures before they occur, optimizing maintenance schedules.

- Smart temperature and speed control systems leverage AI to adapt ironing parameters in real-time based on fabric type, moisture content, and load size, ensuring optimal quality and energy efficiency.

- Integration with broader Laundry Management Systems (LMS) allows for AI-driven workflow optimization, automating sorting, feeding, and folding processes for seamless operation.

- AI-enhanced quality control systems utilize vision algorithms to detect imperfections or wrinkles in linens, flagging items for re-processing and ensuring consistent output standards.

- Energy optimization algorithms powered by AI analyze usage patterns and external factors to minimize energy consumption during operation and standby modes, contributing to lower operational costs and environmental sustainability.

- Operational analytics and reporting tools provide AI-driven insights into machine performance, productivity metrics, and potential bottlenecks, empowering management with data for informed decision-making and continuous improvement.

DRO & Impact Forces Of Roller Ironer Market

The Roller Ironer Market is propelled by several significant drivers. A primary driver is the robust expansion of the global hospitality sector, including hotels, resorts, cruise lines, and catering services, all of which demand impeccably ironed linens to maintain high standards of guest experience and brand reputation. As global tourism continues its recovery and growth, the need for efficient laundry processing in these establishments escalates proportionally. Similarly, the growing healthcare industry, with its stringent hygiene and sterilization requirements for patient linens, surgical drapes, and staff uniforms, significantly contributes to the demand for high-performance roller ironers capable of handling large volumes while meeting health regulations. The increasing awareness and emphasis on hygiene standards across various sectors, exacerbated by recent global health crises, further stimulate investment in professional laundry equipment. Furthermore, rising labor costs and persistent labor shortages in many developed and developing economies compel businesses to seek automation solutions, making roller ironers an attractive investment for their ability to streamline operations and reduce manual labor dependency.

Despite the strong growth drivers, the market faces certain restraints. The high initial capital investment required for acquiring industrial-grade roller ironers can be a significant barrier for smaller businesses or new entrants, limiting market penetration, especially in price-sensitive regions. This initial cost often includes not only the machinery but also installation, specialized electrical infrastructure, and sometimes even structural modifications to accommodate the equipment. Another restraint is the need for specialized maintenance and skilled operators to run and service these complex machines. The intricate mechanical and electrical systems within roller ironers necessitate trained technicians, which can add to operational costs and present challenges in regions with limited technical expertise. Moreover, the substantial space requirements for installing these large machines can be an issue for establishments with limited floor area, particularly in urban environments where real estate is at a premium. The ongoing energy consumption, while improving with newer models, remains a considerable operational expense, influencing purchasing decisions and overall cost of ownership.

Opportunities within the Roller Ironer Market are abundant and diverse. Emerging economies, particularly in Asia Pacific and Latin America, present significant untapped potential as their hospitality, healthcare, and commercial sectors undergo rapid modernization and expansion. As disposable incomes rise and urbanization accelerates in these regions, demand for organized laundry services and high-quality linen care grows, creating fertile ground for market growth. The ongoing technological advancements, including the integration of IoT, AI, and energy-efficient designs, offer substantial opportunities for innovation and product differentiation. Manufacturers can develop smarter, more connected ironers that offer predictive maintenance, remote diagnostics, and optimized performance, appealing to a tech-savvy customer base. Customization and modular design options represent another avenue for growth, allowing businesses to tailor solutions precisely to their operational needs and space constraints. Additionally, the increasing focus on sustainability and eco-friendly operations opens opportunities for roller ironers equipped with advanced heat recovery systems, water recycling capabilities, and mechanisms that reduce chemical usage, aligning with corporate social responsibility goals and attracting environmentally conscious buyers.

Segmentation Analysis

The Roller Ironer Market is comprehensively segmented based on various attributes, including type, application, operation, capacity, and end-use. This segmentation provides a granular view of market dynamics, allowing stakeholders to identify niche opportunities and understand specific demand patterns across different sectors and geographies. The variations in product design, operational capabilities, and intended use cases dictate how these machines are adopted and integrated into diverse laundry environments. Analyzing these segments is critical for manufacturers to tailor their product development strategies, for distributors to optimize their supply chains, and for end-users to select the most appropriate equipment for their specific operational demands. The market's complexity and diverse customer needs necessitate a detailed approach to segmentation to capture its full scope.

- By Type

- Chest-Heated Ironers: Known for superior heat transfer, ideal for heavier fabrics and higher quality finishes.

- Roller-Heated Ironers: Offer faster processing speeds and are generally more versatile for a wider range of flat linen.

- Multi-Roller Ironers: Designed for very high throughput and efficiency, commonly used in large commercial laundries.

- By Application

- Hospitality (Hotels, Resorts, Cruise Ships): Dominant segment due to extensive linen requirements for guest satisfaction.

- Healthcare (Hospitals, Clinics, Care Homes): Driven by strict hygiene standards and large volumes of patient and staff linens.

- Commercial Laundries: Services a diverse client base, requiring high-capacity and durable machines.

- Industrial (Uniform Rental, Manufacturing Facilities): For processing workwear and specialized industrial textiles.

- Others (Correctional Facilities, Spas, Catering): Niche applications with specific laundry needs.

- By Operation

- Manual Feeding Ironers: Requires manual loading of linens.

- Automatic Feeding Ironers: Incorporates automated systems for linen feeding, enhancing efficiency and reducing labor.

- Integrated Ironer-Folder Systems: Combines ironing and folding into one continuous automated process.

- By Capacity

- Small Capacity (e.g., up to 50 kg/hr): Suitable for small hotels, restaurants, or niche laundries.

- Medium Capacity (e.g., 50-150 kg/hr): Common for mid-sized hotels, hospitals, and commercial laundries.

- Large Capacity (e.g., over 150 kg/hr): Designed for high-volume industrial and commercial laundry operations.

- By Heating Method

- Electric Heating: Common for smaller to medium units, convenient and relatively easy to install.

- Steam Heating: Highly efficient for large-scale operations, requiring a steam boiler infrastructure.

- Gas Heating: Offers cost-effective operation for medium to large-scale ironers, particularly where natural gas is readily available.

- Thermal Oil Heating: Provides consistent and even heat distribution, suitable for high-quality finishes and specific fabric types.

- By Automation Level

- Semi-Automatic: Requires some manual intervention for feeding or folding.

- Fully Automatic: Minimizes human input throughout the ironing and often folding process.

Value Chain Analysis For Roller Ironer Market

The value chain for the Roller Ironer Market is a sophisticated network encompassing various stages, from raw material sourcing to end-user deployment and after-sales services. Upstream analysis focuses on the procurement of essential raw materials and components, which form the bedrock of roller ironer manufacturing. This includes high-grade steel for chassis and rollers, specialized metals for heating elements, durable fabrics and insulation materials, and advanced electronic components for control systems and automation features. Suppliers of these materials play a crucial role in ensuring the quality, durability, and performance of the final product. Strong relationships with reliable and cost-effective suppliers are vital for manufacturers to maintain competitive pricing and consistent product quality. Innovation in material science, such as more heat-resistant or energy-efficient materials, directly impacts the evolution and capabilities of new roller ironer models. The efficiency of the upstream supply chain directly affects production costs and time-to-market for new machines.

Further along the value chain, the manufacturing stage involves intricate processes of design, assembly, testing, and quality control. Leading manufacturers invest heavily in research and development to innovate designs, enhance energy efficiency, improve automation features, and incorporate smart technologies like IoT and AI. Post-manufacturing, the downstream analysis focuses on the distribution, installation, and after-sales support networks that deliver the product to the end-user. Distribution channels are varied and typically include direct sales teams for large industrial clients, a network of authorized distributors and dealers who cater to smaller businesses and provide local support, and sometimes online platforms for accessory sales or informational purposes. The complexity and size of roller ironers necessitate specialized logistics for transportation and professional installation by trained technicians to ensure proper functioning and safety compliance. This stage also includes crucial aspects like training for operators at the client site, which ensures efficient utilization and prolongs the lifespan of the equipment.

The final crucial component of the value chain involves after-sales services, which are critical for customer satisfaction and long-term loyalty. This encompasses routine maintenance, repair services, provision of spare parts, and technical support. A robust service network ensures minimal downtime for clients, which is paramount in high-volume laundry operations where equipment failure can lead to significant operational disruptions and financial losses. Manufacturers often offer comprehensive service contracts, extended warranties, and remote diagnostic capabilities to enhance customer service. The feedback loop from after-sales service and customer support also provides invaluable insights for product improvement and future innovation, thereby closing the loop of the value chain. Both direct and indirect distribution channels play pivotal roles; direct channels allow for deeper customer relationships and customized solutions, while indirect channels provide broader market reach and localized support, making both indispensable for a comprehensive market strategy.

Roller Ironer Market Potential Customers

The Roller Ironer Market serves a diverse range of end-users and buyers, each with specific requirements and operational scales. The most prominent segment comprises the hospitality industry, encompassing hotels of all sizes, luxury resorts, boutique accommodations, cruise ship lines, and event venues. These establishments require vast quantities of high-quality, impeccably pressed linens – from bed sheets and pillowcases to tablecloths and napkins – to maintain their brand image and ensure guest comfort and satisfaction. The sheer volume and frequent turnover of linens in this sector make efficient, high-capacity roller ironers an indispensable asset. Their purchasing decisions are often driven by factors such as finish quality, operational speed, energy efficiency, ease of use, and the reliability of after-sales service, as any downtime directly impacts their guest experience and profitability. The rapid expansion of global tourism and the continuous upgrade of facilities directly correlate with increased demand from this customer base.

Another significant group of potential customers lies within the healthcare sector, which includes hospitals, clinics, nursing homes, assisted living facilities, and specialized medical centers. In these environments, hygiene and sterilization are paramount, and the constant need for clean, properly pressed patient gowns, bed linens, surgical drapes, and staff uniforms drives demand for roller ironers. The equipment must meet stringent health and safety standards, often requiring features that support thermal disinfection and maintain fabric integrity after repeated high-temperature washes. Factors influencing purchasing decisions in healthcare include robust construction for durability, capacity to handle heavy-duty loads, precise temperature control for delicate medical fabrics, and integration with overall laundry workflow to ensure a continuous supply of sanitized linens. The aging global population and the expansion of healthcare infrastructure continue to fuel the growth of this customer segment, emphasizing the need for reliable and efficient laundry solutions.

Beyond hospitality and healthcare, commercial laundries constitute a substantial and continuously growing customer segment. These businesses operate as third-party service providers, handling laundry for a multitude of clients, which can range from small restaurants and spas to large industrial facilities and uniform rental companies. Their business model relies heavily on efficiency, throughput, and cost-effectiveness, making high-capacity, automated roller ironers essential to their operations. Commercial laundries often prioritize machines that offer high processing speeds, low operational costs (especially energy and labor), and minimal maintenance requirements to maximize profitability. Furthermore, other niche but important end-users include governmental institutions such as correctional facilities and military bases, large corporate campuses with on-site laundries, sports clubs and fitness centers requiring towel services, and industrial manufacturers with specific textile processing needs. These diverse applications underscore the widespread utility and broad customer base for roller ironers across various economic sectors.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.35 Billion |

| Market Forecast in 2033 | USD 2.15 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Jensen-Group, Kannegiesser, Pellerin Milnor Corporation, FMB Laundry, BÖWE Textile Cleaning GmbH, Primus, Ipso, Lapauw, Chicago Dryer Company, Grandimpianti I.L.E., Electrolux Professional, Girbau, Tecnolux, Sankosha, Tingue Brown & Co., Miele Professional, Forenta, Alliance Laundry Systems (Speed Queen, Huebsch), Domus Laundry, Tolkar. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Roller Ironer Market Key Technology Landscape

The Roller Ironer Market is characterized by a rapidly evolving technology landscape, with manufacturers continuously integrating innovations to enhance efficiency, performance, and user experience. A prominent technological trend is the incorporation of Internet of Things (IoT) connectivity, transforming traditional ironers into smart machines capable of collecting and transmitting real-time operational data. This data enables remote monitoring, predictive maintenance, and performance analytics, allowing operators to optimize workflows, identify potential issues before they cause downtime, and manage multiple machines from a centralized platform. IoT integration also facilitates seamless communication with other laundry equipment, enabling fully automated and integrated laundry processing lines, from washing and drying to ironing and folding. This connectivity is crucial for large-scale commercial laundries seeking maximum throughput and minimal human intervention.

Another critical area of technological advancement is focused on energy recovery and efficiency. With rising energy costs and growing environmental concerns, manufacturers are developing sophisticated heat recovery systems that capture and reuse heat generated during the ironing process, significantly reducing energy consumption. Advanced insulation materials and optimized heating elements further contribute to lower operational expenses and a reduced carbon footprint. Variable speed drives and intelligent control systems adjust roller speeds and temperatures based on fabric type, moisture content, and desired finish, ensuring optimal energy use for each load. Furthermore, the adoption of ergonomic designs and user-friendly interfaces, often featuring touchscreen controls and intuitive programming, is improving operator comfort and ease of use, reducing the learning curve and enhancing overall productivity in busy laundry environments. These technological improvements collectively aim to make roller ironers more sustainable, economical, and responsive to the diverse needs of modern commercial and industrial laundry operations.

Beyond efficiency and connectivity, advanced automation and material handling technologies are profoundly shaping the roller ironer market. Automated feeding and folding systems, often employing sophisticated sensors and robotic arms, significantly reduce the manual labor required at both ends of the ironing process, further boosting productivity and minimizing human error. These systems can accurately align, feed, and then fold linens, preparing them for storage or immediate use. Developments in roller technology, such as specialized roller coatings and designs, are enhancing heat transfer efficiency and providing superior finishes for a wider variety of fabrics, from delicate silks to heavy cottons. The integration of artificial intelligence (AI) and machine learning (ML) algorithms is beginning to emerge, enabling ironers to learn and adapt to different fabric properties, predict maintenance needs, and optimize operational parameters autonomously. This future-forward approach promises even greater levels of automation, precision, and intelligence, further solidifying the roller ironer's role as a cornerstone of modern laundry technology.

Regional Highlights

- North America: The North American market for roller ironers is characterized by a strong demand from large-scale commercial laundries, hospitality chains, and healthcare institutions. The region benefits from high levels of automation adoption driven by substantial labor costs and a focus on operational efficiency. Technological advancements, including IoT integration and energy-efficient models, are readily embraced here. The market is mature, with key players focusing on offering advanced, high-capacity, and durable equipment, alongside comprehensive after-sales service and support. Strict hygiene regulations in the healthcare sector also contribute to consistent demand.

- Europe: Europe represents a highly mature and competitive market for roller ironers, distinguished by a strong emphasis on innovation, energy efficiency, and compliance with stringent environmental regulations. Countries like Germany, France, Italy, and the UK are at the forefront of adopting advanced ironing technologies, driven by high labor costs, a strong commitment to sustainability, and a well-established hospitality and healthcare infrastructure. The European market sees a preference for highly automated systems that offer precise control, superior finish quality, and minimal environmental impact.

- Asia Pacific (APAC): The Asia Pacific region is projected to be the fastest-growing market for roller ironers, driven by rapid economic development, booming tourism, and significant investments in healthcare and hospitality infrastructure, particularly in emerging economies. Countries such as China, India, Japan, and Australia are key contributors to this growth. The expanding middle class, urbanization, and increasing disposable incomes are fueling demand for organized laundry services and higher standards in hospitality.

- Latin America: The Latin American roller ironer market is experiencing steady growth, fueled by the expansion of its tourism sector, particularly in countries like Brazil, Mexico, and Argentina. The increasing number of international hotel chains and resorts, alongside a growing healthcare sector, is stimulating demand for professional laundry equipment. While the market may not be as mature as North America or Europe, there is a clear trend towards modernizing laundry operations and adopting more efficient machinery to reduce operational costs and improve service quality.

- Middle East and Africa (MEA): The MEA region is witnessing considerable growth in the roller ironer market, largely propelled by significant investments in the hospitality and tourism sectors, particularly in the Gulf Cooperation Council (GCC) countries. The construction of numerous luxury hotels, resorts, and entertainment complexes, especially in destinations like UAE, Saudi Arabia, and Qatar, creates a strong demand for state-of-the-art laundry equipment. Government initiatives to diversify economies away from oil, focusing on tourism and healthcare, are major catalysts for market expansion.

The United States and Canada are leading countries within North America, exhibiting significant investment in upgrading existing laundry facilities and establishing new ones that prioritize automation and sustainability. The robust tourism industry, especially in major urban centers and popular travel destinations, ensures a continuous need for high-quality linen finishing. Furthermore, the strong presence of large institutional clients, such as universities and government facilities, also contributes significantly to market demand. Manufacturers and distributors in this region often emphasize customization capabilities to meet diverse client needs, along with offering financing and leasing options to facilitate procurement for a broad spectrum of businesses.

Innovation in Europe is also spurred by the demand for ergonomic designs that enhance operator comfort and safety. Manufacturers are keenly focused on developing compact, modular solutions that fit into diverse facility layouts while delivering high performance. The region's extensive network of specialized commercial laundries serving various industries, coupled with a high standard of living that supports premium hospitality services, ensures sustained demand. European companies often lead in exporting advanced roller ironer technologies globally, setting benchmarks for quality and technological sophistication in the international market.

The APAC market is characterized by a blend of demand for both cost-effective and advanced automation solutions. While there is a strong focus on affordability in some segments, the rapid modernization in urban areas and the expansion of international hotel chains are driving the adoption of high-capacity, technologically advanced ironers. Local manufacturing is also growing, often competing with international brands by offering customized solutions at competitive prices. The region presents immense opportunities for market penetration and expansion for both established global players and local manufacturers, benefiting from large populations and dynamic economic growth.

Investment in infrastructure development and economic stabilization efforts are positively influencing market dynamics in Latin America. Manufacturers often focus on providing durable and easy-to-maintain equipment that can withstand varying operational conditions, while also addressing budget constraints. As the region continues to integrate into the global economy, the demand for high-quality laundry services is expected to rise, creating further opportunities for market expansion and the introduction of more sophisticated roller ironer technologies.

African countries are also showing increasing potential as their economies develop and urbanization accelerates, leading to growth in commercial and institutional laundry services. The demand in MEA is often for high-capacity and robust machines that can operate reliably in challenging environmental conditions, such as high temperatures. Energy efficiency is also a growing concern, as is the availability of reliable after-sales support. The region's strategic location and ongoing development projects position it as a dynamic market with significant long-term growth prospects for roller ironer manufacturers and suppliers.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Roller Ironer Market.- Jensen-Group

- Kannegiesser

- Pellerin Milnor Corporation

- FMB Laundry

- BÖWE Textile Cleaning GmbH

- Primus

- Ipso

- Lapauw

- Chicago Dryer Company

- Grandimpianti I.L.E.

- Electrolux Professional

- Girbau

- Tecnolux

- Sankosha

- Tingue Brown & Co.

- Miele Professional

- Forenta

- Alliance Laundry Systems (Speed Queen, Huebsch)

- Domus Laundry

- Tolkar

Frequently Asked Questions

Analyze common user questions about the Roller Ironer market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is a roller ironer and its primary function?

A roller ironer, also known as a flatwork ironer or rotary ironer, is a commercial laundry machine designed to efficiently press and dry large quantities of flat linen items such as sheets, tablecloths, and towels. Its primary function is to deliver a consistently smooth, high-quality finish while significantly reducing the labor and time typically required for manual ironing in high-volume settings, primarily by using heated rollers or chests to simultaneously dry and press fabrics.

Which industries are the main adopters of roller ironers?

The main industries adopting roller ironers are the hospitality sector (hotels, resorts, cruise ships), healthcare facilities (hospitals, clinics, nursing homes), and commercial laundries. These sectors have extensive flat linen processing requirements, where efficiency, hygiene, and a professional finish are critical. Other adopters include industrial uniform rental companies, correctional facilities, spas, and large-scale catering operations.

What are the key benefits of investing in a modern roller ironer?

Investing in a modern roller ironer offers numerous benefits, including enhanced operational efficiency and speed in laundry processing, significant labor cost savings through automation, consistent and superior finish quality for linens, improved energy efficiency through advanced heat recovery systems, and compliance with stringent hygiene standards, particularly in healthcare settings. Modern units also offer features like IoT connectivity for predictive maintenance and remote monitoring.

How is AI impacting the future of roller ironers?

AI is transforming roller ironers by enabling predictive maintenance, smart temperature and speed controls that adapt to fabric types, and seamless integration with broader laundry management systems for workflow optimization. AI-enhanced quality control systems can detect imperfections, and AI algorithms can optimize energy consumption. These advancements lead to more autonomous, efficient, and reliable operations, reducing downtime and operational costs while improving output quality.

What factors should be considered when choosing a roller ironer?

When choosing a roller ironer, key factors to consider include the required capacity (kg/hr), heating method (electric, steam, gas, thermal oil), level of automation (manual, automatic feeding, integrated folding), type of linens to be processed, available space, initial capital investment versus long-term operational costs (including energy consumption), and the availability of after-sales service and spare parts. Durability, ease of use, and specific features like heat recovery are also crucial for optimal performance and return on investment.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager