Roofing Sheets Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 431992 | Date : Dec, 2025 | Pages : 257 | Region : Global | Publisher : MRU

Roofing Sheets Market Size

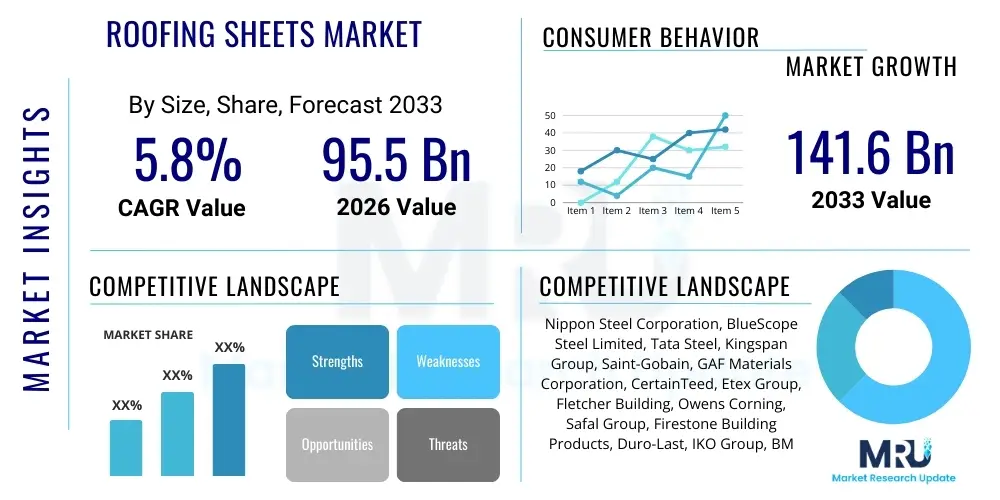

The Roofing Sheets Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 95.5 Billion in 2026 and is projected to reach USD 141.6 Billion by the end of the forecast period in 2033.

Roofing Sheets Market introduction

The global Roofing Sheets Market encompasses a diverse range of materials—including metal, asphalt, plastic, and fiber cement—used primarily for protecting residential, commercial, and industrial structures from environmental elements. These sheets are essential components of modern construction, providing insulation, weather resistance, and structural integrity. Product diversification is rapidly expanding, driven by demand for lightweight, durable, and aesthetically versatile roofing solutions. Major applications span new construction projects, extensive renovation, and infrastructure development, particularly in fast-growing urban centers across Asia Pacific and Latin America. The industry’s focus is increasingly shifting towards sustainable and energy-efficient products, such as cool roofs and photovoltaic-integrated sheets, in alignment with global green building standards.

The market’s performance is intrinsically linked to global macroeconomic stability and fluctuating raw material prices, notably steel, aluminum, and petrochemical derivatives. Roofing sheets are crucial for ensuring structural longevity and minimizing maintenance costs, making them a significant capital expenditure in large-scale construction. Product variants like corrugated sheets, profiled sheets, and standing seam systems cater to specific architectural and functional requirements. For instance, metal roofing sheets are favored in industrial and commercial settings due to their superior durability and recyclability, while asphalt shingles remain dominant in residential segments in North America due to cost-effectiveness and ease of installation. Manufacturers are continually investing in research and development to enhance product features, focusing on fire resistance, seismic stability, and extreme weather resilience, which are critical factors driving consumer choice and regulatory compliance worldwide.

Key market benefits include enhanced energy efficiency through reflective coatings, superior protection against high wind and heavy snow loads, and reduced lifecycle costs compared to traditional roofing materials. Driving factors include rapid urbanization in developing economies, supportive government policies promoting affordable housing and infrastructure development, and increasing consumer awareness regarding sustainable building practices. Furthermore, the persistent need for repairing or replacing aging infrastructure in mature markets, such as Europe and North America, provides a stable replacement demand base. The ongoing technological evolution in coating materials, particularly the introduction of advanced polymer coatings, is extending the lifespan and improving the protective qualities of roofing sheets, thereby sustaining robust market growth.

Roofing Sheets Market Executive Summary

The Roofing Sheets Market is characterized by resilient growth, primarily fueled by the sustained recovery in global construction activities, particularly in the residential and non-residential sectors across emerging markets. Business trends highlight a strong industry focus on product differentiation through material innovation, emphasizing lightweight composites, highly durable alloys, and improved insulation properties. Strategic mergers and acquisitions are common as large players seek to consolidate supply chains, gain access to specialized technology (like advanced coating systems), and expand their geographical footprint, especially into high-growth regions like Southeast Asia and the Middle East. Furthermore, stringent environmental regulations are compelling manufacturers to adopt closed-loop recycling processes and offer products with low embodied carbon, fundamentally altering manufacturing practices and procurement strategies.

Regional trends indicate that the Asia Pacific (APAC) region dominates the global market, driven by massive public and private investments in infrastructure, coupled with burgeoning housing demand, particularly in India, China, and ASEAN nations. North America and Europe, while slower in new construction growth, exhibit high demand for premium, high-performance roofing materials, focusing heavily on sustainability certifications, energy efficiency retrofits, and smart roofing integration. Latin America and the Middle East and Africa (MEA) are emerging as significant growth centers, underpinned by increasing commercial development and the urgent need for durable, climate-resilient roofing solutions capable of withstanding extreme temperature variations and harsh weather conditions.

Segment trends reveal that the metal roofing sheet segment holds a dominant market share due to its exceptional longevity, strength, and high degree of recyclability, making it the material of choice for large industrial and commercial buildings. However, the plastic (Polycarbonate and PVC) segment is projected to experience the fastest growth rate, fueled by its application in agricultural structures, greenhouses, and specialized architectural designs where light transmission is necessary. By application, the residential sector remains the largest consumer, but the commercial and industrial segments are driving value growth dueating to their preference for large-scale, high-specification products requiring advanced protective coatings and longer warranties. The overall market trajectory indicates a strong shift towards value-added, sustainable, and technologically enhanced roofing solutions.

AI Impact Analysis on Roofing Sheets Market

Common user questions regarding AI's impact on the Roofing Sheets Market revolve around predictive maintenance schedules, optimization of complex supply chains, quality control during manufacturing, and generative design for complex architectural requirements. Users are keen to understand how AI can minimize waste, forecast raw material price volatility, and automate quality inspection processes for defect detection on sheet coatings. The key themes summarized from user inquiries indicate high expectations for AI to enhance operational efficiency, reduce labor costs in assembly and inspection, and deliver highly customized roofing solutions that comply instantaneously with localized building codes. Concerns often focus on the required investment in infrastructure, data security, and the necessity of upskilling the existing workforce to manage AI-driven systems effectively.

The implementation of Artificial Intelligence and Machine Learning (ML) algorithms is revolutionizing the upstream manufacturing process of roofing sheets. AI-driven quality inspection systems utilizing computer vision are replacing manual checks, leading to near-perfect defect detection rates in coating thickness, color consistency, and profile geometry, significantly reducing product recalls and improving overall brand reputation. Furthermore, predictive modeling powered by ML is being deployed to optimize the blending ratios for composite and polymer roofing materials, ensuring maximum durability and performance while minimizing the use of expensive virgin raw materials. This data-driven approach allows manufacturers to achieve consistent product specifications regardless of minor variations in input material quality.

Downstream, AI is being utilized extensively in logistics and installation planning. Optimization algorithms determine the most cost-effective and time-efficient delivery routes, crucial for managing the bulky nature of roofing sheets, thereby minimizing transportation costs and site congestion. For large commercial projects, AI-powered BIM (Building Information Modeling) tools are facilitating the generative design of complex roof structures, optimizing sheet layout to reduce cutting waste and installation time. This integration of smart technology is transforming the market from a traditional material supply industry into a highly efficient, technology-enabled construction solutions provider, offering end-to-end efficiency improvements from mill to installation site.

- AI optimizes complex logistics and routing for bulky material delivery, reducing lead times and transportation costs.

- Machine Learning models predict fluctuations in key raw material prices (steel, polymers) to optimize procurement strategies.

- Computer vision systems enable automated, real-time quality control checks for surface defects and coating consistency during manufacturing.

- Generative design tools assist architects in optimizing sheet usage and layout for minimal wastage during complex roofing installations.

- AI-driven predictive maintenance schedules for manufacturing equipment increase uptime and reduce unexpected production delays.

- Advanced analytics support demand forecasting, minimizing inventory holding costs and ensuring timely supply chain response.

DRO & Impact Forces Of Roofing Sheets Market

The Roofing Sheets Market is significantly influenced by a dynamic interplay of Drivers, Restraints, and Opportunities, collectively forming the critical Impact Forces shaping its trajectory. Key drivers include robust global construction activity, particularly driven by rapid industrialization and urbanization across emerging economies, necessitating durable and scalable roofing solutions for new factories, warehouses, and mass housing projects. Government initiatives promoting sustainable infrastructure and mandating compliance with higher standards for energy efficiency in buildings further fuel the adoption of premium, insulated roofing sheets. The increasing frequency and intensity of extreme weather events worldwide also acts as a driver, accelerating the demand for resilient and high-strength roofing materials like specialized metal and fiber cement sheets capable of withstanding high winds, hail, and torrential rainfall.

Conversely, the market faces notable restraints, primarily centered around the volatility of raw material costs, particularly in the steel, aluminum, and petrochemical markets, which directly impact manufacturing costs and final product pricing, sometimes dampening construction spending. Environmental concerns and strict disposal regulations regarding traditional asphalt or non-recyclable polymer materials present a compliance challenge for manufacturers, necessitating costly shifts in production techniques. Furthermore, the availability of alternative roofing technologies, such as green roofs (vegetation-based) or solar tiles, poses a competitive restraint, particularly in high-end, environmentally conscious urban markets. Labor shortages in skilled installation crews also restrain market potential, particularly for specialized or complex roofing systems that require precise handling and sealing techniques.

Opportunities abound in the pursuit of innovative and sustainable solutions. The development of advanced photovoltaic (PV) integrated roofing sheets and cool roof technologies that reflect solar radiation offers significant avenues for market penetration, aligning with global climate objectives and generating dual benefits of protection and energy production. Emerging markets, characterized by rapid population growth and expanding middle classes, represent untapped territories for standardized, cost-effective roofing solutions. Additionally, technological advancements in coating formulations that provide self-cleaning properties, enhanced corrosion resistance, and extended warranties present manufacturers with the opportunity to capture premium pricing segments and build long-term customer loyalty through superior product lifecycle performance, mitigating the impact of raw material fluctuations.

Segmentation Analysis

The Roofing Sheets Market is intricately segmented based on Material Type, Application, End-User, and Construction Type, allowing for targeted market strategies and specialized product development. Material segmentation provides the foundational basis, differentiating products by core composition, durability, cost structure, and ideal application environment. The shift toward sustainable materials has significantly impacted this segmentation, favoring highly recyclable or long-life materials. Application segmentation focuses on the functional structure, such as industrial facilities requiring large span and high-strength sheets, versus residential buildings prioritizing aesthetics and thermal insulation. This granular analysis is crucial for understanding regional market variations, as material preference often correlates directly with localized building codes, climate conditions, and prevailing construction practices.

The End-User classification is critical, separating demand generated by residential, commercial, and industrial construction, each exhibiting distinct purchasing behaviors and volume requirements. For example, residential construction drives bulk volume demand for standardized products, whereas industrial end-users demand customized specifications for chemical resistance or extreme load bearing. Furthermore, segmentation by Construction Type—new construction versus repair and replacement (R&R)—highlights the resilience of the market, as R&R activities often provide a stabilizing factor even when new construction projects slow down due to economic instability. The increasing age of existing building stock in developed nations ensures a stable, consistent demand stream for maintenance and upgrade projects, supporting the repair and replacement segment.

Understanding these segment dynamics is vital for market players defining their product portfolios and pricing strategies. High-performance, specialty coatings and materials designed for hurricane zones or extreme temperature variations fall into niche segments commanding higher margins. Conversely, basic corrugated metal and asphalt sheets dominate the high-volume, low-margin segments driven by affordable housing projects. The trend towards modular construction is also creating a new micro-segment requiring prefabricated, dimensionally precise roofing components delivered as integrated systems rather than individual sheets, further diversifying the market landscape and necessitating supply chain flexibility.

- By Material Type:

- Metal (Steel, Aluminum, Zinc)

- Plastics (Polycarbonate, PVC, FRP)

- Asphalt/Bitumen

- Fiber Cement

- Composites (Glass Fiber Reinforced Plastic)

- By Application:

- Corrugated Roofing Sheets

- Profiled Roofing Sheets

- Standing Seam Roofing Sheets

- Flat Roofing Sheets

- By End-User:

- Residential

- Commercial (Offices, Retail, Hospitality)

- Industrial (Warehouses, Factories, Logistics Centers)

- Agricultural (Sheds, Greenhouses)

- By Construction Type:

- New Construction

- Repair and Replacement (R&R)

Value Chain Analysis For Roofing Sheets Market

The value chain for the Roofing Sheets Market begins with the upstream sourcing and processing of core raw materials, predominantly steel, aluminum, petrochemicals (for plastics and asphalt), and cement/fibers. This upstream segment is highly capital-intensive and subject to significant global commodity price volatility. Manufacturers of roofing sheets, positioned midstream, transform these raw materials using processes such as rolling, coating, profiling, and curing. Technological investment in this stage focuses on automation to maintain tight dimensional tolerances, applying highly specialized protective coatings (e.g., anti-corrosion, UV resistance), and ensuring compliance with sustainability standards, such as energy-efficient manufacturing processes and waste reduction.

The downstream segment involves distribution, sales, and installation services. The distribution channel is bifurcated into direct sales to large commercial contractors and indirect sales through a vast network of distributors, wholesalers, and specialized building material retailers. Direct sales dominate in large-scale industrial projects where customization and long-term supply agreements are necessary. In contrast, the indirect channel serves the fragmented residential market and smaller construction firms, prioritizing availability, quick delivery, and technical support. The effectiveness of the distribution network is paramount, as roofing sheets are bulky and transport costs can be substantial, making localized warehousing and efficient logistics critical for competitive advantage.

Installation and post-sale services form the final, crucial link in the value chain. Professional installation ensures product warranties remain valid and guarantees optimal performance against weather events. Leading manufacturers often differentiate themselves by offering extensive technical training for installers and providing integrated solutions, including fasteners, sealants, and ventilation systems, alongside the sheets themselves. The quality of installation directly affects the perceived value and durability of the roofing system, making certified installers an essential element of the manufacturer's offering. Furthermore, indirect channels, such as large home improvement stores, play a key role in influencing consumer choice for residential repair and renovation projects, often bundling materials and standardized installation services.

Roofing Sheets Market Potential Customers

Potential customers for the Roofing Sheets Market span a broad spectrum of the construction economy, categorized primarily into three main groups: residential builders/homeowners, commercial developers, and industrial operators. The residential segment constitutes the largest volume of demand, driven by both new single-family and multi-family housing projects, as well as the substantial replacement market created by homeowners seeking to upgrade aging roofs for better energy efficiency or superior durability against increasingly severe weather. This segment often values aesthetic appeal, cost-effectiveness, and ease of installation, making material types like asphalt shingles and standardized metal sheets highly relevant.

The commercial sector, including developers of retail complexes, educational institutions, healthcare facilities, and office buildings, represents a high-value customer base that prioritizes longevity, warranty periods, fire resistance, and the integration of smart building technologies. Commercial customers typically purchase high-specification products, such as insulated metal panels (IMPs) or specialized single-ply membrane sheets (often not strictly sheets, but highly competitive alternatives), where thermal performance and minimal maintenance costs over decades are key purchasing criteria. These customers often engage directly with manufacturers or specialized contractors to ensure precise specification adherence and complex architectural requirements are met.

Industrial end-users, encompassing manufacturers, logistics and warehousing companies, and agricultural entities, demand products focused purely on structural strength, corrosion resistance, and coverage area efficiency. Large industrial roofs often cover vast expanses, necessitating lightweight yet robust materials like corrugated galvanized iron or high-strength fiber cement, capable of resisting harsh chemical environments or providing efficient light transmission (e.g., plastic sheets in greenhouses). These procurement decisions are usually driven by total cost of ownership (TCO) over a long asset life, making durability and specific material treatments for environmental resilience paramount in the selection process.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 95.5 Billion |

| Market Forecast in 2033 | USD 141.6 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Nippon Steel Corporation, BlueScope Steel Limited, Tata Steel, Kingspan Group, Saint-Gobain, GAF Materials Corporation, CertainTeed, Etex Group, Fletcher Building, Owens Corning, Safal Group, Firestone Building Products, Duro-Last, IKO Group, BMI Group, Polyglass, Isopan, CSR Limited, Interpon, and Carlisle Companies Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Roofing Sheets Market Key Technology Landscape

The technology landscape in the Roofing Sheets Market is rapidly evolving, driven primarily by demands for enhanced durability, sustainability, and energy performance. A major technological focus is the development of advanced coating systems for metal sheets. High-performance polymer coatings, such such as specialized PVDF (Polyvinylidene Fluoride) and SMP (Silicone Modified Polyester), are crucial for extending product life by offering superior resistance to UV degradation, chalking, fading, and corrosion in harsh industrial or marine environments. These coatings are now being engineered to incorporate self-healing properties, which automatically seal minor scratches or abrasions that could otherwise lead to premature material failure. Furthermore, the integration of reflective pigments for cool roofing technology is a critical innovation, significantly reducing a building’s heat gain and lowering cooling energy consumption, directly addressing mandated energy efficiency standards in many global markets.

Another pivotal area of innovation lies in the material science of composite and plastic sheets. Manufacturers are increasingly utilizing Fiber Reinforced Polymer (FRP) and advanced polycarbonate formulations that offer high impact resistance, excellent light transmission properties, and superior thermal insulation without adding significant weight. Research is concentrating on incorporating recycled content and bio-based polymers into these sheet formulations to enhance sustainability profiles without compromising structural integrity. For instance, sophisticated co-extrusion technologies are used to create multi-layered sheets where each layer is optimized for a specific function—structural support, UV protection, or thermal barrier—resulting in high-specification, yet resource-efficient, products suitable for diverse applications like agricultural greenhouses and advanced commercial skylights.

The manufacturing process itself is witnessing technological transformation through digitalization and automation. Precision profiling and continuous production lines minimize material variations and ensure dimensional accuracy, which is vital for quick and seamless installation on site. Furthermore, the development of integrated roofing systems, where the sheet is supplied with pre-attached insulation, fastening systems, and edge details (such as Insulated Metal Panels or IMPs), represents a significant technological leap. These systems reduce reliance on manual labor, improve installation speed, and guarantee defined thermal performance parameters. The push towards BIPV (Building Integrated Photovoltaics), where solar cells are seamlessly incorporated into the aesthetic design and structure of the roofing sheet itself, is perhaps the most disruptive technology, transforming the roof from a protective covering into an active energy generator, setting a new standard for sustainable construction.

Regional Highlights

The Asia Pacific (APAC) region stands out as the undisputed leader in the global Roofing Sheets Market, primarily due to unprecedented levels of infrastructure development and rapid urbanization, especially across high-density population centers in China, India, and Southeast Asian countries. Massive governmental investments in affordable housing schemes, coupled with exponential growth in the industrial and manufacturing sectors, generate colossal demand for cost-effective, durable metal and fiber cement sheets. While lower-cost corrugated sheets dominate the basic construction segment, there is a burgeoning market for premium, coated sheets driven by foreign direct investment in high-specification commercial and data center construction, leading to significant market diversification and technological adoption.

North America and Europe represent mature markets characterized by stringent regulatory environments focused on energy efficiency, fire safety, and environmental impact. Growth here is primarily driven by the robust Repair and Replacement (R&R) cycle, as aging housing and commercial building stock requires renovation. Demand in these regions is heavily skewed towards high-performance products, including highly insulated metal panels (IMPs), cool roof systems, and sustainable, long-warranty products. The emphasis is less on sheer volume and more on value-added features like integrated smart sensors for leak detection and superior thermal resistance, commanding higher average selling prices compared to basic materials.

Latin America (LATAM) and the Middle East and Africa (MEA) are emerging as high-potential growth zones. LATAM’s market growth is boosted by economic stabilization and a pressing need for resilient housing, particularly in areas susceptible to seismic activity or heavy rainfall, favoring high-strength galvanized steel sheets. The MEA region, particularly the Gulf Cooperation Council (GCC) countries, is witnessing massive commercial and mega-project construction initiatives. The intense solar radiation and high temperatures in this region drive specific demand for cool roofing materials and highly durable, UV-resistant coatings to ensure longevity and mitigate heat island effects, positioning specialized material suppliers for high growth in this specific geographical cluster.

- Asia Pacific (APAC): Dominates the market share driven by massive urbanization, industrial expansion, and government housing projects in India, China, and Indonesia. High demand for both cost-effective galvanized iron and specialty coated steel.

- North America: Focuses on the replacement market and premium products. Strong regulatory push for energy-efficient materials, driving adoption of cool roofs and IMPs (Insulated Metal Panels).

- Europe: Characterized by stringent environmental standards and a high preference for sustainable, aesthetic, and recyclable materials. Steady demand from renovation projects and growth in green building certifications.

- Middle East & Africa (MEA): High growth driven by large-scale infrastructure projects (e.g., hospitality, logistics) and a strong need for climate-resilient sheets with superior heat reflectivity and UV protection.

- Latin America (LATAM): Growth tied to stable economic recovery and housing demand, with materials selected based on resilience to extreme weather and affordability.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Roofing Sheets Market.- Nippon Steel Corporation

- BlueScope Steel Limited

- Tata Steel

- Kingspan Group

- Saint-Gobain

- GAF Materials Corporation

- CertainTeed

- Etex Group

- Fletcher Building

- Owens Corning

- Safal Group

- Firestone Building Products

- Duro-Last

- IKO Group

- BMI Group

- Polyglass

- Isopan

- CSR Limited

- Interpon

- Carlisle Companies Inc.

Frequently Asked Questions

Analyze common user questions about the Roofing Sheets market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the key drivers of demand for sustainable roofing sheets?

The primary drivers are stringent government energy efficiency mandates (e.g., Green Building Codes), escalating corporate sustainability goals (ESG initiatives), and increasing consumer desire for reduced utility bills via energy-saving technologies like cool roofs and BIPV (Building Integrated Photovoltaics).

Which material segment dominates the global Roofing Sheets Market?

The Metal Roofing Sheets segment, particularly steel and aluminum, maintains dominance due to superior longevity, high strength-to-weight ratio, excellent fire resistance, and nearly 100% recyclability, making it the preferred choice for industrial and large commercial applications globally.

How is the volatility of raw material prices impacting market profitability?

Raw material price volatility, especially in steel, aluminum, and petrochemicals, directly compresses manufacturer margins. Companies mitigate this by implementing forward hedging strategies, optimizing production efficiency, and focusing on high-value, coated products where the material cost is a smaller percentage of the final price.

What role does the Repair and Replacement (R&R) segment play in market stability?

The R&R segment is crucial for market stability in mature economies like North America and Europe. It provides resilient, non-cyclical demand independent of new construction booms, driven by the necessity to replace roofs that have reached the end of their lifecycle or sustained damage from increasingly severe weather events.

What is the most significant technological innovation transforming roofing sheets?

The most significant innovation is the integration of advanced functional coatings. These specialized polymer coatings (e.g., PVDF) offer extreme protection against corrosion, UV, and fading, while cool roof coatings drastically improve thermal performance, directly contributing to a building's energy efficiency compliance.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager