Roots Blower Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 432182 | Date : Dec, 2025 | Pages : 243 | Region : Global | Publisher : MRU

Roots Blower Market Size

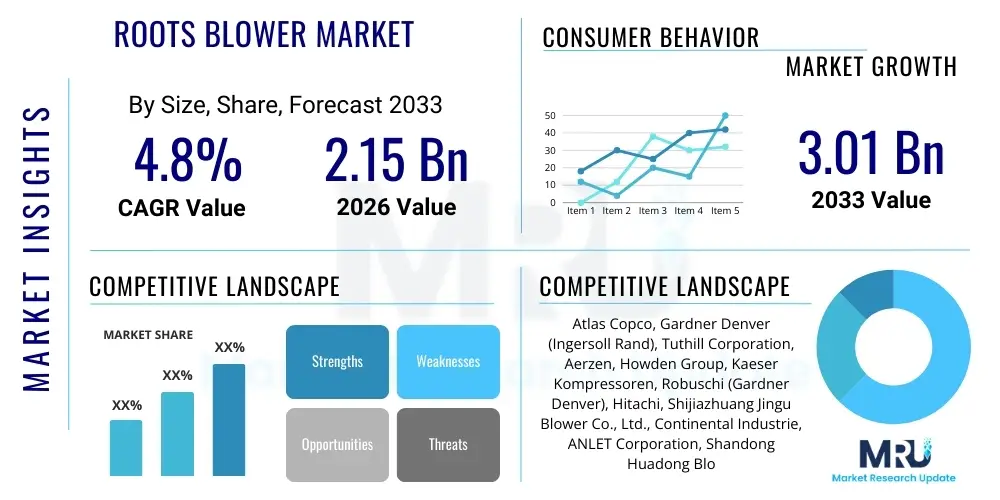

The Roots Blower Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.8% between 2026 and 2033. The market is estimated at $2.15 Billion in 2026 and is projected to reach $3.01 Billion by the end of the forecast period in 2033.

Roots Blower Market introduction

The Roots Blower Market encompasses the production and distribution of positive displacement blowers that utilize rotating interlocking lobes (rotors) to trap and transfer gases, primarily air, in industrial systems. Roots blowers, known for their robust design and ability to deliver consistent air flow at varying pressures, are foundational components in numerous critical infrastructure and manufacturing processes. They operate on the principle of volumetric displacement, ensuring a relatively constant volume of gas is moved with each rotation, making them highly reliable for applications requiring precise flow control. The simplicity of their mechanism—typically featuring two tri-lobe or twin-lobe rotors synchronized by timing gears—contributes to their lower maintenance requirements compared to dynamic compressors, reinforcing their market penetration across mature and emerging economies.

Major applications for Roots blowers are predominantly found in environmental management and material handling sectors. Critically, the wastewater treatment industry relies heavily on these blowers for aeration processes in activated sludge systems, where oxygen is essential for microbial activity to break down pollutants. Beyond aeration, they are indispensable in pneumatic conveying systems, providing the motive force to transport dry bulk materials like powders, granules, and pellets in industries such as cement, food processing, and pharmaceuticals. Their efficacy in maintaining contamination-free air or gas streams, coupled with their cost-effectiveness at lower pressure ratios, solidifies their position as essential equipment.

The market growth is primarily driven by global expansion in municipal infrastructure, stringent environmental regulations necessitating upgraded wastewater treatment facilities, and increased automation in manufacturing requiring efficient pneumatic systems. Key benefits include high volumetric efficiency, relatively simple operation, and durability, especially in demanding environments. However, the market faces constraints related to energy consumption efficiency challenges compared to newer technologies like high-speed turbo blowers, compelling manufacturers to invest heavily in advanced lobe geometries and motor technologies to enhance overall operational performance and meet evolving industry standards.

Roots Blower Market Executive Summary

The Roots Blower Market exhibits stable growth driven primarily by structural investments in global infrastructure, particularly municipal water and wastewater management upgrades across Asia Pacific and Latin America. Key business trends indicate a strong industry focus on optimizing energy efficiency through the adoption of Variable Frequency Drives (VFDs) and specialized acoustic enclosures to meet increasingly strict noise and energy regulatory standards. Competition is escalating, characterized by manufacturers developing differentiated tri-lobe designs over traditional twin-lobe models to minimize pulsations and improve efficiency, coupled with offering comprehensive service and preventative maintenance contracts to secure long-term client relationships.

Regionally, Asia Pacific maintains market dominance, fueled by rapid industrialization, urbanization, and governmental mandates for expanding and modernizing water treatment capabilities in nations like China and India. North America and Europe, while representing mature markets, show consistent demand driven by replacement cycles, technological upgrades to comply with efficiency directives (such as IE4 motor standards), and sustained activity in the chemical and food processing sectors. Latin America and the Middle East and Africa (MEA) are emerging as high-growth regions, spurred by significant investments in mining, oil and gas infrastructure, and developing utility networks.

From a segmentation perspective, the tri-lobe segment is projected to capture a larger market share due to its quieter operation and reduced maintenance costs compared to twin-lobe variants, addressing a critical operational requirement for modern facilities. Application-wise, wastewater treatment remains the largest segment by revenue, though pneumatic conveying is anticipated to register the highest growth rate as logistics and automated material handling become central to industrial efficiency across the manufacturing landscape. The end-use segment is witnessing technological convergence, with robust demand from the general manufacturing and chemical processing sectors requiring durable, reliable air compression solutions for diverse tasks.

AI Impact Analysis on Roots Blower Market

Common user questions regarding AI's impact on the Roots Blower Market often center on predictive maintenance, operational efficiency improvements, and the integration of smart controls. Users are keenly interested in how AI can extend the blower's operational lifespan, reduce unexpected downtime, and optimize energy consumption—a significant operational cost. The major themes emerging from these queries relate to the feasibility of leveraging machine learning algorithms to analyze vibration, temperature, and current draw data collected via integrated sensors, thereby transforming traditional reactive maintenance strategies into proactive, condition-based monitoring systems. Furthermore, users question whether AI-driven control systems can dynamically adjust blower speed (via VFDs) in real-time based on fluctuating demand (e.g., oxygen requirements in a biological reactor), ensuring maximum process efficiency while minimizing power usage.

The integration of Artificial Intelligence primarily affects the operational and service life cycle of Roots blowers rather than their core mechanical design. AI algorithms are increasingly being deployed in Supervisory Control and Data Acquisition (SCADA) systems and dedicated blower control units to provide sophisticated fault detection and diagnostics. By analyzing multivariate data streams, AI can detect subtle anomalies indicative of rotor wear, bearing degradation, or filter clogging long before critical failure occurs. This capability drastically reduces Total Cost of Ownership (TCO) by optimizing maintenance scheduling and inventory management for spare parts, moving away from time-based or routine inspections towards data-driven interventions.

Furthermore, AI is instrumental in enhancing the energy footprint of Roots blower installations, addressing their inherent limitation regarding lower efficiency compared to modern turbo blowers. Machine learning models analyze historical and real-time process data (such as Dissolved Oxygen levels, pressure drops, and throughput rates) to identify the optimal operational curve, ensuring that the blower operates at the most efficient point for the specific duty cycle. This optimization is crucial in high-energy consumption applications like municipal aeration basins, where even small percentage improvements in energy use translate into massive annual savings, solidifying the long-term viability of Roots technology in these critical fields.

- AI-driven Predictive Maintenance: Utilizing machine learning on sensor data (vibration, temperature) to forecast mechanical failures and optimize service intervals, maximizing uptime.

- Energy Optimization Algorithms: Real-time control systems leveraging AI to dynamically adjust blower speed and pressure settings based on process demand (e.g., DO levels in aeration tanks).

- Enhanced Fault Detection: Identifying subtle operational anomalies that human operators or standard alarms might miss, improving diagnostic accuracy.

- Digital Twins Creation: Developing virtual models of blower systems to simulate various operational scenarios and test control strategies before implementation.

- Automated Reporting and Compliance: AI summarizing performance data and generating reports automatically for energy audits and regulatory compliance.

DRO & Impact Forces Of Roots Blower Market

The Roots Blower Market is shaped by a complex interplay of Drivers, Restraints, and Opportunities (DRO), which collectively form the Impact Forces dictating market trajectory. A primary driver is the accelerating global need for improved municipal and industrial wastewater infrastructure, particularly in developing nations, where population growth and industrial discharge necessitate robust aeration solutions. This demand is coupled with mandatory environmental regulations imposing stricter limits on effluent quality, which directly translates into increased investment in reliable aeration equipment like Roots blowers. However, the market faces a significant restraint in the form of intense competition from advanced blower technologies, notably high-speed magnetic bearing turbo blowers and screw blowers, which offer superior energy efficiency and lower noise levels, compelling Roots blower manufacturers to rapidly innovate to bridge the efficiency gap.

A substantial opportunity lies in the retrofitting and replacement market within mature economies. Many older wastewater treatment plants and industrial facilities still utilize outdated, inefficient blower technologies. The high operational costs associated with these legacy systems, combined with incentives for energy efficiency upgrades, create a strong business case for replacing them with modern, VFD-equipped Roots blowers. Furthermore, the expansion of the aquaculture industry, requiring large volumes of reliable air injection for fish farming, presents a high-growth niche application. Impact forces primarily revolve around the Total Cost of Ownership (TCO); while the initial capital investment for a Roots blower is often lower, its perceived higher long-term energy cost relative to competitors acts as a constant pressure point driving technological enhancement in rotor design and sealing mechanisms.

Regulatory frameworks, such as those governing noise pollution (e.g., EU Noise Directive) and motor efficiency standards (e.g., IE3/IE4 requirements), exert significant influence as key impact forces. Compliance with these standards necessitates continuous product redesign, pushing manufacturers toward incorporating specialized acoustic enclosures and integrating premium, highly efficient motors, thereby increasing production costs but enhancing market competitiveness. The persistent demand for simple, durable, and easily maintainable equipment in remote or harsh industrial environments, such as mining and cement production, ensures a foundational level of market stability for the proven Roots blower technology, irrespective of competition in high-tech urban utilities.

Segmentation Analysis

The Roots Blower Market is segmented based on critical parameters including type, application, and end-use industry, providing a granular view of demand distribution and growth opportunities across specific technological niches and operational environments. The analysis reveals that technological segmentation based on lobe design—twin-lobe versus tri-lobe—is crucial, as it directly impacts performance characteristics such as noise levels, pulsation reduction, and overall mechanical efficiency. Application segmentation highlights the distinct operational requirements of critical sectors, ranging from the low-pressure, high-volume demands of wastewater aeration to the high-pressure needs of conveying systems. Understanding these segmentations is paramount for manufacturers aiming to tailor product specifications and marketing strategies effectively to address specialized user needs and regulatory compliance within target industries.

- By Type:

- Twin-Lobe Roots Blower

- Tri-Lobe Roots Blower

- Helical-Lobe Roots Blower

- By Application:

- Wastewater Treatment (Aeration)

- Pneumatic Conveying (Dilute Phase and Dense Phase)

- Chemical and Petrochemical Processing

- Aquaculture and Fisheries

- Power Generation and Flue Gas Desulfurization (FGD)

- General Industrial Applications (Dust Collection, Vacuum systems)

- By End-Use Industry:

- Municipal Utilities and Water Management

- Manufacturing (Textile, Automotive, General Fabrication)

- Cement and Mining

- Food and Beverage Processing

- Oil and Gas

- Pharmaceuticals

- By Drive Type:

- Fixed Speed Blowers

- Variable Frequency Drive (VFD) Blowers

- By Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America (LATAM)

- Middle East and Africa (MEA)

Value Chain Analysis For Roots Blower Market

The value chain for the Roots Blower Market begins upstream with raw material suppliers and specialized component manufacturers. Upstream activities involve sourcing high-quality materials such as cast iron, aluminum alloys, and specialized steels for casing, rotors, and gears, along with critical components like bearings, seals, and highly efficient electric motors (often required to meet IE3/IE4 standards). The relationship between blower manufacturers and precision engineering firms that supply standardized parts is vital, as the reliability and longevity of a Roots blower are highly dependent on the precision machining of the rotors and the quality of the timing gears that maintain rotor synchronization. Fluctuations in commodity prices, particularly steel and aluminum, directly impact the manufacturing cost, necessitating strategic procurement and inventory management by key market players.

The midstream phase centers on the manufacturing, assembly, and testing of the complete blower unit. Leading companies maintain stringent quality control processes and often integrate high-precision CNC machining capabilities in-house to ensure tight tolerances for the rotor-to-casing clearances, which are crucial for volumetric efficiency. Post-manufacturing, the distribution channel plays a pivotal role. The primary channels are categorized into direct sales and indirect sales. Direct sales are typically preferred for large-scale municipal projects or major industrial contracts, enabling manufacturers to provide specialized engineering consultancy, installation, and commissioning services directly to the end-user, ensuring optimal system integration and performance verification.

Indirect distribution relies heavily on regional distributors, specialized industrial equipment resellers, and value-added system integrators (VARS). These partners are essential for reaching smaller industrial clients, providing localized stock, offering immediate technical support, and integrating the blower into larger pneumatic conveying or utility systems. Downstream activities involve comprehensive after-sales support, including spare parts supply, preventative maintenance contracts, and repair services. Given the critical nature of many applications (e.g., wastewater aeration), robust service networks are a key competitive differentiator, ensuring rapid response times and minimal operational downtime for the end-user, thereby maximizing the lifetime value derived from the initial purchase.

Roots Blower Market Potential Customers

Potential customers for Roots blowers are diverse, spanning both the public utility sector and various heavy and light industrial segments, all requiring reliable positive displacement air or gas flow. The most significant customer base comprises municipal authorities and private operators managing wastewater treatment plants. These end-users rely on Roots blowers as the workhorses of their aeration basins, where consistent, oil-free air supply is non-negotiable for the biological treatment process. The purchasing decisions in this sector are driven by factors such as long-term reliability, energy efficiency ratings, ease of maintenance, and adherence to specific regulatory standards regarding dissolved oxygen levels and noise limits.

Another major demographic includes companies within the manufacturing and processing industries that utilize pneumatic conveying for material transport. This encompasses cement production (for kiln feed, dust handling), food and beverage processing (for conveying grain, sugar, or powders), and chemical facilities (for process gas movement). For these industrial buyers, the primary considerations are the blower’s capacity to handle specific pressure requirements, resistance to harsh operating environments, and the ability to ensure clean, contaminant-free conveyance air to prevent product spoilage or process interruption. The longevity and robust nature of Roots blowers make them particularly attractive in applications where continuous duty cycles are the norm and where system failure can lead to severe production losses.

Furthermore, the pharmaceutical, aquaculture, and power generation sectors represent high-value niche customer segments. Pharmaceutical companies use them for vacuum systems and pneumatic transport in controlled environments, demanding high standards of air quality and material compatibility. Aquaculture farms require reliable oxygen delivery to large fish tanks. Power plants utilize Roots blowers in flue gas desulfurization (FGD) processes and ash handling. These diverse customer groups emphasize durability, low noise performance (especially in urban installations), and the availability of sophisticated control integration options (like VFD compatibility) to optimize their specific operational throughput and meet stringent industry quality benchmarks.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $2.15 Billion |

| Market Forecast in 2033 | $3.01 Billion |

| Growth Rate | 4.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Atlas Copco, Gardner Denver (Ingersoll Rand), Tuthill Corporation, Aerzen, Howden Group, Kaeser Kompressoren, Robuschi (Gardner Denver), Hitachi, Shijiazhuang Jingu Blower Co., Ltd., Continental Industrie, ANLET Corporation, Shandong Huadong Blower Co., Ltd., Jiangsu Jintongling Fluid Machine Technology Co., Ltd., Greentech Industrial Blower, Everest Blowers Pvt. Ltd., Shandong Air Blower Co., Ltd., Runtech Systems, Busch Vacuum Solutions, Osaka Blower Mfg. Co., Ltd., Sanyo Techno. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Roots Blower Market Key Technology Landscape

The technology landscape in the Roots Blower Market is primarily focused on incremental innovations aimed at improving energy efficiency, reducing operational noise, and extending maintenance intervals, rather than radical changes to the core positive displacement mechanism. The shift from the traditional twin-lobe design to the more sophisticated tri-lobe configuration remains a central technological trend. Tri-lobe blowers offer smoother flow characteristics and reduced pressure pulsation, which results in significantly lower operational noise levels and vibration. This redesign minimizes the backflow of air, slightly increasing volumetric efficiency and, critically, extending the lifespan of bearings and seals by reducing mechanical stress associated with pulsation, making them essential for compliance with stricter environmental and occupational safety regulations globally.

A second crucial area of technological advancement involves the pervasive integration of advanced Variable Frequency Drives (VFDs) and sophisticated electronic controls. While the core blower unit remains mechanical, its peripheral control system has become highly digitized. VFDs allow the blower speed to be precisely matched to the actual process demand, minimizing energy waste during periods of low load—a significant advantage in fluctuating demand applications like municipal aeration where oxygen needs vary throughout the day. Furthermore, the development of intelligent monitoring systems, incorporating high-precision sensors for temperature, pressure, and vibration, enables the collection of real-time operational data, facilitating the transition towards AI-driven predictive maintenance and further optimization of the entire pneumatic system.

The third major technological focus is the continuous effort to enhance the durability and sealing integrity of the units, particularly through specialized coatings and material science improvements. Manufacturers are exploring advanced materials for rotor coatings and wear plates to minimize internal leakage (slip) which negatively impacts efficiency, especially as the blower ages. Additionally, the adoption of oil-free designs, utilizing specialized sealing arrangements to prevent process air contamination, is becoming standard across sensitive industries like food, pharmaceutical, and wastewater treatment, ensuring product quality and adherence to environmental standards. These incremental, yet vital, technological refinements ensure that Roots blowers remain a viable and competitive option against newer, more complex compression technologies in their established application niches.

Regional Highlights

The Roots Blower Market exhibits distinct dynamics across key geographical regions, with growth primarily concentrated in areas undergoing rapid industrialization or those investing heavily in sustainable infrastructure.

- Asia Pacific (APAC): This region dominates the global market, driven by massive public expenditure on water infrastructure and the exponential growth of manufacturing hubs, particularly in China, India, and Southeast Asian nations. The need for basic utility services, combined with increasing regulatory pressure to manage industrial wastewater discharge effectively, ensures a continuously high demand for robust and cost-effective Roots blower units.

- North America: Characterized by a mature market focused on replacement cycles and efficiency upgrades. Demand is steady, fueled by the stringent requirements for energy efficiency, leading to a high penetration rate of VFD-equipped blowers and premium tri-lobe units that emphasize lower noise and vibration profiles. The oil and gas sector and food processing industries are significant consumers.

- Europe: Similar to North America, Europe is a mature market driven by stringent environmental regulations, particularly those concerning noise emissions and energy consumption (IE4 motor standards). High technological adoption means competition from screw and turbo blowers is strong, prompting Roots manufacturers to focus on delivering customized, integrated blower packages with advanced monitoring capabilities.

- Latin America (LATAM): This region represents a high-potential emerging market. Growth is accelerating due to critical investments in mining operations (Chile, Peru) and necessary expansions of municipal water and sewage networks in Brazil and Mexico, providing opportunities for both small and large capacity blowers. Price sensitivity remains a key factor in procurement decisions.

- Middle East and Africa (MEA): Growth is primarily linked to large-scale infrastructure projects, including petrochemical plants, desalination facilities, and urban development in the GCC countries. The harsh operating conditions (high temperatures, dust) necessitate blowers built with high material durability and robust sealing systems, making the reliability of Roots technology particularly appealing.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Roots Blower Market.- Atlas Copco

- Gardner Denver (Ingersoll Rand)

- Tuthill Corporation

- Aerzen

- Howden Group

- Kaeser Kompressoren

- Robuschi (Gardner Denver)

- Hitachi

- Shijiazhuang Jingu Blower Co., Ltd.

- Continental Industrie

- ANLET Corporation

- Shandong Huadong Blower Co., Ltd.

- Jiangsu Jintongling Fluid Machine Technology Co., Ltd.

- Greentech Industrial Blower

- Everest Blowers Pvt. Ltd.

- Shandong Air Blower Co., Ltd.

- Runtech Systems

- Busch Vacuum Solutions

- Osaka Blower Mfg. Co., Ltd.

- Sanyo Techno

Frequently Asked Questions

Analyze common user questions about the Roots Blower market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between twin-lobe and tri-lobe Roots blowers?

Tri-lobe blowers feature three rotors instead of two, resulting in reduced air pulsation and noise levels compared to twin-lobe designs. This smoother operation enhances mechanical longevity and reduces maintenance requirements, making tri-lobe models generally preferred for quieter, more efficient modern applications.

What is the main driving factor for the Roots Blower Market growth?

The central driver is the global increase in municipal and industrial wastewater treatment infrastructure projects. Roots blowers are essential for the aeration process in activated sludge systems, and stricter environmental regulations worldwide necessitate continuous investment in new and upgraded facilities.

How do Roots blowers compare to newer technologies like screw blowers in terms of efficiency?

Screw blowers generally offer superior isothermal efficiency over Roots blowers, especially at high-pressure ratios, due to internal compression. However, Roots blowers maintain a competitive edge due to their lower initial capital cost, simpler maintenance requirements, and higher reliability in highly demanding or dirty air applications.

What role does the Variable Frequency Drive (VFD) play in modern Roots blower operation?

VFDs are crucial for energy efficiency. They allow the blower speed and output air volume to be precisely modulated based on the real-time needs of the process, preventing energy waste associated with running the blower constantly at maximum capacity, significantly reducing overall operational costs.

Which geographical region holds the largest market share for Roots blowers?

The Asia Pacific (APAC) region currently holds the largest market share. This is attributed to rapid urbanization, sustained industrial expansion, and significant governmental investment in water and wastewater management infrastructure across countries like China and India.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager