Rotary Rheometer Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 434852 | Date : Dec, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Rotary Rheometer Market Size

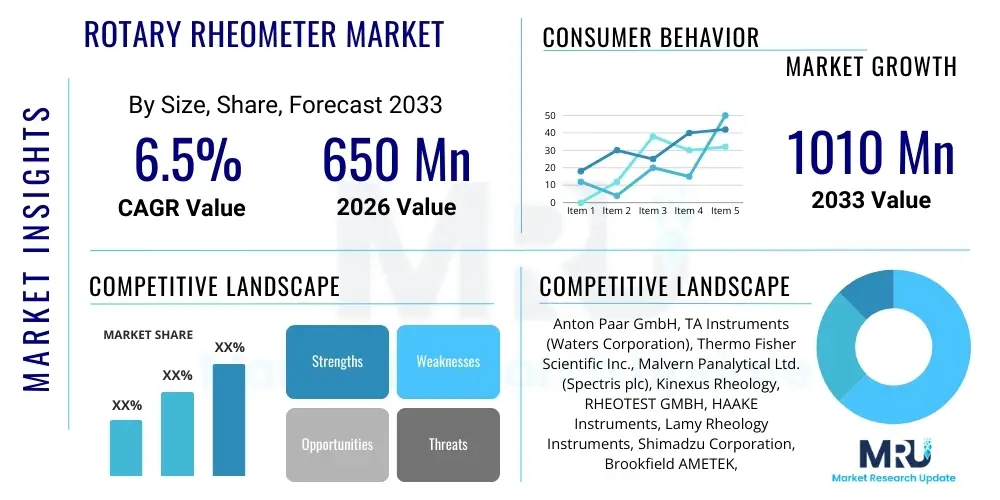

The Rotary Rheometer Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2026 and 2033. The market is estimated at USD 650 Million in 2026 and is projected to reach USD 1010 Million by the end of the forecast period in 2033.

Rotary Rheometer Market introduction

The Rotary Rheometer Market is defined by the manufacturing, sales, and service of instruments designed to measure the flow and deformation properties (rheology) of complex fluids, soft solids, and molten polymers. These instruments apply a controlled shear rate or shear stress to a sample and measure the resultant strain or stress response, providing crucial insights into viscosity, elasticity, yield stress, and thixotropy. Rotary rheometers are indispensable tools across numerous industrial and academic research sectors where material stability, processability, and end-product performance are governed by rheological characteristics. Key applications span quality control in manufacturing lines, fundamental research in material science, and formulation development across highly regulated industries.

The product description encompasses various instrument types, primarily categorized by their geometry (cone-and-plate, parallel plate, coaxial cylinder) and operational modes (stress-controlled or strain-controlled). Modern rotary rheometers incorporate advanced features such as temperature control units (e.g., Peltier plates, convection ovens), high-speed data acquisition systems, and specialized accessories for testing samples under non-ambient conditions, such as high pressure or magnetic fields. The primary benefits of utilizing these sophisticated devices include optimizing manufacturing processes, reducing material waste, ensuring batch-to-batch consistency, accelerating product innovation cycles, and verifying compliance with stringent industry standards, especially in the polymer and pharmaceutical sectors.

Driving factors propelling market expansion include the increasing demand for advanced materials with tailored viscoelastic properties, particularly in the electronics and aerospace industries. Furthermore, the stringent regulatory environment governing product performance and safety in the food and beverage, cosmetics, and pharmaceutical sectors necessitates precise rheological measurements throughout the product lifecycle. The global trend toward digitalization and laboratory automation also contributes significantly, enabling higher throughput and more complex experimental protocols, thereby driving the adoption of high-end rotary rheometer systems capable of unattended operation.

Rotary Rheometer Market Executive Summary

The Rotary Rheometer Market is exhibiting robust growth, fundamentally driven by pervasive applications in quality assurance and research and development across sophisticated manufacturing verticals. Current business trends indicate a strong shift towards automated, modular rheometer systems that integrate seamlessly with existing laboratory information management systems (LIMS) and offer comprehensive predictive analytics capabilities. Major vendors are focusing on developing high-performance instruments featuring magnetic bearing technology to enhance measurement sensitivity and accuracy, particularly for low-viscosity or weak structural samples. Furthermore, increasing investment in material science research by governments and private entities, particularly concerning sustainable and bio-based materials, is fueling demand for versatile and high-precision rheological characterization tools.

Regionally, North America and Europe maintain dominance, primarily due to established research infrastructure, high adoption rates in the petrochemical and pharmaceutical industries, and the presence of leading rheometer manufacturers. However, the Asia Pacific (APAC) region is poised for the highest growth trajectory, fueled by rapid industrialization, massive expansion of the domestic manufacturing sector (especially in polymers, paints, and construction materials) in countries like China, India, and South Korea, and growing governmental focus on establishing world-class research institutions. This regional dynamic is leading to increased localization of manufacturing and service centers by global market participants.

Segment trends reveal that the stress-controlled rheometers segment holds a substantial market share owing to their versatility and ability to simulate real-world processing conditions accurately. Application-wise, quality control and routine testing remain the largest segments, but the research and development sector is showing accelerated growth due to the complex nature of novel formulations requiring advanced oscillatory and transient tests. End-user analysis highlights the polymer and plastics industry as the primary consumer, although the burgeoning biotechnology and personalized medicine fields are rapidly adopting rheometry for analyzing biological fluids, hydrogels, and complex drug delivery matrices, signaling diversification in the end-user landscape.

AI Impact Analysis on Rotary Rheometer Market

Common user questions regarding AI's impact on the Rotary Rheometer Market frequently revolve around automation, predictive maintenance, and the interpretation of complex rheological data. Users are keen to understand how AI algorithms can handle the high dimensionality of oscillatory test data (e.g., strain sweeps, frequency sweeps) and translate raw viscoelastic measurements into actionable material performance metrics faster than traditional methods. Key concerns center on data quality requirements for training robust AI models and the potential for AI to standardize testing protocols globally. Expectations are high regarding AI-driven predictive modeling that can forecast material behavior under untested conditions, significantly reducing the time and cost associated with exhaustive laboratory experimentation and formulation optimization in sectors like polymer compounding and specialty chemicals.

The integration of Artificial Intelligence (AI) and Machine Learning (ML) is fundamentally transforming the operation, data processing, and application of rotary rheometers, moving them beyond simple mechanical testing tools into sophisticated predictive instruments. AI algorithms are increasingly being deployed to optimize measurement parameters automatically based on the sample type and historical data, thereby enhancing efficiency and minimizing operator error, which is critical for complex, shear-sensitive materials. Furthermore, ML models are utilized for advanced anomaly detection in quality control, allowing manufacturers to identify subtle batch variations that might be missed by standard control charts, leading to superior consistency in end-products such as lubricants, coatings, and adhesives.

In the research domain, AI is accelerating the pace of material discovery. By processing vast datasets generated from high-throughput rheometers, ML models can correlate molecular structure, formulation components, and processing conditions directly with complex rheological outputs. This capability enables researchers to inverse-design materials by specifying desired flow properties and having the AI suggest optimal formulations, drastically shortening the R&D cycle for next-generation materials like functionalized hydrogels or self-healing elastomers. This shift towards smart rheology fundamentally alters how material scientists approach characterization and development, maximizing the return on investment in high-end rheometric hardware.

- AI-driven optimization of testing parameters for maximum data fidelity and reduced experimental time.

- Machine learning models used for predictive rheology, forecasting material behavior under varying temperatures and shear rates.

- Enhanced data interpretation and visualization through AI, identifying non-linear viscoelastic fingerprints in complex fluids.

- Integration of AI for autonomous quality control (QC), enabling real-time detection of production inconsistencies.

- Predictive maintenance schedules for rheometer components, improving instrument uptime and measurement reliability.

DRO & Impact Forces Of Rotary Rheometer Market

The Rotary Rheometer Market is shaped by a powerful interplay of Drivers, Restraints, Opportunities (DRO), and inherent Impact Forces stemming from technological maturity and industrial demand. The primary driver is the accelerating complexity of modern materials, particularly multi-phase systems and nano-composites, which require intricate rheological characterization beyond simple viscosity measurements to ensure functional integrity. Concurrently, the rigorous enforcement of quality standards (e.g., ISO, ASTM) and safety regulations across pharmaceuticals, medical devices, and construction materials necessitates reliable, quantifiable data only achievable through advanced rheometry. Restraints include the high initial cost of advanced stress-controlled instruments and the need for highly skilled personnel to operate, calibrate, and interpret complex oscillatory data, creating adoption barriers for smaller laboratories and emerging market entities. Opportunities abound in the development of portable, user-friendly, and cost-effective rheometers designed for on-site quality checks, alongside the expansion into emerging fields like additive manufacturing (3D printing feedstock rheology) and personalized therapeutics.

Impact forces are centered on competitive intensity and technological innovation. The market exhibits medium-high rivalry among established global leaders who compete fiercely on instrument precision, software capabilities, and post-sales service networks. The power of buyers (large chemical, pharma, and polymer companies) is moderate, as they often require customized solutions and long-term service contracts, but the limited number of high-tier suppliers mitigates extreme downward pricing pressure. Suppliers of key components, such as magnetic bearings and high-resolution torque transducers, exert moderate power due to the specialized nature of these technologies. Technological change is a high impact force, constantly pushing manufacturers toward greater automation, wider operational temperature ranges, and integration with spectroscopic techniques (rheo-optical methods) to gain deeper structural insights into flowing materials.

Furthermore, globalization of supply chains and manufacturing processes mandates global consistency in material testing, elevating the importance of standardized rheological testing across multi-national operations. This drives demand for rheometers capable of cross-platform comparability and robust calibration standards. Geopolitical stability and trade policies can influence the cost and accessibility of high-precision electronic components used in rheometer manufacturing. Overall, while technological complexity poses restraints, the intrinsic need for quality assurance in advanced manufacturing provides continuous, strong upward momentum for market growth, particularly in systems offering advanced transient and extensional rheology capabilities critical for processing simulations.

Segmentation Analysis

The Rotary Rheometer Market is primarily segmented based on Type (Rotational Rheometers, Oscillatory Rheometers), Operating Mode (Stress-Controlled Rheometers, Strain-Controlled Rheometers), Application (Research & Development, Quality Control, Process Monitoring), and End-User Industry (Polymers & Plastics, Chemicals, Pharmaceuticals & Biotechnology, Food & Beverage, Cosmetics & Personal Care, Petroleum & Lubricants). These segmentations reflect the diverse technical requirements and specific industry standards dictating the choice of rheometric measurement technique. Rotational rheometers, focused mainly on shear rate and steady shear viscosity, cater predominantly to quality control in high-volume industries like paints and coatings. Conversely, oscillatory rheometers, which measure viscoelastic properties such as storage and loss moduli, are essential for characterizing complex structured fluids and soft solids in advanced R&D settings.

Stress-controlled rheometers, where the torque (stress) is applied directly to the sample, offer superior sensitivity at low shear rates, making them indispensable for studying materials at rest, such as monitoring yield stress or long-term stability in pharmaceutical suspensions. Strain-controlled rheometers, though historically prevalent, are now often integrated within hybrid systems, providing specific advantages when high shear rates or large deformations are required. The proliferation of specialized accessories, including high-pressure cells and rheo-microscopes, further defines niche market segments, driving demand for customizable, high-end modular instruments that can adapt to evolving material characterization challenges, especially in academic research and advanced material development.

The end-user segmentation underscores the market's reliance on industrial output and regulatory stringency. The polymers and plastics sector utilizes rheometers extensively for melt flow analysis and optimizing polymer processing (extrusion, molding), while the pharmaceutical segment relies heavily on precise rheology for evaluating tablet coating effectiveness, characterizing bio-inks for 3D bioprinting, and ensuring the shelf stability and syringability of injectable drugs. The increasing complexity of consumer products, requiring tailored texture and consistency (e.g., premium cosmetics, specialty sauces), ensures steady demand growth from the food & beverage and cosmetics sectors, which demand instruments capable of rapid, repeatable texture profile analysis.

- Type:

- Rotational Rheometers (Steady Shear)

- Oscillatory Rheometers (Dynamic Shear)

- Hybrid Rheometers

- Operating Mode:

- Stress-Controlled Rheometers

- Strain-Controlled Rheometers

- Application:

- Research & Development (R&D)

- Quality Control (QC) and Routine Testing

- Process Monitoring and Optimization

- End-User Industry:

- Polymers and Plastics

- Chemicals and Coatings (Paints, Inks, Adhesives)

- Pharmaceuticals and Biotechnology

- Food and Beverage

- Cosmetics and Personal Care

- Petroleum and Lubricants

- Others (Construction, Aerospace, Electronics)

Value Chain Analysis For Rotary Rheometer Market

The value chain of the Rotary Rheometer Market begins with upstream activities, focusing on the procurement and precision engineering of highly specialized components. This includes securing advanced magnetic bearings, ultra-sensitive torque sensors, high-resolution encoders, and sophisticated temperature control units (e.g., Peltier elements). The cost and quality of these foundational components significantly influence the final instrument performance and manufacturing costs. Suppliers operating in this highly specialized niche often exert considerable leverage due to the need for strict tolerances and proprietary technology. Effective supply chain management focuses on vertical integration or long-term strategic partnerships to mitigate risks associated with component sourcing and maintain quality control.

Midstream, the activities involve the manufacturing, assembly, and rigorous calibration of the rheometer systems. This stage requires significant investment in cleanroom facilities, highly specialized electronic assembly expertise, and proprietary software development for data acquisition and analysis. Key value addition occurs through the development of intuitive user interfaces, advanced firmware, and specialized accessories that expand the instrument's capabilities (e.g., extensional rheology fixtures, UV curing setups). Marketing and sales activities are crucial here, often relying on highly technical sales representatives and applications scientists who can demonstrate the rheometer's capability to solve specific customer material challenges, particularly in complex R&D environments.

Downstream distribution channels are characterized by a mix of direct and indirect approaches. Major market players typically employ a direct sales model for high-value instruments to large institutional and corporate customers, ensuring intimate technical support, installation, and operator training. Indirect channels, involving authorized distributors and regional agents, are primarily utilized in developing markets or for less complex, routine testing instruments. Post-sales service and support, including preventative maintenance, recalibration services, and specialized applications consulting, form a critical element of the downstream value proposition, contributing significantly to customer loyalty and recurring revenue streams, especially given the sophisticated nature of the equipment and the regulatory requirements of end-user industries.

Rotary Rheometer Market Potential Customers

Potential customers for Rotary Rheometers encompass a wide spectrum of organizations involved in the formulation, processing, quality control, and academic study of complex fluid and semi-solid materials. The primary buyers are large multinational corporations within the Polymers and Plastics industry, including resin manufacturers and compounders, who rely on rheometers to ensure the melt processability and performance integrity of their materials before extrusion or injection molding. Similarly, key pharmaceutical and biotechnology companies purchase these instruments extensively to optimize the stability, dispersibility, and bioavailability of complex drug formulations, such as biologics, vaccines, and high-concentration protein solutions, often driven by strict FDA and EMA compliance requirements.

Mid-tier customers include specialty chemical manufacturers, focusing on high-performance coatings, adhesives, and sealants. These industries require precise rheological data to control application characteristics (e.g., sag resistance, leveling) and final product cure behavior. Furthermore, the Food and Beverage sector, including major manufacturers of dairy products, sauces, and confectioneries, utilizes rheometry to control texture, mouthfeel, and shelf-life stability, often integrating rheometers directly into their central R&D and quality assurance laboratories.

Institutional buyers represent a significant purchasing segment, comprising major universities, government research laboratories, and independent contract testing facilities. These entities typically acquire highly modular and versatile research-grade rheometers for fundamental material science studies and the development of cutting-edge materials. The growing trend of academic-industrial partnerships further consolidates the demand for state-of-the-art rheometers capable of facilitating collaborative research projects focused on addressing future material challenges, such as sustainable packaging or advanced energy storage solutions.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 650 Million |

| Market Forecast in 2033 | USD 1010 Million |

| Growth Rate | 6.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Anton Paar GmbH, TA Instruments (Waters Corporation), Thermo Fisher Scientific Inc., Malvern Panalytical Ltd. (Spectris plc), Kinexus Rheology, RHEOTEST GMBH, HAAKE Instruments, Lamy Rheology Instruments, Shimadzu Corporation, Brookfield AMETEK, PCE Instruments, BOHLIN INSTRUMENTS, Cannon Instrument Company, Reologica Instruments AB, ATS RheoSystems, GBC Scientific Equipment, Goettfert GmbH, Alpha Technologies. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Rotary Rheometer Market Key Technology Landscape

The technological landscape of the Rotary Rheometer Market is characterized by continuous innovation focused on improving measurement sensitivity, expanding operational ranges, and enhancing automation capabilities. A cornerstone technology involves the use of high-performance magnetic or air bearing systems. Magnetic bearings virtually eliminate friction, particularly in stress-controlled instruments, allowing for extremely precise torque measurements at very low shear rates crucial for characterizing structural recovery (thixotropy) in materials like paints or pharmaceutical gels. This focus on frictionless measurement enables the accurate study of weakly structured, low-viscosity fluids and subtle molecular interactions, which is indispensable for advanced R&D.

Another pivotal development is the rise of modular and hybrid rheometers. Modern instruments are designed with versatile connectivity options, allowing rapid integration of specialized measurement geometries (e.g., double gap, vane, high-pressure cells) and environmental control units (ECUs). This modularity extends to combining traditional rotational measurements with advanced features like extensional rheometry, which measures how materials stretch—a critical property for processing techniques like fiber spinning or coating. Furthermore, advanced software platforms are crucial, offering sophisticated data processing tools, built-in standard operating procedures (SOPs), and features for compliance with regulatory standards such as 21 CFR Part 11, essential for pharmaceutical users.

The latest frontier involves the integration of non-rheological techniques directly within the rheometer setup, creating synergistic analytical tools. Rheo-optical techniques (combining rheometry with microscopy or light scattering) allow scientists to observe structural changes in real-time as the material is sheared, providing fundamental insights into flow-induced transitions like shear thickening or shear thinning. Coupled with automated sample handling systems and robotics, these high-throughput rheology platforms drastically accelerate the material screening process, allowing simultaneous testing across wide ranges of temperature and concentration, thereby maximizing laboratory efficiency and accelerating product formulation cycles.

Regional Highlights

- North America: This region holds a leading position, driven by significant R&D spending in the biotechnology, energy (shale gas fracturing fluids and lubricants), and advanced materials sectors. The presence of major pharmaceutical companies and leading academic institutions, coupled with stringent quality control standards, ensures high demand for sophisticated, high-end rheometers. The United States remains the largest single market, favoring technologically advanced, fully automated systems.

- Europe: Europe represents a mature market, characterized by strong demand from the automotive, chemical, and industrial coatings industries, particularly in Germany (specialty chemicals) and the UK (pharmaceuticals). Strict adherence to REACH regulations and a strong emphasis on sustainability in material development fuel the need for precise rheological characterization of new, environmentally friendly formulations.

- Asia Pacific (APAC): APAC is the fastest-growing market globally, propelled by rapid industrial expansion in China, India, and Japan. Increased foreign direct investment in manufacturing (especially polymers and electronics) and government initiatives to boost domestic research capabilities are driving demand. While price sensitivity exists for routine QC instruments, there is rapidly growing adoption of premium rheometers in the burgeoning R&D centers in South Korea and Singapore.

- Latin America (LATAM): Growth in LATAM is steady, primarily centered around Brazil and Mexico, focusing on the food and beverage, cosmetics, and petrochemical industries. Market penetration is generally focused on standard, reliable rotational rheometers for quality assurance in commodity production, with slow but increasing adoption of advanced instruments in academic centers.

- Middle East and Africa (MEA): The MEA market is largely dependent on the petroleum, petrochemical, and construction sectors. Demand is concentrated in the Gulf Cooperation Council (GCC) countries, focusing on rheology testing for drilling fluids, lubricants, and high-performance cement mixtures. Growth is moderate but stable, tied closely to global commodity price trends and local infrastructure development projects.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Rotary Rheometer Market.- Anton Paar GmbH

- TA Instruments (Waters Corporation)

- Thermo Fisher Scientific Inc.

- Malvern Panalytical Ltd. (Spectris plc)

- Kinexus Rheology

- RHEOTEST GMBH

- HAAKE Instruments

- Lamy Rheology Instruments

- Shimadzu Corporation

- Brookfield AMETEK

- PCE Instruments

- BOHLIN INSTRUMENTS

- Cannon Instrument Company

- Reologica Instruments AB

- ATS RheoSystems

- Goettfert GmbH

- Alpha Technologies

- Metravib SAS

- GBC Scientific Equipment

- Tinius Olsen

Frequently Asked Questions

Analyze common user questions about the Rotary Rheometer market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between stress-controlled and strain-controlled rheometers?

Stress-controlled rheometers apply a constant or oscillating torque (stress) and measure the resulting deformation (strain), offering superior sensitivity for characterizing weakly structured or low-viscosity materials, critical for yield stress determination. Strain-controlled rheometers, conversely, apply a known deformation and measure the resulting stress, often favored for high shear rate applications or when controlling the deformation magnitude is paramount.

Which industry is the largest end-user segment for rotary rheometers?

The Polymers and Plastics industry remains the largest end-user segment. Rotary rheometers are essential for analyzing the viscoelastic properties of polymer melts, determining material processability, optimizing compounding processes, and ensuring consistency in final products like films, fibers, and molded components across diverse processing conditions.

How does the integration of AI enhance rheometer functionality?

AI enhances rheometer functionality by automating parameter selection, optimizing experimental protocols based on material history, and providing advanced interpretation of complex data sets, particularly oscillatory measurements. This integration accelerates research cycles, improves measurement accuracy by reducing operator dependency, and enables predictive modeling of material behavior.

What are the key technological advancements driving market growth?

Key technological advancements include the adoption of magnetic bearing technology for ultra-sensitive measurements, the development of modular hybrid systems (combining rotational and extensional capabilities), and the integration of rheometry with spectroscopic or optical techniques (rheo-optics) for real-time structural analysis under flow.

What role do rotary rheometers play in the pharmaceutical industry?

In the pharmaceutical industry, rotary rheometers are crucial for ensuring the stability and processability of suspensions, emulsions, and gels. They are used to measure critical properties such as viscosity, syringeability of injectables, flow behavior during tablet coating, and the long-term physical stability of drug formulations, ensuring compliance with strict regulatory standards.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager