Royal Icing Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 438357 | Date : Dec, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Royal Icing Market Size

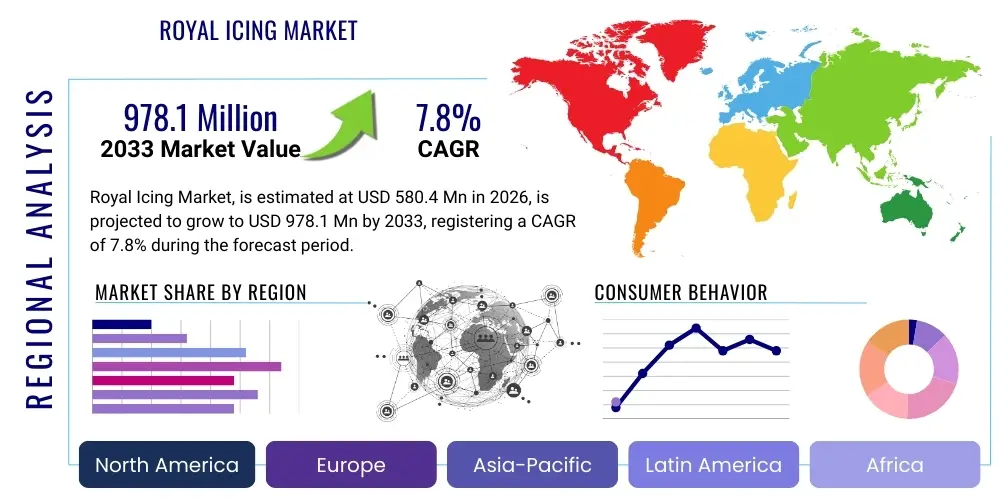

The Royal Icing Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2026 and 2033. The market is estimated at $580.4 Million in 2026 and is projected to reach $978.1 Million by the end of the forecast period in 2033.

Royal Icing Market introduction

The Royal Icing Market encompasses the production, distribution, and consumption of a hard-setting icing typically made from powdered sugar, raw or pasteurized egg whites (or meringue powder/albumen), and often lemon juice or cream of tartar. This specialized confectionery ingredient is highly valued for its ability to dry quickly to a smooth, non-tacky finish, making it the preferred medium for intricate decorative work on cookies, cakes, gingerbread houses, and other baked goods. Its defining characteristic is its hardness and structural integrity once dried, allowing for delicate piping, flood filling, and the creation of durable three-dimensional decorations, known as run-outs or color flow decorations.

Major applications of Royal Icing span across commercial bakeries, artisanal patisseries, seasonal confectionary production (especially Christmas and Easter), and the rapidly expanding home baking segment driven by DIY trends and social media influence. The intrinsic benefits of using royal icing include exceptional stability, long shelf life of decorated products, and unparalleled aesthetic flexibility compared to buttercream or fondant. Furthermore, the increasing demand for customized and visually appealing baked goods for events such as weddings, birthdays, and corporate functions is continually driving market expansion.

Key driving factors accelerating the market growth include the globalization of Western baking techniques, high consumer engagement in decorative food trends often propagated via platforms like Instagram and Pinterest, and continuous innovation in product formats. Manufacturers are successfully addressing traditional limitations by offering convenient, ready-to-use royal icing pouches, high-quality meringue powders, and specialized vegan or allergen-free formulations, thereby widening the product’s usability and appeal across diverse consumer bases and dietary preferences.

Royal Icing Market Executive Summary

The Royal Icing Market is experiencing robust growth fueled by several converging business trends, most notably the shift towards premiumization in confectionery and the persistent rise of the celebration economy. A significant trend involves manufacturers focusing on enhancing convenience by offering products that minimize preparation time, such as pre-mixed dry formulations requiring only water, or ready-to-pipe tubs. Additionally, the industry is witnessing substantial investment in automation technologies within commercial decorating facilities to handle large-volume production of intricately decorated items, maintaining quality and consistency across various product lines and seasonal offerings.

Geographically, North America and Europe remain the primary revenue generators, characterized by mature baking industries and high consumer spending on specialized baked goods. However, the Asia Pacific (APAC) region is projected to be the fastest-growing market, driven by rapid urbanization, increasing disposable incomes, and the strong adoption of Western culinary practices, particularly in countries like China and India, where themed baking and confectionery art are gaining traction. Regional trends also show a distinct preference for naturally derived colors and flavors in royal icing formulations, compelling suppliers to reformulate existing product lines to meet clean-label consumer demands, especially in Western European nations.

Segmentation analysis highlights the increasing dominance of the dry mix/powdered segment due to its excellent shelf stability and cost-effectiveness in storage and transport, appealing strongly to commercial users. Concurrently, the ready-to-use (RTU) segment is capturing significant household consumer share due to its sheer convenience and ease of application. The application segment is overwhelmingly led by commercial bakeries, but the household/DIY segment is growing at an accelerated rate, particularly through specialized e-commerce platforms and baking supply stores. Overall, the market trajectory indicates sustained expansion driven by innovation, convenience, and global aesthetic trends.

AI Impact Analysis on Royal Icing Market

Common user and industry queries regarding AI's impact on the Royal Icing Market center on optimizing the complex supply chain for key volatile ingredients like sugar and eggs (or derived albumin), ensuring consistency in large-scale production, and exploring novel methods for personalized decoration. Users often question how AI can predict ingredient shortages or price spikes, enabling manufacturers to secure buffer stock efficiently. Furthermore, commercial decorators and large confectioners are interested in AI algorithms that can analyze visual trends, automatically generate complex piping patterns suitable for automated application systems, and ensure precise color matching across various production batches, thus minimizing waste and maximizing aesthetic compliance.

The integration of Artificial Intelligence and Machine Learning (ML) is fundamentally changing the operational landscape of high-volume royal icing production. ML models are being deployed to optimize mixing parameters—such as hydration levels, whipping speed, and duration—based on environmental factors like humidity and temperature, ensuring perfect peak formation and drying consistency regardless of the manufacturing location or time of year. This data-driven approach significantly reduces batch variability, which is a common challenge in traditional royal icing preparation where consistency heavily relies on operator skill and highly controlled environments. AI also plays a critical role in quality control, utilizing image recognition software on conveyor belts to identify and reject decorated products with piping errors or imperfect surface finishes, achieving quality levels unfeasible with manual inspection.

In the consumer-facing sector, AI contributes to enhanced product customization. Retailers and specialized cake shops are beginning to implement AI-powered design tools that allow customers to upload images or specify complex patterns, which the AI then translates into precise, executable instructions for 3D printing or robotic piping systems utilizing royal icing. This capability allows for mass personalization, catering to the strong consumer demand for unique and hyper-specific decorations for celebratory events. Simultaneously, predictive maintenance powered by AI ensures that specialized mixing and piping machinery operates continuously with minimal downtime, forecasting component failures before they occur, thereby safeguarding high-throughput production schedules crucial for seasonal peaks.

- AI-driven supply chain forecasting optimizes procurement of raw materials (sugar, albumen), mitigating price volatility risks.

- Machine Learning algorithms enhance consistency in mixing and whipping processes, compensating for environmental variations (humidity/temperature).

- Robotic piping systems leverage computer vision and AI for highly detailed, precise, and complex decoration application at scale.

- Automated quality control systems use image recognition to detect and flag aesthetic defects on decorated baked goods rapidly.

- AI-powered customization interfaces allow consumers to design personalized decorations for robotic execution.

- Predictive maintenance schedules for high-speed confectionery equipment reduce unexpected downtime during critical production periods.

- Optimization of recipe formulations for alternative ingredients (e.g., vegan substitutes) based on stability and texture parameters.

DRO & Impact Forces Of Royal Icing Market

The market dynamics are defined by a complex interplay of strong consumer demand for high-quality aesthetics and persistent technical challenges related to ingredient sourcing and application. The primary driver is the global consumer preference for visually stunning baked goods, heavily influenced by social media aesthetics and competitive baking programs, which inherently require the structural and smooth finish provided by royal icing. This demand is further amplified by the versatility of royal icing, enabling applications from intricate wedding cake details to commercially viable decorated cookies with extensive shelf stability. However, the market faces significant restraints, chiefly concerning the high cost and volatility of high-quality egg whites or specialized meringue powder, coupled with the inherent difficulties in achieving consistent, streak-free results in less controlled household or small-scale environments. Labor intensity associated with traditional piping methods remains a cost barrier for many smaller enterprises.

Opportunities for growth are concentrated in the development and scaling of specialized formulations. The increasing incidence of egg allergies and the strong surge in veganism present a substantial untapped segment for plant-based royal icing alternatives that can mimic the rapid drying time and structural integrity of traditional products, often utilizing ingredients like aquafaba or specialized starches. Furthermore, manufacturers are exploring opportunities in the convenience sector, specifically focusing on developing aerosolized or pressure-dispensed royal icing products designed for quick, basic decoration by the average consumer, bridging the gap between professional application and household usability. The emerging markets in Asia and Latin America represent a significant opportunity for market penetration as their baking traditions evolve toward Western styles.

The impact forces driving the market expansion are characterized by high market attractiveness due to the specialized nature of the product, necessitating specific formulation expertise, and low threat of substitutes in the high-end decorative segment where alternatives like simple buttercreams cannot deliver the required structural rigidity. The bargaining power of suppliers remains moderate to high, particularly concerning high-grade egg albumen and specialized coloring agents, exerting upward pressure on manufacturing costs. Nevertheless, the high switching cost for large commercial bakeries that have invested in specific automation equipment tailored for royal icing application provides strong stability to the demand side, ensuring long-term contractual commitments and market resilience against minor economic fluctuations.

Segmentation Analysis

The Royal Icing market segmentation offers a detailed view of product formats, end-use applications, and distribution channels, reflecting varying consumer needs ranging from professional efficiency to household convenience. Key market differentiation occurs between dry powdered mixes, which offer optimal shelf life and transport efficiency crucial for global commercial operations, and ready-to-use (RTU) formulations, which cater to the premium convenience demands of smaller patisseries and the rapidly growing segment of amateur home bakers. Understanding these segment differences is vital for strategic product positioning and targeted marketing efforts within the specialized confectionery supply chain.

Segmentation by application reveals the pronounced influence of the commercial sector, where Royal Icing is indispensable for mass-produced celebratory and seasonal items, often leveraging automation for high-throughput decorating. Conversely, the household segment, while smaller in volume, drives innovation in ease-of-use packaging and accessibility, highly influenced by trends seen on social media platforms. The proliferation of specialized baking equipment stores and dedicated online retail channels further fragments the distribution landscape, making robust omnichannel strategies essential for market participants seeking maximum reach and consumer engagement across all geographic regions.

Beyond the fundamental structural breakdown, emerging niche segments such as specialty diet royal icing (vegan, gluten-free, reduced sugar) are gaining traction, often commanding premium prices. These specialized segments are primarily driven by health-conscious consumer trends and regulatory shifts towards cleaner labels and reduced artificial ingredients. Manufacturers strategically investing in these niche segments are positioning themselves to capitalize on future shifts in dietary preferences and ethical sourcing requirements, ensuring market relevance in increasingly diversified consumer environments.

- By Type:

- Dry Powdered Mix

- Ready-to-Use (RTU)

- By Application:

- Commercial Bakeries (High Volume Production)

- Artisanal Patisseries and Specialized Cake Shops

- Household/DIY Baking and Decoration

- Food Service (Hotels and Catering)

- By Distribution Channel:

- Online Retail (E-commerce Platforms, Specialized Baking Websites)

- Offline Retail (Supermarkets, Hypermarkets, Specialty Food Stores, Wholesale Clubs)

- By Source/Ingredient:

- Egg-Based (Albumen/Meringue Powder)

- Vegan/Plant-Based Substitutes (e.g., Aquafaba-derived)

Value Chain Analysis For Royal Icing Market

The value chain for the Royal Icing Market begins with upstream activities focusing on the sourcing and processing of core raw materials, predominantly high-quality refined sugar, specialized food-grade egg whites (often in powdered or frozen albumen form), and stabilizing agents like citric acid or cream of tartar. Consistency and purity at this stage are paramount, as the chemical composition directly dictates the final product's setting properties and structural stability. Key industry players often establish long-term contracts with specialized sugar refineries and major egg processing facilities to ensure a stable supply of materials that meet stringent food safety and quality standards, essential for the reliable performance required by commercial users.

The midstream stage involves the manufacturing process, where advanced blending and processing technologies are used to create either the dry mix or the ready-to-use paste. This phase includes precise measurement, high-speed mixing, potential pasteurization (for liquid products), and specialized packaging that ensures moisture control and extended shelf life. Efficiency in manufacturing focuses on reducing batch-to-batch variability and minimizing processing time, particularly for ready-to-use formats which are more susceptible to spoilage. Downstream activities involve distribution channels, which are bifurcated into direct sales to large commercial customers and indirect channels utilizing third-party logistics and retail networks to reach smaller businesses and end consumers.

The distribution channel is critical, with the direct model (manufacturer to commercial bakery) ensuring bulk delivery and specific product customization. The indirect distribution model heavily relies on specialized baking supply distributors and mass-market retailers. Online distribution is rapidly gaining significance, allowing niche suppliers of vegan or organic royal icing to reach a global customer base directly. Success in the downstream market is increasingly determined by efficient warehousing of temperature-sensitive ingredients and effective digital marketing strategies targeting the aesthetic demands of the end-user, often emphasizing product tutorials and application versatility through visually rich online content.

Royal Icing Market Potential Customers

The primary customer base for Royal Icing is highly segmented but centers predominantly on entities involved in professional confectionery decoration and high-volume seasonal baking. Large commercial bakeries represent the highest volume buyers, utilizing royal icing for industrial-scale decoration of seasonal cookies, pre-packaged gingerbread kits, and long shelf-life items destined for mass grocery retail. These clients prioritize cost efficiency, consistent bulk supply, and performance compatibility with high-speed automated piping and decorating equipment, requiring specialized, often proprietary, industrial formulations.

A secondary, high-value customer segment comprises artisanal patisseries, specialized cake decorators, and boutique baking businesses. These professional end-users demand superior quality, fine texture, and excellent color absorption, often sourcing smaller, premium batches suitable for bespoke wedding cakes, elaborate sugar flowers, and complex three-dimensional decorative elements. For this segment, the product’s aesthetic outcome and reliability in intricate work outweigh minor price fluctuations, driving demand for top-tier dry mixes and proprietary ready-to-use formulations.

Finally, the household and educational sector forms the fastest-growing customer base. This includes enthusiastic home bakers, hobbyists, and participants in culinary arts schools. These customers are highly influenced by convenience and accessibility, favoring smaller, ready-to-use pouches, brightly colored pre-mixed sets, and readily available products through easily navigable online marketplaces and mainstream grocery stores. The seasonal spikes in demand from this segment, particularly around major holidays, necessitates robust inventory management and flexible supply chain responses from manufacturers.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $580.4 Million |

| Market Forecast in 2033 | $978.1 Million |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Wilton Brands LLC, CK Products, SugarVeil, Squires Kitchen, Rainbow Dust Colours Ltd., Cake Craft World, Americolor, Bakels Worldwide, Renshaw, PME Cake Decorating, Satin Ice, Global Sugar Art, Chefmaster, Macphie, Dawn Foods, FunCakes, Dr. Oetker, CSM Bakery Solutions, Tate & Lyle, Ewald-Gelatine. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Royal Icing Market Key Technology Landscape

The manufacturing of high-quality Royal Icing relies heavily on precision blending and advanced powder processing technologies, particularly for the dominant dry mix segment. Key technological investments are focused on sophisticated fluid-bed dryers and micronization equipment to ensure the sugar and meringue powder components are processed to an optimal, consistent particle size. This particle uniformity is critical for achieving the smooth, lump-free consistency required when the icing is reconstituted, directly impacting the final product's texture and piping performance. Furthermore, manufacturers are increasingly adopting advanced moisture control technologies within packaging lines to prevent premature activation or caking of the dry mix, thereby guaranteeing extended shelf stability and product integrity during long-distance distribution.

In the ready-to-use (RTU) segment, the technological landscape is dominated by aseptic processing and specialized homogenization equipment. Aseptic packaging techniques are employed to preserve the perishable liquid or paste formulations without relying solely on chemical preservatives, catering to the growing clean-label movement. High-pressure homogenization ensures that the solid particles (sugar, stabilizers) remain perfectly suspended within the liquid matrix, preventing separation or settling which can compromise piping consistency. This technological focus enables manufacturers to offer convenient, high-performance RTU products that maintain professional-grade quality, significantly lowering the barrier to entry for novice decorators.

Looking forward, the integration of robotics and 3D printing technology is a transformative element in the application of Royal Icing. High-speed, multi-axis robotic arms equipped with specialized piping tips are replacing manual labor in commercial operations, allowing for precision decoration that is both rapid and perfectly repeatable. Additive manufacturing (3D printing) using customized royal icing formulations allows for the creation of incredibly detailed, edible structural elements, providing a new dimension to cake and cookie design that traditional piping techniques cannot match. This fusion of material science and robotics is setting new standards for efficiency and aesthetic complexity in the commercial decorating sector, pushing the boundaries of what is possible in edible art.

Regional Highlights

Market consumption patterns and growth trajectories for Royal Icing display significant regional variances influenced by cultural baking practices, economic development, and regulatory environments.

- North America (NA): Dominates the global market in terms of value, driven by a deeply ingrained tradition of holiday baking (especially Christmas cookies and gingerbread houses) and a large, established industry for specialty wedding and celebration cakes. The US is a hub for innovation, particularly in ready-to-use products and specialized coloring techniques. High consumer spending and robust e-commerce channels facilitate strong sales in both commercial and household segments.

- Europe: Characterized by a strong emphasis on artisanal quality and adherence to traditional patisserie standards. Western European countries, particularly the UK and Germany, are major consumers. The market here is highly sensitive to clean-label trends, pushing manufacturers toward natural colors and flavors, and driving strong demand for high-quality dry meringue powder over liquid albumen due to regulatory scrutiny and consumer preference for consistency.

- Asia Pacific (APAC): The fastest-growing region, experiencing exponential adoption of Western-style confectionery and baking as urbanization accelerates and middle-class populations expand. Countries like China, India, and South Korea are seeing rapid growth in specialized baking schools and a burgeoning demand for decorative ingredients. The market is highly opportunistic for manufacturers offering shelf-stable dry mixes tailored to humid climates.

- Latin America (LATAM): Exhibits steady growth, concentrated primarily in urban centers like Brazil and Mexico. Demand is often linked to major festive celebrations and imported US/European confectionery trends. Price sensitivity is higher in this region, leading to stronger adoption of cost-effective bulk powdered formats for commercial use.

- Middle East and Africa (MEA): A nascent but developing market, characterized by localized luxury confectionery demand, particularly in the GCC countries. The high per capita income in the Gulf region supports a niche market for premium, imported, specialized decorating supplies used in lavish celebration events, though overall market penetration remains relatively low compared to North America and Europe.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Royal Icing Market, recognizing their contribution to product innovation, market reach, and competitive strategy.- Wilton Brands LLC

- CK Products

- SugarVeil

- Squires Kitchen

- Rainbow Dust Colours Ltd.

- Cake Craft World

- Americolor

- Bakels Worldwide

- Renshaw

- PME Cake Decorating

- Satin Ice

- Global Sugar Art

- Chefmaster

- Macphie

- Dawn Foods

- FunCakes

- Dr. Oetker

- CSM Bakery Solutions

- Tate & Lyle

- Ewald-Gelatine

Frequently Asked Questions

Analyze common user questions about the Royal Icing market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between Royal Icing and other icing types?

Royal Icing is distinguished by its unique ability to dry completely hard and brittle, resulting in a smooth, matte finish and structural integrity crucial for intricate piping, creating edible structural elements, and durable cookie decoration, unlike soft buttercreams or smooth glazings.

Are there viable vegan alternatives to traditional egg-based Royal Icing?

Yes, the market is rapidly expanding its offering of plant-based royal icing, frequently utilizing stabilizers and hydrocolloids such as specialized vegetable gums or aquafaba (chickpea liquid) to replicate the necessary setting and structural properties without using animal-derived egg whites.

Which application segment drives the highest volume consumption of Royal Icing?

The Commercial Bakeries segment drives the highest volume consumption, primarily due to the industrial production of seasonal confectionery items, pre-packaged decorating kits, and mass-market decorated cookies that require the stability and long shelf life royal icing provides.

How is technology impacting the application of Royal Icing in commercial settings?

Advanced technologies, including multi-axis robotic piping systems and specialized 3D food printers, are being adopted to automate the application process, ensuring superior precision, rapid turnaround, and consistent quality necessary for high-volume commercial production.

Which geographic region is projected to experience the fastest growth rate?

The Asia Pacific (APAC) region is forecasted to exhibit the highest Compound Annual Growth Rate (CAGR), driven by the increasing Westernization of dietary preferences, rising disposable incomes, and the growing popularity of personalized and aesthetic confectionery art.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager