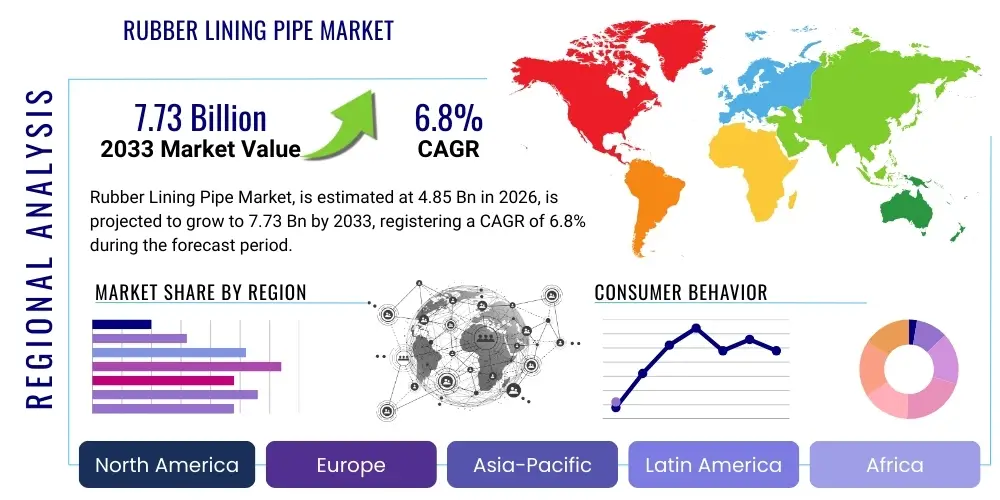

Rubber Lining Pipe Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439693 | Date : Jan, 2026 | Pages : 249 | Region : Global | Publisher : MRU

Rubber Lining Pipe Market Size

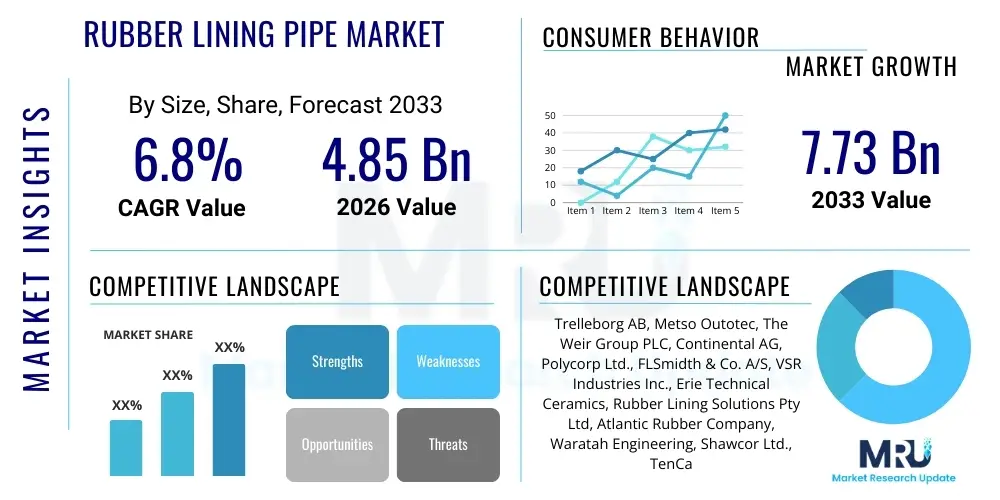

The Rubber Lining Pipe Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 4.85 billion in 2026 and is projected to reach USD 7.73 billion by the end of the forecast period in 2033.

Rubber Lining Pipe Market introduction

The Rubber Lining Pipe Market encompasses a critical industrial segment dedicated to protecting piping systems from abrasive wear, corrosive chemicals, and high-impact conditions. These specialized pipes, integral across a multitude of heavy industries, are standard steel or other robust pipe materials internally coated with a layer of natural or synthetic rubber. This rubber lining acts as a sacrificial barrier, significantly extending the lifespan of the underlying pipe and ensuring operational integrity.

Major applications for rubber lining pipes include the transportation of abrasive slurries in mining and metallurgy, the conveyance of corrosive chemicals in processing plants, and critical roles in wastewater treatment facilities, power generation, and pulp and paper manufacturing. The inherent benefits of rubber lining, such as superior resistance to abrasion, impact, and chemical attack, combined with noise reduction and vibration dampening properties, make them indispensable. They mitigate wear and tear, reduce maintenance costs, prevent environmental contamination, and enhance worker safety by minimizing leaks and structural failures.

The market is primarily driven by escalating industrial activities, particularly in mining, chemical processing, and infrastructure development across emerging economies. The global demand for raw materials fuels expansion in industries prone to severe wear, necessitating durable solutions for material transport. Additionally, the increasing focus on environmental protection and stringent safety regulations compels industries to adopt reliable piping systems that prevent leaks and spills, further bolstering the demand for high-performance rubber-lined pipes. Innovations in rubber compound formulations also contribute to market growth by offering enhanced performance characteristics tailored to specific industrial challenges.

Rubber Lining Pipe Market Executive Summary

The Rubber Lining Pipe Market is experiencing robust growth, driven by an accelerating pace of industrialization and infrastructure development worldwide. Business trends indicate a strong emphasis on technological advancements in rubber compounding, aimed at enhancing resistance to extreme temperatures, aggressive chemicals, and severe abrasion, thereby expanding the applicability of these pipes. Manufacturers are increasingly focusing on customized solutions and superior adhesion technologies to meet diverse industrial demands, leading to a competitive landscape characterized by innovation and strategic partnerships. Furthermore, the market is witnessing a shift towards sustainable manufacturing practices and the development of longer-lasting, more durable lining materials, reducing the frequency of replacements and overall environmental impact, which are key business drivers.

From a regional perspective, the Asia Pacific (APAC) region continues to dominate the market, primarily fueled by extensive mining operations, rapid industrial expansion, and significant investments in infrastructure projects in countries like China, India, and Australia. North America and Europe represent mature markets, where demand is largely driven by the replacement of aging infrastructure and the stringent regulatory requirements for industrial safety and environmental protection. Emerging economies in Latin America, the Middle East, and Africa are showing considerable growth potential due to new industrial projects and increasing exploitation of natural resources, which necessitate robust material handling solutions.

In terms of segmentation, the market is primarily characterized by the type of rubber used, ranging from natural rubber for its excellent abrasion resistance to various synthetic rubbers like EPDM, butyl, and neoprene for their specific chemical and temperature resistances. Applications in slurry and tailings management within the mining sector, chemical transfer lines, and wastewater treatment continue to be pivotal segments. The end-use industry segment is seeing sustained demand from mining, chemical processing, and power generation, all of which require highly durable and resilient piping solutions to maintain operational efficiency and safety. These segments collectively contribute to the market's upward trajectory, adapting to evolving industrial needs and technological innovations.

AI Impact Analysis on Rubber Lining Pipe Market

The integration of Artificial Intelligence (AI) is poised to significantly transform the rubber lining pipe market, addressing common user questions about enhancing operational efficiency, predictive maintenance, and quality control. Users are keenly interested in how AI can minimize downtime, optimize material selection for specific applications, and improve the overall longevity and performance of rubber-lined systems. The overarching theme of these inquiries revolves around leveraging AI to transition from reactive maintenance to proactive management, thereby reducing costs and improving safety. This includes questions on AI's ability to analyze operational data for early fault detection, automate quality inspections, and streamline manufacturing processes to achieve higher precision and consistency in lining application.

The impact of AI extends to various facets of the rubber lining pipe lifecycle, from design and manufacturing to installation and ongoing maintenance. By employing machine learning algorithms, manufacturers can predict material behavior under diverse stress conditions, leading to optimized rubber formulations and adhesion techniques. In operational settings, AI-powered sensor networks can monitor pipe integrity in real-time, detecting early signs of wear, corrosion, or delamination, thus enabling scheduled maintenance rather than emergency repairs. This predictive capability is crucial for industries where pipe failures can lead to significant financial losses and environmental hazards.

Furthermore, AI can revolutionize supply chain management for rubber lining pipes by optimizing inventory levels, predicting demand fluctuations, and enhancing logistics, ensuring timely delivery of custom solutions. Automated visual inspection systems, leveraging computer vision, can identify microscopic defects during the manufacturing process, guaranteeing higher product quality and reducing rejection rates. While the market is still in the early stages of widespread AI adoption, the potential for increased efficiency, reduced operational expenditure, enhanced safety, and prolonged asset life is driving significant interest and investment in AI-driven solutions across the rubber lining pipe sector.

- Predictive maintenance for early detection of wear and failure.

- Optimized material selection through data-driven performance analysis.

- Enhanced quality control with AI-powered automated inspection systems.

- Streamlined manufacturing processes for increased precision and consistency.

- Improved supply chain efficiency and demand forecasting.

- Real-time monitoring of pipe integrity and operational conditions.

- Reduced operational costs and minimized unplanned downtime.

- Development of smart linings with integrated sensors for performance feedback.

- Simulation and modeling for design optimization and stress analysis.

- Enhanced worker safety by preventing catastrophic failures.

DRO & Impact Forces Of Rubber Lining Pipe Market

The Rubber Lining Pipe Market is significantly influenced by a confluence of drivers, restraints, and opportunities that collectively shape its growth trajectory and competitive landscape. Key drivers include the relentless expansion of global industrial sectors such as mining, chemical processing, and power generation, which inherently require robust solutions for abrasive and corrosive material handling. The increasing focus on infrastructure development, particularly in emerging economies, alongside the need to replace aging infrastructure in developed nations, provides a consistent demand base for durable piping systems. Furthermore, stricter environmental regulations and safety standards across industries compel companies to invest in highly reliable and leak-proof piping solutions, where rubber lining offers a distinct advantage in preventing contamination and ensuring operational integrity.

However, the market also faces notable restraints. The initial high capital investment associated with the installation of rubber-lined pipes can be a barrier for smaller enterprises or projects with limited budgets. The specialized expertise and equipment required for proper lining application and maintenance also present challenges, contributing to overall project costs and potential delays. Additionally, volatility in raw material prices, particularly for natural and synthetic rubbers, can impact manufacturing costs and product pricing, leading to market uncertainties. Competition from alternative lining materials, such as various types of plastics or composite materials, which may offer different cost-benefit profiles for specific applications, also acts as a restraint.

Despite these challenges, substantial opportunities exist for market expansion. Emerging economies in Asia Pacific, Latin America, and the Middle East and Africa offer untapped potential due to their rapid industrialization, urbanization, and ongoing large-scale infrastructure projects. Technological advancements in rubber compounding, adhesion chemistry, and application techniques are leading to the development of more durable, high-performance, and cost-effective lining solutions that can withstand even more extreme operating conditions. The growing emphasis on sustainability and circular economy principles is also driving demand for longer-lasting products that reduce waste and resource consumption, positioning rubber lining pipes as a favorable choice. The pursuit of customized solutions tailored to specific industrial challenges presents another avenue for growth, allowing manufacturers to differentiate their offerings and capture niche markets.

Segmentation Analysis

The Rubber Lining Pipe Market is meticulously segmented to provide a granular understanding of its diverse applications, material preferences, and end-user demands. This segmentation allows market participants to identify specific growth areas, tailor product offerings, and devise targeted strategies. The market can be broadly categorized based on the type of rubber material utilized, the pipe diameter and pressure rating, the specific application of the pipes, and the overarching end-use industry they serve. Each segment reflects unique operational requirements and performance criteria, highlighting the versatility and specialized nature of rubber lining solutions across the industrial spectrum.

Understanding these segments is crucial for analyzing market dynamics, competitive positioning, and future growth prospects. For instance, segments based on rubber type differentiate products by their chemical resistance, abrasion resistance, and temperature tolerance, catering to varying industrial environments. Application-based segments illustrate the primary functions these pipes fulfill, from handling abrasive slurries in mining to corrosive chemicals in processing plants. End-use industry segmentation provides insights into the major consumers and their specific needs, enabling manufacturers to focus R&D efforts and sales strategies effectively across different vertical markets. This comprehensive segmentation framework underscores the market's complexity and the necessity for tailored solutions to meet stringent industrial demands.

- By Rubber Type

- Natural Rubber

- Synthetic Rubber

- Butylene Rubber

- Ethylene Propylene Diene Monomer (EPDM)

- Chloroprene Rubber (Neoprene)

- Styrene-Butadiene Rubber (SBR)

- Butyl Rubber

- Nitrile Rubber

- Specialty Rubber Compounds

- By Pipe Diameter

- Small Diameter Pipes (Up to 150mm)

- Medium Diameter Pipes (150mm to 600mm)

- Large Diameter Pipes (Above 600mm)

- By Pressure Rating

- Low Pressure

- Medium Pressure

- High Pressure

- By Application

- Slurry & Tailings Transport

- Chemical Transfer

- Water & Wastewater Treatment

- Flue Gas Desulfurization (FGD)

- Abrasive Materials Handling

- Corrosive Fluid Handling

- Pneumatic Conveying

- Hydraulic Conveying

- Specialty Process Lines

- By End-Use Industry

- Mining & Metallurgy

- Chemical & Petrochemical

- Power Generation (Thermal & Hydroelectric)

- Water & Wastewater Treatment

- Pulp & Paper

- Construction

- Food & Beverage

- Pharmaceuticals

- Oil & Gas

- Steel Manufacturing

Value Chain Analysis For Rubber Lining Pipe Market

The value chain for the Rubber Lining Pipe Market is an intricate network of activities spanning from raw material sourcing to the final installation and maintenance of lined piping systems, illustrating the flow of value creation. At the upstream end, the chain begins with the procurement of essential raw materials, primarily various grades of natural and synthetic rubbers, chemical additives, steel or other pipe materials, and specialized adhesives. Key players in this segment include rubber plantations, chemical manufacturers, and steel pipe producers. The quality and consistent supply of these foundational components are critical, as they directly influence the performance and durability of the final rubber-lined product. Relationships with reliable suppliers are paramount for maintaining product quality and managing costs effectively.

Moving downstream, the core of the value chain involves the specialized manufacturing processes for rubber lining pipes. This includes the preparation of pipe substrates, compounding and mixing of rubber materials to achieve desired properties, the meticulous application of the rubber lining to the interior of the pipes through processes like cold bonding or hot vulcanization, and rigorous quality control testing. Manufacturers in this segment, often highly specialized, invest heavily in advanced machinery, skilled labor, and proprietary technologies to ensure optimal adhesion, uniformity, and resistance characteristics of the lining. Post-production, the products are moved through distribution channels to reach end-users, which can involve both direct and indirect routes.

Distribution channels are multifaceted. Direct sales typically involve large-scale industrial projects where manufacturers engage directly with major clients, engineering procurement and construction (EPC) contractors, or end-users such as mining companies or chemical plants for customized solutions and technical support. Indirect channels involve a network of distributors, agents, and local suppliers who manage warehousing, logistics, and often provide local installation and after-sales support. These intermediaries play a crucial role in extending market reach, especially to smaller clients or geographically dispersed projects. The effectiveness of these distribution channels, coupled with efficient installation services and ongoing maintenance support, significantly impacts customer satisfaction and market penetration, ensuring the longevity and optimal performance of the rubber-lined pipe systems.

Rubber Lining Pipe Market Potential Customers

Potential customers for the Rubber Lining Pipe Market span a broad spectrum of heavy industries that contend with severe operational environments, including the movement of abrasive slurries, corrosive chemicals, and high-temperature fluids. The primary end-users are entities that prioritize asset protection, operational longevity, and safety in their fluid and material handling systems. These include major players in the mining and metallurgical sectors, where rubber-lined pipes are indispensable for transporting mineral slurries, tailings, and process water due to their superior abrasion and impact resistance. Chemical and petrochemical processing plants represent another significant customer base, requiring linings that can withstand aggressive chemical attack from acids, alkalis, and solvents, ensuring process integrity and preventing environmental contamination.

Furthermore, the water and wastewater treatment industry extensively utilizes rubber-lined pipes for conveying corrosive effluent, sewage, and chemical reagents, protecting vital infrastructure from premature degradation. Power generation facilities, particularly thermal power plants, employ these pipes in flue gas desulfurization (FGD) systems to manage abrasive limestone slurries and corrosive byproducts. The pulp and paper industry also relies on rubber linings for transporting corrosive pulps and process chemicals. Construction and infrastructure projects, particularly those involving tunneling or large-scale civil engineering with slurry transportation, also constitute an expanding customer segment. Each of these industries seeks robust, long-lasting, and reliable piping solutions to minimize downtime, reduce maintenance costs, and comply with stringent safety and environmental regulations, making them ideal potential customers for the rubber lining pipe market.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 4.85 Billion |

| Market Forecast in 2033 | USD 7.73 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Trelleborg AB, Metso Outotec, The Weir Group PLC, Continental AG, Polycorp Ltd., FLSmidth & Co. A/S, VSR Industries Inc., Erie Technical Ceramics, Rubber Lining Solutions Pty Ltd, Atlantic Rubber Company, Waratah Engineering, Shawcor Ltd., TenCate Geosynthetics, Bekaert, Vulkem, InduMar Products, KRAHN Chemie GmbH, Dux Manufacturing, Ti Group, Corrosioneering Group. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Rubber Lining Pipe Market Key Technology Landscape

The Rubber Lining Pipe Market is continually evolving, driven by advancements in material science, manufacturing processes, and inspection technologies aimed at enhancing performance, durability, and cost-effectiveness. A key aspect of the technological landscape involves innovations in rubber compounding, where manufacturers are developing advanced formulations of natural and synthetic rubbers. These new compounds offer superior resistance to specific challenges such as extreme temperatures, highly aggressive chemicals, or severe impact and abrasion, extending the applicability of rubber-lined pipes to more demanding industrial environments. Research into nanoparticle reinforcement and polymer blends is leading to linings with improved mechanical properties and longer service lives, directly addressing end-user needs for reduced maintenance and operational continuity.

Furthermore, advancements in adhesion technology are critical, focusing on developing stronger and more reliable bonds between the rubber lining and the pipe substrate. This includes novel adhesive systems, surface preparation techniques, and curing processes that prevent delamination, which is a common failure mode in harsh conditions. The introduction of cold bonding methods alongside traditional hot vulcanization techniques offers greater flexibility in installation and repair, especially for on-site applications or larger diameter pipes. These technologies contribute significantly to the integrity and longevity of the lined pipes, crucial for ensuring safety and preventing environmental contamination in industrial settings. Automated application systems are also emerging, improving consistency and efficiency in the manufacturing process.

In addition to material and application technologies, the market is witnessing the integration of smart technologies and advanced inspection methods. Non-destructive testing (NDT) techniques, such as ultrasonic testing, eddy current, and thermal imaging, are becoming more sophisticated, allowing for precise and early detection of defects or wear without compromising the pipe structure. The concept of "smart linings" is also gaining traction, involving the embedment of sensors within the rubber to monitor parameters like temperature, pressure, and wear levels in real-time. This allows for predictive maintenance, enabling operators to identify potential issues before they escalate into costly failures, thereby optimizing operational schedules and extending the service life of the entire piping system. These technological shifts are not only enhancing product performance but also driving significant operational efficiencies across the value chain.

Regional Highlights

- Asia Pacific (APAC): Dominates the rubber lining pipe market, driven by rapid industrialization, extensive mining activities, and significant infrastructure development in countries like China, India, and Australia. The region's expanding chemical and power generation sectors further fuel demand.

- North America: Characterized by a mature industrial base and a strong emphasis on replacing aging infrastructure. Strict environmental regulations and safety standards in the United States and Canada ensure a consistent demand for high-quality, durable rubber-lined pipes, particularly in mining, oil & gas, and wastewater treatment.

- Europe: A significant market with robust demand from chemical processing, power generation, and water treatment industries. Countries such as Germany, the UK, and France focus on technological advancements, stringent quality control, and sustainable solutions, driving the adoption of specialized rubber lining systems.

- Latin America: Exhibiting substantial growth potential, primarily due to expanding mining operations in countries like Chile, Brazil, and Peru, alongside increasing investments in infrastructure and industrial projects. The need for robust solutions to handle abrasive slurries is a key market driver.

- Middle East & Africa (MEA): Emerging as a growth hub driven by large-scale infrastructure projects, expansion in oil & gas, mining, and water desalination plants. Rapid industrial development and diversification initiatives are creating new opportunities for rubber lining pipe manufacturers across the region, particularly in Saudi Arabia and South Africa.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Rubber Lining Pipe Market.- Trelleborg AB

- Metso Outotec

- The Weir Group PLC

- Continental AG

- Polycorp Ltd.

- FLSmidth & Co. A/S

- VSR Industries Inc.

- Erie Technical Ceramics

- Rubber Lining Solutions Pty Ltd

- Atlantic Rubber Company

- Waratah Engineering

- Shawcor Ltd.

- TenCate Geosynthetics

- Bekaert

- Vulkem

- InduMar Products

- KRAHN Chemie GmbH

- Dux Manufacturing

- Ti Group

- Corrosioneering Group

Frequently Asked Questions

What are rubber lining pipes primarily used for?

Rubber lining pipes are mainly used to protect internal pipe surfaces from abrasion, corrosion, and impact damage caused by transporting aggressive media such as abrasive slurries, corrosive chemicals, and high-temperature fluids in industrial applications. They are critical in mining, chemical processing, and wastewater treatment.

What types of rubber are commonly used for lining pipes?

Common rubber types include natural rubber for excellent abrasion resistance, and synthetic rubbers like EPDM (for chemical and temperature resistance), Butyl (for gas impermeability), Neoprene (for oil and chemical resistance), and SBR (for general-purpose applications). Specialty compounds are also developed for specific industrial demands.

How do rubber-lined pipes contribute to operational cost savings?

Rubber-lined pipes significantly extend the lifespan of piping systems by preventing wear and corrosion, drastically reducing the need for frequent replacements and maintenance. This leads to fewer operational downtimes, lower repair costs, and improved overall productivity, translating into substantial long-term cost savings for industries.

What are the key driving factors for the Rubber Lining Pipe Market?

The market is driven by increasing industrialization, particularly in mining, chemical, and power generation sectors, alongside global infrastructure development and the growing need to replace aging infrastructure. Stringent environmental regulations and safety standards also compel industries to adopt reliable and leak-proof piping solutions.

How is Artificial Intelligence (AI) impacting the rubber lining pipe industry?

AI is transforming the industry through predictive maintenance, optimizing manufacturing processes, and enhancing quality control. AI-powered systems can detect early signs of wear, suggest optimal material formulations, and streamline production, leading to improved product longevity, reduced operational costs, and enhanced safety.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager