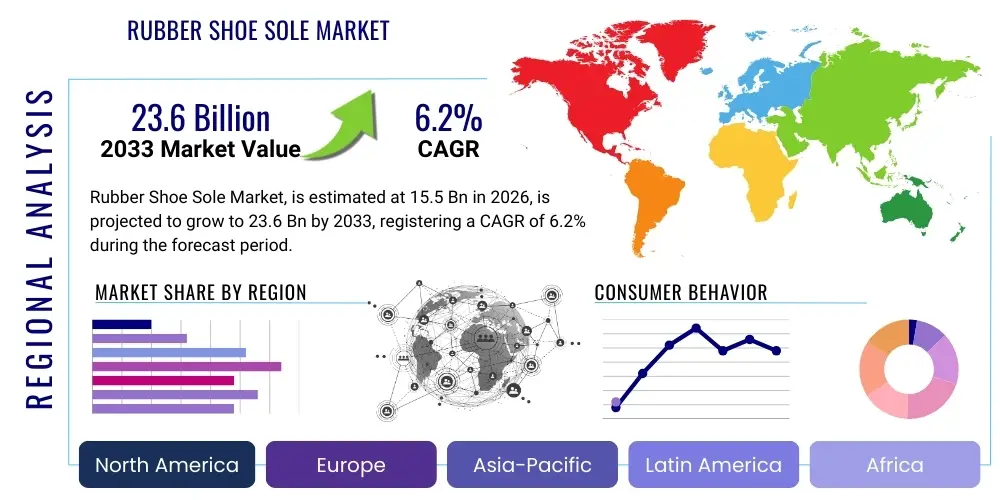

Rubber Shoe Sole Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439525 | Date : Jan, 2026 | Pages : 246 | Region : Global | Publisher : MRU

Rubber Shoe Sole Market Size

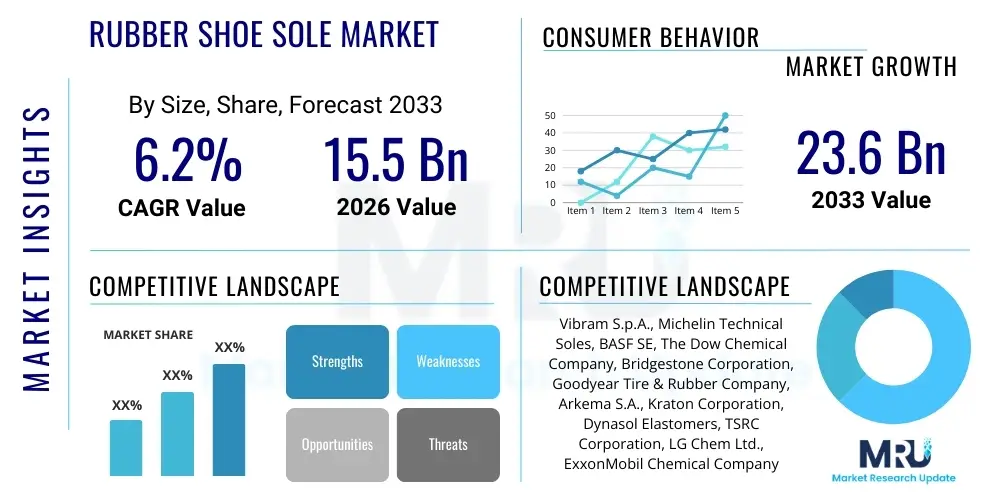

The Rubber Shoe Sole Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.2% between 2026 and 2033. The market is estimated at USD 15.5 Billion in 2026 and is projected to reach USD 23.6 Billion by the end of the forecast period in 2033.

Rubber Shoe Sole Market introduction

The global rubber shoe sole market represents a critical component of the footwear industry, providing the foundational element for diverse shoe types ranging from high-performance athletic wear to durable industrial safety boots. This market is characterized by a constant drive for innovation, fueled by evolving consumer demands for enhanced comfort, durability, traction, and increasingly, sustainability. Rubber soles, whether derived from natural rubber or various synthetic rubber compounds, offer superior properties such as shock absorption, abrasion resistance, and excellent grip, making them indispensable for footwear manufacturers worldwide. The intricate process of sole design and material selection significantly impacts a shoe's overall functionality and lifespan, directly influencing consumer preference and brand reputation.

Major applications of rubber shoe soles span across athletic footwear, casual and fashion footwear, formal shoes, and specialized segments like safety, occupational, and outdoor adventure footwear. In athletic shoes, advanced rubber compounds are engineered to provide optimal responsiveness, energy return, and multi-directional traction, critical for sports performance. For casual and formal wear, the emphasis shifts towards comfort, flexibility, and aesthetic integration, often incorporating lighter or more aesthetically pleasing rubber blends. The inherent benefits of rubber, including its elasticity, waterproofing capabilities, and resistance to various environmental factors, position it as a material of choice across these diverse applications.

The market's growth is primarily driven by several macroeconomic and industry-specific factors. A surging global interest in sports, fitness, and outdoor activities, coupled with rising disposable incomes in emerging economies, significantly boosts the demand for specialized and high-quality footwear. Urbanization trends and the increasing adoption of athleisure wear contribute to the expansion of casual and everyday performance shoe segments. Furthermore, continuous advancements in rubber chemistry and manufacturing technologies enable the development of lighter, more resilient, and environmentally friendly soles, addressing both performance needs and growing consumer preference for sustainable products. These innovations are crucial for manufacturers seeking to gain a competitive edge in a dynamic global market.

Rubber Shoe Sole Market Executive Summary

The rubber shoe sole market is undergoing significant transformation, marked by dynamic business trends, evolving regional landscapes, and segmented growth patterns. A prominent business trend is the escalating focus on sustainability, driving innovation in recycled rubber content, bio-based polymers, and closed-loop manufacturing processes. Companies are investing heavily in research and development to create high-performance yet eco-conscious materials, responding to both consumer demand and regulatory pressures. Automation and digitalization of manufacturing processes are also gaining traction, enhancing production efficiency, consistency, and enabling faster time-to-market for new designs. Furthermore, strategic collaborations between sole manufacturers and footwear brands are becoming more common, fostering co-creation and specialized product development to meet niche market requirements.

Regionally, the Asia-Pacific continues its dominance as a manufacturing hub, benefiting from lower labor costs and extensive supply chain infrastructure, particularly in countries like China, Vietnam, and India. This region is also experiencing robust growth in domestic consumption, driven by an expanding middle class and increasing penetration of international footwear brands. North America and Europe, while mature markets, lead in innovation and premium product adoption, with a strong emphasis on performance attributes, comfort technologies, and sustainable sourcing. Latin America and the Middle East & Africa are emerging as high-growth potential regions, characterized by rising disposable incomes, urbanization, and a growing interest in sports and leisure activities, prompting footwear companies to expand their distribution and manufacturing footprints in these areas.

Segmentation trends reveal distinct growth trajectories across various categories. The athletic footwear segment remains the largest and most innovative, constantly pushing the boundaries of material science and design to deliver superior performance. Demand for specialized soles in running, basketball, and training shoes continues to drive significant research and development. The casual footwear segment is witnessing steady growth, particularly with the proliferation of "athleisure" styles that blend comfort with fashion, requiring flexible and durable rubber soles. The safety and industrial footwear sector maintains consistent demand, driven by stringent workplace regulations and the need for highly protective and slip-resistant soles. Material-wise, synthetic rubbers continue to hold a larger market share due to their versatile properties, but natural rubber and blends are gaining traction, especially with advancements in sustainable sourcing and processing techniques.

AI Impact Analysis on Rubber Shoe Sole Market

User inquiries regarding AI's influence on the rubber shoe sole market frequently revolve around its potential to revolutionize design, optimize manufacturing processes, enhance material properties, and personalize footwear experiences. Key themes consistently emerging include AI's role in accelerating the discovery of novel rubber compounds, predicting material performance under various conditions, streamlining production logistics, improving quality control, and enabling bespoke sole designs. Consumers and industry professionals alike are eager to understand how AI can contribute to more sustainable manufacturing practices, reduce waste, and develop "smart soles" with integrated functionalities. The overarching expectation is that AI will introduce unprecedented levels of efficiency, innovation, and customization throughout the entire value chain, from raw material to end-user product.

- Design Optimization and Simulation: AI algorithms can analyze vast datasets of biomechanical information, material properties, and design parameters to generate optimized sole geometries that enhance cushioning, stability, and traction. This accelerates the iterative design process, reducing the need for extensive physical prototyping by simulating performance under various stresses and environments, thereby improving efficiency and reducing development costs.

- Advanced Material Discovery and Formulation: Machine learning models can predict the properties of new rubber formulations based on their chemical composition, enabling quicker identification of optimal blends for specific performance requirements like abrasion resistance, grip, or flexibility. AI can also assist in discovering sustainable alternatives or enhancing the performance of recycled and bio-based rubber materials, aligning with eco-conscious trends.

- Predictive Maintenance and Quality Control: AI-powered systems monitor manufacturing equipment in real-time, predicting potential failures before they occur, thus minimizing downtime and optimizing production schedules. In quality control, computer vision and AI can identify subtle defects in sole production with greater accuracy and speed than human inspection, ensuring consistent product quality and reducing waste.

- Supply Chain Optimization and Demand Forecasting: AI enhances the efficiency of the entire supply chain by predicting demand fluctuations, optimizing inventory levels, and streamlining logistics. This allows sole manufacturers to respond more agilely to market shifts, manage raw material procurement more effectively, and reduce lead times, leading to significant cost savings and improved customer satisfaction.

- Personalization and Mass Customization: AI can process individual foot scans and user preferences to generate custom sole designs tailored to a consumer's unique biomechanics and aesthetic choices. This enables mass customization, allowing brands to offer highly personalized footwear experiences at scale, moving beyond traditional standardized sizing and fit.

- Sustainable Manufacturing and Waste Reduction: AI can optimize resource usage in manufacturing processes, such as rubber mixing and molding, to minimize material waste and energy consumption. By precisely controlling parameters, AI contributes to more efficient production cycles and supports the transition towards circular economy principles within the rubber shoe sole industry.

DRO & Impact Forces Of Rubber Shoe Sole Market

The rubber shoe sole market is shaped by a confluence of driving forces, inherent restraints, and emerging opportunities, all interacting to define its growth trajectory. Key drivers include the global surge in demand for athletic and leisure footwear, propelled by increasing health consciousness and the popularization of athleisure fashion. Rising disposable incomes, particularly in developing economies, enable consumers to invest in diverse and specialized footwear, further boosting the market. Moreover, continuous technological advancements in material science are leading to the development of lighter, more durable, and performance-enhancing rubber compounds, which in turn fuels innovation in sole design and functionality, attracting consumers seeking superior comfort and performance. The growing awareness and demand for ergonomic footwear also contribute significantly to market expansion.

Conversely, several restraints impede market growth and stability. The volatility of raw material prices, particularly for natural rubber and petrochemical-derived synthetic rubbers, poses a significant challenge, impacting manufacturing costs and profit margins. Environmental concerns surrounding the production and disposal of synthetic rubber, coupled with increasing regulatory scrutiny, necessitate substantial investments in sustainable practices, adding to operational complexities. Intense competition among both raw material suppliers and sole manufacturers, often leading to price wars, can erode profitability. Furthermore, the reliance on a global supply chain makes the market vulnerable to geopolitical tensions, trade barriers, and logistics disruptions, as evidenced by recent global events.

Despite these challenges, the market presents substantial opportunities. The growing consumer demand for sustainable and eco-friendly products creates a fertile ground for innovations in recycled rubber, bio-based polymers, and biodegradable sole materials. The integration of smart technologies, such as sensors for activity tracking or pressure mapping, into rubber soles offers a lucrative avenue for product differentiation and value addition. Expanding into emerging markets, where footwear consumption is rapidly increasing, represents a significant growth opportunity for manufacturers. Moreover, advancements in manufacturing technologies like 3D printing and advanced compounding offer possibilities for customizable soles and more efficient production processes, catering to niche demands and fostering product innovation.

Segmentation Analysis

The rubber shoe sole market is comprehensively segmented to provide a granular understanding of its diverse components, allowing for targeted market strategies and insights. This segmentation is primarily based on material type, application, and end-use, with geographical regions further delineating market characteristics and growth patterns. Each segment reflects unique demand drivers, technological preferences, and competitive landscapes, crucial for stakeholders to analyze and capitalize on specific market niches. Understanding these segments is paramount for manufacturers to tailor their product offerings, optimize supply chains, and identify promising areas for investment and expansion, ensuring relevance in a dynamic global footwear industry.

- By Material:

- Natural Rubber: Valued for elasticity, grip, and biodegradability.

- Synthetic Rubber:

- Styrene Butadiene Rubber (SBR): Widely used for abrasion resistance and good traction, cost-effective.

- Butadiene Rubber (BR): Known for its high resilience and resistance to low temperatures.

- Nitrile Butadiene Rubber (NBR): Offers oil, fuel, and chemical resistance, commonly used in industrial and safety footwear.

- Ethylene Propylene Diene Monomer (EPDM): Provides excellent weather resistance, ozone resistance, and heat stability.

- Others (e.g., Polyurethane (PU), Thermoplastic Rubber (TPR)): Offer specialized properties for cushioning, lightness, or specific aesthetics.

- Blends: Combinations of natural and synthetic rubbers to achieve specific performance characteristics like enhanced durability, flexibility, or reduced weight.

- By Application:

- Athletic Footwear:

- Running Shoes: Focus on cushioning, energy return, and traction.

- Training Shoes: Emphasize stability, flexibility, and multi-directional grip.

- Basketball Shoes: Require exceptional ankle support, shock absorption, and court grip.

- Tennis Shoes: Demand lateral support, durability, and specific court traction patterns.

- Football/Soccer Shoes: Need lightweight, aggressive traction for field performance.

- Others (e.g., Hiking, Cycling, Golf): Specialized requirements based on sport.

- Casual Footwear: Prioritizes comfort, flexibility, and aesthetic appeal for everyday wear.

- Formal Footwear: Focuses on lightweight, sleek profiles, often with integrated comfort features.

- Safety & Industrial Footwear: Demands extreme slip resistance, oil resistance, puncture resistance, and durability for hazardous environments.

- Outdoor & Trekking Footwear: Requires rugged durability, superior grip on varied terrains, and weather resistance.

- Athletic Footwear:

- By End-Use:

- Men's Footwear: Dominant segment, diverse range across all applications.

- Women's Footwear: Growing segment, influenced by fashion and comfort trends.

- Kids' Footwear: Focus on durability, flexibility, and anatomical support for growing feet.

- By Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America

- Middle East & Africa (MEA)

Value Chain Analysis For Rubber Shoe Sole Market

The value chain of the rubber shoe sole market encompasses a series of interconnected stages, from raw material sourcing to the final consumer, highlighting the complex interplay between various stakeholders. The upstream segment involves the extraction and processing of raw materials, primarily natural rubber from plantations and synthetic rubber chemicals derived from petrochemicals. Key players at this stage include rubber growers, chemical manufacturers, and compounders who mix and formulate specific rubber compounds tailored for sole production. This stage is critical as the quality and cost of raw materials directly impact the properties and pricing of the finished soles. Innovation in this segment often focuses on developing sustainable materials and efficient processing techniques.

Midstream activities involve the manufacturing of rubber soles, which includes processes such as molding (compression, injection), cutting, and finishing. This stage typically includes specialized sole manufacturers who produce soles according to design specifications from footwear brands. These manufacturers invest heavily in machinery and technology to achieve precision, consistency, and efficiency in mass production. They also conduct rigorous quality control to ensure soles meet performance and durability standards. The choices made at this stage regarding manufacturing technology and scale significantly affect production costs, turnaround times, and the ability to customize for various footwear applications.

The downstream segment primarily consists of footwear manufacturers who integrate these soles into their final shoe products. This includes global athletic brands, fashion footwear companies, and manufacturers of safety and industrial shoes. Distribution channels for rubber soles can be direct, where large footwear brands purchase directly from sole manufacturers, establishing long-term partnerships for custom designs and bulk orders. Indirect channels involve distributors or agents who supply smaller footwear manufacturers or provide a wider range of standard sole options. Ultimately, the finished footwear products reach consumers through various retail channels, including brick-and-mortar stores, online platforms, and specialized footwear boutiques. Effective logistics and strong relationships across all these stages are crucial for efficient market operation.

Rubber Shoe Sole Market Potential Customers

The primary potential customers and end-users of rubber shoe soles are diverse, spanning the entire spectrum of the footwear industry, from global giants to niche artisanal producers. These customers seek rubber soles that align with their specific product requirements, brand identity, and target consumer base. Major athletic footwear companies, for instance, are constantly seeking innovative, high-performance soles that offer superior cushioning, traction, and durability to enhance athletic performance and prevent injuries. Their demand is driven by rapid technological advancements in sports science and evolving consumer expectations for advanced footwear features. These customers often engage in extensive R&D collaborations with sole manufacturers to develop proprietary sole technologies.

Beyond athletic wear, manufacturers of casual and fashion footwear represent a substantial customer segment. Their purchasing decisions are influenced by factors such as comfort, aesthetic appeal, flexibility, and increasingly, sustainability. These brands require a wide variety of rubber sole types, from lightweight and flexible options for everyday sneakers to more robust and stylish designs for boots and fashion-forward shoes. The ability of sole manufacturers to offer diverse designs, colors, and textures, along with consistent quality, is paramount for securing business from this segment. Market trends, consumer preferences for specific styles, and rapid seasonal changes heavily influence the demand patterns from these customers.

Another significant segment comprises manufacturers of safety, industrial, and occupational footwear. For these customers, the primary drivers are compliance with stringent safety regulations, extreme durability, and specialized protective properties such as slip resistance, oil resistance, chemical resistance, and puncture protection. Companies producing outdoor, trekking, and tactical footwear also fall into this category, requiring soles engineered for harsh environments, providing exceptional grip on varied terrains, and offering long-term resilience. Furthermore, custom shoemakers, government contractors (for military and police footwear), and private label brands also constitute potential customers, each with unique volume, design, and performance specifications that sole manufacturers must be equipped to meet. The ability to offer tailored solutions and reliable supply chains is key to serving this broad customer base effectively.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 15.5 Billion |

| Market Forecast in 2033 | USD 23.6 Billion |

| Growth Rate | 6.2% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Vibram S.p.A., Michelin Technical Soles, BASF SE, The Dow Chemical Company, Bridgestone Corporation, Goodyear Tire & Rubber Company, Arkema S.A., Kraton Corporation, Dynasol Elastomers, TSRC Corporation, LG Chem Ltd., ExxonMobil Chemical Company, Lanxess AG, Trinseo S.A., Kumho Petrochemical Co. Ltd., Zeon Chemicals L.P., Sumitomo Chemical Co. Ltd., Sinopec Corporation, Asahi Kasei Corporation, Versalis S.p.A. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Rubber Shoe Sole Market Key Technology Landscape

The rubber shoe sole market is continuously evolving, driven by advancements in material science, manufacturing processes, and digital technologies. Traditional technologies like vulcanization remain fundamental, enhancing the elasticity and durability of rubber compounds. However, modern approaches such as advanced compounding techniques are increasingly prevalent, allowing for the precise mixing of various rubbers, additives, and fillers to achieve highly specific performance characteristics, including improved grip, enhanced cushioning, or reduced weight. This enables manufacturers to tailor soles for specialized applications, from high-performance athletic footwear to industrial safety shoes. The development of custom formulations is a key differentiator, providing brands with unique competitive advantages in terms of sole functionality and feel.

In manufacturing, injection molding and compression molding techniques are extensively utilized, offering efficiency and scalability in producing complex sole designs with consistent quality. However, the adoption of more innovative processes such as 3D printing is gaining traction, particularly for prototyping, customization, and small-batch production of intricate sole geometries. 3D printing allows for rapid iteration of designs and the creation of highly personalized soles tailored to individual biomechanics, pushing the boundaries of what is possible in footwear innovation. Furthermore, robotics and automation are being integrated into production lines to improve precision, reduce labor costs, and enhance overall manufacturing throughput, leading to more efficient and cost-effective production cycles.

The integration of smart materials and sustainable processing techniques also defines the current technological landscape. Research into bio-based and recycled rubber alternatives is crucial, driven by environmental concerns and consumer demand for eco-friendly products. Technologies for effectively processing these sustainable materials while maintaining desired performance attributes are rapidly developing. Additionally, the emergence of "smart soles" incorporating sensors for tracking activity, analyzing gait, or providing targeted cushioning represents a significant technological frontier. These innovations merge material science with IoT capabilities, creating interactive footwear experiences and opening new avenues for product development and market expansion, further solidifying technology as a core driver in the rubber shoe sole industry.

Regional Highlights

- Asia Pacific (APAC): This region dominates the rubber shoe sole market both in terms of production and consumption. Countries like China, Vietnam, and India are major manufacturing hubs due to cost-effective labor, extensive supply chains, and large production capacities. The growing disposable incomes, rapid urbanization, and increasing participation in sports and outdoor activities are driving substantial domestic demand for footwear, making APAC a critical growth engine for the market.

- North America: Characterized by a high demand for premium and performance-oriented footwear, North America is a significant market for advanced rubber sole technologies. The region leads in innovation, with a strong focus on ergonomic design, smart footwear integration, and sustainable materials. Consumer preferences for athletic and casual shoes, coupled with a robust e-commerce sector, contribute to consistent market growth.

- Europe: Europe is a mature market with a strong emphasis on fashion, quality, and sustainability. Countries like Germany, Italy, and France are key players, often setting trends in design and eco-friendly manufacturing practices. There is a growing demand for high-performance soles in sports footwear and an increasing consumer preference for sustainable and ethically produced shoes, driving innovation in recycled and bio-based rubber compounds.

- Latin America: This region presents significant growth opportunities due to its expanding middle class, rising disposable incomes, and increasing urbanization. Brazil and Mexico are leading markets, experiencing growing demand for both athletic and everyday footwear. Local manufacturing capabilities are also developing, aiming to cater to the domestic market and reduce reliance on imports.

- Middle East & Africa (MEA): The MEA region is an emerging market for rubber shoe soles, driven by population growth, increasing infrastructure development, and a rising interest in sports and fitness activities. While production capacities are still developing, the demand for both conventional and specialized footwear is on the rise, attracting international brands and creating opportunities for market expansion.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Rubber Shoe Sole Market.- Vibram S.p.A.

- Michelin Technical Soles

- BASF SE

- The Dow Chemical Company

- Bridgestone Corporation

- Goodyear Tire & Rubber Company

- Arkema S.A.

- Kraton Corporation

- Dynasol Elastomers

- TSRC Corporation

- LG Chem Ltd.

- ExxonMobil Chemical Company

- Lanxess AG

- Trinseo S.A.

- Kumho Petrochemical Co. Ltd.

- Zeon Chemicals L.P.

- Sumitomo Chemical Co. Ltd.

- Sinopec Corporation

- Asahi Kasei Corporation

- Versalis S.p.A.

Frequently Asked Questions

What are rubber shoe soles primarily made of?

Rubber shoe soles are primarily made from either natural rubber, derived from rubber trees, or various types of synthetic rubber such as Styrene Butadiene Rubber (SBR), Butadiene Rubber (BR), or Ethylene Propylene Diene Monomer (EPDM). Often, blends of these materials are used to optimize specific properties like durability, flexibility, and grip for different footwear applications.

What are the main advantages of rubber shoe soles?

Rubber shoe soles offer superior advantages including excellent traction and grip on various surfaces, high abrasion resistance for durability, effective shock absorption for cushioning and comfort, and good flexibility for natural foot movement. Many rubber soles also provide water resistance and are highly adaptable to different environmental conditions.

How do rubber soles contribute to sustainable footwear?

Rubber soles contribute to sustainable footwear through innovations in recycled content, where post-consumer or post-industrial rubber waste is incorporated into new soles. Additionally, advancements in bio-based rubbers and more efficient, less resource-intensive manufacturing processes are reducing the environmental footprint of sole production, aligning with circular economy principles.

What are the key factors driving the growth of the rubber shoe sole market?

Key growth drivers for the rubber shoe sole market include the increasing global demand for athletic and leisure footwear, rising disposable incomes in emerging economies, continuous technological advancements in material science leading to enhanced sole performance, and a growing consumer focus on comfort and ergonomic design in footwear.

What role does technology play in modern rubber shoe sole manufacturing?

Technology plays a crucial role in modern rubber shoe sole manufacturing through advanced compounding techniques for custom material properties, efficient molding processes like injection and compression molding, and emerging technologies such as 3D printing for rapid prototyping and customization. AI and automation are also increasingly used for design optimization, quality control, and predictive maintenance.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager