Salt Fog Chambers Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439209 | Date : Jan, 2026 | Pages : 245 | Region : Global | Publisher : MRU

Salt Fog Chambers Market Size

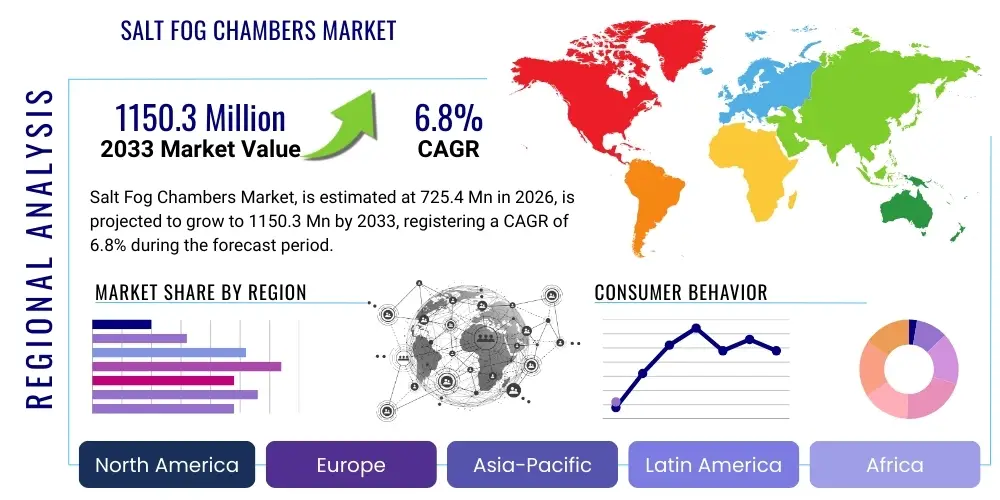

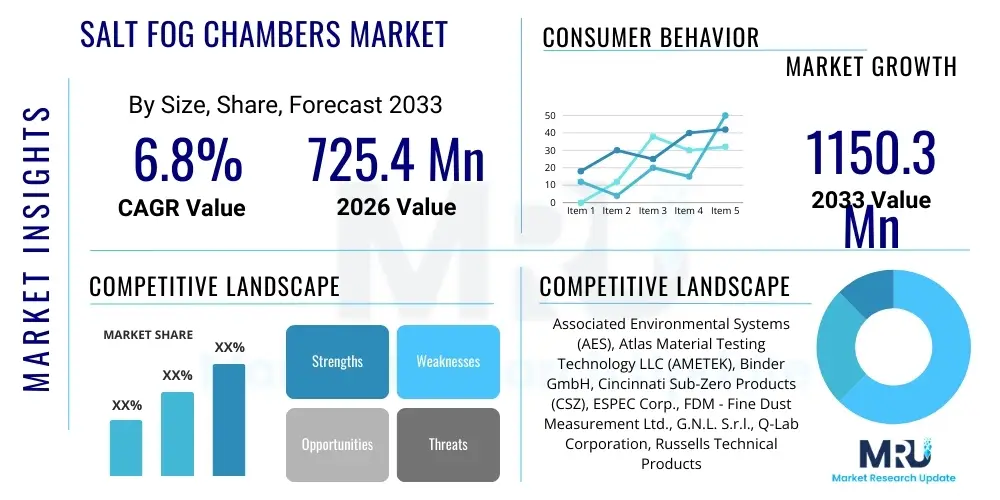

The Salt Fog Chambers Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 725.4 Million in 2026 and is projected to reach USD 1150.3 Million by the end of the forecast period in 2033. This consistent growth underscores the critical role these chambers play in ensuring product longevity and material integrity across a multitude of industries, driven by increasingly stringent quality and safety standards worldwide.

Salt Fog Chambers Market introduction

Salt fog chambers, also known as salt spray or cyclic corrosion test chambers, are specialized environmental testing equipment designed to simulate corrosive atmospheres under controlled laboratory conditions. These chambers subject materials, components, and finished products to a corrosive environment, typically a saltwater solution, to accelerate the effects of corrosion and evaluate their resistance. The primary objective is to assess the long-term durability and performance of products when exposed to harsh conditions, which might include marine environments, road salt applications, or industrial pollution. They operate by atomizing a precise salt solution into a fine mist within a sealed chamber, maintaining specific temperature and humidity levels to replicate real-world corrosive stress.

The major applications of salt fog chambers span across critical sectors such as automotive, aerospace and defense, electronics, marine, construction, and paints and coatings. In the automotive industry, these chambers are indispensable for testing car parts like body panels, braking systems, and electrical connectors to ensure they withstand the corrosive effects of road salts and environmental moisture. For aerospace components, they verify resistance to atmospheric corrosion at high altitudes and varying climates. Within electronics, they are used to validate the reliability of circuit boards and enclosures against humidity and salt ingress. The marine industry relies heavily on these tests for ship components, offshore structures, and navigational equipment, while the paints and coatings sector utilizes them to evaluate the protective qualities and adhesion of various surface treatments on metallic substrates.

The benefits derived from using salt fog chambers are manifold, including significant cost savings by identifying material weaknesses early in the design and development phases, thereby preventing costly recalls and warranty claims. They enable manufacturers to comply with various international standards such as ASTM B117, ISO 9227, and MIL-STD-810, ensuring global market acceptance and regulatory adherence. The driving factors behind the market's expansion include the escalating demand for high-quality, durable, and reliable products across all industries, coupled with the increasing complexity of materials and coatings that require rigorous validation. Furthermore, the global emphasis on product safety, extended warranty periods, and the push towards sustainable, long-lasting products are continuously fueling the adoption of advanced corrosion testing solutions like salt fog chambers.

Salt Fog Chambers Market Executive Summary

The salt fog chambers market is currently experiencing robust growth, propelled by several overarching business trends. Manufacturers are increasingly focusing on developing advanced, energy-efficient chambers with enhanced automation and digital control systems to meet evolving industry demands. There is a discernible trend towards modular and customizable solutions, allowing end-users to tailor chambers to specific testing requirements, ranging from standard salt spray tests to complex cyclic corrosion profiles that mimic real-world conditions more accurately. Furthermore, the market is witnessing an uptick in demand for chambers with integrated data logging and remote monitoring capabilities, facilitating easier compliance and more efficient test management. Strategic collaborations and partnerships among chamber manufacturers, material science companies, and testing laboratories are also contributing to market innovation and wider adoption of these critical testing technologies, as companies seek to consolidate expertise and optimize product development cycles.

Regionally, the market exhibits diverse growth patterns. Asia Pacific, particularly countries like China, India, and South Korea, is emerging as a dominant force due to rapid industrialization, burgeoning automotive and electronics manufacturing sectors, and increasing investments in research and development activities. North America and Europe, while mature markets, continue to demonstrate steady growth, primarily driven by stringent regulatory frameworks, a strong emphasis on product quality, and continuous innovation in materials science and engineering. Latin America and the Middle East & Africa regions are also showing promising growth trajectories, albeit from a smaller base, as industrial infrastructure develops and local manufacturing capabilities expand. The varying environmental conditions across these regions, from humid coastal areas to desert climates, further necessitate robust corrosion testing, contributing to sustained regional demand.

Segmentation trends within the salt fog chambers market highlight a shift towards more sophisticated and versatile testing solutions. While benchtop and walk-in chambers remain foundational, the cyclic corrosion test chambers segment is witnessing accelerated growth. These chambers offer the ability to simulate a broader range of environmental conditions, including wet, dry, and humid cycles, which more accurately replicate natural weathering processes and corrosion mechanisms. This allows for a more comprehensive evaluation of material performance under realistic stresses. Moreover, the end-user segment reveals strong demand from the automotive, aerospace, and electronics industries, which require precise and repeatable testing environments to ensure the longevity and reliability of their high-value components. The focus on developing new alloys, coatings, and composite materials further drives the need for advanced, specialized testing capabilities that traditional salt spray tests alone cannot fully address.

AI Impact Analysis on Salt Fog Chambers Market

Users frequently inquire about how artificial intelligence will transform the traditional landscape of salt fog chambers, seeking insights into enhanced efficiency, predictive capabilities, and overall testing accuracy. Common questions revolve around AI's potential to optimize test parameters, automate data analysis, and even predict material degradation more precisely, moving beyond conventional empirical methods. Users are particularly interested in the integration of smart sensors, machine learning algorithms for pattern recognition in corrosion data, and how AI can lead to more robust, reliable, and cost-effective testing protocols. Concerns also exist regarding the initial investment in AI-enabled systems, the complexity of implementation, and the need for specialized expertise, yet the overarching expectation is that AI will usher in a new era of intelligent, proactive material testing, minimizing human error and maximizing throughput.

- AI can optimize test parameters by learning from vast datasets of past tests, suggesting ideal conditions for specific material-coating combinations, leading to more efficient and accurate corrosion simulation.

- Predictive analytics powered by AI can forecast material degradation rates and remaining useful life based on real-time test data, moving from reactive observation to proactive material assessment.

- Automation of data acquisition and analysis through AI algorithms can significantly reduce manual intervention, improving consistency, reducing human error, and accelerating the interpretation of complex corrosion patterns.

- AI-driven smart chambers can integrate with IoT sensors to monitor internal conditions, component wear, and energy consumption, allowing for predictive maintenance and optimized operational efficiency.

- Machine learning can identify subtle corrosion trends and anomalies that might be missed by human observation, leading to earlier detection of material weaknesses and more robust product designs.

- Enhanced test repeatability and reproducibility can be achieved through AI's ability to precisely control and adjust chamber environments, ensuring highly consistent test conditions across multiple runs and different chambers.

- AI can facilitate the development of digital twins for materials and components, enabling virtual corrosion testing and rapid iteration of design changes, significantly shortening the product development cycle.

DRO & Impact Forces Of Salt Fog Chambers Market

The Salt Fog Chambers Market is significantly influenced by a confluence of drivers, restraints, opportunities, and broader impact forces that shape its growth trajectory. Among the primary drivers is the ever-increasing demand for product quality and reliability across nearly all manufacturing sectors. As global competition intensifies and consumer expectations for durable goods rise, industries such as automotive, aerospace, and electronics are compelled to conduct rigorous material testing, making salt fog chambers indispensable for validating corrosion resistance. The proliferation of complex materials, advanced coatings, and multi-layered finishes further necessitates sophisticated testing methods to ensure their long-term performance in various environmental conditions. Additionally, the tightening of international regulatory standards and industry-specific certifications, such as ASTM, ISO, and various military specifications, mandates the use of certified testing equipment, including salt fog chambers, for compliance, thereby driving consistent demand. Rapid industrialization in emerging economies and the expansion of manufacturing bases in these regions also fuel the adoption of these chambers for local production and export market requirements. Furthermore, the growing focus on extending product lifecycles and minimizing warranty claims pushes manufacturers to invest in comprehensive quality assurance protocols, with corrosion testing being a fundamental component.

Despite these strong drivers, the market faces several restraints. The high initial capital investment required for purchasing and installing advanced salt fog chambers can be a significant barrier for small and medium-sized enterprises (SMEs), limiting their ability to upgrade or acquire new testing equipment. Operational costs, including energy consumption, specialized salt solutions, and regular maintenance, also contribute to the overall expense, impacting the total cost of ownership. The need for skilled personnel to operate, calibrate, and interpret results from these sophisticated chambers presents another challenge, as specialized training is often required. Moreover, the availability of alternative, albeit often less comprehensive, testing methods or outsourced testing services can sometimes dampen the in-house procurement of chambers, especially for companies with infrequent testing needs. Economic uncertainties and fluctuations in global manufacturing output can lead to reduced R&D budgets and capital expenditure, temporarily slowing down market growth. The space requirements for larger walk-in or customized chambers can also be a logistical restraint for facilities with limited laboratory space.

Opportunities for growth in the salt fog chambers market are substantial and diverse. The most prominent opportunity lies in the integration of smart technologies, such as the Internet of Things (IoT) and artificial intelligence (AI), into new generations of chambers. These 'smart chambers' can offer enhanced automation, real-time data monitoring, remote control capabilities, predictive maintenance, and advanced data analytics, significantly improving efficiency and accuracy. The expanding market in emerging economies, particularly in Asia Pacific and Latin America, presents significant avenues for market penetration as these regions continue to invest heavily in manufacturing infrastructure and quality control. Furthermore, the increasing complexity of materials, including lightweight composites, advanced alloys, and functional coatings, creates demand for highly specialized and versatile cyclic corrosion test chambers that can simulate more intricate and realistic environmental cycles. The growing adoption of electric vehicles (EVs) and renewable energy technologies (e.g., solar panels, wind turbine components) also opens new application areas, as these sectors require rigorous testing for components exposed to harsh outdoor conditions. Customization and modularity in chamber design, allowing for tailor-made solutions to unique industry challenges, represent another key growth opportunity, catering to niche market demands.

The impact forces influencing this market extend beyond the immediate drivers and restraints. Technological advancements in sensor technology, control systems, and material science continuously redefine the capabilities and expectations for corrosion testing. Regulatory changes, particularly those related to environmental protection and product safety, compel industries to adopt more stringent testing protocols. Global economic fluctuations, including trade policies and currency exchange rates, can affect both the cost of manufacturing chambers and the purchasing power of end-users. The competitive landscape, characterized by a mix of established global players and niche regional manufacturers, drives innovation and pricing strategies. Finally, increasing environmental concerns and the push towards sustainability influence product design and material selection, indirectly impacting the demand for chambers capable of testing environmentally friendly materials and coatings, or those designed for extended durability to reduce waste.

Segmentation Analysis

The salt fog chambers market is comprehensively segmented to provide a detailed understanding of its diverse landscape, enabling stakeholders to pinpoint specific areas of demand and growth. These segmentations are typically based on the type of chamber, the application they serve, the end-user industry, and the geographical region. This granular analysis reveals varied preferences and requirements across different market verticals, from basic salt spray testing to complex cyclic corrosion simulations, addressing the needs of a broad spectrum of industries focused on material durability and product longevity.

- Type

- Benchtop Salt Spray Chambers

- Walk-in Salt Spray Chambers

- Cyclic Corrosion Test Chambers

- Combined Environmental Test Chambers

- Application

- Automotive Testing

- Aerospace & Defense

- Electronics & Electrical

- Industrial & Manufacturing

- Research & Development

- Marine

- Coatings & Materials

- End-User

- Manufacturers (OEMs, Component Suppliers)

- Research Institutions (Universities, Private Labs)

- Testing Laboratories (Contract Testing Labs)

- Government & Military Organizations

- Region

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East & Africa

Value Chain Analysis For Salt Fog Chambers Market

The value chain for the salt fog chambers market is an intricate network encompassing various stages, from raw material sourcing to end-user application, highlighting the interdependencies and value creation at each step. Upstream analysis begins with the procurement of critical components and raw materials, including high-grade corrosion-resistant plastics (like PVC, polypropylene), stainless steel, specialized sensors (temperature, humidity, pressure), spray nozzles, heating elements, control systems (PLCs, microcontrollers), and various electrical components. Suppliers in this segment focus on providing materials that meet stringent quality and durability standards, as the performance and longevity of the entire chamber depend heavily on the integrity of these foundational inputs. Key considerations at this stage include material cost, availability, supply chain reliability, and adherence to environmental and safety regulations. Manufacturers often form long-term relationships with trusted suppliers to ensure consistent quality and mitigate supply chain risks, which is crucial for producing reliable and consistent testing equipment.

The manufacturing stage involves the design, engineering, assembly, and quality control of the salt fog chambers. This is where innovation in chamber design, energy efficiency, automation features, and compliance with international testing standards (e.g., ASTM B117, ISO 9227) takes place. Manufacturers invest heavily in R&D to develop chambers with advanced capabilities, such as cyclic corrosion testing, improved temperature and humidity control, and integrated data logging systems. The assembly process requires skilled technicians capable of handling precision components and ensuring the chamber’s structural integrity and operational accuracy. Quality assurance and testing are paramount at this stage to verify that each chamber meets design specifications and performance criteria before it reaches the customer. Post-manufacturing, the chambers are packaged and prepared for distribution, often requiring specialized logistics due to their size and sensitive components.

Downstream analysis focuses on the distribution channels and the ultimate end-users. Distribution typically involves a mix of direct sales by manufacturers, a network of authorized distributors, and third-party sales agents. Direct sales are common for larger, customized chambers or for major industrial clients, allowing for direct communication and tailored solutions. Distributors and agents play a crucial role in market penetration, especially in regions where manufacturers do not have a direct presence, providing local sales support, technical expertise, and often installation and after-sales services. These channels help in reaching a diverse customer base, including automotive OEMs, aerospace contractors, electronics manufacturers, research institutions, and independent testing laboratories. The end-users, who are the ultimate buyers of these chambers, utilize them for quality control, research and development, material qualification, and regulatory compliance. The effectiveness of the value chain is measured by its ability to efficiently deliver high-quality, reliable salt fog chambers that meet the specific testing needs of various industries, supported by comprehensive after-sales service and technical support, ultimately enhancing product durability and safety in the broader market.

Salt Fog Chambers Market Potential Customers

The potential customers for salt fog chambers represent a broad and diverse spectrum of industries, all united by the critical need to assess and ensure the corrosion resistance and long-term durability of their products and materials. At the forefront are automotive manufacturers and their extensive supply chain, including Tier 1 and Tier 2 suppliers. These entities utilize salt fog chambers to rigorously test components such as engine parts, chassis components, body panels, braking systems, electrical connectors, and various interior and exterior trim pieces against the corrosive effects of road salt, humidity, and atmospheric pollutants. The demand for reliable, long-lasting vehicles, coupled with increasing warranty periods and stringent safety standards, makes these chambers indispensable for verifying material integrity and coating performance in harsh operating environments.

Another significant customer segment is the aerospace and defense industry. Aircraft components, military vehicles, weapon systems, and communication equipment are frequently exposed to extreme environmental conditions, including varying altitudes, temperatures, and corrosive agents present in marine or industrial settings. Salt fog chambers are essential for qualifying materials, coatings, and assemblies for use in these demanding applications, ensuring operational reliability and safety over extended lifespans. Similarly, the electronics and electrical industry represents a growing customer base, as printed circuit boards, connectors, sensors, and enclosures must withstand humidity, salt spray, and other corrosive elements to prevent malfunction and ensure data integrity. The miniaturization of components and the increasing complexity of electronic systems further amplify the need for precise and repeatable corrosion testing.

Beyond these major sectors, the market also serves a myriad of other end-users. The marine industry, encompassing shipbuilding, offshore oil and gas, and recreational boating, relies on these chambers for testing components exposed to saltwater environments. The paints and coatings industry uses them to evaluate the protective qualities, adhesion, and aesthetic durability of various surface treatments on metallic substrates. Research and development institutions, including universities and private laboratories, employ salt fog chambers for material science research, new product development, and failure analysis. Furthermore, government agencies responsible for infrastructure, military procurement, and public safety often mandate the use of corrosion-resistant materials, making them direct and indirect purchasers of testing services and equipment. The growing demand for robust infrastructure, such as bridges and public utilities, also contributes to the need for corrosion testing of construction materials. These diverse applications underscore the widespread utility and critical importance of salt fog chambers across the global industrial landscape.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 725.4 Million |

| Market Forecast in 2033 | USD 1150.3 Million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Associated Environmental Systems (AES), Atlas Material Testing Technology LLC (AMETEK), Binder GmbH, Cincinnati Sub-Zero Products (CSZ), ESPEC Corp., FDM - Fine Dust Measurement Ltd., G.N.L. S.r.l., Q-Lab Corporation, Russells Technical Products, Singleton Corporation, Scientific Climate Systems, Test Equity LLC, Thermotron Industries, Vötsch Industrietechnik GmbH (weiss technik), Wewon Environmental Chambers Co., Ltd., Sanwood Environmental Test Chamber, KOMEG Technology Ind Co., Ltd., Hastest Solutions, Presto Group, Taber Industries. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Salt Fog Chambers Market Key Technology Landscape

The key technology landscape of the salt fog chambers market is characterized by a continuous evolution towards greater precision, automation, and versatility, driven by the increasing complexity of materials and the need for more realistic corrosion simulations. Modern chambers incorporate advanced digital control systems, often leveraging Programmable Logic Controllers (PLCs) or sophisticated microprocessors, to precisely regulate temperature, humidity, and salt solution atomization rates. This level of control ensures high repeatability and reproducibility of test conditions, crucial for adhering to stringent international testing standards such as ASTM B117, ISO 9227, and various military specifications. User-friendly human-machine interfaces (HMIs) with touchscreens are becoming standard, offering intuitive programming of test cycles and real-time monitoring of chamber parameters, simplifying operation and reducing the learning curve for technicians.

A significant technological advancement is the rise of cyclic corrosion test (CCT) chambers, which move beyond traditional continuous salt spray by integrating various environmental conditions, including wet, dry, and humid cycles, along with temperature fluctuations. These chambers often feature sophisticated air conditioning systems, dehumidifiers, and precise water spray mechanisms to mimic real-world weathering effects more accurately. This capability allows for a more comprehensive evaluation of material performance under realistic stresses, addressing limitations of basic salt fog tests. Furthermore, innovations in materials used for chamber construction, such as high-grade corrosion-resistant plastics (e.g., PVC, PP, fiberglass reinforced plastics) and specialized stainless steels, contribute to the longevity and reliability of the chambers themselves, ensuring they can withstand aggressive internal environments without degradation or contamination.

The integration of the Internet of Things (IoT) and data analytics is transforming salt fog chambers into 'smart' testing devices. IoT sensors embedded within chambers enable real-time monitoring of internal conditions, component health, and operational parameters, facilitating predictive maintenance and optimized energy consumption. Remote access and control capabilities allow technicians to monitor tests from anywhere, enhancing operational flexibility and efficiency. Data logging systems capture extensive test data, which can then be analyzed using advanced software for trend identification, statistical process control, and comprehensive report generation. Some cutting-edge chambers even incorporate machine learning algorithms to analyze corrosion patterns and predict material behavior, offering deeper insights into material degradation mechanisms. This technological evolution aims not only to improve the accuracy and reliability of corrosion testing but also to streamline the testing process, reduce operational costs, and accelerate product development cycles, making them more valuable assets in quality assurance and research settings.

Regional Highlights

- North America: The North American market for salt fog chambers is characterized by a mature industrial base and stringent regulatory frameworks, particularly in the automotive, aerospace, and defense sectors. The United States, a dominant player, sees significant demand driven by continuous innovation in material science and a strong emphasis on product reliability. Canada also contributes to this demand, particularly from its automotive and natural resource industries. The region benefits from substantial R&D investments and a well-established network of testing laboratories and research institutions. The presence of leading chamber manufacturers and a high adoption rate of advanced testing technologies, including cyclic corrosion chambers and smart features, further solidifies its market position. The emphasis on high-quality manufacturing and extended product warranties by major corporations fuels consistent procurement of state-of-the-art corrosion testing equipment.

- Europe: Europe represents another significant market, driven by its robust automotive, electronics, and industrial manufacturing sectors, especially in countries like Germany, France, the UK, and Italy. The region is known for its stringent environmental regulations and a strong commitment to sustainable and durable product design, which necessitates rigorous material testing. European manufacturers frequently adhere to demanding international standards such as ISO 9227, pushing for advanced and reliable salt fog chamber solutions. There is a growing trend towards energy-efficient and eco-friendly chamber designs in response to regional environmental policies. The widespread presence of specialized testing service providers and an active research community further bolsters market growth, with a particular focus on developing innovative coatings and materials that require sophisticated corrosion validation.

- Asia Pacific (APAC): The Asia Pacific region is rapidly emerging as the fastest-growing market for salt fog chambers, primarily propelled by rapid industrialization, burgeoning manufacturing capabilities, and significant foreign direct investments. Countries such as China, India, Japan, South Korea, and Southeast Asian nations are experiencing exponential growth in automotive, electronics, consumer goods, and infrastructure development. This industrial expansion directly translates into a surging demand for quality control and material testing equipment. Governments in these regions are increasingly investing in R&D and mandating higher product quality standards for both domestic consumption and export markets. The presence of a vast and competitive manufacturing landscape, combined with a growing awareness of product durability, positions APAC as a key growth engine for the global salt fog chambers market.

- Latin America: The Latin American market for salt fog chambers is experiencing steady growth, driven by expanding industrial sectors and increasing investments in manufacturing infrastructure, particularly in countries like Brazil, Mexico, and Argentina. The automotive industry in Mexico and Brazil, in particular, contributes significantly to the demand for corrosion testing equipment to meet international quality standards for vehicles and components produced for both regional and export markets. As industrialization progresses and local manufacturing capabilities mature, there is a growing emphasis on product quality and compliance, spurring the adoption of environmental test chambers. Economic development and rising foreign investments in manufacturing facilities are expected to continue fueling this market's expansion, albeit from a smaller base compared to more established regions.

- Middle East & Africa (MEA): The Middle East & Africa region, while representing a smaller share of the global market, is showing promising growth potential for salt fog chambers. This growth is primarily attributed to significant investments in infrastructure development, oil and gas exploration, and a nascent but growing manufacturing sector. Countries in the Gulf Cooperation Council (GCC) are diversifying their economies away from oil, investing in industries such as automotive assembly, electronics, and construction, which require robust material testing. The harsh environmental conditions, including high temperatures, humidity, and coastal salinity, in many parts of the region naturally drive the need for comprehensive corrosion testing solutions. As industrialization and quality control practices mature across the MEA, the demand for salt fog chambers is anticipated to increase, supported by both local and international manufacturers entering the market.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Salt Fog Chambers Market.- Associated Environmental Systems (AES)

- Atlas Material Testing Technology LLC (AMETEK)

- Binder GmbH

- Cincinnati Sub-Zero Products (CSZ)

- ESPEC Corp.

- FDM - Fine Dust Measurement Ltd.

- G.N.L. S.r.l.

- Q-Lab Corporation

- Russells Technical Products

- Singleton Corporation

- Scientific Climate Systems

- Test Equity LLC

- Thermotron Industries

- Vötsch Industrietechnik GmbH (weiss technik)

- Wewon Environmental Chambers Co., Ltd.

- Sanwood Environmental Test Chamber

- KOMEG Technology Ind Co., Ltd.

- Hastest Solutions

- Presto Group

- Taber Industries

Frequently Asked Questions

Analyze common user questions about the Salt Fog Chambers market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is a salt fog chamber and why is it essential for industries?

A salt fog chamber is specialized equipment that simulates corrosive environments, primarily by atomizing a saltwater solution, to accelerate corrosion effects on materials and products. It is essential for industries like automotive, aerospace, and electronics to evaluate product durability, ensure compliance with international standards, and prevent costly material failures or recalls under real-world corrosive conditions. These chambers help validate the long-term performance and reliability of components, coatings, and finished goods.

How do cyclic corrosion test (CCT) chambers differ from traditional salt spray chambers?

Cyclic corrosion test (CCT) chambers offer a more advanced and realistic simulation of natural weathering compared to traditional continuous salt spray chambers. While salt spray chambers maintain a constant salt fog environment, CCT chambers cycle through various conditions including wet, dry, and humid phases, along with temperature changes. This cycling more accurately replicates the complex environmental stresses materials face in real-world scenarios, leading to more predictive and comprehensive test results regarding corrosion resistance and material degradation.

What are the primary factors driving the growth of the salt fog chambers market?

The market's growth is primarily driven by the increasing demand for high-quality, durable, and reliable products across various industries, coupled with stringent international quality standards and regulatory compliance requirements. Expanding global manufacturing bases, particularly in emerging economies, alongside significant investments in research and development for new materials and coatings, further fuel the adoption of these chambers. The need to extend product lifecycles and minimize warranty claims also compels manufacturers to invest in comprehensive corrosion testing solutions.

What impact is AI expected to have on the future of salt fog chambers?

AI is anticipated to significantly enhance salt fog chambers by enabling smarter operations, predictive capabilities, and improved testing efficiency. AI can optimize test parameters based on historical data, automate data analysis to identify subtle corrosion patterns, and facilitate predictive maintenance for the chambers themselves. Integration with IoT sensors will allow for real-time monitoring and remote control, leading to more precise, repeatable, and cost-effective corrosion testing, ultimately accelerating product development and ensuring higher material reliability.

Which industries are the largest end-users of salt fog chambers?

The largest end-users of salt fog chambers primarily include the automotive, aerospace and defense, and electronics industries. Automotive manufacturers use them for testing vehicle components against road salts and humidity. Aerospace and defense sectors employ them to qualify materials for extreme environmental exposure. The electronics industry relies on them to ensure the reliability of circuit boards and enclosures. Other significant end-users include the marine sector, paints and coatings manufacturers, and various research and development institutions for material science.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager