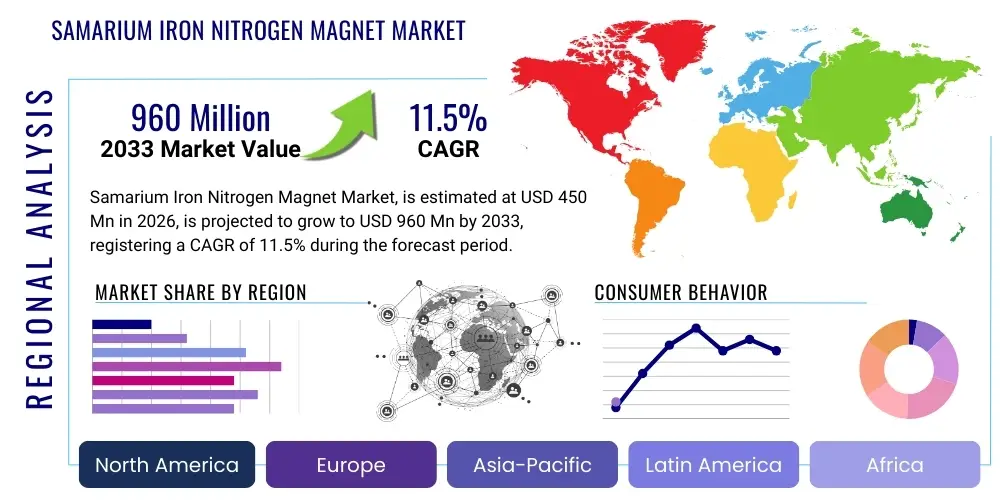

Samarium Iron Nitrogen Magnet Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 436249 | Date : Dec, 2025 | Pages : 242 | Region : Global | Publisher : MRU

Samarium Iron Nitrogen Magnet Market Size

The Samarium Iron Nitrogen Magnet Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 11.5% between 2026 and 2033. The market is estimated at USD 450 Million in 2026 and is projected to reach USD 960 Million by the end of the forecast period in 2033. This robust expansion is primarily driven by the increasing global demand for high-performance magnetic materials that exhibit superior thermal stability and corrosion resistance compared to traditional alternatives like Neodymium Iron Boron (NdFeB), especially in critical applications requiring operation at elevated temperatures, such as advanced electric vehicle propulsion systems, aerospace actuators, and high-frequency electronics.

Samarium Iron Nitrogen Magnet Market introduction

The Samarium Iron Nitrogen (Sm-Fe-N) Magnet Market encompasses the production and commercialization of a class of rare earth permanent magnets celebrated for their exceptionally high saturation magnetization and high Curie temperature, often exceeding those of widely used NdFeB magnets. Sm-Fe-N is synthesized through complex processes, typically involving mechanical alloying, gas-phase nitriding, or advanced rapid solidification techniques, yielding materials with properties crucial for high-efficiency motors and miniaturized devices. Major applications include precision sensors, high-temperature motors, generators for renewable energy systems, and specialized consumer electronics where size and operational temperature are critical constraints. The primary benefits of Sm-Fe-N magnets lie in their inherent resistance to demagnetization at high temperatures and excellent corrosion stability without requiring extensive coatings, simplifying manufacturing and extending product lifespan. Key driving factors include the transition toward electrification in the automotive sector, demanding magnets capable of enduring intense thermal cycles, coupled with continuous investment in miniaturization across industrial robotics and communication infrastructure.

Samarium Iron Nitrogen Magnet Market Executive Summary

The global Samarium Iron Nitrogen Magnet market is positioned for significant structural evolution, characterized by intense research and development aimed at overcoming current manufacturing challenges, particularly related to the powder metallurgy and sintering processes necessary for large-scale production. Business trends highlight strategic collaborations between specialized material science firms and major automotive or aerospace component manufacturers to secure proprietary supply chains for high-performance magnets critical for next-generation electric powertrains and aerospace control systems. Regional trends indicate that the Asia Pacific region, led by China and Japan, maintains dominance both in the production capacity and the consumption of these advanced magnets, driven by expansive electronic manufacturing and the rapid adoption of electric mobility solutions. Segment trends show that the application segment focused on electric motors and actuators is projected to experience the highest growth rate, fueled by the necessity for lighter, more powerful, and thermally stable components. Overall, market stakeholders are strategically investing in developing grain boundary diffusion technologies and novel synthesis routes to achieve commercial viability and cost parity with established magnetic material technologies.

AI Impact Analysis on Samarium Iron Nitrogen Magnet Market

User queries regarding AI's influence in the Sm-Fe-N domain center predominantly on how artificial intelligence can accelerate the discovery of novel compositions, optimize complex manufacturing parameters, and predict material performance under extreme operating conditions. A significant concern revolves around using AI to navigate the supply chain volatility associated with rare earth elements, specifically Samarium, by predicting geopolitical impacts and optimizing inventory management. Users also anticipate AI being instrumental in refining the challenging nitriding processes used in Sm-Fe-N synthesis, where parameters like temperature, pressure, and gas flow critically determine the final magnetic properties. The expectation is that AI algorithms, particularly machine learning models applied to materials informatics, will drastically reduce the time and cost associated with developing high-coercivity, high-temperature magnets, moving the technology from laboratory curiosity to industrial scalability, thereby democratizing the access to superior magnet technology and reducing reliance on legacy, less efficient magnetic systems.

- AI accelerates the discovery and optimization of Sm-Fe-N compositions with enhanced intrinsic magnetic properties.

- Machine learning algorithms optimize complex powder preparation and gas-solid nitriding processes, ensuring consistency and yield.

- Predictive maintenance models using AI analyze magnetic degradation patterns in application, extending component lifespan.

- AI optimizes supply chain logistics for Samarium and Iron precursors, mitigating volatility and procurement risks.

- Computational materials science, powered by AI, simulates magnetic domain structures and thermal stability before physical testing.

DRO & Impact Forces Of Samarium Iron Nitrogen Magnet Market

The market expansion is robustly driven by the increasing need for high-efficiency magnets in electric vehicles (EVs) and industrial automation where high temperature resistance is non-negotiable, positioning Sm-Fe-N as a critical enabler for next-generation technology. However, the market faces significant restraints, primarily stemming from the complexity and cost of synthesis, particularly the challenge of achieving high-density, sintered Sm-Fe-N bulk magnets without decomposition of the metastable nitride phase, which limits large-scale commercialization compared to well-established NdFeB technology. Opportunities abound in developing proprietary thin-film deposition techniques for micro-electronic magnetic components and in leveraging advanced composite structures that combine Sm-Fe-N powder with polymeric binders to create lightweight, flexible magnets for specialized applications in medical devices and portable electronics. The primary impact force shaping this market is the ongoing geopolitical emphasis on reducing reliance on critical raw materials and finding alternatives to Dysprosium and Terbium used in high-temperature NdFeB, granting Sm-Fe-N a strategic advantage if manufacturing hurdles are overcome and scalability is achieved, potentially disrupting the existing dominance of sintered rare earth magnet producers.

Segmentation Analysis

The Samarium Iron Nitrogen Magnet market is extensively segmented based on the form of the magnetic material, the specific application areas where its unique thermal stability is leveraged, and the end-use industries driving demand. Analyzing these segments provides crucial insights into growth trajectories, highlighting areas where technological advancements and commercial viability intersect. The fundamental differentiation in segmentation arises from the technological maturity of the material forms, distinguishing between highly mature powder forms used primarily for bonded magnets or research, and the nascent bulk sintered forms which promise the highest performance but face the greatest manufacturing barriers. Furthermore, the application segmentation reflects the high-value nature of the material, focusing on industries where the performance gain justifies the increased cost profile, ensuring strategic resource allocation by manufacturers targeting the most profitable and demanding sectors globally.

- By Product Form:

- Powder (for bonded magnets, fillers, or research)

- Bulk Sintered Magnets (highly challenging, high-performance)

- Thin Films (for micro-electromechanical systems (MEMS))

- By Application:

- Electric Motors and Actuators (EVs, Robotics, Industrial)

- Sensors and Switches (High-temperature environments)

- Generators (Wind Turbines, Portable Power)

- Magnetic Separation Equipment

- Communication Infrastructure and Radar Systems

- By End-Use Industry:

- Automotive (Electric Vehicles, Hybrid Vehicles)

- Aerospace and Defense (Actuators, Guidance Systems)

- Industrial Automation and Robotics

- Energy (Renewable Energy Generation)

- Consumer Electronics and IT

Value Chain Analysis For Samarium Iron Nitrogen Magnet Market

The Samarium Iron Nitrogen magnet value chain begins with complex upstream analysis focused on securing and processing rare earth elements, primarily Samarium (Sm), and ensuring high-purity iron precursors. This upstream phase is highly capital intensive and sensitive to geopolitical dynamics, requiring sophisticated extraction and refinement techniques to isolate the necessary raw materials. The intermediate step involves specialized material processing firms that perform mechanical alloying, hydrogenation-disproportionation-desorption-recombination (HDDR) processing, and the crucial gas-phase nitriding to produce the metastable Sm2Fe17N3 compound, which is the core magnetic material. Controlling particle size and composition uniformity during these stages is paramount for final magnet performance.

Downstream analysis focuses heavily on the manufacturing of final magnetic components, which involves either bonding the Sm-Fe-N powder with polymers (leading to lower energy product but easier processing) or, more ambitiously, attempting to sinter the material into bulk magnets while preserving the nitride phase. The distribution channel for Sm-Fe-N components tends to be highly specialized. Direct sales are common for large volume OEM contracts, especially within the automotive and aerospace sectors, where technical consultation and customized component design necessitate close collaboration between the magnet manufacturer and the end-user. The limited number of firms capable of producing high-grade Sm-Fe-N material means the distribution network is often concentrated, emphasizing technical expertise over broad market penetration.

Indirect distribution involves specialized distributors who handle smaller orders or niche applications like advanced research laboratories and smaller industrial automation firms that require specialized magnetic components for rapid prototyping or small-batch production runs. The technical complexity of integrating these magnets into end products means the value addition throughout the chain is substantial, moving from raw material refinement to highly engineered, application-specific magnetic solutions. The high technological barrier to entry at the processing stage ensures that the majority of the profit margin is captured by firms mastering the synthesis and fabrication of the magnetic material itself, positioning them as critical bottlenecks in the global supply chain for thermally stable magnets.

Samarium Iron Nitrogen Magnet Market Potential Customers

Potential customers for Samarium Iron Nitrogen Magnets are predominantly entities within high-reliability and high-temperature operating environments that currently utilize, or seek superior alternatives to, NdFeB magnets that require significant quantities of expensive Dysprosium for thermal stability. The primary end-users fall into three critical categories: Electric Vehicle component manufacturers, particularly those designing high-power density motors for premium or performance-oriented EVs; aerospace and defense contractors requiring light, reliable actuators and sensors for guidance systems and flight controls operating under extreme thermal fluctuations; and industrial robotics firms demanding precise, miniature motors capable of prolonged operation without performance degradation due to heat accumulation.

Furthermore, the renewable energy sector, specifically specialized wind turbine generator manufacturers and developers of compact, high-efficiency power converters, represents a growing segment. These customers require materials that can withstand continuous operational stress and environmental exposure while maximizing power density. The appeal of Sm-Fe-N magnets to these customers lies in the reduced need for active cooling systems, simplification of motor designs, and inherent corrosion resistance, leading to lower total ownership costs and enhanced system reliability compared to alternative magnet technologies, justifying the higher initial material cost associated with this advanced magnetic compound.

A smaller, yet strategically significant, segment includes high-frequency electronics developers and specialized medical device manufacturers. In electronics, Sm-Fe-N thin films are sought for micro-sensors and magnetic recording heads where extreme miniaturization and thermal stability are essential prerequisites. In the medical field, high-field Magnetic Resonance Imaging (MRI) equipment and miniature surgical robotics require magnets with exceptional field strength and stability in confined spaces, positioning Sm-Fe-N as a high-potential material solution for advancing diagnostic and interventional capabilities in controlled environments where conventional materials may exhibit thermal drift or inadequate coercivity.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450 Million |

| Market Forecast in 2033 | USD 960 Million |

| Growth Rate | 11.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | TDK Corporation, Hitachi Metals Ltd., Shin-Etsu Chemical Co., Ltd., VACUUMSCHMELZE GmbH & Co. KG, Arnold Magnetic Technologies, Daido Steel Co., Ltd., Ningbo Yunsheng Co., Ltd., Zhaobao Magnet, Neo Performance Materials, Electron Energy Corporation, Lynas Rare Earths Ltd., Sanxin Magnetism, GKN Sinter Metals, UGIMAG, Advanced Magnetic Materials. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Samarium Iron Nitrogen Magnet Market Key Technology Landscape

The technological landscape of the Samarium Iron Nitrogen Magnet market is defined by innovation aimed at synthesizing the highly magnetic, yet thermally fragile, Sm2Fe17N3 phase and subsequently stabilizing it for commercial applications. A critical technology is the mechanical alloying and subsequent gas-phase nitriding (GPN) process, which involves subjecting precursor alloy powders to a nitrogen-rich atmosphere at specific elevated temperatures. Precise control over temperature and pressure is vital, as excessive heat can cause the desirable metastable nitride phase to decompose, significantly degrading the magnetic performance. Current R&D efforts are heavily invested in optimizing GPN reactors and refining precursor powder characteristics, such as particle size distribution and chemical homogeneity, to maximize the volume fraction of the Sm2Fe17N3 phase achieved during the process, leading to enhanced energy products.

Another pivotal area is the advancement in bulk magnet fabrication, which remains the single largest technical hurdle for Sm-Fe-N. Unlike NdFeB magnets which are readily sintered, Sm-Fe-N tends to decompose during high-temperature sintering. Therefore, technologies like Spark Plasma Sintering (SPS) or advanced hot pressing under highly controlled nitrogen atmospheres are being explored. These techniques aim to densify the powdered material quickly and at lower temperatures, minimizing the decomposition kinetics. Additionally, grain boundary engineering techniques, analogous to those used in Dy-free NdFeB, are being investigated to enhance coercivity by modifying the interfaces between magnetic grains, ensuring the magnet resists demagnetization even at operating temperatures exceeding 200°C, a threshold often beyond the reliable performance range of standard NdFeB magnets.

Furthermore, technologies surrounding magnetic component integration and modeling are also critical. Finite Element Method (FEM) analysis and sophisticated magnetic circuit design software are essential tools for end-users, enabling precise prediction of flux density and thermal performance before physical prototyping. The development of thin-film deposition technologies, such as sputtering and pulsed laser deposition (PLD), is crucial for enabling the use of Sm-Fe-N in micro-scale devices, particularly in MEMS and spintronic applications. These manufacturing processes, coupled with rigorous quality control utilizing advanced characterization techniques like X-ray diffraction (XRD) and vibrating sample magnetometry (VSM), solidify the technological foundation necessary for the commercial viability and long-term market penetration of high-performance Samarium Iron Nitrogen magnets across various demanding industrial applications.

Regional Highlights

The Samarium Iron Nitrogen Magnet market exhibits distinct regional dynamics driven by manufacturing concentration, policy support for electrification, and local demand for high-performance materials in strategic industries such as automotive and aerospace. Asia Pacific (APAC) currently dominates the global landscape, primarily due to the established rare earth processing infrastructure and the massive scale of electronics and electric vehicle manufacturing centers in China, Japan, and South Korea. China, in particular, controls a significant portion of the rare earth supply chain and is rapidly investing in advanced magnetic materials research to enhance its domestic capabilities in producing high-end EV motors and robotic systems, positioning it as both the leading producer and the largest consumer of Sm-Fe-N materials.

Europe represents a high-value market, characterized by stringent environmental regulations and a strong focus on high-efficiency industrial machinery and premium automotive manufacturing. Countries like Germany and the UK are crucial consumers, especially in sectors requiring specialized industrial automation and defense components that leverage the superior thermal performance of Sm-Fe-N. European investment is geared towards establishing independent processing capabilities to mitigate supply chain risks originating from APAC, driving innovation in sustainable material synthesis and component recycling techniques specific to rare earth magnets, ensuring regional autonomy in critical technology supply.

North America, led by the United States, is a key region for demand, particularly within the highly competitive aerospace and defense sectors, where reliability and high-temperature operation are paramount. Significant investment in domestic research and development, often backed by government grants aimed at securing strategic materials, supports the exploration of Sm-Fe-N technology as a domestic, non-Neodymium-reliant source of high-performance magnetism. While manufacturing scale is currently smaller compared to APAC, the high average selling price and strategic importance of applications in North America ensure its pivotal role in driving technological standards and early adoption of bulk sintered Sm-Fe-N magnetic components.

- Asia Pacific (APAC): Dominates production and consumption, driven by EV and consumer electronics manufacturing hubs in China and Japan.

- Europe: Focuses on high-reliability industrial automation, premium automotive applications, and R&D for localized supply chains.

- North America: Key demand center for aerospace, defense, and high-performance sensor technologies, driven by strategic material independence initiatives.

- Latin America & MEA: Emerging markets with potential growth in localized renewable energy projects and specialized industrial machinery maintenance.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Samarium Iron Nitrogen Magnet Market.- TDK Corporation

- Hitachi Metals Ltd.

- Shin-Etsu Chemical Co., Ltd.

- VACUUMSCHMELZE GmbH & Co. KG

- Arnold Magnetic Technologies

- Daido Steel Co., Ltd.

- Ningbo Yunsheng Co., Ltd.

- Zhaobao Magnet

- Neo Performance Materials

- Electron Energy Corporation

- Lynas Rare Earths Ltd.

- Sanxin Magnetism

- GKN Sinter Metals

- UGIMAG

- Advanced Magnetic Materials

- Baoji Lixing Titanium Group Co., Ltd.

- Beijing Zhong Ke San Huan Hi-Tech Co., Ltd.

- Hunan New Rare Earth Magnet Co., Ltd.

- JPM Group

- Magnet-Schultz GmbH & Co. KG

Frequently Asked Questions

Analyze common user questions about the Samarium Iron Nitrogen magnet market and generate a concise list of summarized FAQs reflecting key topics and concerns.What distinguishes Samarium Iron Nitrogen (Sm-Fe-N) magnets from traditional Neodymium Iron Boron (NdFeB) magnets?

Sm-Fe-N magnets possess a significantly higher Curie temperature and superior thermal stability compared to NdFeB, meaning they retain their magnetic strength at much higher operating temperatures (often above 200°C). This makes them ideal for demanding applications like high-performance EV motors and aerospace actuators, often eliminating the need for heavy cooling or reliance on expensive heavy rare earth elements like Dysprosium, which is required to stabilize NdFeB.

What are the primary manufacturing challenges limiting the bulk commercialization of Sm-Fe-N magnets?

The main challenge is achieving high-density bulk sintered magnets. The critical magnetic phase (Sm2Fe17N3) is metastable and decomposes at the high temperatures typically required for traditional sintering processes. Researchers are focusing on advanced methods like Spark Plasma Sintering (SPS) or using resin-bonded powders to overcome this issue, but producing fully dense, high-performance bulk magnets at scale remains the principal restraint on market growth and cost reduction.

Which end-use industries are driving the highest demand and technological investment in Sm-Fe-N magnets?

The Automotive industry, particularly the Electric Vehicle (EV) and Hybrid Vehicle sector, is the leading driver, demanding magnets for traction motors that operate under high heat and high rotational speeds without demagnetization. The Aerospace and Defense sector also drives significant demand due to the critical requirement for thermally stable actuators and sensors in extreme operating environments where reliability cannot be compromised, justifying the premium cost of Sm-Fe-N material.

How does the supply chain risk associated with Sm-Fe-N compare to NdFeB magnets?

Both Sm-Fe-N and NdFeB rely on rare earth elements (Samarium and Neodymium, respectively), leading to inherent geopolitical supply risks. However, Sm-Fe-N potentially reduces reliance on the heavy rare earth elements (HREs) like Dysprosium and Terbium, which are often required in high-temperature NdFeB formulations and are notoriously scarce and expensive. Thus, Sm-Fe-N offers a strategic alternative for high-temperature applications seeking to diversify away from HRE-dependent magnets.

What is the role of advanced technology, such as AI and machine learning, in the future development of the Sm-Fe-N market?

AI is crucial in accelerating material innovation by predicting optimal alloy compositions and microstructure evolution, drastically reducing experimental trial-and-error. Machine learning models are being utilized to optimize the complex gas-phase nitriding parameters (temperature, pressure, time) to ensure consistent quality and maximum yield of the critical magnetic phase, thereby accelerating the transition of Sm-Fe-N from research novelty to scalable, industrially viable magnetic technology.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager