Sausage Hotdog Casings Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 438681 | Date : Dec, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Sausage Hotdog Casings Market Size

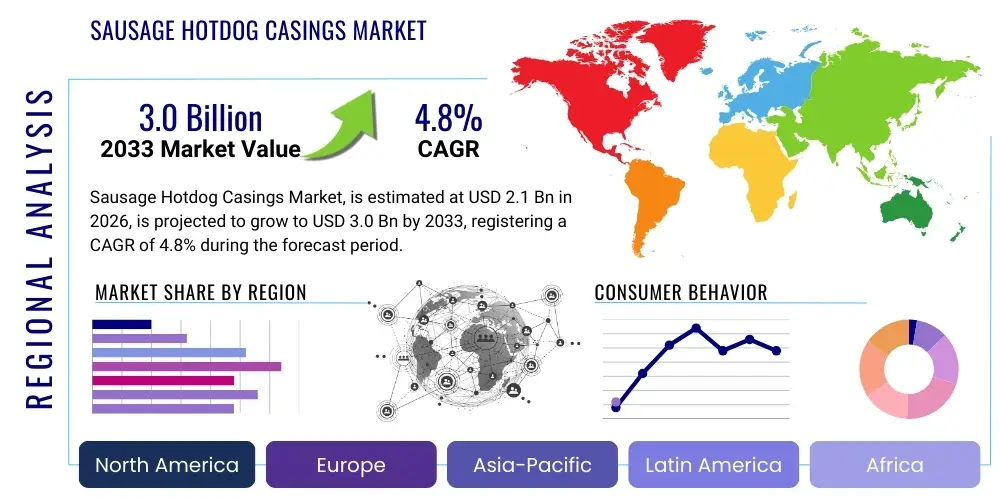

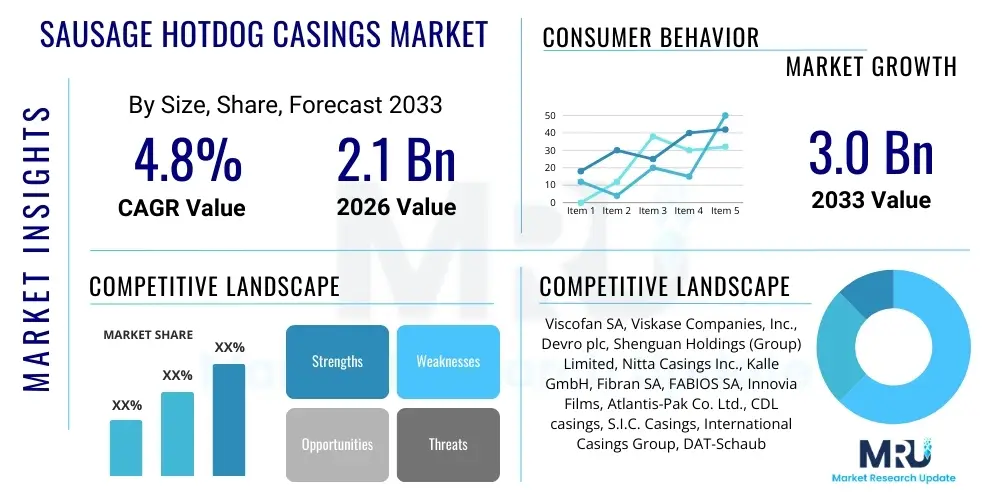

The Sausage Hotdog Casings Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.8% between 2026 and 2033. The market is estimated at USD 2.1 Billion in 2026 and is projected to reach USD 3.0 Billion by the end of the forecast period in 2033.

Sausage Hotdog Casings Market introduction

The Sausage Hotdog Casings Market encompasses the production and distribution of various materials used to encapsulate ground meat products, providing structure, protection, and shape during processing and cooking. These casings are crucial components in the production of hotdogs, frankfurters, bologna, and other emulsified sausage products, serving both functional and aesthetic purposes. The market is broadly categorized into natural casings, derived primarily from the submucosa of animal intestines (pigs, cattle, sheep), and artificial casings, which include collagen, cellulose, fibrous, and plastic materials. The choice of casing directly influences the product's texture, shelf life, flavor absorption, and handling characteristics, making it a critical element in large-scale meat processing operations.

Product descriptions within this segment highlight materials engineered for specific applications; for instance, edible collagen casings are preferred for their consistent diameter and bite quality in breakfast sausages and hotdogs, while non-edible fibrous casings are utilized for large diameter, dry-cured sausages requiring strength and high permeability for smoking. Major applications of hotdog casings are overwhelmingly centered in the processed meat industry, supplying manufacturers of ready-to-eat and ready-to-cook packaged foods distributed globally through retail and foodservice channels. The inherent functional benefit of casings is their ability to withstand the rigors of high-speed stuffing, cooking, smoking, and chilling processes, ensuring product uniformity and safety.

Driving factors for sustained market growth are deeply rooted in global demographic shifts, including rapid urbanization and increasing consumer preference for convenience foods that offer quick preparation times, such as packaged hotdogs and sausages. Furthermore, the steady rise in disposable income in emerging economies, particularly across the Asia Pacific region, fuels the demand for protein-rich, value-added meat products. Technological advancements in artificial casing manufacturing, such as improved barrier properties and customized print options, enhance product appeal and extend shelf stability. The market continues to innovate, focusing on bio-based materials and improved production efficiency to meet stringent food safety standards and high-volume demand from meat processors worldwide.

Sausage Hotdog Casings Market Executive Summary

The global Sausage Hotdog Casings Market is experiencing dynamic shifts, driven by evolving consumer diets and technological innovation within the food processing sector. Business trends emphasize a strategic pivot towards artificial casings, primarily collagen and cellulose, due to their superior consistency, scalability, and cost-effectiveness compared to traditional natural casings, though natural casings retain premium positioning in niche markets. Major industry players are heavily investing in automation and digitalization across manufacturing lines to enhance production speed and reduce material wastage. Furthermore, there is a distinct trend towards developing clean label casings, focusing on sustainable sourcing and minimizing chemical treatments, addressing growing consumer skepticism regarding highly processed food ingredients. Mergers and acquisitions remain a key strategy for market consolidation, allowing large corporations to gain access to proprietary technologies, expand geographic footprints, and secure raw material supplies efficiently.

Regional trends indicate that the Asia Pacific (APAC) region is poised for the highest growth rate, fueled by substantial population growth, increasing Westernization of diets, and significant expansion of organized retail chains distributing processed meat products. While North America and Europe currently hold the largest market shares due to established meat consumption traditions and robust processing infrastructure, growth in these regions is moderated by saturated markets and heightened regulatory scrutiny concerning meat consumption and welfare standards. Conversely, emerging markets in Latin America and the Middle East and Africa (MEA) are showing strong potential, driven by improvements in cold chain logistics and rising middle-class consumption patterns. Localization of production facilities is a critical regional strategy to circumvent trade barriers and reduce transportation costs, thereby increasing competitiveness.

Segmentation trends highlight the dominance of the collagen segment by value, attributed to its versatility, edibility, and suitability for high-speed automated production of standard hotdogs and sausages. Within the application segment, the standard hotdog and breakfast sausage categories represent the largest volume consumers of casings globally. However, the rise of specialized applications, such as plant-based sausages, is prompting innovation in the cellulose and specialized polymer casing segments, requiring materials that offer texture and handling characteristics similar to meat-based counterparts. Sustainability is a major segment trend, pushing manufacturers to develop biodegradable and bio-sourced options, ensuring that packaging components align with global environmental mandates and consumer preferences for eco-friendly products.

AI Impact Analysis on Sausage Hotdog Casings Market

Common user questions regarding AI’s impact on the Sausage Hotdog Casings Market frequently revolve around optimizing complex manufacturing processes, ensuring consistent quality control for edible products, and managing volatile raw material procurement cycles. Users are particularly keen on understanding how AI can enhance the precision of the shirring process (folding casings), minimize material defects like tears or perforations, and provide predictive maintenance schedules for high-throughput extrusion equipment. Another key area of concern is leveraging AI and machine learning (ML) to forecast demand accurately across diverse global markets, allowing casing manufacturers to optimize inventory levels and reduce spoilage, especially concerning natural casing handling which requires strict environmental control. The overarching expectation is that AI integration will lead to higher operational efficiencies, lower manufacturing costs, and ultimately, a more consistent end product delivered to meat processors.

- AI-driven Predictive Maintenance: Utilizing sensor data from extrusion lines and shirring machines to anticipate equipment failures, minimizing unexpected downtime and maximizing operational uptime, critical for meeting high-volume hotdog production schedules.

- Enhanced Quality Control Systems: Implementation of computer vision and ML algorithms for real-time defect detection (e.g., thickness variation, air bubbles, structural integrity) in casings during production, ensuring adherence to strict diameter and strength specifications.

- Optimized Raw Material Sourcing and Inventory: AI algorithms analyze global commodity prices, livestock cycles (for natural casings), and demand forecasts to optimize procurement strategies for collagen hides, cellulose pulp, or specialized polymers, reducing cost volatility.

- Supply Chain and Logistics Optimization: ML models predict optimal distribution routes and storage conditions, particularly for temperature-sensitive natural and collagen casings, minimizing transit time and ensuring product integrity upon delivery to meat packers.

- Automation of Complex Processing Steps: Robotics guided by AI can manage delicate handling processes, such as the initial preparation and sorting of natural casings, increasing throughput while maintaining superior hygiene and reducing labor intensity.

- Personalized Product Development: AI analyzes consumer data and market trends to identify gaps for new casing types (e.g., specific permeabilities for unique smoking profiles or customized colors/printing for branding), accelerating R&D cycles.

DRO & Impact Forces Of Sausage Hotdog Casings Market

The dynamics of the Sausage Hotdog Casings Market are primarily governed by the robust global demand for processed meat convenience products (Driver), countered by significant health and dietary concerns surrounding processed foods (Restraint), while technological advancements in sustainable and functional materials present key avenues for market expansion (Opportunity). Impact forces, combining the influence of these factors, dictate pricing strategies, regulatory compliance, and the rate of innovation. The inherent need for rapid, cost-effective, and safe encapsulation in the massive global sausage industry provides continuous momentum for casing manufacturers. Conversely, the market must constantly navigate the complexities of raw material price volatility, especially in the natural casing segment, alongside increasing scrutiny from health organizations regarding sodium content and fat levels in final sausage products, forcing processors to demand leaner and cleaner casing options.

Key drivers center on the efficiency and adaptability of modern artificial casings. The uniformity in size and strength offered by collagen and fibrous casings enables meat processors to operate at extremely high speeds, drastically reducing labor costs and improving product consistency, which is vital in a highly competitive food manufacturing environment. Population growth and urbanization, especially in Asian and African markets, translate directly into increased consumption of mass-produced sausages and hotdogs. Furthermore, innovations such as edible collagen casings that offer superior 'snap' or bite resistance are highly valued by consumers, driving product premiumization and higher margins for specialty casings. The ability of artificial casings to be tailored for specific smoking or cooking requirements provides a necessary functional advantage that traditional methods often cannot match.

Major restraints include the growing anti-meat consumption movement, spurred by environmental concerns (livestock impact) and dietary advice linking processed meats to adverse health outcomes. This societal shift prompts consumers to seek alternatives, indirectly limiting the growth potential of traditional sausage casings. Additionally, the dependency on livestock byproducts for natural and collagen casings subjects the market to risks related to animal diseases (e.g., African swine fever, Bovine Spongiform Encephalopathy), which can cause sudden spikes in raw material costs and disruptions in the supply chain. Opportunities lie primarily in developing plant-based, vegan-friendly casing alternatives made from algae, polysaccharide derivatives, or modified cellulose that can mimic the characteristics of collagen, catering to the rapidly expanding market for meat substitutes. Further opportunities exist in enhancing the barrier properties of casings to naturally extend the shelf life of sausages without relying heavily on chemical preservatives, aligning with the clean label trend.

- Drivers:

- Increasing Global Consumption of Processed and Convenience Meats.

- Advancements in High-Speed Automated Stuffing and Processing Technology.

- Cost-Effectiveness and Uniformity of Artificial Casings (Collagen and Cellulose).

- Rising Demand for Protein-Rich Foods in Emerging Economies.

- Restraints:

- Heightened Consumer Concerns Regarding the Health Implications of Processed Meats.

- Volatility in Raw Material Prices (Livestock Byproducts and Polymer Feedstocks).

- Stringent Food Safety Regulations and Import/Export Restrictions on Animal-Derived Products.

- Opportunities:

- Development of Sustainable, Biodegradable, and Plant-Based Casings.

- Innovation in Customized Casings for Meat Analogs and Vegetarian Sausages.

- Integration of Enhanced Barrier Technologies for Extended Shelf Life (Clean Label focus).

- Impact Forces:

- Pricing Power of Major Global Meat Processors.

- Influence of Government Policies on Food Safety and Animal Welfare Standards.

- Technological Differentiation between High-Performance Synthetic and Natural Casings.

Segmentation Analysis

The Sausage Hotdog Casings Market is highly segmented based on the material composition, which fundamentally dictates the casing’s functional properties and end-use application. Segmentation by material (Natural, Collagen, Cellulose, Fibrous, Plastic) is crucial as it reflects the varying processing requirements, edibility, and cost points relevant to different sausage types, ranging from gourmet dry-cured salami (Fibrous/Natural) to mass-market hotdogs (Collagen/Cellulose). Further granular segmentation based on product type (Edible vs. Non-edible) and application (Hotdogs/Frankfurters, Breakfast Sausages, Specialized Sausages) allows manufacturers to tailor their production and marketing efforts toward specific consumer demands and industrial needs. Geographically, the segmentation highlights regional dietary preferences and infrastructure maturity, with industrialized nations favoring high-volume artificial casings, and regions with strong culinary traditions maintaining demand for high-quality natural options.

- By Material:

- Natural Casings (Hog, Beef, Sheep)

- Artificial Casings

- Collagen Casings (Edible, Non-edible)

- Cellulose Casings

- Fibrous Casings

- Plastic Casings (e.g., Polyamide, Polyethylene)

- By Product Type:

- Edible Casings (Natural, Collagen)

- Non-Edible Casings (Fibrous, Plastic, Cellulose for peeling)

- By Application:

- Hotdogs and Frankfurters

- Breakfast and Fresh Sausages

- Cured and Smoked Sausages (Salami, Pepperoni)

- Specialty Sausages (e.g., Bratwurst, Chorizo)

- By End-User:

- Industrial Meat Processors

- Butcher Shops and Local Producers

- Food Service Providers

Value Chain Analysis For Sausage Hotdog Casings Market

The value chain for the Sausage Hotdog Casings Market begins with the upstream procurement and preparation of highly specialized raw materials. For natural and collagen casings, this involves strict sourcing and processing of animal hides and intestines, requiring specialized slaughterhouse operations and extensive cleaning, curing, and sizing processes to minimize contamination. For cellulose and fibrous casings, the upstream focus is on sourcing high-grade wood pulp (cellulose) or regenerated materials, followed by complex chemical treatment and extrusion processes. This initial stage requires significant capital investment in highly specialized machinery, quality assurance protocols, and maintaining compliance with global health standards, forming the base of the chain’s complexity and cost structure.

The manufacturing stage involves the extrusion, drying, shirring (creating pleated sticks), and packaging of the casings. High technological capability is required here, especially for artificial casings, where precise control over diameter, strength, permeability, and barrier properties is essential. Direct distribution channels involve manufacturers selling high volumes of casings directly to large multinational industrial meat processors (downstream). These processors utilize automated stuffing and linking equipment that are often customized to specific casing specifications. The efficiency of this direct relationship minimizes costs and ensures technical support and quality traceability, which is paramount in the food sector. Key players often maintain global distribution networks, managing large temperature-controlled warehouses to handle both perishable natural casings and stable artificial products.

Indirect distribution, involving regional distributors and specialized food ingredient suppliers, typically serves smaller butcher shops, local sausage makers, and niche food service providers who require lower volumes and specialized natural casing varieties. Downstream activities are dominated by meat processing, where the casings are stuffed, cooked, smoked, and packaged. The final link is the retail and foodservice consumption, where the casing’s appearance and function directly influence consumer purchasing decisions. Efficiency across the entire chain is crucial; any disruption in the upstream supply of raw materials or bottlenecks in the midstream manufacturing can severely impact the production schedules of major downstream meat processors, highlighting the critical interdependence within this specialized supply framework.

Sausage Hotdog Casings Market Potential Customers

The primary customers for Sausage Hotdog Casings are large industrial meat processors and manufacturers who produce hotdogs, frankfurters, and various types of sausages on a massive scale for both domestic and international markets. These entities, including major global food corporations, require consistent, high-quality, and high-volume casing solutions, making them the largest purchasing segment by volume and value. Their procurement decisions are heavily influenced by the casing's performance on automated stuffing machines, its cost-per-unit, its edibility status, and its barrier properties, which affect the final product’s shelf life and appearance. The shift towards large-scale production mandates the preferential use of artificial casings, particularly collagen and cellulose, due to their unmatched uniformity and high-speed processing capabilities.

A secondary, yet vital, customer base consists of smaller, independent butcher shops, specialized artisan sausage makers, and regional food cooperatives. These buyers often prioritize quality, traditional methods, and specific flavor profiles, leading to a higher demand for high-grade natural casings (such as sheep or high-quality hog casings) or specialized fibrous casings for gourmet dry-cured products like salami. While their volume demand is lower, their need for specific sizing and sourcing dictates a different approach to distribution, often relying on specialized regional distributors rather than direct manufacturer sales. This segment maintains the cultural relevance of traditional casings and often drives innovation in premium and specialty markets.

Furthermore, the emerging sector of manufacturers specializing in plant-based and meat analog products represents a rapidly growing segment of potential customers. As vegetarian and vegan sausage consumption rises, these companies require specialized non-animal-derived casings, typically customized cellulose or advanced polymer films, that can replicate the visual and textual attributes traditionally provided by natural or collagen casings. These customers place a high value on sustainability, vegan certification, and the ability of the casing to perform reliably under the unique heating and processing methods used for non-meat formulations. Catering to these diverse requirements ensures market resilience and adaptability across the changing landscape of protein consumption.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 2.1 Billion |

| Market Forecast in 2033 | USD 3.0 Billion |

| Growth Rate | 4.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Viscofan SA, Viskase Companies, Inc., Devro plc, Shenguan Holdings (Group) Limited, Nitta Casings Inc., Kalle GmbH, Fibran SA, FABIOS SA, Innovia Films, Atlantis-Pak Co. Ltd., CDL casings, S.I.C. Casings, International Casings Group, DAT-Schaub Group, Townsville Casing Co., Crown National, Symrise AG, Almi Ges.m.b.H, Weschenfelder, Sparboe Companies |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Sausage Hotdog Casings Market Key Technology Landscape

The technological landscape of the Sausage Hotdog Casings Market is characterized by continuous refinement of extrusion, film formation, and post-processing techniques aimed at improving product uniformity, consistency, and functional performance, particularly for artificial casings. In collagen casing production, advancements focus on optimizing the acid treatment and polymerization stages of hide material to achieve specific tensile strength and edible 'snap' characteristics that mimic natural casings while maintaining strict diameter consistency essential for automated high-speed stuffing lines. Extrusion technology has evolved to allow for multi-layer co-extrusion of plastic casings, integrating specialized barrier materials (e.g., EVOH) to significantly improve oxygen and moisture protection, thereby extending the shelf life of highly perishable products without requiring additional chemical preservatives.

For cellulose and fibrous casings, the critical technological focus is on enhancing permeability control. Cellulose casings, often peeled off after cooking (non-edible), are manufactured using regeneration processes that dictate their strength and ability to be easily peeled while retaining the sausage's shape. Fibrous casings, utilized for smoked and cured products, rely on advanced fiber netting and treatment processes to ensure uniform smoke penetration and adhesion characteristics, providing the necessary strength for hanging and curing large sausage products. Furthermore, the development of functional additives, such as natural colorants and antimicrobial agents embedded within the casing matrix, represents an ongoing technological trend aimed at improving safety and visual appeal while adhering to clean label demands.

A significant area of R&D is directed towards automation and smart manufacturing. Casing manufacturers are adopting sophisticated sensors and machine vision systems integrated with AI (as discussed previously) to monitor the entire production process in real-time, from the consistency of the raw material slurry to the final shirring density. The shirring process itself, which compacts meters of casing onto a short stick, requires highly precise, proprietary technology to ensure the casings run smoothly and efficiently on the processor’s stuffing equipment. Furthermore, new material science research is exploring bio-based polymers derived from algae, chitin, or other renewable resources to create genuinely sustainable and fully biodegradable casings that meet performance criteria while addressing environmental responsibility concerns, positioning the industry for future regulatory shifts.

Regional Highlights

The global consumption and production patterns of sausage hotdog casings vary significantly by region, influenced by dietary habits, economic development, and meat processing infrastructure maturity. North America and Europe collectively represent the most mature markets, characterized by high per capita consumption of processed meats, leading to established demand for both high-volume artificial casings (cellulose and collagen) and premium natural casings. In North America, the massive scale of hotdog and breakfast sausage production necessitates efficient, high-speed collagen and peelable cellulose casings. European markets, particularly Germany, Poland, and Spain, maintain strong artisanal traditions, sustaining a robust segment for natural casings and specialized fibrous casings for regional delicatessen products, alongside significant industrial demand.

Asia Pacific (APAC) stands out as the fastest-growing region, driven by explosive population growth, rapid urbanization, and a notable shift towards convenient packaged Western-style foods. Countries like China, India, and Southeast Asian nations are rapidly modernizing their meat processing sectors, creating immense opportunities for artificial casing penetration due to their scalability and consistency, factors crucial for serving expanding urban populations. The rising middle class in APAC contributes directly to higher expenditure on protein sources and convenience food items. Local production of casings is also increasing in this region to mitigate import costs and align products with local flavor profiles and processing requirements.

Latin America and the Middle East and Africa (MEA) are emerging markets exhibiting strong growth potential. In Latin America, particularly Brazil and Argentina, high livestock production provides a strong foundation for both natural and collagen casing supply and consumption, catering to local traditions of churrasco and specialty sausages. The MEA region, though smaller, is showing increasing demand for processed meat products, especially in urban centers of the Gulf Cooperation Council (GCC) countries and South Africa. This demand is often met through imports, but local manufacturing investment is gradually increasing. The regulatory environment and adherence to Halal standards are critical considerations for casing manufacturers operating in the MEA, particularly impacting the sourcing and preparation of animal-derived casings.

- North America: Dominant market share due to established industrial meat processing infrastructure; high adoption of automated high-speed machinery requiring standard collagen and cellulose casings; strong presence of key global manufacturers.

- Europe: Large, diversified market balancing high industrial demand with substantial traditional/artisanal segments; high demand for natural casings and specialized fibrous casings for traditional cured meats; stringent EU food safety standards influencing material selection.

- Asia Pacific (APAC): Highest CAGR fueled by urbanization and rising processed meat consumption; significant investment in new processing plants; massive opportunity for cost-effective artificial casings to meet volume demand.

- Latin America: Growth driven by local livestock production and established meat consumption culture; increasing use of collagen casings, particularly in countries like Brazil and Mexico; emerging export potential.

- Middle East and Africa (MEA): Growing demand linked to urbanization and retail expansion; consumption sensitive to Halal certification requirements; reliance on imported casings, though local capacity is developing slowly.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Sausage Hotdog Casings Market.- Viscofan SA

- Viskase Companies, Inc.

- Devro plc

- Shenguan Holdings (Group) Limited

- Nitta Casings Inc.

- Kalle GmbH

- Fibran SA

- FABIOS SA

- Innovia Films

- Atlantis-Pak Co. Ltd.

- CDL casings

- S.I.C. Casings

- International Casings Group

- DAT-Schaub Group

- Townsville Casing Co.

- Crown National

- Symrise AG

- Almi Ges.m.b.H

- Weschenfelder

- Sparboe Companies

Frequently Asked Questions

Analyze common user questions about the Sausage Hotdog Casings market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary advantages of collagen casings over natural casings?

Collagen casings offer superior diameter uniformity, consistent tensile strength, and are significantly more cost-effective for high-speed automated sausage production lines. They provide an edible option without the high labor and material variability associated with natural animal intestines.

How is the growing demand for plant-based meat substitutes impacting the casings market?

The plant-based trend is driving technological innovation in the cellulose and specialized polymer casing segments, requiring manufacturers to develop non-animal-derived casings that can replicate the functional properties (snap, texture, smoke permeability) needed for vegan sausage production.

What is the difference between edible and non-edible casings, and what materials are used for each?

Edible casings, primarily natural and certain types of thin collagen, are consumed with the sausage. Non-edible casings, such as fibrous, plastic, and peelable cellulose, are designed to be removed after the sausage is cooked, smoked, or cured, providing structure during processing.

Which geographical region is expected to show the fastest growth in the Sausage Hotdog Casings Market?

The Asia Pacific (APAC) region is projected to exhibit the fastest growth rate, fueled by rapid urbanization, increasing per capita income, and the adoption of modern, high-volume processed meat production techniques across its key economies.

What role does sustainability play in the development of new sausage casing materials?

Sustainability is a crucial factor, driving research into biodegradable materials, bio-sourced polymers (like algae derivatives), and enhanced barrier technologies to extend shelf life naturally, minimizing reliance on non-renewable resources and chemical preservatives to meet clean label demands.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager