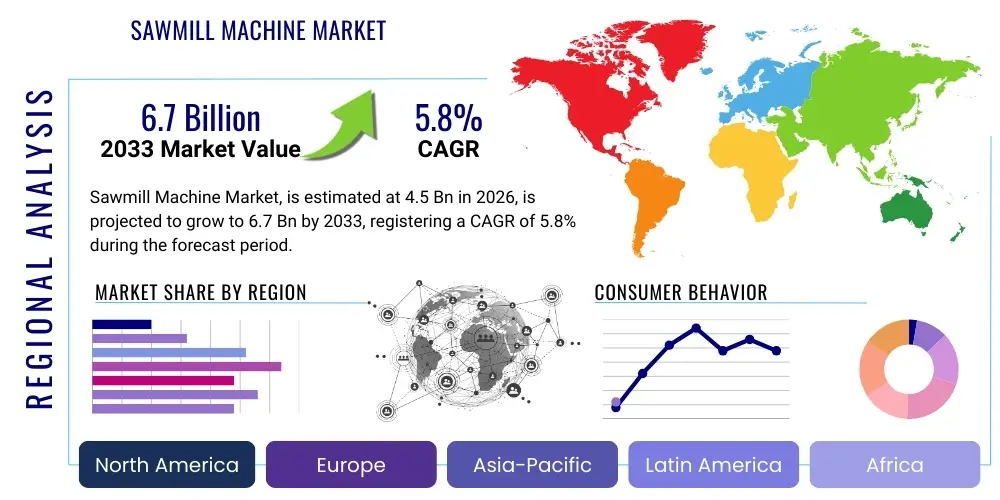

Sawmill Machine Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440001 | Date : Jan, 2026 | Pages : 249 | Region : Global | Publisher : MRU

Sawmill Machine Market Size

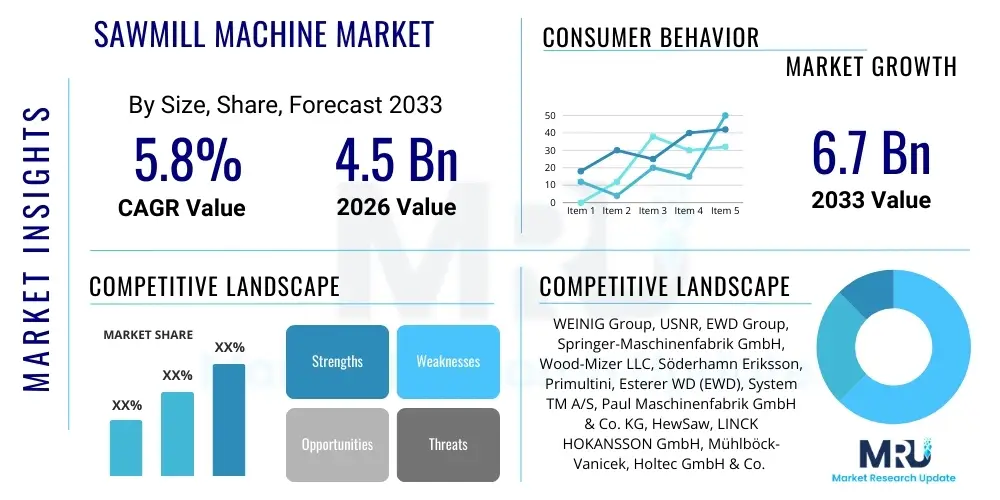

The Sawmill Machine Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 4.5 Billion in 2026 and is projected to reach USD 6.7 Billion by the end of the forecast period in 2033. This growth is primarily fueled by increasing global demand for processed timber in construction, furniture manufacturing, and packaging industries, coupled with technological advancements enhancing operational efficiency and product quality.

Sawmill Machine Market introduction

The Sawmill Machine Market encompasses the global industry involved in the manufacturing, distribution, and servicing of machinery used for converting logs into lumber and other wood products. These machines are fundamental to the timber processing industry, performing essential functions such as debarking, log scanning, sawing, edging, trimming, and stacking. The core purpose of sawmill machinery is to maximize yield from raw timber, minimize waste, and produce high-quality, uniformly sized wood products for various end-use applications, ranging from structural components in construction to intricate furniture pieces and pulp for paper production.

The product portfolio within this market includes a wide array of equipment, such as band saws, circular saws, gang saws, edgers, trimmers, log carriages, and sorters, each designed for specific stages of the milling process. Major applications span across primary sawmills, secondary wood processing plants, furniture manufacturing facilities, and pulp & paper mills, all reliant on precise and efficient wood conversion. The primary benefits derived from modern sawmill machines include enhanced operational efficiency, improved lumber recovery rates, reduced labor costs, superior product consistency, and increased worker safety through automation. These machines are critical enablers for meeting the escalating global demand for wood products, driven by urbanization, infrastructure development, and a growing consumer preference for sustainable materials.

Key driving factors for the sawmill machine market include robust growth in the construction sector globally, particularly in emerging economies, alongside a continuous demand from the furniture industry. Furthermore, technological advancements leading to greater automation, precision cutting, and integration with digital control systems are significantly contributing to market expansion. The emphasis on sustainable forest management and efficient resource utilization also propels the adoption of advanced machinery capable of optimizing log processing and minimizing environmental impact. Additionally, the replacement of aging equipment with newer, more efficient models across established timber-producing regions further stimulates market growth.

Sawmill Machine Market Executive Summary

The global Sawmill Machine Market is currently experiencing a dynamic phase, characterized by significant business trends driven by technological innovation and shifting global demand patterns. Manufacturers are increasingly focusing on developing highly automated and intelligent sawmill solutions that integrate artificial intelligence, IoT, and advanced robotics to optimize operational efficiency, enhance lumber recovery, and reduce production costs. This trend towards "smart sawmills" is reshaping competitive landscapes, pushing companies to invest heavily in R&D to offer differentiated and value-added machinery. Furthermore, there is a growing emphasis on modular and flexible machine designs that can be adapted to various log sizes and processing requirements, catering to a broader range of sawmill operations from small-scale enterprises to large industrial facilities.

From a regional perspective, the market exhibits diverse growth trajectories. The Asia Pacific region is anticipated to be a primary growth engine, fueled by rapid urbanization, infrastructure development projects, and a burgeoning furniture industry, particularly in countries like China, India, and Southeast Asian nations. North America and Europe, while mature markets, continue to demonstrate stable demand, driven by stringent quality standards, environmental regulations promoting sustainable practices, and continuous upgrades to existing machinery. Latin America and the Middle East & Africa regions are emerging as promising markets due to increasing timber production, expanding construction sectors, and efforts to modernize local wood processing industries. Each region presents unique opportunities and challenges influenced by timber availability, regulatory frameworks, and economic development levels.

Segmentation trends within the sawmill machine market highlight a growing preference for automated and semi-automated machinery due to their capabilities in improving productivity and precision compared to traditional manual systems. By machine type, band saws and circular saws continue to dominate due to their versatility and efficiency in primary breakdown operations. The market is also seeing increasing adoption of specialized equipment like edgers and trimmers that optimize secondary processing and lumber finishing. End-user segmentation reveals that primary sawmills remain the largest consumers, though demand from secondary wood processing plants and furniture manufacturers is steadily rising, driven by their needs for customized and high-quality wood components. The push for sustainability and optimized resource utilization is also influencing demand for machines that can handle smaller logs or defective timber more efficiently.

AI Impact Analysis on Sawmill Machine Market

Common user questions regarding AI's impact on the Sawmill Machine Market often revolve around its potential to revolutionize operational efficiency, improve yield, and address labor shortages. Users frequently inquire about how AI can enhance log scanning and grading, optimize cutting patterns to minimize waste, predict machinery maintenance needs, and automate complex decision-making processes on the mill floor. Concerns often include the initial investment cost, the complexity of integrating AI systems with existing machinery, data security, and the need for a skilled workforce to manage these advanced technologies. Expectations are high for AI to deliver significant gains in productivity, product quality, and resource sustainability, transforming traditional sawmill operations into highly intelligent and adaptive production environments.

- Process Optimization: AI-powered systems can analyze log characteristics in real-time (e.g., diameter, length, defects) to determine optimal cutting solutions, maximizing lumber recovery and value by identifying the best sawing patterns.

- Predictive Maintenance: AI algorithms analyze sensor data from sawmill machinery to predict potential failures, allowing for proactive maintenance and reducing costly downtime, extending equipment lifespan.

- Quality Control and Grading: Vision systems combined with AI can automatically detect and classify defects in lumber, ensuring consistent quality and accurate grading, which reduces manual inspection errors.

- Resource Management: AI helps optimize raw material utilization by intelligently sorting and directing logs to specific processing lines based on their characteristics and desired end products, minimizing waste.

- Safety Enhancements: AI-driven monitoring systems can detect hazardous situations or anomalies in machine operation, alerting operators and potentially preventing accidents in the sawmill environment.

- Supply Chain Optimization: AI can be used to forecast timber demand and supply, optimize logistics for raw material procurement, and manage inventory more efficiently across the entire value chain.

- Energy Efficiency: AI algorithms can optimize machine operating parameters to reduce energy consumption, contributing to lower operational costs and a smaller environmental footprint.

- Labor Efficiency and Automation: AI facilitates higher levels of automation, taking over repetitive or hazardous tasks, thereby increasing labor efficiency and addressing skilled labor shortages.

- Customization and Flexibility: AI-driven systems enable sawmills to quickly adapt to changing market demands by reconfiguring cutting patterns and production schedules for customized lumber products.

DRO & Impact Forces Of Sawmill Machine Market

The Sawmill Machine Market is significantly influenced by a complex interplay of Drivers, Restraints, and Opportunities, which collectively form the impact forces shaping its trajectory. Key drivers include the escalating global demand for wood and wood products, particularly from the robust construction and furniture industries, which necessitates efficient log processing. Additionally, the continuous pursuit of operational efficiency, cost reduction, and improved lumber recovery rates by sawmills worldwide is propelling the adoption of advanced, automated machinery. Technological advancements, such as the integration of IoT, AI, and robotics, are also powerful drivers, enabling higher precision, faster processing speeds, and reduced labor dependency. The growing emphasis on sustainable forest management and responsible sourcing further encourages investment in modern machines that optimize resource utilization and minimize waste, aligning with environmental objectives.

Conversely, the market faces several significant restraints. High initial capital investment required for modern sawmill machinery acts as a major barrier, particularly for smaller and medium-sized enterprises (SMEs) or those in developing economies with limited access to financing. Fluctuations in raw material prices and availability, stemming from factors like climate change, deforestation concerns, and strict environmental regulations, can disrupt supply chains and impact sawmill profitability, consequently affecting investment in new machinery. Furthermore, the increasing stringency of environmental regulations regarding timber harvesting and processing, while promoting sustainability, can sometimes impose operational limitations and increase compliance costs for sawmill operators. The complexity of operating and maintaining advanced machinery also necessitates a skilled workforce, which can be a challenge in regions facing labor shortages or lacking adequate technical training infrastructure.

Opportunities within the sawmill machine market are abundant, primarily in developing economies experiencing rapid urbanization and industrialization, leading to an increased demand for construction materials and furniture. The trend towards "smart factories" and Industry 4.0 provides a fertile ground for the development and adoption of highly integrated, data-driven sawmill solutions that offer unprecedented levels of control and optimization. Moreover, the increasing demand for customized and specialized wood products, driven by architectural trends and consumer preferences, opens avenues for machinery capable of versatile processing. The focus on biomass energy production and the utilization of wood waste for various industrial applications also present new markets for machinery designed to process timber by-products. The continuous evolution of material science and engineering also contributes to the development of more durable and efficient machine components, further enhancing market potential.

Segmentation Analysis

The Sawmill Machine Market is comprehensively segmented based on various critical parameters, providing a detailed understanding of its underlying structure and dynamics. These segmentations allow for a granular analysis of market trends, competitive landscapes, and growth opportunities across different product types, levels of automation, and end-user applications. Understanding these distinctions is crucial for stakeholders to tailor their strategies, ranging from product development and marketing to investment decisions, ensuring alignment with specific market needs and demands. The segmentation framework reflects the diverse technological advancements and operational requirements within the global timber processing industry, from basic log breakdown to sophisticated lumber finishing.

- By Machine Type:

- Band Saws (Horizontal Band Saws, Vertical Band Saws, Twin Band Saws)

- Circular Saws (Single Circular Saws, Twin Circular Saws, Multi-rip Circular Saws)

- Gang Saws (Frame Saws, Gang Edgers)

- Log Carriages

- Edgers

- Trimmers (Optimizing Trimmers, Fixed Length Trimmers)

- Debarkers (Ring Debarkers, Rotor Debarkers)

- Chippers

- Sorters and Stackers

- Other Auxiliary Equipment (Conveyors, Grinders, Sharpeners)

- By Automation Level:

- Manual

- Semi-Automatic

- Automatic (Fully Automated Systems)

- By Operation Type:

- Primary Breakdown (Head Rigs)

- Secondary Processing (Resaws, Edgers, Trimmers)

- Log Handling and Sorting

- Material Handling

- By End-User Industry:

- Primary Sawmills

- Secondary Wood Processing Plants

- Furniture Manufacturing

- Pulp and Paper Industry

- Wood Panel Industry (Plywood, Particleboard, MDF)

- Construction and Building Materials

- Bioenergy and Biomass Production

- Other Wood Products Manufacturers

- By Capacity:

- Small Capacity Sawmills (e.g., up to 20,000 cubic meters/year)

- Medium Capacity Sawmills (e.g., 20,000 to 100,000 cubic meters/year)

- Large Capacity Sawmills (e.g., above 100,000 cubic meters/year)

Value Chain Analysis For Sawmill Machine Market

The value chain for the Sawmill Machine Market is intricate, beginning with the upstream activities of raw material procurement and extending through manufacturing, distribution, and end-user consumption. Upstream analysis involves the sourcing of essential components and materials such as high-grade steel, advanced electronics, hydraulic systems, and specialized cutting tools from a network of global suppliers. The quality and availability of these raw materials directly impact the manufacturing efficiency and the ultimate performance and durability of sawmill machinery. Manufacturers often engage in strategic partnerships with component suppliers to ensure stable supply chains and integrate cutting-edge technologies into their designs, fostering innovation and maintaining competitive advantage.

In the downstream segment, the focus shifts to the utilization and support of sawmill machines by end-users. This involves the installation, operation, maintenance, and eventual upgrading or replacement of equipment. Post-sales services, including technical support, spare parts availability, and training for operators, are crucial components of the downstream value chain, directly influencing customer satisfaction and long-term equipment performance. The efficiency with which lumber is produced, processed, and distributed after coming off the sawmill machines also impacts the perceived value and success of the initial machinery investment. Effective downstream operations contribute to sustainable timber production and the smooth functioning of the broader wood products industry.

The distribution channel for sawmill machinery typically involves a mix of direct sales and indirect channels. Direct sales are common for large-scale, customized sawmill lines, where manufacturers engage directly with major sawmill operators, offering tailored solutions and comprehensive support packages. Indirect distribution channels primarily involve a network of authorized dealers, distributors, and agents who manage sales, marketing, and often provide localized installation and maintenance services for smaller and standardized machinery. These intermediaries play a vital role in reaching diverse geographic markets, particularly in regions where direct presence might be economically unfeasible for manufacturers. The choice of distribution strategy often depends on the type of machinery, the target market's maturity, and the manufacturer's global reach and resource capabilities, aiming to optimize market penetration and customer accessibility.

Sawmill Machine Market Potential Customers

The potential customers for sawmill machinery are diverse and span across various segments of the wood processing and related industries, all sharing a common need for efficient and precise timber conversion. Primary sawmills, ranging from small, family-owned operations to large, integrated industrial complexes, represent the largest and most direct customer base. These entities are dedicated to the initial breakdown of raw logs into rough lumber, timber, and other primary wood products. Their purchasing decisions are heavily influenced by factors such as machine capacity, automation levels, lumber recovery rates, energy efficiency, and overall operational costs, as they seek to maximize yield and profitability from their timber resources.

Beyond primary sawmills, secondary wood processing plants form a significant customer segment. These facilities take the rough lumber from primary sawmills and further process it into more refined products, such as dimensioned lumber, flooring, panels, and specialized components. This category also includes furniture manufacturers, who require high-precision cutting and shaping machinery to produce components for various furniture designs. The pulp and paper industry is another key end-user, utilizing specific types of sawmill machinery, such as chippers, to prepare wood chips for pulp production. Additionally, the growing wood panel industry, encompassing manufacturers of plywood, particleboard, and Medium-Density Fiberboard (MDF), requires machinery for veneer production and panel sizing.

Furthermore, the construction and building materials sector, although primarily a consumer of lumber, indirectly drives demand for sawmill machines by necessitating a consistent supply of processed timber. Companies involved in bioenergy and biomass production, which process wood waste and residues into energy, also constitute a niche but growing customer segment for specific types of comminution and chipping equipment. Each of these customer groups has unique requirements, demanding different types of machinery, levels of automation, and after-sales support, which manufacturers must address to capture market share effectively. The continuous demand for wood products globally underpins the robust customer base for the sawmill machine market.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 4.5 Billion |

| Market Forecast in 2033 | USD 6.7 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | WEINIG Group, USNR, EWD Group, Springer-Maschinenfabrik GmbH, Wood-Mizer LLC, Söderhamn Eriksson, Primultini, Esterer WD (EWD), System TM A/S, Paul Maschinenfabrik GmbH & Co. KG, HewSaw, LINCK HOKANSSON GmbH, Mühlböck-Vanicek, Holtec GmbH & Co. KG, Vollmer Werke, Valon Kone, Baxley Equipment Company, BID Group, TimberPro, Comact (part of BID Group). |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Sawmill Machine Market Key Technology Landscape

The Sawmill Machine Market is undergoing a profound technological transformation, driven by the principles of Industry 4.0 and the relentless pursuit of efficiency and precision. One of the most significant advancements is the integration of advanced sensor technologies, including 3D scanning and optical sensors, which provide real-time, high-resolution data on log geometry, internal defects, and fiber orientation. This data is crucial for optimizing cutting solutions and maximizing lumber recovery, forming the backbone of modern "smart sawmills." These scanning systems feed information into sophisticated computer-aided design (CAD) and manufacturing (CAM) software, allowing for dynamic adjustment of cutting patterns based on each log's unique characteristics, a stark contrast to traditional fixed-pattern sawing.

The increasing adoption of Artificial Intelligence (AI) and Machine Learning (ML) algorithms is another pivotal technology reshaping the landscape. AI is being applied to process optimization, where algorithms analyze vast datasets from log scanners and production lines to identify the most efficient cutting strategies, predict equipment failures through predictive maintenance, and enhance automated quality control and grading of lumber. Robotics and automation are also playing an expanded role, with robotic arms handling log manipulation, sorting, and stacking, reducing human intervention in hazardous or repetitive tasks. This not only improves worker safety but also boosts operational speed and consistency, mitigating the impact of labor shortages in some regions.

Furthermore, the development of more energy-efficient motors, variable frequency drives (VFDs), and regenerative braking systems is contributing to lower operational costs and a reduced environmental footprint for sawmill operations. Connectivity technologies such as the Internet of Things (IoT) enable seamless communication between different machines on the mill floor, providing comprehensive data for real-time monitoring, diagnostics, and remote control. This interconnected ecosystem allows for holistic optimization of the entire sawmill process, from log intake to finished product. The combination of these technologies is not only improving the efficiency and output of sawmill machines but also enabling greater flexibility, allowing mills to adapt to diverse log types and market demands with unprecedented agility.

Regional Highlights

- North America: A mature market characterized by high adoption of advanced, automated sawmill machinery. Driven by strong demand from the housing and construction sectors, coupled with a focus on sustainable forestry and maximizing yield from valuable timber resources. Manufacturers here prioritize technological innovation and robust, high-capacity equipment.

- Europe: Exhibits a strong emphasis on precision, environmental sustainability, and energy efficiency. European sawmills are known for integrating advanced software, robotics, and highly accurate cutting technologies to optimize lumber recovery and meet stringent quality standards. Significant investment in modernization and automation is ongoing.

- Asia Pacific (APAC): The fastest-growing region, propelled by rapid urbanization, infrastructure development, and a burgeoning furniture industry in countries like China, India, and Southeast Asia. Demand for both high-capacity and cost-effective machinery is increasing, often leading to a mix of new technology adoption and traditional methods. Raw material availability and local economic development significantly influence market dynamics.

- Latin America: A resource-rich region with vast timber reserves, experiencing growing demand for modern sawmill equipment as countries like Brazil and Chile seek to enhance their timber processing capabilities for both domestic consumption and export. Investments are driven by the need for increased efficiency, particularly in harvesting and primary breakdown.

- Middle East and Africa (MEA): An emerging market for sawmill machinery, driven by increasing infrastructure projects, growing construction sectors, and efforts to diversify economies beyond oil. While currently smaller, the region presents long-term growth potential as local timber industries develop and adopt more sophisticated processing technologies, albeit with challenges related to raw material consistency and skilled labor.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Sawmill Machine Market.- WEINIG Group

- USNR

- EWD Group

- Springer-Maschinenfabrik GmbH

- Wood-Mizer LLC

- Söderhamn Eriksson (part of Springer-Maschinenfabrik GmbH)

- Primultini

- Esterer WD (EWD)

- System TM A/S

- Paul Maschinenfabrik GmbH & Co. KG

- HewSaw

- LINCK HOKANSSON GmbH

- Mühlböck-Vanicek

- Holtec GmbH & Co. KG

- Vollmer Werke

- Valon Kone

- Baxley Equipment Company

- BID Group

- TimberPro

- Comact (part of BID Group)

Frequently Asked Questions

What is the projected growth rate of the Sawmill Machine Market?

The Sawmill Machine Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033, driven by increased demand for wood products and technological advancements.

How is AI impacting the Sawmill Machine Market?

AI is significantly impacting the market by enabling process optimization, predictive maintenance, enhanced quality control, efficient resource management, and improved safety in sawmill operations, leading to higher efficiency and yield.

What are the primary drivers for the Sawmill Machine Market?

Key drivers include the escalating global demand for wood products in construction and furniture, the continuous pursuit of operational efficiency and cost reduction, and technological advancements like automation and IoT integration.

Which regions are leading the growth in the Sawmill Machine Market?

The Asia Pacific region is anticipated to be the primary growth engine due to rapid urbanization and infrastructure development, while North America and Europe maintain stable demand driven by modernization and sustainability efforts.

What types of machines are included in the Sawmill Machine Market?

The market includes a wide array of machines such as band saws, circular saws, gang saws, log carriages, edgers, trimmers, debarkers, chippers, sorters, stackers, and other auxiliary equipment for processing logs into lumber.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager