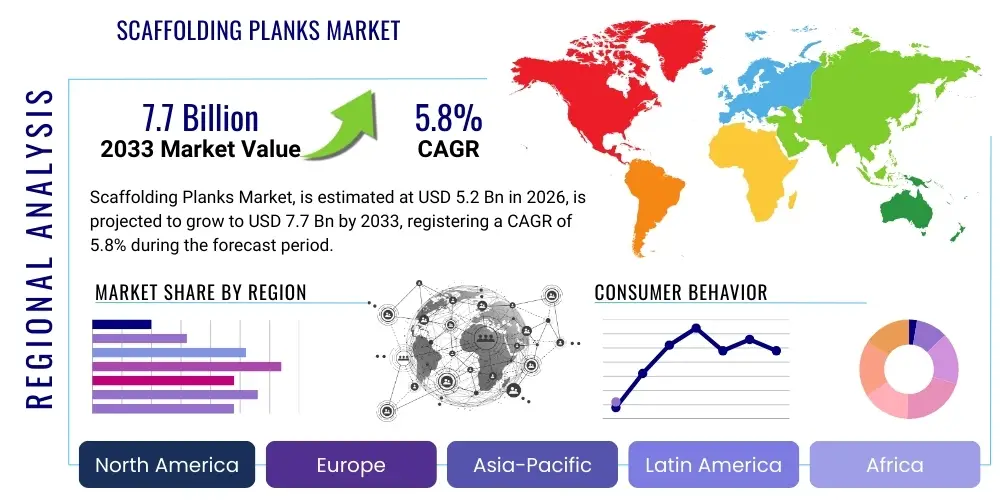

Scaffolding Planks Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 438920 | Date : Dec, 2025 | Pages : 255 | Region : Global | Publisher : MRU

Scaffolding Planks Market Size

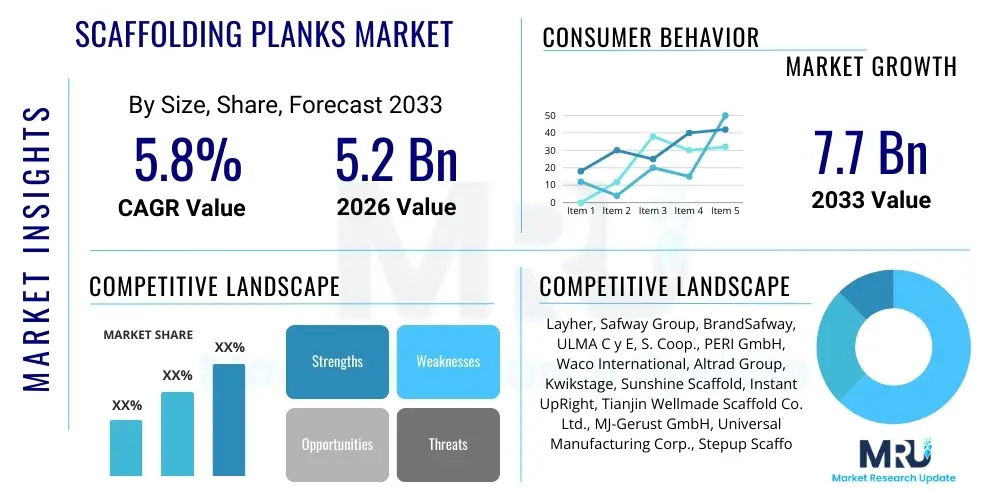

The Scaffolding Planks Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 5.2 Billion in 2026 and is projected to reach USD 7.7 Billion by the end of the forecast period in 2033.

Scaffolding Planks Market introduction

The Scaffolding Planks Market encompasses the production and distribution of temporary work platforms utilized in construction, maintenance, and repair activities globally. Scaffolding planks, often referred to as scaffold boards or decking, form the crucial horizontal component of a scaffolding system, providing a secure and stable surface for workers, tools, and materials. These platforms are indispensable across various sectors, ensuring operational safety and efficiency at elevated heights. The fundamental role of these components in adhering to stringent global safety regulations drives their consistent demand, particularly in regions experiencing rapid urbanization and infrastructure development. Material innovation, focusing on durability, reduced weight, and fire resistance, is becoming a central theme in market evolution.

Scaffolding planks are categorized primarily by the material used in their construction, including traditional wood (lumber), aluminum, steel, and advanced composite materials. Each material offers distinct advantages regarding load-bearing capacity, lifespan, cost, and suitability for specific environments, such as corrosive industrial settings or lightweight residential projects. Major applications span commercial building construction, where high stability and long-term use are required, large-scale infrastructure projects like bridges and power plants, and routine industrial maintenance tasks. The selection criteria for planks often involve regulatory compliance, ensuring they meet standards set by bodies like OSHA (Occupational Safety and Health Administration) or European equivalents.

Key market benefits delivered by high-quality scaffolding planks include enhanced worker safety through reliable footing, improved productivity by allowing easy movement of resources, and compliance with increasingly strict global construction standards. The market is fundamentally driven by continuous investment in real estate and public infrastructure, particularly in developing economies, coupled with mandatory safety upgrades in mature markets. Furthermore, the growing trend toward modular and prefabricated construction techniques, which require standardized and robust access solutions, further propels the demand for certified scaffolding planks that integrate seamlessly with various frame and system scaffolding types.

Scaffolding Planks Market Executive Summary

The Scaffolding Planks Market is characterized by resilient growth, primarily fueled by a post-pandemic rebound in global construction expenditure and intensified regulatory focus on worker safety. Business trends indicate a significant shift towards material diversification, with aluminum and composite planks gaining market share over traditional timber due to their extended lifespan, resistance to rot, and lighter weight, which improves site logistics and reduces installation time. Strategic initiatives among leading manufacturers focus heavily on automation in production and the adoption of rental business models, which allow construction firms greater flexibility and reduced capital outlay. Consolidation is observed, particularly in specialized composite material segments, as companies seek to acquire patented technologies for enhanced durability and sustainability features.

Regionally, the Asia Pacific (APAC) stands out as the primary growth engine, driven by massive infrastructure projects in China, India, and Southeast Asian nations, alongside explosive residential and commercial development. North America and Europe, while being mature markets, exhibit strong demand underpinned by renovation, repair, and maintenance (RR&M) activities, especially the retrofitting of aging structures and strict enforcement of revised safety mandates. European trends also favor sustainable sourcing, pushing manufacturers toward certified timber or advanced, recyclable composite materials. Latin America and the Middle East continue to see robust growth correlated with government-backed industrialization and mega-project developments, such as those related to oil, gas, and major urban expansion plans.

Segment-wise, the aluminum planks segment is projected to demonstrate the highest CAGR, attributed to its corrosion resistance and lightweight nature, making it ideal for high-frequency use and extreme weather conditions. The application segment remains dominated by commercial construction, although infrastructure projects are rapidly increasing their consumption share due to the scale and duration of modern public works. Manufacturers are also prioritizing the development of standardized, load-rated planks designed specifically for frame scaffolding systems, ensuring interoperability and reduced risk of on-site incompatibility, thereby optimizing supply chain management for large construction contractors.

AI Impact Analysis on Scaffolding Planks Market

Common user questions regarding AI's impact on the Scaffolding Planks Market often center on how automation affects production efficiency, quality control, and the safety monitoring of scaffold structures. Users are frequently concerned about whether AI-driven manufacturing processes can reduce defects in composite or welded metal planks, leading to standardized, reliable products that meet strict safety tolerances. Key themes include the implementation of predictive maintenance for scaffolding assets (including plank integrity checks), optimizing inventory and logistics management for plank distribution, and using computer vision systems to monitor plank usage and potential overload conditions on active construction sites. Expectations are high regarding AI's ability to minimize human error in assembly and inspection, thereby drastically improving overall safety performance.

While AI does not directly alter the chemical or physical properties of the planks themselves, its influence is transformative in the lifecycle management and application of the products. AI-driven vision systems deployed via drones or fixed cameras are becoming critical for real-time monitoring of installed scaffolding, ensuring that planks are correctly placed, secured, and not subjected to overloading beyond their safe working limits. Furthermore, machine learning algorithms are optimizing cutting and molding processes in manufacturing, minimizing material waste, and ensuring precise dimensions, which is vital for system scaffolding compatibility. This adoption enhances not just operational efficiency but significantly bolsters the confidence in the structural integrity of the temporary work platforms.

- AI-Powered Quality Control: Utilizing computer vision for automated detection of surface defects, cracks, or warping in newly manufactured planks, ensuring adherence to safety standards before shipping.

- Predictive Maintenance: Applying machine learning models to analyze usage data and environmental conditions (humidity, temperature, load cycles) to predict the expected lifespan and recommend replacement schedules for plank inventory.

- Optimized Logistics and Inventory: Implementing AI algorithms to forecast regional demand for specific plank materials (e.g., aluminum vs. wood) and optimize warehousing and transport routes, reducing delivery delays and operational costs.

- Site Safety Monitoring: Deployment of AI-enabled cameras on construction sites to monitor proper plank installation, identify unauthorized modifications, or detect potential overloading situations in real-time, sending immediate alerts to site managers.

- Design Optimization: Using generative design tools, powered by AI, to explore innovative plank cross-sections that maximize strength-to-weight ratio for composite materials while maintaining regulatory compliance.

DRO & Impact Forces Of Scaffolding Planks Market

The market dynamics are shaped by powerful forces encompassing robust drivers, inherent restraints, substantial opportunities, and broader impactful environmental factors. Key drivers include aggressive global governmental spending on infrastructure renewal and expansion, particularly in high-growth regions, coupled with increasingly stringent occupational safety laws worldwide that mandate the use of certified and regularly inspected scaffolding components. These safety regulations necessitate periodic replacement and upgrade of existing plank inventory. However, the market faces significant restraints, primarily the volatile prices of raw materials such as steel, aluminum, and high-grade lumber, which impact manufacturing costs and pricing stability. Furthermore, the inherent risk of counterfeiting and the proliferation of non-certified, cheaper products in some emerging markets pose a challenge to established, quality-focused manufacturers.

Opportunities in the market center around the burgeoning demand for lightweight, high-performance, and sustainable materials. There is a substantial opportunity for manufacturers to innovate in composite plank technology, offering products that combine the structural rigidity of steel with the weight advantages of aluminum and improved fire resistance compared to wood. The expansion of rental and leasing services for scaffolding systems presents another avenue for growth, allowing suppliers to maintain quality control over their assets and offer subscription-based safety assurance. Geographically, untapped potential lies in expanding distribution networks in underserved secondary cities and rural development zones across Africa and parts of South Asia, where construction activities are accelerating but modern scaffolding penetration remains low.

The primary impact forces include rapid urbanization, which perpetually increases the volume and complexity of high-rise construction, demanding specialized and robust planks. Secondly, technological advancements in construction automation (like robotic assembly) require highly standardized and precise plank dimensions. Regulatory harmonization across trading blocs, such as ongoing efforts to standardize EU construction equipment norms, also forces manufacturers to invest in product certification, creating a competitive moat for compliant firms. Finally, the growing global emphasis on Environmental, Social, and Governance (ESG) criteria is a critical force, driving demand for scaffolding planks made from recycled content or sustainably sourced timber, thereby influencing the entire value chain from material selection to end-of-life recycling programs.

Segmentation Analysis

The Scaffolding Planks Market is comprehensively segmented based on material type, load capacity, width, and end-use application, allowing for a detailed understanding of consumer preferences and operational requirements across diverse construction environments. Analyzing these segments is crucial for manufacturers to tailor their product offerings, optimize production processes, and target marketing efforts toward specific buyer groups, such as heavy industrial contractors favoring steel planks or residential builders preferring lightweight aluminum options. The segmentation highlights the market's diversity and its alignment with varying regulatory standards and project specifications globally.

- Material Type: Wood Planks, Aluminum Planks, Steel Planks, Composite Planks

- Load Capacity: Light Duty (Up to 25 psf), Medium Duty (25–50 psf), Heavy Duty (50–75 psf), Extra Heavy Duty (75+ psf)

- Width: 9 inches, 12 inches, Other Standard Widths

- Application: Residential Construction, Commercial Construction (Office, Retail, Hospitality), Infrastructure Projects (Bridges, Dams, Roads), Industrial Maintenance (Power Plants, Petrochemical Facilities)

Value Chain Analysis For Scaffolding Planks Market

The value chain for the Scaffolding Planks Market begins with upstream activities focused on raw material sourcing and primary processing. This initial stage involves the procurement of high-grade lumber (e.g., laminated veneer lumber or dimensional timber), aluminum billets, steel coils, and composite resins. Fluctuations in commodity prices significantly affect manufacturing costs at this stage, compelling manufacturers to implement robust supply chain risk mitigation strategies. The middle segment of the value chain involves rigorous manufacturing processes, including precise cutting, welding (for metal planks), lamination, and the application of anti-slip coatings or fire-retardant treatments. Certification and quality assurance, often involving third-party testing, are paramount here to meet stringent global safety standards like ANSI/SSFI, BS EN 12811, and OSHA requirements, adding substantial value and ensuring product credibility.

The downstream segment focuses on distribution channels and end-user engagement. Scaffolding planks are typically distributed through a combination of direct sales to large construction companies and rental firms, and indirect channels such as specialized scaffolding equipment distributors, general construction supply retailers, and hardware stores. The rental model has gained considerable traction globally, particularly for high-cost metal and composite planks, as it allows contractors access to certified equipment without significant upfront capital investment. Direct channels are generally preferred for large-scale infrastructure projects where customization or bulk purchasing is involved. Effective inventory management and quick fulfillment capabilities are critical success factors in the distribution phase, ensuring minimal downtime for construction projects dependent on timely plank supply.

Scaffolding Planks Market Potential Customers

The primary consumers, or potential customers, of scaffolding planks are large general contractors and specialized sub-contractors involved in complex commercial and infrastructure projects. These buyers prioritize product longevity, certified load ratings, and compatibility with their existing scaffolding systems (e.g., modular or system scaffolding). Major infrastructure developers procuring services for extended periods, such as highway construction or energy facility maintenance, represent high-value, recurring clients. Their purchasing decisions are heavily influenced by total cost of ownership, including replacement rates, resistance to extreme weather, and adherence to specific project safety protocols.

A second major customer category includes scaffolding rental and leasing companies, which act as intermediaries by purchasing large volumes of planks and renting them out to smaller construction firms, residential builders, and facilities management companies. These rental firms focus on durability and repairability, as their profitability depends on the asset's lifespan and utilization rate. They typically prefer robust materials like aluminum or heavy-duty composite planks that can withstand continuous transportation and varied site conditions. Residential builders and small, independent contractors represent the third significant segment, often opting for more cost-effective solutions like timber planks, provided they meet minimum local safety standards for low-rise and short-duration projects.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 5.2 Billion |

| Market Forecast in 2033 | USD 7.7 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Layher, Safway Group, BrandSafway, ULMA C y E, S. Coop., PERI GmbH, Waco International, Altrad Group, Kwikstage, Sunshine Scaffold, Instant UpRight, Tianjin Wellmade Scaffold Co. Ltd., MJ-Gerust GmbH, Universal Manufacturing Corp., Stepup Scaffold, China Scaffolding Co. Ltd., XMWY Group, HAKI AB, Doka GmbH, Scafom-Rux, Ischebeck Titan Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Scaffolding Planks Market Key Technology Landscape

The technological landscape of the Scaffolding Planks Market is primarily driven by material science innovation and advanced manufacturing techniques aimed at enhancing durability, safety, and operational efficiency. A core technology advancement is the development and commercial adoption of high-strength, glass-fiber-reinforced polymer (GFRP) or advanced composite planks. These materials offer superior corrosion resistance, substantial weight reduction (up to 50% lighter than traditional lumber), and non-conductive properties, making them essential for specialized projects in petrochemical, utility, and harsh marine environments. Manufacturing relies heavily on pultrusion and high-pressure lamination techniques to ensure consistency in structural properties, minimizing the variability often associated with natural wood products.

Another crucial technological development involves surface treatments and integration capabilities. Planks are increasingly being manufactured with standardized, proprietary locking mechanisms that interface seamlessly with modular scaffolding systems (e.g., ring-lock or cup-lock), minimizing the need for separate securing components and reducing erection time. Furthermore, the application of durable, anti-skid coatings, often incorporating advanced polymer matrices and abrasive particles, is mandatory to comply with slip resistance standards. Smart technologies, such as embedded RFID tags or QR codes, are becoming standard for inventory management and tracking, allowing contractors and rental companies to instantly verify the plank’s load rating, maintenance history, and compliance status, thereby integrating the physical asset with digital asset management systems (DAMS).

Regional Highlights

Regional dynamics profoundly influence the demand and material preferences within the Scaffolding Planks Market, reflecting local construction practices, economic development levels, and regulatory environments. Asia Pacific (APAC) represents the largest and fastest-growing market, primarily due to robust construction activities across India, China, and Southeast Asian countries. The sheer volume of residential and commercial development, coupled with substantial infrastructure spending (e.g., Belt and Road Initiative projects), drives massive demand, predominantly for cost-effective wood and increasingly, high-volume steel planks. However, safety standards are rapidly catching up, pushing demand for higher-quality, certified products in urban centers.

North America and Europe are characterized by market maturity and high regulatory compliance. In these regions, growth is steady, fueled largely by renovation, maintenance, and complex industrial projects. Material preference leans heavily towards lightweight, durable, and highly engineered products, such as aluminum and premium composites, due to stringent labor safety requirements and higher labor costs that necessitate faster assembly times. European markets, in particular, emphasize sustainability, favoring planks derived from responsibly managed forests or fully recyclable composite materials, aligning with the EU’s Green Deal initiatives.

The Middle East and Africa (MEA) region shows significant potential, driven by oil and gas infrastructure maintenance and large-scale urban development projects (like Saudi Arabia's Vision 2030 and Dubai's expansion). High temperatures and corrosive environments common in the GCC nations necessitate the use of corrosion-resistant materials like galvanized steel and specialized aluminum alloys. Latin America, though experiencing uneven economic growth, demonstrates increasing demand for modern scaffolding solutions as it adopts safer, standardized construction practices modeled after North American and European norms, gradually replacing older, less compliant traditional wood platforms.

- Asia Pacific (APAC): Dominant market volume driven by urbanization; focus shifting from low-cost wood to standardized steel and high-volume systems.

- North America: High safety standards driving demand for premium, lightweight aluminum and composite planks; strong market for rental services.

- Europe: Emphasis on sustainability and labor efficiency; strong regulatory framework favoring certified timber and advanced recyclable composites.

- Middle East and Africa (MEA): Rapid growth linked to mega-projects and energy infrastructure; high demand for corrosion-resistant galvanized steel and specialized aluminum.

- Latin America: Emerging market gradually adopting international safety standards, leading to increased demand for robust, certified scaffolding systems.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Scaffolding Planks Market.- Layher

- Safway Group

- BrandSafway

- ULMA C y E, S. Coop.

- PERI GmbH

- Waco International

- Altrad Group

- Kwikstage

- Sunshine Scaffold

- Instant UpRight

- Tianjin Wellmade Scaffold Co. Ltd.

- MJ-Gerust GmbH

- Universal Manufacturing Corp.

- Stepup Scaffold

- China Scaffolding Co. Ltd.

- XMWY Group

- HAKI AB

- Doka GmbH

- Scafom-Rux

- Ischebeck Titan Ltd.

Frequently Asked Questions

Analyze common user questions about the Scaffolding Planks market and generate a concise list of summarized FAQs reflecting key topics and concerns.What material types dominate the Scaffolding Planks Market and why?

The market is primarily dominated by traditional timber (wood) planks globally due to their low cost and historical prevalence, especially in residential and short-term projects. However, engineered materials like aluminum and high-strength composite planks are rapidly gaining market share, particularly in developed regions and large commercial or industrial applications, owing to their superior lifespan, lightweight handling, and high resistance to environmental corrosion and fire hazards, aligning with modern safety regulations and demanding high-use rental cycles.

How do global safety regulations influence the pricing and manufacturing of scaffolding planks?

Stringent global safety regulations, such as those imposed by OSHA, ANSI, and European Standards (EN 12811), are the primary drivers of quality and pricing. These regulations mandate specific load-bearing capacities, standardized dimensions, and the use of certified materials, necessitating costly manufacturing processes, rigorous quality control testing, and frequent third-party certification. This regulatory environment creates a barrier to entry and favors established manufacturers, ultimately increasing the average selling price of compliant, high-quality planks compared to uncertified alternatives.

What is the projected growth rate (CAGR) for the Scaffolding Planks Market through 2033?

The Scaffolding Planks Market is projected to exhibit a steady Compound Annual Growth Rate (CAGR) of 5.8% between the forecast years of 2026 and 2033. This growth is underpinned by persistent infrastructure development initiatives worldwide, particularly in Asia Pacific, coupled with the increasing adoption of highly standardized and durable metal and composite planks that command higher market prices and offer reduced long-term maintenance costs for end-users.

Which application segment provides the greatest growth opportunities for specialized scaffolding planks?

The Infrastructure Projects and Industrial Maintenance segments offer the greatest growth opportunities for specialized scaffolding planks. Infrastructure projects (bridges, refineries, power generation) require planks with extra heavy-duty load capacities, exceptional corrosion resistance, and specific fire ratings, often demanding premium steel or composite solutions. The long duration and demanding environments of these applications ensure higher consumption rates and a preference for proprietary, long-lasting materials that minimize the risk of structural failure and replacement frequency.

How is technology, specifically material science, transforming the traditional wooden plank segment?

Material science is transforming the market by introducing engineered wood products, such as Laminated Veneer Lumber (LVL) and composite planks, which significantly improve upon traditional timber. LVL planks offer standardized dimensions and superior structural integrity by eliminating the defects found in solid wood, reducing warping and improving fire resistance through specialized treatments. Composite materials are also replacing wood in harsh environments, offering non-conductive, non-slip surfaces that meet stricter modern performance requirements without the drawbacks of biological degradation or heavy weight.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager