Scarifier Drums Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 432506 | Date : Dec, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Scarifier Drums Market Size

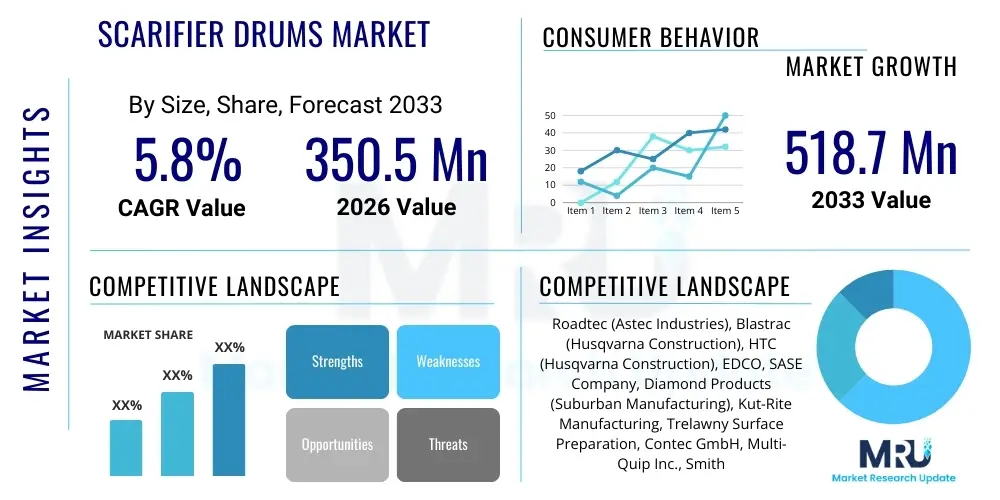

The Scarifier Drums Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at $350.5 Million in 2026 and is projected to reach $518.7 Million by the end of the forecast period in 2033.

Scarifier Drums Market introduction

The Scarifier Drums Market encompasses specialized tooling designed for aggressive surface preparation, material removal, and texturing operations, primarily utilized in the construction, infrastructure, and heavy-duty maintenance sectors. Scarifier drums, which are integral components of scarifying and planning machines, consist of cylindrical assemblies fitted with numerous cutters, flails, or tines, often made from hardened steel or tungsten carbide tipped materials. These drums rotate at high speeds, systematically abrading or chipping away concrete, asphalt, mastic, and epoxy coatings, preparing the substrate for new overlays or ensuring compliance with surface profile specifications.

The primary application areas for scarifier drums include roadway repair, bridge deck rehabilitation, airport runway maintenance, industrial floor preparation, and removal of hazardous floor coatings. Product innovation focuses heavily on enhancing durability, optimizing cutter geometry for different materials, and improving dust suppression mechanisms. The market is highly influenced by infrastructure spending globally, particularly in developed and rapidly urbanizing economies requiring constant upkeep of transportation networks and commercial facilities. The effectiveness of scarifier drums in achieving rapid and controlled removal rates makes them indispensable tools, offering superior results compared to traditional grinding or shot blasting in certain applications.

Key driving factors supporting the market expansion include stringent regulatory requirements regarding surface friction on roads and runways, the need for cost-effective repair methods that minimize downtime, and the increasing adoption of preventive maintenance strategies for infrastructure assets. Furthermore, the rising popularity of high-performance floor coatings in industrial settings mandates precise surface preparation, ensuring maximum adhesion and longevity of the subsequent layers. The benefits derived from using specialized scarifier drums include extended equipment life, enhanced operational safety, minimized material waste, and the ability to handle a diverse range of substrate hardness and removal depths.

Scarifier Drums Market Executive Summary

The Scarifier Drums Market exhibits robust growth driven by escalating global investments in infrastructure maintenance and repair. Business trends indicate a strong shift towards specialized, application-specific drums, particularly those featuring advanced tungsten carbide cutters for extended wear life and efficiency when dealing with high-strength concrete or thick coatings. Key manufacturers are focusing on modular drum systems that allow quick cutter replacement and adaptation to various machine models, catering to both rental fleet operators and large construction contractors. Sustainable practices, such as incorporating recycling mechanisms for removed material and designing longer-lasting components to reduce overall waste, are becoming significant competitive differentiators across the industry value chain, influencing procurement decisions heavily.

Regionally, North America and Europe currently dominate the market due to aging infrastructure, high labor costs necessitating efficient machine utilization, and the early adoption of advanced construction machinery. Asia Pacific, however, is projected to demonstrate the highest CAGR, primarily fueled by massive infrastructural projects in China, India, and Southeast Asian nations focused on rapid urbanization and expansion of road and airport networks. These emerging markets represent significant long-term growth opportunities, although pricing sensitivity and local manufacturing competition remain critical factors influencing penetration strategies. Regulatory standards concerning road safety and pavement integrity are accelerating the demand for precision scarifying equipment in these developing regions.

Segment trends reveal that the "Tungsten Carbide Cutter Drum" segment holds the largest market share due to its superior durability and efficiency across diverse applications, overshadowing standard steel cutter drums. Based on application, highway and bridge deck rehabilitation remains the most dominant segment, reflecting the massive scale of road maintenance globally. Furthermore, the trend toward smaller, specialized walk-behind scarifiers for precision removal in confined spaces is increasing the demand for narrower drum widths and specialized cutter configurations, providing market diversity and catering to niche applications within the commercial flooring sector.

AI Impact Analysis on Scarifier Drums Market

User inquiries regarding AI's influence on the Scarifier Drums Market primarily revolve around how machine learning can optimize maintenance schedules, predict component failure (especially cutter wear), and enhance operational precision. Common questions include whether AI can automate depth control during scarifying, how predictive maintenance affects drum lifespan, and if AI integration will lead to autonomous scarifying equipment. The consensus expectation is that while AI will not directly change the physical drum design in the short term, it will dramatically improve the ecosystem surrounding the equipment. This includes using computer vision for real-time surface analysis to adjust cutter pressure automatically, optimizing fleet management, and deploying intelligent inventory systems that forecast replacement drum and cutter needs based on usage patterns and material hardness data transmitted from telematics systems, thus maximizing uptime and reducing operational waste.

- AI-driven Predictive Maintenance: Analyzing vibration, torque, and temperature data from the scarifier machine to predict optimal times for drum and cutter replacement, minimizing unexpected breakdowns.

- Automated Depth Control: Utilization of machine learning algorithms integrated with sensors (e.g., LiDAR, ultrasonic) to ensure consistent and precise removal depth across uneven surfaces, improving surface profile quality.

- Optimized Inventory Management: AI forecasting demand for specific drum types and cutter materials based on project pipelines and geographical material composition (e.g., hard aggregate vs. soft aggregate).

- Enhanced Fleet Utilization: Machine learning optimizing scheduling and routing of scarifying equipment, ensuring the right drum configuration is deployed for specific job requirements.

- Robotics and Autonomy Integration: Potential future development of fully autonomous scarifying vehicles where AI systems govern movement, operation, and environmental interaction, reducing human labor requirements.

- Data-Driven Design Improvement: Using real-world operational data collected via IoT and analyzed by AI to inform manufacturers about performance bottlenecks, leading to iterative improvements in drum material science and cutter geometry.

DRO & Impact Forces Of Scarifier Drums Market

The market dynamics for Scarifier Drums are governed by a complex interplay of internal and external forces. Key drivers include increasing governmental spending on road and runway rehabilitation projects, especially in major economies focused on modernizing aging infrastructure. Furthermore, the stringent safety and regulatory standards, such as those related to pavement friction indices and adherence protocols for new coatings, necessitate the use of precision scarifying equipment. The inherent efficiency of scarifying—offering high material removal rates compared to conventional methods—provides a compelling cost-benefit analysis for large-scale operations, thereby accelerating adoption across construction fleets globally. These drivers create a sustained baseline demand, essential for vendor profitability and ongoing product development.

Conversely, the market faces significant restraints. The high initial capital investment required for specialized scarifying machinery and associated drum assemblies acts as a barrier to entry for smaller contractors. The operational noise and dust generated during the scarifying process often necessitate strict environmental compliance measures and labor safety protocols, sometimes restricting usage in densely populated urban areas or sensitive environmental zones. Moreover, the cyclical nature of infrastructure spending, which is often tied to political funding cycles and economic recessions, introduces volatility into long-term demand forecasting. The lifespan of scarifier drums is finite, subject to severe wear and tear, meaning the replacement market is stable, but high replacement costs can sometimes influence end-users to seek cheaper, lower-quality alternatives.

Opportunities for growth are concentrated in the development of innovative, sustainable materials that extend drum life and reduce operational costs. The untapped potential in emerging markets, driven by rapid urbanization and the establishment of new national highway networks, presents substantial avenues for geographical expansion. Technological advancements, such as the integration of telematics and IoT for monitoring drum performance and enabling predictive maintenance, offer competitive advantages. Impact forces, including competitive pricing pressure from regional manufacturers offering lower-cost replacement parts and the necessity for continuous innovation in cutter technology (e.g., developing specialized ceramics or advanced alloys for extreme applications), continuously shape the market structure and influence market share distribution among key players.

Segmentation Analysis

The Scarifier Drums Market is comprehensively segmented based on three critical parameters: the type of cutter material used, the physical dimensions (width) of the drum, and the specific application sector where the equipment is deployed. This segmentation allows for precise market sizing and strategic targeting, reflecting the varied operational requirements across the construction and maintenance industry. The performance characteristics, cost structure, and longevity of the drum assembly are inherently determined by the chosen segmentation criteria, providing end-users with tailored solutions for specific surface preparation challenges, ranging from minor floor repair to massive bridge deck hydro-demolition preparation.

- By Cutter Type:

- Tungsten Carbide Cutters

- Steel Cutters

- Milling Cutters (Flails)

- Specialized Cutters (e.g., Starters, Bevels)

- By Drum Width/Size:

- Narrow Width Drums (Below 8 inches)

- Medium Width Drums (8 to 16 inches)

- Large Width Drums (Above 16 inches)

- By Application:

- Roadway and Highway Rehabilitation

- Bridge Deck Preparation

- Airport Runway Maintenance

- Industrial and Commercial Floor Preparation

- Parking Lot and Surface Demarcation Removal

- By End-Use Industry:

- Construction and Engineering Contractors

- Rental Companies

- Government and Public Works Departments

Value Chain Analysis For Scarifier Drums Market

The value chain for the Scarifier Drums Market initiates with upstream activities centered on the procurement and processing of raw materials, predominantly high-grade specialty steel alloys for the drum body and specialized tungsten carbide or hardened tool steel for the cutters. Suppliers of these materials operate in a global market, and efficiency in sourcing dictates initial manufacturing costs and final product quality. Critical upstream considerations involve metallurgical expertise to ensure component longevity under extreme operational stress, as the performance of the drum hinges entirely on the resistance of its components to abrasion and impact. Manufacturer reputation is often built on proprietary heat treatment processes and component manufacturing precision, ensuring seamless fit and optimal cutter rotation dynamics.

The midstream phase involves the core manufacturing process, encompassing precision machining of the drum cylinder, assembly of the cutter shafts, and the complex process of affixing or housing the cutters and spacers. Key activities here include quality control for balance and alignment, which are crucial for minimizing vibration and maximizing the efficiency and safety of the scarifying machine. This phase also includes branding, packaging, and securing necessary certifications. Research and development activities, focusing on improved cutter configuration (e.g., maximizing coverage area or developing specialized depth control mechanisms), are integrated into this stage to maintain competitive product offerings.

Downstream activities involve the distribution channel, which spans direct sales to major rental fleets and large contractors, or indirect sales through regional specialized equipment distributors and authorized dealers. The efficacy of the distribution network, including logistics for handling heavy and often specialized shipments, determines market reach. Post-sales service and support, including technical training, provision of replacement cutter kits, and maintenance guidance, are crucial value-added services. The final stage involves the end-user application (construction companies, public works), where the drum's performance is utilized, and usage data feeds back into the value chain for product iteration and improvement. Direct channels often serve major governmental contracts, while indirect channels cater efficiently to smaller, geographically dispersed contractors requiring localized support.

Scarifier Drums Market Potential Customers

The primary consumers of scarifier drums are professional entities engaged in surface preparation and material removal across civil infrastructure and commercial construction projects. These customers require robust, reliable tooling that can withstand high-impact, continuous-duty cycles while achieving precise surface profiles. The customer base is highly specialized, necessitating technical expertise in product selection, as the optimal drum and cutter configuration varies dramatically based on the substrate (e.g., brittle concrete versus flexible asphalt) and the depth of removal required. Rental equipment companies form a significant customer segment, continually replenishing their fleet with durable, standardized drum assemblies capable of fitting various machine makes and models to maximize rental utilization rates.

Government agencies and municipalities, often acting through specialized public works departments or partnering with general contractors, are major indirect customers, funding the vast majority of large-scale highway and airport maintenance projects. Their purchasing decisions are heavily influenced by regulatory compliance, projected lifespan, and total cost of ownership rather than just initial purchase price. The increasing global focus on quick-turnaround maintenance, minimizing traffic disruption, further accelerates the demand for high-efficiency tooling capable of rapid deployment and execution. This segment often demands documentation detailing environmental compliance, particularly concerning dust and noise mitigation features integrated into the associated scarifying machines.

The remaining core customer segments include specialized industrial flooring contractors who prepare surfaces for high-performance epoxy, polyurethane, or polished concrete systems, where precise Concrete Surface Profile (CSP) achievement is paramount. Also critical are demolition and refurbishment contractors focused on removing hazardous materials, such as old lead-based paint or asbestos-containing mastics, from large industrial facilities or bridges. These niche applications often require extremely specific cutter types, such as depth-limiting or vacuum-shrouded drum designs, driving innovation toward safety and environmental controls. The ability of manufacturers to provide customized, high-performance tooling for these varied end-use cases is essential for market penetration.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $350.5 Million |

| Market Forecast in 2033 | $518.7 Million |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Roadtec (Astec Industries), Blastrac (Husqvarna Construction), HTC (Husqvarna Construction), EDCO, SASE Company, Diamond Products (Suburban Manufacturing), Kut-Rite Manufacturing, Trelawny Surface Preparation, Contec GmbH, Multi-Quip Inc., Smith Manufacturing, BEFARD, Airtec, Bartell Global, CS Unitec, Superabrasive Inc., Floor Preparation Systems, Tyrolit Construction, SPE International, and Scanmaskin. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Scarifier Drums Market Key Technology Landscape

The technological landscape of the Scarifier Drums Market is characterized by continuous material science innovation and optimization of mechanical design aimed at extending component life and improving removal efficiency. A primary focus is on advanced cutter material composition, where sophisticated metallurgy yields tungsten carbide teeth with enhanced impact resistance and abrasion tolerance. Manufacturers employ techniques like vacuum brazing and proprietary sintering processes to ensure the carbide tips are securely and optimally bonded to the steel shanks, minimizing premature failure under aggressive use. The geometry of these cutters—including their thickness, angle of attack, and spacing—is constantly refined through computational fluid dynamics and finite element analysis (FEA) to maximize material fracture rate while controlling dust generation and minimizing wear on the drum bearings.

Beyond the cutters themselves, the technology extends to the overall drum assembly design. Modern scarifier drums often feature quick-change mechanisms that minimize machine downtime by allowing operators to rapidly swap out cutter configurations or replace worn assemblies without specialized tools. Balancing technology is also critical; high-speed rotation demands precise dynamic balancing of the drum assembly to prevent excessive machine vibration, which can lead to premature wear on the scarifier machine itself and reduced operator comfort and safety. Integration with telemetry systems represents another significant technological advancement, allowing operators and fleet managers to monitor usage metrics, stress levels, and operational hours remotely.

Furthermore, specialized drum technologies are emerging for niche applications, such as passive dust control shrouds integrated directly into the drum housing to improve vacuum efficiency, or hydro-scarifying drums that use high-pressure water jets in conjunction with mechanical flails to reduce concrete spalling and minimize micro-cracking during deep removal. The increasing demand for surface preparation tools that can manage precise depths—down to millimeter accuracy—has spurred the development of spring-tensioned or hydraulically dampened drum systems, ensuring consistent, high-quality results for demanding applications like thin overlay removal or precise texturing for improved road grip.

Regional Highlights

The global Scarifier Drums Market exhibits distinct regional consumption patterns and growth trajectories, heavily correlated with local infrastructure spending habits and regulatory environments.

- North America (United States and Canada): This region constitutes a mature market segment, characterized by high adoption rates of advanced machinery and a substantial focus on equipment rental fleets. The demand is primarily driven by the consistent need for repair and restoration of extensive highway and bridge networks, many of which are reaching the end of their engineered lifespan. Labor costs are high, necessitating the deployment of high-efficiency, wide-drum scarifiers to maximize productivity. The US market emphasizes stringent specifications for surface preparation, particularly for Department of Transportation (DOT) projects, sustaining high demand for premium Tungsten Carbide cutter drums. Regulatory mandates around silica dust control also push technological investment in integrated vacuum systems and environmentally compliant tooling.

- Europe (Germany, UK, France, Scandinavia): Europe is another dominant market, showing strong demand driven by continuous upkeep of historical city centers and trans-European transport networks. Germany and the UK lead in technological adoption, often prioritizing environmentally friendly and quiet operating equipment suitable for dense urban environments. The focus here is balanced between standard road rehabilitation and highly specialized industrial floor preparation, where precision and minimal vibration are crucial. Scandinavia showcases a strong preference for durable, long-life components due to extreme weather conditions, driving manufacturers to offer robust, highly engineered drum assemblies suitable for icy or snow-damaged pavements.

- Asia Pacific (APAC) (China, India, Japan, Southeast Asia): APAC is anticipated to be the fastest-growing region, fueled by massive, ongoing urbanization and infrastructure development projects. China and India are undertaking unprecedented expansion of road, rail, and airport infrastructure, leading to explosive demand for construction machinery and, consequently, scarifier drums. While the market initially favors cost-effective steel cutter drums, the rapid increase in project quality standards, particularly in economies like Japan and South Korea, is driving a transition towards higher-performance Tungsten Carbide variants. The sheer scale of construction activity ensures long-term volume demand, despite potential price sensitivity challenges from local manufacturers.

- Latin America (Brazil, Mexico, Argentina): This region is characterized by volatile but potentially high demand, linked closely to fluctuating governmental infrastructure budgets and commodity prices. Market growth is sporadic but significant in key industrial centers. Demand often focuses on medium-duty applications and pavement repairs rather than large-scale new construction, utilizing a mix of medium and narrow width drums. Supply chain stability and the reliance on imported premium equipment remain key challenges, often making local sourcing of consumables preferred when available.

- Middle East and Africa (MEA): Growth in MEA is concentrated in the Gulf Cooperation Council (GCC) countries, driven by mega-infrastructure projects, particularly in Saudi Arabia and the UAE (e.g., airport expansion, smart city construction). The extreme heat and challenging material properties (often high-density concrete and specific aggregates) necessitate specialized, durable equipment, creating a niche demand for high-heat-resistant drum materials and robust designs. Africa represents a nascent market, with potential growth tied directly to foreign investment in mining and resource extraction infrastructure development, driving demand for heavy-duty, reliable surface preparation equipment.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Scarifier Drums Market.- Roadtec (Astec Industries)

- Blastrac (Husqvarna Construction)

- HTC (Husqvarna Construction)

- EDCO

- SASE Company

- Diamond Products (Suburban Manufacturing)

- Kut-Rite Manufacturing

- Trelawny Surface Preparation

- Contec GmbH

- Multi-Quip Inc.

- Smith Manufacturing

- BEFARD

- Airtec

- Bartell Global

- CS Unitec

- Superabrasive Inc.

- Floor Preparation Systems

- Tyrolit Construction

- SPE International

- Scanmaskin

Frequently Asked Questions

Analyze common user questions about the Scarifier Drums market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between scarifier drums utilizing steel cutters and those using tungsten carbide cutters?

The key differentiator lies in material longevity and application suitability. Tungsten carbide cutters are significantly more durable, offering extended lifespan and superior efficiency when removing hard materials like high-strength concrete, thick epoxy, or asphalt. Steel cutters, while cheaper upfront, are typically suitable only for lighter removal tasks, softer materials, or cleaning operations, and require much more frequent replacement due to rapid wear.

How does the choice of scarifier drum width impact project efficiency and cost?

Drum width directly affects productivity and maneuverability. Wider drums (e.g., 16 inches+) cover more surface area per pass, significantly reducing project time and labor costs for large, open areas like highways or airport runways. Narrower drums (e.g., below 8 inches) are essential for detailed work, edge preparation, confined spaces, and intricate pattern removal, prioritizing precision and accessibility over high volume removal speed.

Which application segment drives the highest demand for specialized scarifier drums globally?

The highest specialized demand is consistently driven by the Roadway and Highway Rehabilitation segment. This segment requires high-performance drums for crucial tasks such as removal of deteriorating pavement layers, hydro-demolition preparation on bridge decks, and achieving precise surface profiles (texturing) necessary to meet strict governmental friction and safety standards.

What technological advancements are currently reducing the downtime associated with scarifier drum maintenance?

Technological advancements focus on quick-change drum assemblies and modular cutter systems. Manufacturers now offer precision-engineered drum cartridges that can be rapidly swapped out (often tool-free) by field personnel. This minimizes the machine’s operational downtime, allowing contractors to quickly switch cutter types or replace heavily worn components, thereby maximizing fleet utilization and project throughput.

How is environmental regulation influencing the design and adoption of new scarifier drums?

Environmental regulations, particularly those concerning airborne crystalline silica dust, mandate better dust capture at the source. This is influencing drum design toward integrated vacuum ports, specialized shrouds, and cutter configurations that minimize particle dispersion. The focus is shifting towards cleaner, safer operations, increasing the market demand for premium drums optimized for high-efficiency vacuum attachment and compliance with worker safety standards.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager