Schlieren Imaging System Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 432979 | Date : Dec, 2025 | Pages : 253 | Region : Global | Publisher : MRU

Schlieren Imaging System Market Size

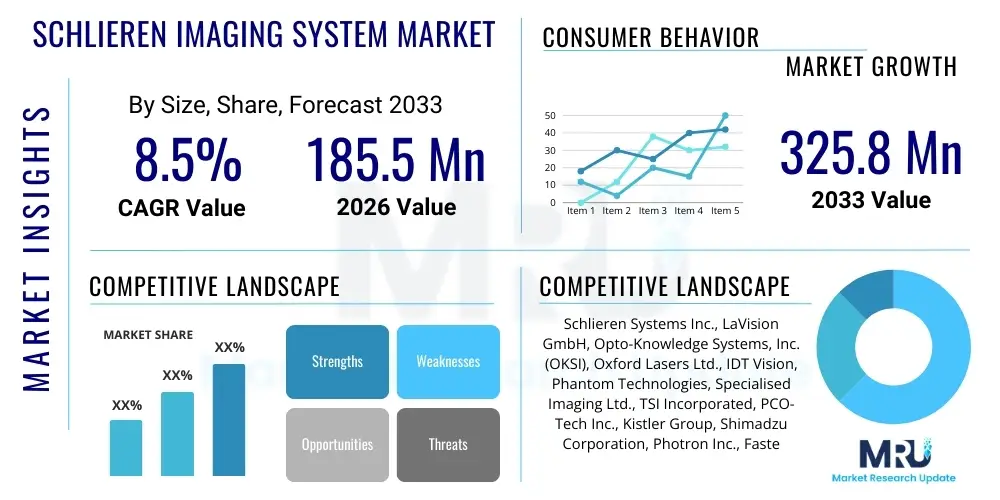

The Schlieren Imaging System Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.5% between 2026 and 2033. The market is estimated at USD 185.5 Million in 2026 and is projected to reach USD 325.8 Million by the end of the forecast period in 2033.

Schlieren Imaging System Market introduction

The Schlieren imaging system market encompasses advanced optical diagnostic tools designed to visualize density gradients within transparent media, such as gases and liquids. This non-intrusive technique operates based on the principle that variations in the refractive index, caused by density changes (e.g., due to temperature, pressure, or concentration fluctuations), deflect light rays. By using specialized optical configurations, including point sources, lenses, mirrors, and knife-edges, these systems convert these light deflections into intensity variations that are captured by high-speed cameras or detectors, thereby providing a clear visual representation of flow phenomena, heat transfer, and wave propagation.

Major applications of Schlieren imaging span crucial sectors like aerospace engineering, where it is vital for studying shock waves, supersonic flows, and combustion processes in jet engines and rocket propulsion systems. In biomedical research, it is utilized for visualizing fluid dynamics and mass transfer, particularly in microfluidic devices and drug delivery studies. Furthermore, the automotive industry employs these systems to optimize internal combustion engine performance and analyze air flow dynamics around vehicles. The inherent benefits of Schlieren systems, such as high spatial resolution, non-invasiveness, and the ability to capture transient phenomena, firmly establish their importance in experimental fluid mechanics and thermal science.

Key driving factors propelling market expansion include the escalating demand for high-fidelity flow visualization tools in research and development institutions globally, particularly those focusing on clean energy technologies, hypersonic flight, and advanced materials processing. The continuous technological refinement of components, such as high-speed cameras and integrated optics that facilitate portable and digital Schlieren setups, further enhances accessibility and applicability across diverse industrial and academic settings. As regulatory requirements push for greater efficiency and safety in thermal and mechanical systems, the role of detailed flow analysis provided by Schlieren technology becomes increasingly indispensable.

Schlieren Imaging System Market Executive Summary

The Schlieren Imaging System Market is experiencing robust growth driven by increasing investments in fundamental research across aerospace, automotive, and energy sectors, coupled with the miniaturization and digitization of imaging components. Business trends indicate a strong move toward turn-key, easy-to-integrate digital Schlieren systems that offer real-time visualization and quantitative data analysis capabilities, shifting away from complex, traditional optical benches. Key vendors are focusing on developing high-frame-rate systems optimized for transient flow analysis, leveraging advanced machine vision components and proprietary software algorithms for enhanced image processing and noise reduction, leading to elevated product reliability and performance metrics.

Regional trends highlight North America and Europe as dominant markets, primarily due to the substantial presence of major aerospace and defense contractors, alongside well-funded academic research labs specializing in fluid dynamics and combustion science. However, the Asia Pacific region, particularly China and India, is emerging as the fastest-growing market, propelled by rapid industrialization, burgeoning automotive manufacturing hubs, and significant government expenditure directed toward establishing high-tech research infrastructure focused on sustainable energy and high-speed rail transportation. Strategic partnerships between Western technology providers and Asian research institutions are accelerating technology adoption in APAC.

Segmentation trends reveal that the Digital Schlieren Systems segment, utilizing CCD/CMOS sensors, dominates the market due to superior image quality, immediate data processing, and integration with modern computing environments, overshadowing the traditional Analog systems. Based on application, the Aerodynamics and Combustion Research segments retain the largest market share, essential for optimizing thermal efficiency and reducing emissions. Within the end-user landscape, Academic and Research Institutions represent the core consumer base, although industrial adoption is rapidly accelerating, specifically within quality control and R&D divisions of large manufacturing entities focused on thermal management solutions.

AI Impact Analysis on Schlieren Imaging System Market

Users frequently inquire about how Artificial Intelligence (AI), specifically machine learning and computer vision algorithms, is transforming the traditionally complex and operator-dependent nature of Schlieren imaging. Common questions revolve around AI’s ability to automate image analysis, enhance signal-to-noise ratios (SNR) in complex flow fields, and accelerate the transition from qualitative visualization to quantitative data extraction. Users are keen to understand if AI can effectively classify turbulent structures, predict flow instability, or optimize experimental parameters without extensive human intervention. The prevailing sentiment is that AI represents a pivotal technological shift, promising to unlock deeper insights from the vast amounts of visual data generated by high-speed Schlieren systems, thereby reducing experimental time and minimizing human error in interpretation.

The integration of AI algorithms is fundamentally changing the functional scope of Schlieren systems, moving them beyond simple visualization tools toward advanced diagnostic platforms. Machine learning models, trained on large datasets of flow patterns, are increasingly used for automated feature recognition, allowing systems to instantly identify and quantify specific phenomena like shock wave locations, boundary layer separation points, or flame front speeds. This automation significantly reduces the post-processing burden on researchers and provides real-time quantitative metrics that were previously inaccessible or required painstaking manual analysis. Furthermore, Deep Learning techniques are being employed for image reconstruction and enhancement, mitigating optical aberrations and improving the clarity of visualizations taken in challenging environments, such as high-temperature or optically dense fields.

The expectation among researchers and industrial users is that AI integration will democratize access to sophisticated flow analysis, enabling engineers without specialized optical physics expertise to leverage the power of Schlieren technology effectively. This transition is fostering a new generation of smart Schlieren systems capable of predictive modeling—where observed flow data is fed back into computational fluid dynamics (CFD) models in real time to refine simulations—creating a powerful feedback loop essential for iterative design optimization in aerospace and automotive applications. This synergy between physical experimentation and digital intelligence is the key driver of future value in the market.

- AI enhances automated feature recognition, classifying shock waves and turbulent structures instantly.

- Machine learning optimizes real-time image processing, improving Signal-to-Noise Ratio (SNR) in high-speed captures.

- Deep learning models facilitate quantitative data extraction (e.g., temperature and density profiles) from visualization data.

- AI enables predictive analysis by integrating experimental flow data directly into Computational Fluid Dynamics (CFD) models.

- Automation reduces reliance on highly specialized optical expertise, lowering the operational barrier for new users.

DRO & Impact Forces Of Schlieren Imaging System Market

The dynamics of the Schlieren Imaging System market are governed by a robust interplay of Drivers (D), Restraints (R), and Opportunities (O), which collectively define the Impact Forces shaping its trajectory. Key drivers include the escalating global investment in aerospace and defense sectors, particularly in hypersonic research and next-generation propulsion systems, necessitating precise visualization of high-speed airflows and combustion phenomena. Simultaneously, the restraints revolve primarily around the high initial cost of advanced optical setups and the necessity for highly trained personnel to operate, align, and interpret the intricate data produced by these sensitive systems, limiting adoption in budget-constrained settings or smaller industrial R&D departments.

Opportunities are significant, stemming from the technological convergence of optics, high-speed digital sensing, and advanced computing, leading to the development of compact, portable, and user-friendly digital Schlieren systems. The burgeoning field of microfluidics and biomedical engineering also presents a fertile ground for application expansion, utilizing Schlieren for non-invasive analysis of mass transport and mixing within biological samples and microchannels. The impact forces are characterized by moderate technological disruption driven by sensor advancements and strong economic influence derived from mandated efficiency improvements across energy and transport industries globally, pushing organizations to adopt superior diagnostic tools for compliance and optimization.

The primary impact force remains the relentless pursuit of energy efficiency and safety in complex thermal-fluid systems. Industries such as gas turbine manufacturing and nuclear energy require unparalleled accuracy in understanding heat transfer and fluid instabilities, solidifying the continuous demand for high-performance Schlieren systems. Furthermore, the global push toward sustainable aviation fuels and cleaner combustion processes mandates the use of advanced visualization techniques to optimize burn efficiency and minimize pollutant formation, securing the market's long-term growth potential against the backdrop of capital investment hesitancy.

Segmentation Analysis

The Schlieren Imaging System Market is highly specialized and segmented based on technology, component type, application, and end-user, allowing for a detailed analysis of specific demand centers. The segmentation based on technology is critical, distinguishing between classical Z-type and focused-lens systems, though the primary division now lies between Analog and Digital systems, with digital platforms rapidly dominating due to their integration capabilities and superior data processing throughput. Analyzing these segments reveals varying growth rates, where digital solutions exhibit aggressive expansion due funded research programs and industrial demands for quantifiable, real-time results.

The component segmentation highlights the importance of proprietary optical elements, specialized light sources (like pulsed LEDs or lasers for high-speed synchronization), and the high-performance cameras which often dictate the system's overall cost and operational capability. The application segment provides insight into consumption patterns, with Aerodynamics and Combustion consistently leading due to the fundamental role Schlieren imaging plays in shockwave studies, flow transition analysis, and flame optimization. Identifying the key customer segments, namely Aerospace/Defense and Academic Research, allows vendors to tailor their product offerings, focusing either on rugged, reliable industrial systems or highly versatile, customizable research setups.

- Technology Type:

- Digital Schlieren Systems (Dominant Segment)

- Analog Schlieren Systems (Traditional/Legacy)

- Optical Configuration:

- Z-Type (Two Mirror Configuration)

- Telescopic/Focused Schlieren Systems

- Background Oriented Schlieren (BOS)

- Component:

- Light Sources (High-speed LED, Laser, Flash Lamps)

- Optics (Mirrors, Lenses, Knife Edges)

- Detectors/Cameras (High-speed CCD/CMOS Cameras)

- Software and Data Acquisition Units

- Application:

- Aerodynamics and Fluid Dynamics Research

- Combustion and Heat Transfer Studies

- Shockwave and Ballistics Analysis

- Microfluidics and Biomedical Imaging

- Non-Destructive Testing (NDT)

- End-User:

- Academic and Research Institutions

- Aerospace and Defense Industry

- Automotive Industry

- Chemical and Process Industry

- Energy and Power Generation

Value Chain Analysis For Schlieren Imaging System Market

The value chain for the Schlieren Imaging System market commences with upstream activities centered around the meticulous sourcing and manufacturing of high-precision optical components and specialized sensor technology. Upstream suppliers are typically highly specialized firms providing custom high-speed cameras, diffraction-limited mirrors, large-aperture lenses, and proprietary light sources. Quality control and precision engineering at this stage are paramount, as the performance of the entire imaging system hinges on the flawless integration and calibration of these core components. Relationships with these niche component suppliers are strategic, often involving long-term supply contracts and co-development initiatives to ensure components meet the rigorous standards required for scientific measurement and visualization.

The midstream phase involves the core manufacturers who design, assemble, calibrate, and integrate the proprietary Schlieren configurations (Z-type, focused systems, etc.) with advanced data acquisition hardware and sophisticated image processing software. This stage adds significant value through intellectual property related to system architecture, alignment procedures, and specialized software algorithms for quantitative analysis. Distribution channels are typically a mix of direct sales to large governmental research facilities and academic institutions, and indirect channels relying on specialized regional distributors or system integrators who can provide localized installation, maintenance, and expert application support to the end-users.

The downstream segment is dominated by installation, user training, and post-sale technical support, which is critical given the complexity of the equipment. Direct distribution is favored when addressing high-profile aerospace and defense clients, ensuring security and direct expert intervention. Indirect channels are crucial for penetrating decentralized academic markets and international territories where local expertise is necessary for market acceptance. The value realization is maximized when the system delivers reliable, high-fidelity quantitative data, enabling breakthroughs in areas like combustion optimization or hypersonic flow control, justifying the high capital expenditure for the end-user.

Schlieren Imaging System Market Potential Customers

Potential customers for Schlieren Imaging Systems are heavily concentrated within high-technology sectors requiring non-contact visualization and analysis of density gradients, primarily driven by R&D requirements rather than mass production needs. The quintessential buyers are senior researchers, principal investigators, and engineering teams operating in government-funded national laboratories, such as NASA, the European Space Agency (ESA), and national defense research organizations, who rely on these systems for fundamental studies in fluid dynamics, propulsion, and materials testing under extreme conditions. Their purchasing decisions are often based on system capabilities, measurement precision, and the ability to integrate with existing high-speed testing infrastructure, rather than solely on cost.

Beyond governmental and academic entities, the industrial end-user base encompasses major original equipment manufacturers (OEMs) in aerospace, particularly those involved in developing jet engines, rockets, and supersonic aircraft (e.g., General Electric Aviation, Rolls-Royce). The automotive sector, especially performance and race car engineering teams, utilizes Schlieren systems for detailed analysis of air intake, exhaust flows, and thermal management within high-efficiency engines. Furthermore, companies involved in gas turbine production and high-power energy generation are critical customers, requiring visualization tools to optimize fuel mixing and ensure operational safety and efficiency.

An emerging customer segment includes biomedical and pharmaceutical researchers leveraging microfluidic platforms. These users require systems capable of visualizing subtle concentration gradients and mixing dynamics in small volumes, facilitating drug screening, cellular analysis, and diagnostics development. The trend toward non-destructive testing (NDT) using advanced optical methods also attracts buyers in the materials science sector, looking to visualize internal structural defects or thermal stress distribution without physically altering the sample under examination. These diverse applications underscore the wide, though specialized, appeal of Schlieren technology across multiple innovative domains.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 185.5 Million |

| Market Forecast in 2033 | USD 325.8 Million |

| Growth Rate | 8.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Schlieren Systems Inc., LaVision GmbH, Opto-Knowledge Systems, Inc. (OKSI), Oxford Lasers Ltd., IDT Vision, Phantom Technologies, Specialised Imaging Ltd., TSI Incorporated, PCO-Tech Inc., Kistler Group, Shimadzu Corporation, Photron Inc., Fastec Imaging, Vision Research (Ametek), Integrated Design Tools (IDT), Cordin Company, Hamamatsu Photonics K.K., Edmund Optics, MKS Instruments, Inc., and Spectronix. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Schlieren Imaging System Market Key Technology Landscape

The contemporary Schlieren Imaging System market is defined by several core technological advancements that enhance both the accessibility and precision of flow visualization. Fundamentally, the transition from traditional photographic film techniques to fully digital systems utilizing high-resolution, high-frame-rate CMOS and CCD cameras represents the most impactful shift. These advanced digital sensors allow for the capture of highly transient phenomena, such as turbulent eddies and shockwave formation, with microsecond precision, which is essential for modern aerospace and propulsion research. Furthermore, the development of sophisticated image processing software, often incorporating quantitative tools, has transformed the output from qualitative images into actionable, numerically verified data (e.g., density field reconstruction via algorithms like Tomographic Schlieren).

Another pivotal technological development involves the light source architecture. Traditional arc lamps are increasingly being replaced by ultra-bright, pulsed Light Emitting Diodes (LEDs) or Nd:YAG lasers. Pulsed LEDs offer highly stable, repeatable illumination necessary for synchronization with high-speed cameras, drastically improving temporal resolution and image sharpness in fast-moving flows. Laser sources, especially when integrated into Background-Oriented Schlieren (BOS) or focused systems, provide coherent light required for visualizing minute density gradients over large test sections, improving the system’s sensitivity. The continued refinement of these light sources addresses the long-standing challenge of achieving high illumination intensity without compromising pulse duration or spatial uniformity.

Finally, the growing adoption of modular and flexible optical configurations is changing system design. Modern Schlieren systems are moving away from fixed, complex optical tables toward smaller, ruggedized, and often portable Z-type or focused configurations. This design evolution, coupled with automated alignment mechanisms driven by stepper motors and integrated control software, significantly reduces setup time and the expertise required for operation. Moreover, the integration of advanced optics, including large-aperture, low-aberration mirrors and specialized knife-edge techniques (like color-filter Schlieren or speckle imaging), continues to push the boundaries of spatial resolution and contrast, making complex flow structures more visible and quantifiable than ever before.

Regional Highlights

- North America: This region holds a dominant market share, primarily due to immense government and private sector investment in aerospace, defense, and fundamental fluid dynamics research. Key drivers include projects related to hypersonic flight technology (DARPA/NASA) and advanced combustion research conducted by major university consortia. The presence of numerous key players, robust R&D infrastructure, and high expenditure capacity solidify its leading position. The demand here is centered on high-fidelity, high-speed, and custom-engineered Schlieren systems.

- Europe: Europe represents a mature and technologically advanced market, driven largely by the automotive industry’s rigorous demands for engine efficiency and emissions reduction (e.g., in Germany and France) and extensive pan-European collaborations on aerospace projects (e.g., Airbus, European Space Agency). Academic research institutions are heavily funded, focusing on microfluidics, plasma physics, and renewable energy technologies. The region exhibits high adoption rates of advanced digital and quantitative Schlieren techniques.

- Asia Pacific (APAC): APAC is projected to be the fastest-growing regional market over the forecast period. This rapid expansion is fueled by massive infrastructure development, increasing defense budgets (especially in China and India), and the establishment of new, state-of-the-art research centers. Countries in this region are prioritizing indigenous aerospace and high-speed rail development, generating substantial demand for flow visualization tools. Price sensitivity remains a factor, driving demand for localized manufacturing and more cost-effective digital solutions.

- Latin America (LATAM): The LATAM market is relatively smaller but growing steadily, driven mainly by academic research in fluid mechanics and civil engineering, particularly in Brazil and Mexico. Industrial adoption is limited, though increasing in oil & gas exploration and regional aerospace maintenance, repair, and overhaul (MRO) facilities. Growth is dependent on governmental research funding stability and partnerships with international research organizations.

- Middle East and Africa (MEA): Growth in MEA is primarily concentrated in the Gulf Cooperation Council (GCC) countries, focusing on establishing advanced research institutes specializing in thermal management for arid climates and energy sector research (gas turbines, power generation). Defense spending also contributes to demand for ballistics and aerospace testing facilities. Market size remains constrained by the limited number of high-tech manufacturing bases.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Schlieren Imaging System Market.- LaVision GmbH

- Schlieren Systems Inc.

- Opto-Knowledge Systems, Inc. (OKSI)

- Oxford Lasers Ltd.

- Specialised Imaging Ltd.

- TSI Incorporated

- IDT Vision

- Photron Inc.

- Vision Research (Ametek)

- PCO-Tech Inc.

- Kistler Group

- Shimadzu Corporation

- Fastec Imaging

- Integrated Design Tools (IDT)

- Cordin Company

- Hamamatsu Photonics K.K.

- Edmund Optics

- MKS Instruments, Inc.

- Spectronix

- Continuum Electro-Optics, Inc.

Frequently Asked Questions

Analyze common user questions about the Schlieren Imaging System market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the fundamental difference between Schlieren and Shadowgraph techniques?

Schlieren imaging visualizes the first derivative of the refractive index (density gradient) by introducing a knife-edge to block deflected light, providing detailed structure and contrast based on flow direction. Shadowgraph, conversely, visualizes the second derivative of the refractive index (rate of change of the gradient), making it better suited for sharply defining boundaries like shock waves or large eddies, but offering less detail on subtle flow structures.

How is the Schlieren market benefiting from advancements in high-speed camera technology?

High-speed camera advancements (CMOS/CCD sensors) are critical, enabling systems to capture transient, microsecond-scale flow phenomena (like supersonic combustion or turbulent mixing) that were previously impossible to resolve. This capability is essential for generating the quantitative data necessary for validating complex Computational Fluid Dynamics (CFD) models and optimizing advanced fluid systems in real-time.

What are the primary challenges restraining the widespread adoption of Schlieren systems?

The main restraints are the substantial initial investment required for high-quality, large-aperture optics (mirrors/lenses) and the demanding requirement for expert personnel to execute precise optical alignment, calibration, and subsequent data interpretation. This complexity limits adoption in non-specialized industrial settings or small research labs with constrained budgets or limited optical expertise.

Which application segment currently drives the highest demand in the Schlieren Imaging Market?

The Aerodynamics and Fluid Dynamics Research segment, specifically focusing on aerospace applications such as shockwave analysis, wind tunnel testing, and jet propulsion studies, constitutes the largest demand center. This is due to the non-invasive nature and high sensitivity of Schlieren systems, making them indispensable for optimizing high-speed flow performance and safety.

How does Background-Oriented Schlieren (BOS) compare to classical Schlieren methods?

BOS is a less invasive and often more flexible technique that relies on tracking the apparent displacement of a speckled background pattern caused by density gradients in the foreground fluid. Unlike classical Z-type Schlieren, BOS does not require expensive, large-aperture mirrors or precise knife-edge placement, making it ideal for large-scale, field-based experiments, although classical Schlieren generally provides superior spatial resolution for fine structure visualization.

The Schlieren Imaging System Market is undergoing significant transformation, driven by technological breakthroughs in high-speed sensing and the integration of AI for automated analysis. The necessity for precise, non-intrusive visualization in critical sectors such as aerospace and energy ensures sustained demand. North America maintains its leadership due to robust defense and R&D spending, while the Asia Pacific region emerges as a crucial growth engine. Vendors are increasingly focusing on delivering turnkey digital solutions that minimize complexity and maximize quantitative output, thereby broadening the market's appeal beyond specialized academic circles and into mainstream industrial quality control and optimization processes. Continued advancements in light sources and optical component manufacturing promise to reduce system footprint and cost, facilitating future market expansion.

In conclusion, the market's future trajectory is strongly correlated with global investment in next-generation transportation systems, clean energy technologies, and fundamental fluid science research. The persistent technical challenges related to system complexity are being systematically addressed through automation and digital integration, reinforcing the Schlieren system’s role as an essential diagnostic tool in advanced engineering and scientific domains. Strategic partnerships and product diversification, especially toward microfluidic and biomedical applications, will be key differentiators for market players seeking long-term revenue growth and competitive advantage in this highly specialized segment of the optical technology landscape.

The core value proposition of Schlieren imaging remains its unique ability to render invisible flow phenomena visible and quantifiable. As computational power increases, facilitating the real-time processing of high-volume image data, the adoption cycle for sophisticated Schlieren systems is expected to accelerate. This shift means that the market is moving from simply providing visualization equipment to offering comprehensive diagnostic platforms that merge physical experimentation with sophisticated data analytics, securing its relevance in the future of advanced thermal and fluid engineering research worldwide. Market players must prioritize software innovation and system integration capabilities to capture this evolving demand curve effectively.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager