Scroll Chiller Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439785 | Date : Jan, 2026 | Pages : 258 | Region : Global | Publisher : MRU

Scroll Chiller Market Size

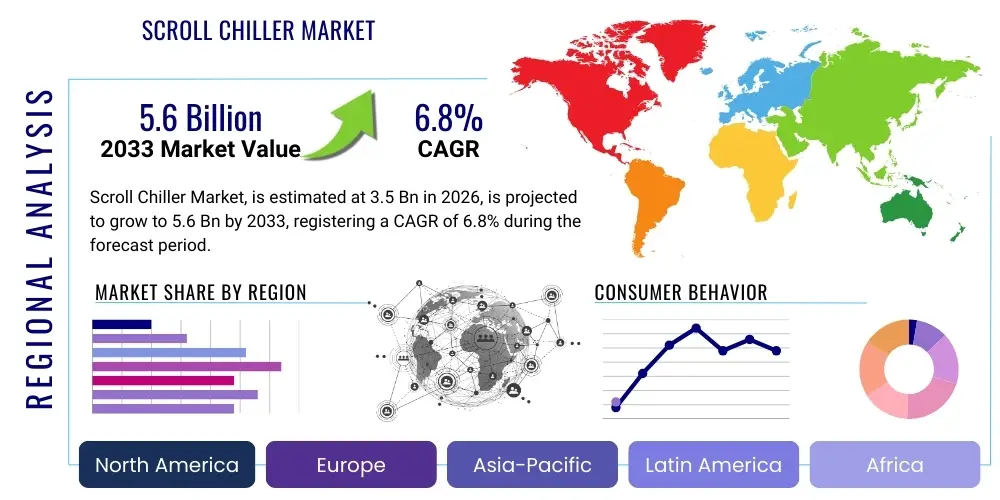

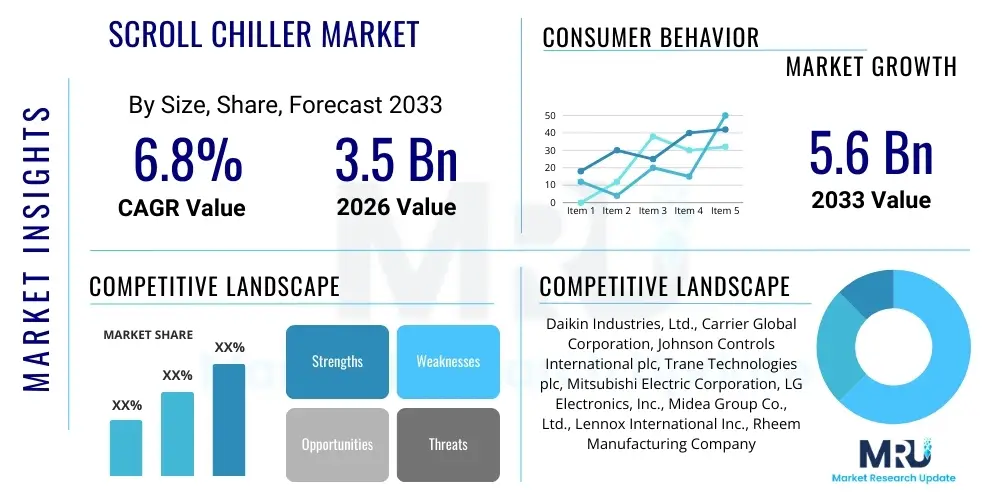

The Scroll Chiller Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 3.5 Billion in 2026 and is projected to reach USD 5.6 Billion by the end of the forecast period in 2033.

Scroll Chiller Market introduction

The global Scroll Chiller Market is characterized by its foundational role in providing efficient and reliable cooling solutions across diverse industrial, commercial, and institutional settings. Scroll chillers are refrigeration systems that utilize scroll compressors to circulate refrigerant, effectively removing heat from a process or space. Their design features, including fewer moving parts compared to reciprocating compressors, contribute to their inherent advantages such as quiet operation, high energy efficiency, and extended operational lifespans, making them a preferred choice for numerous applications requiring precise temperature control.

Key applications for scroll chillers span a wide spectrum, including comfort cooling in commercial buildings like offices, hotels, hospitals, and educational institutions, as well as critical process cooling in industrial environments such as data centers, manufacturing plants, and pharmaceutical facilities. The product's versatility allows for deployment in various capacities, from small-scale cooling needs to large integrated HVAC systems. Benefits derived from their implementation include reduced energy consumption due to their high Coefficient of Performance (COP), lower maintenance requirements, and enhanced reliability, which collectively contribute to a lower total cost of ownership over their operational lifetime.

Driving factors for the market's sustained growth include stringent energy efficiency regulations globally, mandating the adoption of more eco-friendly and energy-saving cooling technologies. The rapid urbanization and expanding construction sector, particularly in emerging economies, are fueling demand for advanced HVAC systems. Furthermore, the increasing need for precise temperature control in sensitive applications, such as data centers and healthcare facilities, is bolstering the adoption of scroll chillers. The continuous technological advancements focused on improving chiller performance, integrating smart controls, and utilizing refrigerants with lower Global Warming Potential (GWP) are also pivotal in propelling market expansion.

Scroll Chiller Market Executive Summary

The Scroll Chiller Market is currently navigating a dynamic landscape shaped by evolving technological innovations, global economic shifts, and increasing environmental consciousness. Business trends indicate a strong emphasis on smart chiller solutions, incorporating IoT capabilities, predictive maintenance analytics, and remote monitoring to optimize performance and reduce operational downtime. Manufacturers are focusing on modular designs that offer greater flexibility in installation and scalability, catering to diverse project requirements from commercial HVAC to specialized industrial cooling. Furthermore, there is a growing consolidation within the market as larger players acquire smaller, niche technology providers to expand their product portfolios and geographical reach, fostering intensified competition and innovation in the segment.

Regional trends reveal varied growth trajectories and market drivers. Asia Pacific, spearheaded by countries like China and India, is emerging as a dominant market due to rapid industrialization, burgeoning commercial construction, and governmental initiatives promoting energy-efficient infrastructure development. North America and Europe, while mature markets, are experiencing growth driven by the retrofitting of aging infrastructure with high-efficiency scroll chillers and stringent environmental regulations pushing for the replacement of less efficient systems. Latin America, the Middle East, and Africa are showing significant potential, spurred by urban development projects and increasing investment in commercial and industrial sectors requiring robust cooling solutions, albeit with unique challenges related to climate and infrastructure development.

Segmentation trends within the scroll chiller market are primarily influenced by capacity, application, and end-user requirements. The market for small to medium-capacity chillers continues to dominate due to their widespread use in commercial buildings and light industrial applications, offering a balance between cost-effectiveness and performance. Larger capacity scroll chillers are seeing increased adoption in large-scale commercial complexes and heavy industrial facilities where cooling demands are substantial and continuous. From an application standpoint, comfort cooling remains a significant segment, but process cooling, particularly in sectors like data centers and pharmaceuticals, is experiencing accelerated growth due to critical environmental control needs. The imperative for energy efficiency and sustainability is also driving the adoption of chillers that utilize natural refrigerants or have lower GWP, influencing product development and market dynamics across all segments.

AI Impact Analysis on Scroll Chiller Market

User questions regarding the impact of AI on the Scroll Chiller Market frequently revolve around how artificial intelligence can enhance energy efficiency, enable predictive maintenance, optimize operational costs, and facilitate smarter system integration. Users are keen to understand the practical applications of AI in real-time performance monitoring, fault detection, and intelligent control of chiller plants. Concerns often touch upon the initial investment costs associated with AI integration, data security and privacy, and the level of technical expertise required to manage such advanced systems. Expectations are high for AI to transform scroll chiller operations from reactive maintenance to proactive management, significantly extending equipment lifespan and reducing overall carbon footprint, thereby making cooling solutions more sustainable and economically viable in the long run.

- AI-driven predictive maintenance schedules reduce unexpected downtime and repair costs by identifying potential component failures before they occur through advanced algorithm analysis of operational data.

- Optimized energy consumption through AI algorithms that learn and adapt to real-time environmental conditions, load demands, and energy prices, fine-tuning chiller operations for maximum efficiency.

- Enhanced fault detection and diagnostics using machine learning models to quickly identify anomalies, pinpoint root causes, and suggest corrective actions, minimizing diagnostic time and maintenance efforts.

- Integration with building management systems (BMS) for comprehensive HVAC optimization, allowing scroll chillers to communicate and coordinate with other building systems for holistic energy management.

- Remote monitoring and control capabilities empowered by AI, enabling facility managers to oversee and adjust chiller performance from anywhere, improving responsiveness and operational flexibility.

- Personalized performance insights and recommendations based on historical data and operational patterns, helping facility managers make informed decisions for system upgrades and adjustments.

- Development of self-optimizing chillers that can autonomously adjust settings to maintain desired environmental conditions while minimizing energy use, leading to greater operational autonomy.

- Improved refrigerant leak detection and management through AI, contributing to environmental protection and compliance with evolving regulatory standards.

DRO & Impact Forces Of Scroll Chiller Market

The Scroll Chiller Market is propelled by several robust drivers, primarily the escalating demand for energy-efficient cooling solutions across commercial and industrial sectors due to rising electricity costs and environmental mandates. The burgeoning construction industry globally, particularly in developing nations, significantly contributes to market expansion as new buildings require advanced HVAC systems. Additionally, the increasing focus on sustainable development and the adoption of green building initiatives are fostering the demand for chillers with lower Global Warming Potential (GWP) refrigerants and higher energy efficiency ratios (EERs) or coefficients of performance (COPs).

However, the market also faces notable restraints. High initial investment costs for advanced scroll chiller systems, especially those with integrated smart technologies, can be a deterrent for small and medium-sized enterprises (SMEs) and projects with budget constraints. The complex regulatory landscape regarding refrigerants and energy efficiency standards, which vary significantly across regions, presents a challenge for manufacturers in standardizing products and distribution. Furthermore, the intense competition from alternative cooling technologies, such as centrifugal and screw chillers, which might be preferred for specific large-scale applications or specialized industrial processes, can limit market penetration for scroll chillers in certain segments.

Opportunities within the scroll chiller market are abundant and promising. The ongoing technological advancements in compressor design, heat exchanger efficiency, and control systems offer significant avenues for product differentiation and market growth. The increasing integration of Internet of Things (IoT) and Artificial Intelligence (AI) into chiller systems presents an opportunity to develop "smart chillers" that provide predictive maintenance, optimized performance, and remote monitoring capabilities, catering to the growing demand for intelligent building solutions. Moreover, the expanding application scope in process cooling for data centers, pharmaceuticals, and food and beverage industries, where precise temperature control is paramount, provides fertile ground for market expansion. The trend towards modular and customizable chiller solutions also opens new markets by allowing greater flexibility and scalability for various project requirements.

Segmentation Analysis

The Scroll Chiller Market is comprehensively segmented across various critical dimensions, providing a granular view of market dynamics and potential growth areas. These segmentations typically include analyses by type (e.g., air-cooled, water-cooled), capacity (e.g., low, medium, high), application (e.g., comfort cooling, process cooling), and end-use industry (e.g., commercial, industrial, residential). Understanding these segments is crucial for stakeholders to tailor their product offerings, marketing strategies, and investment decisions, ensuring they effectively address the diverse needs of different customer bases and market niches. Each segment exhibits unique characteristics driven by specific technological preferences, regulatory frameworks, and economic factors.

- By Type:

- Air-Cooled Scroll Chillers

- Water-Cooled Scroll Chillers

- By Capacity:

- Low Capacity (up to 50 TR)

- Medium Capacity (51 TR to 200 TR)

- High Capacity (above 200 TR)

- By Application:

- Comfort Cooling

- Process Cooling

- Data Centers

- Pharmaceuticals

- Food & Beverages

- Plastics & Rubber

- Metalworking

- Other Industrial Processes

- By End-Use Industry:

- Commercial Buildings

- Offices

- Hospitals & Healthcare

- Hotels & Resorts

- Retail & Supermarkets

- Educational Institutions

- Government Buildings

- Industrial

- Manufacturing

- Chemicals

- Automotive

- Power Generation

- Residential (Multi-family dwellings, large custom homes)

- Data Centers

Value Chain Analysis For Scroll Chiller Market

The value chain for the Scroll Chiller Market begins with upstream activities involving the sourcing and manufacturing of critical components, which include scroll compressors, heat exchangers (evaporators and condensers), expansion valves, fans, pumps, and control systems. Key raw materials such as copper, aluminum, steel, and refrigerants are procured from specialized suppliers. Compressor manufacturers, in particular, play a pivotal role, as the efficiency and reliability of the scroll compressor significantly dictate the overall performance of the chiller unit. Relationships with these upstream suppliers are critical for ensuring quality, cost-effectiveness, and timely delivery of components, directly impacting the final product's competitiveness and market positioning.

Midstream activities primarily encompass the design, assembly, and testing of the scroll chiller units by original equipment manufacturers (OEMs). This stage involves sophisticated engineering processes to integrate various components into a cohesive, high-performance system, adhering to strict quality control and energy efficiency standards. Research and development investments are crucial at this stage to innovate new designs, enhance energy efficiency, incorporate smart technologies, and develop chillers compatible with environmentally friendly refrigerants. The manufacturing processes often involve advanced robotics and automation to ensure precision and scale, optimizing production costs and improving product consistency, which are vital for maintaining market leadership.

Downstream activities focus on the distribution, installation, and after-sales services of scroll chillers. Distribution channels are varied, encompassing direct sales to large industrial clients, partnerships with HVAC contractors, and indirect sales through a network of distributors and dealers. Direct sales allow for closer client relationships and customization, while indirect channels provide broader market reach and local presence. Post-purchase services, including installation, commissioning, maintenance contracts, repairs, and spare parts supply, form a significant part of the value proposition. The effectiveness of these services is crucial for customer satisfaction, brand loyalty, and securing recurring revenue streams. A robust service network ensures optimal chiller performance throughout its lifecycle and minimizes operational disruptions for end-users, enhancing the overall value derived from the product.

Scroll Chiller Market Potential Customers

Potential customers for scroll chillers represent a broad and diverse spectrum of end-users, each with unique cooling requirements and operational priorities. The largest segment comprises commercial building operators and developers, including owners of office complexes, shopping malls, hotels, hospitals, educational institutions, and government facilities. These customers primarily seek efficient and reliable cooling for occupant comfort, often prioritizing energy savings, quiet operation, and system longevity. Facility managers within these entities are keen on solutions that integrate seamlessly with existing Building Management Systems (BMS) and offer ease of maintenance and remote monitoring capabilities.

Another significant customer base is found within the industrial sector, encompassing a wide array of specialized applications. This includes data centers, which require precise and continuous cooling to prevent server overheating and ensure operational continuity; pharmaceutical and biotechnology companies needing stable temperatures for process control and product storage; food and beverage manufacturers demanding consistent cooling for production lines and cold storage; and various manufacturing facilities (e.g., plastics, metalworking) where process equipment generates significant heat. For industrial clients, the critical factors often include reliability, precise temperature control, adaptability to specific process demands, and robust construction to withstand demanding operational environments. They often seek chillers that can handle varying loads and provide redundancy for critical processes.

Beyond these primary segments, other potential customers include owners of large residential properties or multi-family dwellings seeking centralized cooling solutions that offer efficiency and reliability. Additionally, original equipment manufacturers (OEMs) who integrate chillers into their own products, such as specialized machinery or medical equipment, also represent a crucial customer segment. Consulting engineers and HVAC system designers play an influential role in the purchasing decisions of these end-users, often specifying scroll chiller brands and models based on performance, energy efficiency, and cost-effectiveness. The increasing global focus on sustainability also means that customers are increasingly prioritizing chillers that utilize environmentally friendly refrigerants and offer higher levels of energy efficiency, aligning with their corporate social responsibility initiatives and compliance with environmental regulations.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 3.5 Billion |

| Market Forecast in 2033 | USD 5.6 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Daikin Industries, Ltd., Carrier Global Corporation, Johnson Controls International plc, Trane Technologies plc, Mitsubishi Electric Corporation, LG Electronics, Inc., Midea Group Co., Ltd., Lennox International Inc., Rheem Manufacturing Company, York (Johnson Controls), Dunham-Bush, Inc., Blue Star Limited, Kirloskar Chillers Private Limited, Climaveneta S.p.A. (Mitsubishi Electric), Smardt Chiller Group Inc., McQuay International (Daikin), Toshiba Carrier Corporation, GEA Group AG, Euroklimat S.r.l., Panasonic Corporation |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Scroll Chiller Market Key Technology Landscape

The Scroll Chiller Market's technological landscape is continuously evolving, driven by innovation aimed at enhancing energy efficiency, improving operational intelligence, and minimizing environmental impact. A primary area of focus is on advanced scroll compressor technology, including variable speed drives (VSD) or inverter technology. VSDs allow compressors to operate at varying speeds, precisely matching cooling loads and significantly reducing energy consumption during partial load conditions, which constitute a majority of operational hours. This contrasts sharply with traditional fixed-speed compressors that cycle on and off, leading to less efficient operation and greater wear and tear. Further advancements include tandem and trio compressor configurations, offering increased capacity modulation and redundancy, thereby improving system reliability and flexibility for diverse applications.

Another critical technological development involves intelligent control systems and Building Management System (BMS) integration. Modern scroll chillers are equipped with sophisticated microprocessors and algorithms that optimize refrigerant flow, fan speed, and water flow based on real-time operational data, weather conditions, and predicted load requirements. The integration of IoT sensors and cloud-based platforms enables remote monitoring, predictive maintenance, and data analytics, allowing facility managers to gain deep insights into chiller performance. These smart controls facilitate proactive fault detection, energy benchmarking, and automated adjustments, moving away from reactive maintenance towards a more efficient, preventative operational model. Such systems are crucial for achieving peak performance and extending the operational lifespan of the equipment, reducing overall lifecycle costs.

Furthermore, the industry is witnessing significant advancements in heat exchanger design and refrigerant technologies. Microchannel coils and plate heat exchangers are increasingly being adopted due to their higher heat transfer efficiency and compact footprints, contributing to more efficient and smaller chiller units. There is also a strong push towards the adoption of refrigerants with lower Global Warming Potential (GWP) to comply with stringent environmental regulations and contribute to climate change mitigation. This includes the development and use of hydrofluoroolefins (HFOs) and natural refrigerants like R290 (propane) and CO2 (R744) in specialized scroll chiller designs. These innovations not only improve the environmental profile of scroll chillers but also often contribute to enhanced energy efficiency, aligning with global sustainability goals. The combination of these technological strides ensures that scroll chillers remain competitive and relevant in the evolving HVAC and process cooling markets, addressing both performance and environmental considerations.

Regional Highlights

- North America: A mature market characterized by a strong emphasis on energy efficiency and smart building technologies. Growth is driven by the replacement of aging infrastructure with high-efficiency chillers and the expansion of data centers. Stringent energy codes and environmental regulations, particularly in the U.S. and Canada, propel the adoption of advanced scroll chiller solutions.

- Europe: Dominated by regulations focusing on sustainability and F-gas phase-downs, driving demand for chillers using low-GWP refrigerants and high energy efficiency. Germany, the UK, and France are key markets, showing robust growth in commercial HVAC and industrial process cooling sectors, often preferring modular and environmentally conscious designs.

- Asia Pacific (APAC): The fastest-growing market, fueled by rapid urbanization, industrialization, and massive construction activities in countries like China, India, and Southeast Asian nations. Increased investment in commercial infrastructure, data centers, and manufacturing plants contributes significantly to market expansion, with a rising demand for cost-effective and energy-efficient cooling solutions.

- Latin America: Experiencing steady growth driven by expanding commercial and residential construction projects and increasing foreign investments in industrial sectors. Brazil and Mexico are leading markets, with a growing awareness of energy efficiency and the need for reliable cooling systems in diverse climatic conditions.

- Middle East and Africa (MEA): Marked by significant construction booms, particularly in the GCC countries (e.g., UAE, Saudi Arabia) and South Africa. High ambient temperatures necessitate robust and efficient cooling solutions, driving demand for scroll chillers in commercial, hospitality, and infrastructure development projects. Investment in energy-efficient solutions is also growing due to sustainability initiatives.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Scroll Chiller Market.- Daikin Industries, Ltd.

- Carrier Global Corporation

- Johnson Controls International plc

- Trane Technologies plc

- Mitsubishi Electric Corporation

- LG Electronics, Inc.

- Midea Group Co., Ltd.

- Lennox International Inc.

- Rheem Manufacturing Company

- York (Johnson Controls)

- Dunham-Bush, Inc.

- Blue Star Limited

- Kirloskar Chillers Private Limited

- Climaveneta S.p.A. (Mitsubishi Electric)

- Smardt Chiller Group Inc.

- McQuay International (Daikin)

- Toshiba Carrier Corporation

- GEA Group AG

- Euroklimat S.r.l.

- Panasonic Corporation

Frequently Asked Questions

What are the primary advantages of scroll chillers over other chiller types for commercial applications?

Scroll chillers offer distinct advantages for commercial applications due to their exceptional energy efficiency, particularly at partial loads, which results in significant operational cost savings. Their design, featuring fewer moving parts compared to reciprocating compressors, leads to quieter operation and enhanced reliability, crucial for environments such as offices, hospitals, and hotels where noise levels and uptime are critical. Additionally, scroll chillers typically have a compact footprint, making them easier to install in spaces with limited room, and their modularity allows for flexible capacity expansion, providing scalability as cooling demands evolve. These benefits collectively contribute to a lower total cost of ownership and a more comfortable indoor environment.

How do energy efficiency regulations impact the global Scroll Chiller Market, and what is the role of refrigerants?

Energy efficiency regulations globally significantly influence the Scroll Chiller Market by mandating higher performance standards (e.g., SEER, EER, COP) for new installations and replacements, thereby driving manufacturers to innovate and develop more efficient products. These regulations, such as those from the EPA, EU F-Gas Regulation, and various national building codes, aim to reduce energy consumption and greenhouse gas emissions. Simultaneously, regulations governing refrigerants, particularly the phase-down of high Global Warming Potential (GWP) hydrofluorocarbons (HFCs), compel the industry to adopt lower GWP alternatives like hydrofluoroolefins (HFOs) or natural refrigerants. This dual regulatory pressure accelerates technological advancements, pushing the market towards more sustainable and environmentally friendly scroll chiller solutions, ultimately benefiting end-users through lower operational costs and reduced environmental footprint.

What role does smart technology and IoT play in the evolution of scroll chillers?

Smart technology and the Internet of Things (IoT) are transforming scroll chillers from standalone units into integral components of intelligent building ecosystems. IoT integration enables real-time monitoring of chiller performance parameters, such as temperature, pressure, and energy consumption, from anywhere via cloud platforms. This data, when analyzed by AI algorithms, facilitates predictive maintenance, identifying potential faults before they lead to breakdowns, thereby minimizing downtime and costly emergency repairs. Furthermore, smart controls allow for dynamic optimization of chiller operation based on occupancy, weather forecasts, and electricity prices, leading to significant energy savings. This integration enhances operational efficiency, prolongs equipment lifespan, and provides facility managers with unprecedented control and insight into their cooling infrastructure, paving the way for more autonomous and sustainable building management.

What are the key drivers for the adoption of scroll chillers in data centers, and what specific features are sought after?

Data centers are critical consumers of scroll chillers due to their immense and continuous cooling requirements to prevent server overheating and ensure uninterrupted operation. The key drivers for adoption include the demand for high energy efficiency to manage escalating power costs, the need for reliable and redundant cooling systems to maintain uptime, and the compact design of scroll chillers which can be crucial for space-constrained facilities. Data center operators specifically seek features such as precise temperature and humidity control, crucial for IT equipment performance; high reliability with rapid restart capabilities; modularity for scalable cooling capacity as data loads increase; and integration with Data Center Infrastructure Management (DCIM) systems for comprehensive monitoring and control. The emphasis is on solutions that offer a low Total Cost of Ownership (TCO) through energy savings, reduced maintenance, and superior operational stability, often including options for free cooling or partial free cooling to further reduce energy consumption.

How is the market for scroll chillers segmented by capacity, and what are the typical applications for each segment?

The scroll chiller market is segmented by capacity into low, medium, and high categories, each catering to distinct application requirements. Low-capacity scroll chillers, typically up to 50 TR (tons of refrigeration), are widely used in smaller commercial buildings, retail stores, small offices, and light industrial applications where cooling demands are moderate. Medium-capacity chillers, ranging from 51 TR to 200 TR, find extensive application in larger commercial complexes like hotels, hospitals, educational institutions, and mid-sized industrial processes, balancing efficiency with substantial cooling power. High-capacity scroll chillers, exceeding 200 TR, are deployed in large-scale commercial facilities, major industrial plants, large data centers, and district cooling schemes where significant and continuous cooling is paramount. This segmentation allows manufacturers to offer tailored solutions that meet specific cooling loads and budget constraints, optimizing performance and cost-effectiveness across the diverse spectrum of end-user needs.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager