Seamless Garments Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 431869 | Date : Dec, 2025 | Pages : 253 | Region : Global | Publisher : MRU

Seamless Garments Market Size

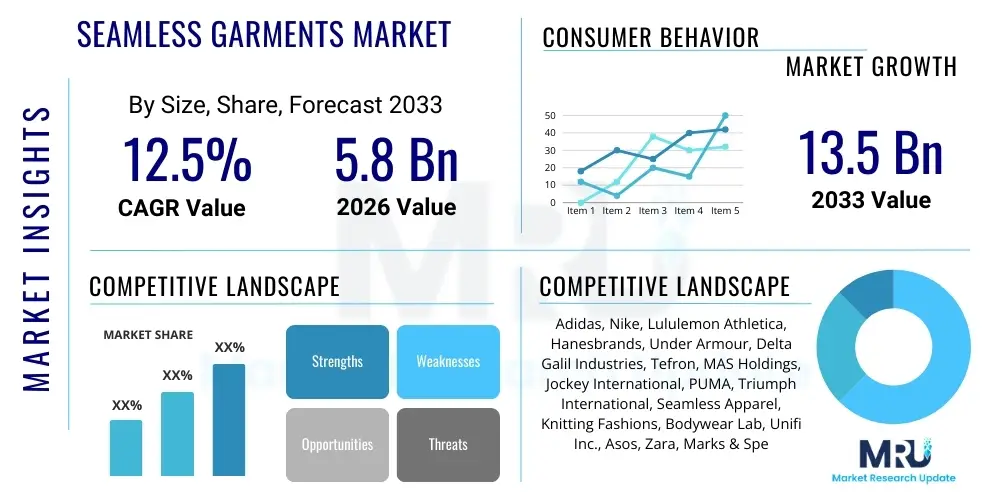

The Seamless Garments Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 12.5% between 2026 and 2033. The market is estimated at $5.8 Billion in 2026 and is projected to reach $13.5 Billion by the end of the forecast period in 2033.

Seamless Garments Market introduction

The Seamless Garments Market encompasses the production and distribution of apparel manufactured using circular knitting techniques that eliminate the need for traditional cut-and-sew methods, resulting in garments that are virtually free of seams. This advanced manufacturing process is primarily utilized to create intimate apparel, activewear, shapewear, and specialized medical textiles, providing superior fit, comfort, and performance characteristics compared to conventional clothing. Seamless technology offers significant benefits, including enhanced stretch, reduced chafing, improved aesthetic appeal due to smooth lines, and optimized material usage, minimizing textile waste during production.

The core product description revolves around a 3D knitting capability where the entire garment, or major components thereof, is knitted on one machine in a continuous cycle, often integrating varying stitch patterns, ventilation zones, and compression levels directly into the fabric structure. Major applications span high-performance sportswear, where breathability and ergonomic fit are paramount, and the highly demanding intimate apparel sector, which prioritizes invisibility and support under outer clothing. Furthermore, the medical sector employs seamless technology for compression wear and therapeutic textiles, demonstrating the versatility and technical maturity of the manufacturing process.

The market growth is fundamentally driven by the explosion of the global athleisure trend, which demands clothing capable of transitioning fluidly between athletic activity and casual wear without sacrificing style or comfort. Consumers are increasingly valuing durability, sustainable production methods, and technological integration within their apparel. Key benefits driving adoption include superior comfort through the elimination of irritating seams, enhanced garment longevity due to uniform stress distribution, and the aesthetic advantage of a sleek, second-skin fit. These combined factors solidify the position of seamless garments as a premium segment within the broader textile and apparel industry.

Seamless Garments Market Executive Summary

The Seamless Garments Market is experiencing robust growth fueled by technological advancements in knitting machinery and changing consumer preferences favoring comfort and multi-functional apparel, significantly driven by the sustained expansion of the athleisure category globally. Key business trends indicate a shift toward mass customization and on-demand production, enabled by sophisticated knitting software and automation, which allows brands to respond rapidly to micro-trends and reduce inventory risk. Furthermore, sustainability is becoming a non-negotiable factor; manufacturers are increasingly using recycled yarns and adopting closed-loop production cycles to appeal to environmentally conscious millennials and Gen Z consumers, thereby influencing supply chain practices from raw material sourcing to final product assembly.

Regional trends highlight the Asia Pacific (APAC) region as the dominant manufacturing hub, leveraging expertise in textile production and substantial investment in high-speed seamless knitting technology, making it critical for global supply. However, North America and Europe remain the primary revenue generators, driven by high consumer spending power, strong brand presence in performance wear, and early adoption of innovative products like smart seamless textiles integrated with biometric sensors. The competitive landscape is characterized by vertical integration, where major players control both manufacturing and distribution, often utilizing direct-to-consumer (D2C) models to manage brand narrative and capture higher margins, intensifying the focus on digital engagement and rapid product cycle iteration.

Segment trends underscore the dominance of the Application segment, specifically Activewear, which commands the largest market share due to its frequent replacement cycle and the high perceived value of performance-enhancing seamless features like moisture-wicking and targeted compression. The Material segment is seeing accelerated adoption of synthetic fibers like nylon and polyester for their durability and elasticity, though natural blends and bio-based polymers are gaining traction in the luxury and sustainability-focused sub-segments. The market is also witnessing significant crossover in technology, with features traditionally reserved for shapewear, such as targeted support, now being integrated into everyday casual wear, blurring the lines between functional and aesthetic apparel categories.

AI Impact Analysis on Seamless Garments Market

Common user questions regarding AI's impact on the Seamless Garments Market frequently center on personalization, supply chain efficiency, and automated design. Consumers and industry professionals are keen to understand how AI algorithms can revolutionize sizing accuracy, reduce physical prototyping waste, and optimize knitting patterns for specific performance requirements, such as personalized compression zones for athletes. Key thematic concerns often revolve around the initial investment required for integrating sophisticated AI platforms, the need for highly specialized data scientists in textile manufacturing environments, and the ethical implications of using deep learning for analyzing personal body scan data to generate hyper-customized apparel. Users express high expectations for AI to solve historical industry pain points related to inaccurate forecasting, slow product development cycles, and the massive environmental footprint associated with overproduction and excessive sampling.

AI is fundamentally transforming the product design phase through Generative Design and Virtual Prototyping. By processing vast datasets of human body morphology, material properties, and performance requirements, AI tools can rapidly generate optimal seamless knitting patterns, suggesting the ideal yarn tension, stitch density, and ergonomic structure tailored to the target consumer group or even individual. This capability dramatically shortens the product lifecycle, allowing designers to iterate on digital models instead of costly physical samples. Furthermore, predictive analytics driven by machine learning algorithms enhance demand forecasting accuracy by analyzing real-time sales data, social media trends, and macroeconomic indicators, minimizing the risk of inventory surplus or shortage, which is crucial in the fast-paced fashion segment.

In manufacturing and supply chain management, AI optimizes the operation of sophisticated circular knitting machines. Machine learning models analyze real-time sensor data from the equipment to predict potential maintenance needs (predictive maintenance), ensuring minimal downtime and consistent quality. Supply chain logistics benefit from AI-driven optimization routes, inventory management systems, and smart factory floor planning that maximize material flow and production throughput. The ultimate integration of AI in this market aims to enable true mass customization, where a unique, perfectly fitted garment can be designed and produced economically, specifically for a single consumer based on their digital profile, thus redefining the direct-to-consumer seamless experience.

- AI-driven personalized sizing and fit recommendations based on 3D body scan data and historical purchase patterns.

- Generative design software accelerating pattern creation for complex seamless compression and support structures.

- Predictive maintenance schedules for high-precision circular knitting machines, reducing operational downtime.

- Optimization of supply chain routes and raw material inventory using machine learning forecasting models.

- Enhanced quality control through computer vision systems that detect minuscule knitting defects in real-time.

- Smart factory automation enabling flexible batch sizes and instantaneous switching between different product specifications.

DRO & Impact Forces Of Seamless Garments Market

The market dynamics are defined by a strong set of drivers primarily focused on consumer lifestyle changes and technological advancements, countered by persistent restraints related to manufacturing complexity and cost structure, all contributing to numerous opportunities for differentiation and market expansion. The dominant driving factor is the surging global demand for performance-based apparel, particularly in the activewear and athleisure segments, where comfort and mobility are paramount. Coupled with this is the aesthetic advantage of a smooth, invisible finish, making seamless garments ideal for intimate wear. The continuous innovation in specialty yarns—such as those offering antimicrobial properties, UV protection, or superior moisture management—further propels market adoption, offering tangible functional benefits that justify premium pricing.

Key restraints significantly impacting market scalability involve the high initial capital expenditure required for sophisticated, multi-gauge seamless knitting machines, often costing substantially more than traditional industrial sewing equipment. This high entry barrier limits competition and concentrates production capacity among a few large, specialized manufacturers. Furthermore, achieving optimal quality control in seamless production, especially when integrating different materials and tension zones, requires specialized technical expertise and complex programming, posing a challenge for rapid scaling. The difficulty in efficiently manufacturing complex garment shapes, such as sleeves or collars, entirely seamlessly still requires some level of post-knitting finishing or joining, preventing true 100% seam elimination in all product categories.

Opportunities for growth are abundant, particularly in emerging applications such as technical protective wear, specialized medical textiles (e.g., orthopedic supports, diabetic socks), and smart apparel incorporating embedded sensors for health monitoring. The shift toward sustainable fashion presents a massive opportunity, prompting manufacturers to invest in zero-waste production models and the utilization of recycled or biodegradable input materials, catering to the ethical consumer segment. The crucial impact forces driving market penetration include aggressive D2C marketing by specialized seamless brands, emphasizing the experiential benefits of comfort and performance, and the decreasing cost and increasing capability of circular knitting technology, gradually allowing more competitive pricing and broader consumer access.

Segmentation Analysis

The Seamless Garments Market is segmented comprehensively based on Material, Application, and Distribution Channel, reflecting the diverse end-uses and supply routes within the industry. The segmentation framework provides essential insights into high-growth areas, allowing stakeholders to focus resources on segments showing the highest potential returns, particularly those driven by rapid consumer adoption in performance-related categories. Analyzing the Material split is crucial as it dictates the final garment's functional properties—such as stretch, breathability, and durability—while the Application segment highlights the core end-user demand centers, with Activewear consistently dominating revenue generation due to high consumer turnover and continuous product innovation cycles.

Within the Material segment, synthetic fibers such as Nylon, Polyester, and Spandex (Elastane) form the backbone of the market due to their excellent elastic recovery, moisture management capabilities, and resilience necessary for high-performance seamless knits. However, cotton blends and specialized materials like modal and Tencel are increasingly integrated, especially in intimate wear and casual segments, to offer a softer hand feel and improved sustainability profile, catering to premium and comfort-focused buyers. The Application segmentation is highly granular, separating major volume drivers like Activewear and Intimate Wear from niche, high-value segments such as Shapewear, which focuses on targeted body contouring, and specialized Medical Textiles, which require stringent regulatory compliance and functional precision.

The Distribution Channel analysis is key to understanding market access and penetration strategies. The market is primarily fragmented between conventional Retail Stores, which offer immediate try-on and traditional purchasing experiences, and the rapidly growing E-commerce sector, which facilitates direct-to-consumer (D2C) sales, provides access to niche brands, and leverages digital technology for personalized fitting recommendations. The continued success of the D2C model is redefining brand-consumer relationships, prioritizing digital content, community building, and loyalty programs to drive repeat purchases of seamless apparel, which often relies on accurate online sizing guides rather than physical inspection.

- By Material:

- Nylon

- Polyester

- Spandex/Elastane

- Cotton Blends

- Others (Modal, Tencel, Specialty Yarns)

- By Application:

- Activewear (Sportswear, Athleisure)

- Intimate Wear (Underwear, Bras)

- Shapewear and Hosiery

- Medical Textiles (Compression Garments)

- Casual Wear

- By Distribution Channel:

- Offline Retail Stores (Specialty Stores, Supermarkets, Departmental Stores)

- Online/E-commerce (Direct-to-Consumer, Multi-brand Portals)

Value Chain Analysis For Seamless Garments Market

The value chain for the Seamless Garments Market is characterized by high technological specialization and an increasingly integrated structure, beginning with the upstream sourcing of specialized raw materials. This upstream analysis focuses on key inputs, primarily high-performance synthetic polymers (nylon, polyester, elastane) and specialty yarns, where quality and chemical treatment (for properties like moisture-wicking or antimicrobial resistance) are critical. Due to the precision required by seamless knitting machinery, suppliers of raw materials must meet extremely strict technical specifications regarding yarn consistency, elasticity, and count. Major manufacturers often establish long-term relationships with select yarn producers to ensure a stable supply of materials optimized for circular knitting technology, thereby ensuring quality control from the earliest stage.

The central manufacturing stage involves complex midstream processes, dominated by the investment in and utilization of sophisticated circular knitting machines (such as Santoni, Lonati, or Comez models). This stage involves pattern programming, knitting, specialized dyeing, and essential post-processing steps like heat setting and garment finishing, which ensure the garment retains its shape and performance characteristics. The manufacturing capability acts as a key barrier to entry, as the intellectual property and technical expertise required for programming intricate seamless patterns (integrating features like varying mesh structures and compression zones) are highly specialized. Successful companies often vertically integrate this manufacturing process to maintain control over quality and minimize lead times, especially crucial for fast-fashion and activewear market segments.

The downstream analysis focuses on the distribution channels, which are bifurcated into direct and indirect routes. Indirect channels involve wholesalers, retailers, and departmental stores, which offer broad market visibility but dilute margins. Conversely, the direct distribution model (D2C via proprietary e-commerce platforms and dedicated brand stores) is growing rapidly. This direct approach allows seamless garment brands to maintain higher profitability, control the customer experience, and gather crucial data on fit and consumer preferences, which can feed back into the design and production cycle. This feedback loop, enabled by digital channels, is a competitive necessity, distinguishing successful seamless apparel brands that can quickly iterate their product lines based on real-world usage and fit reviews.

Seamless Garments Market Potential Customers

The primary end-users and buyers of seamless garments span across diverse demographics, fundamentally centered around individuals prioritizing comfort, performance, and aesthetic discretion in their apparel choices. The largest potential customer base is comprised of fitness enthusiasts and athletes who require high-performance activewear offering superior flexibility, moisture management, and targeted muscle support through compression zones integrated directly into the fabric. The athleisure movement has significantly expanded this demographic to include mainstream consumers seeking functional, comfortable clothing suitable for both light exercise and daily casual activities, making professional women and highly active young adults core target groups.

A second major segment consists of buyers in the intimate apparel and shapewear markets. These customers seek garments that provide smooth, undetectable lines under outer clothing, addressing aesthetic concerns related to minimizing visible panty lines (VPL) and achieving a flattering silhouette. For this segment, seamless technology is vital for products ranging from lightweight, everyday undergarments to high-compression shapewear designed for post-operative recovery or aesthetic enhancement. This demographic is predominantly composed of women aged 25-55, who value innovation in fabric technology that enhances confidence and comfort without compromising style or fit.

Emerging potential customers include patients requiring medical textiles and specialized occupational workers. Medical customers purchase seamless compression garments for managing circulatory conditions, aiding recovery post-surgery, or providing relief for conditions like lymphedema. These garments require high precision and medical-grade materials. The professional segment includes specific occupations, such as military personnel or industrial workers, who require high-durability base layers offering thermal regulation, moisture control, and long-term comfort under heavy uniforms. These niche applications represent high-value opportunities, requiring manufacturers to adhere to specialized material and performance standards beyond typical consumer product requirements.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $5.8 Billion |

| Market Forecast in 2033 | $13.5 Billion |

| Growth Rate | 12.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Adidas, Nike, Lululemon Athletica, Hanesbrands, Under Armour, Delta Galil Industries, Tefron, MAS Holdings, Jockey International, PUMA, Triumph International, Seamless Apparel, Knitting Fashions, Bodywear Lab, Unifi Inc., Asos, Zara, Marks & Spencer, Victoria's Secret, Spanx. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Seamless Garments Market Key Technology Landscape

The technology landscape of the Seamless Garments Market is fundamentally defined by the evolution of circular knitting machines and the sophistication of computer-aided design (CAD) and manufacturing (CAM) software used to program complex patterns. The core technology lies in high-speed, multi-feed knitting machines, primarily manufactured by companies like Santoni (part of the Lonati Group), which can produce entire tubular garments without interruption, eliminating the need for side seams and minimizing waste. These advanced machines are equipped with electronic needle selection and sophisticated microprocessors, allowing the simultaneous integration of varying material gauges, compression levels, and intricate stitch patterns—such as mesh for ventilation—all within a single manufacturing process, moving far beyond basic textile production into complex 3D garment engineering.

A secondary, but increasingly vital, technology involves 3D body scanning and digital prototyping, which bridges the gap between design conceptualization and machine programming. 3D scanning technology captures precise body measurements, generating data points that are then fed into specialized CAD software. This software allows designers to digitally map support and fit characteristics onto the digital human model before sending the pattern directly to the knitting machine. This digital pipeline drastically reduces the time and cost associated with physical sampling and fitting, leading to improved accuracy and a faster time-to-market. Furthermore, the integration of technical textiles, including yarns with microencapsulated features (e.g., cooling agents or moisturizers) and bio-based fibers, relies heavily on this precise technological capability to ensure even distribution and retention of functional properties throughout the seamless structure.

Innovation is also highly concentrated in the materials science and finishing stages. Technical advancements include the development of conductive yarns and textile electrodes that can be seamlessly knitted into garments for biometric monitoring, forming the basis of 'Smart Seamless Wear.' In terms of post-production, advanced heat-setting and finishing techniques are crucial for setting the garment's final shape and elasticity, ensuring that the seamless product maintains its integrity and intended performance characteristics, such as specific compression ratings, after repeated washing and wear. Continuous R&D efforts focus on increasing machine gauge capacity and feed rates, thereby lowering the unit cost of seamless production and enabling the penetration of this technology into more price-sensitive casual wear segments, ultimately driving volume growth across the entire market.

Regional Highlights

Regional dynamics play a crucial role in shaping the Seamless Garments Market, defined by manufacturing concentration, consumer spending power, and varying adoption rates of athleisure trends. North America and Europe currently represent the highest revenue-generating regions, driven by strong consumer demand for high-end activewear, sophisticated intimate apparel, and early adoption of smart seamless textiles. The market maturity in these regions means consumers are highly sensitive to brand loyalty, performance specifications, and increasingly, sustainability credentials, which necessitates continuous innovation and premium pricing strategies by regional market leaders.

- North America (U.S. and Canada): Dominant consumer market characterized by high per capita expenditure on active lifestyle products and the overwhelming popularity of major athleisure brands like Lululemon and Nike. The region prioritizes performance, comfort, and direct-to-consumer (D2C) channels. Key focus areas include advanced compression wear and the integration of seamless technology into everyday casual fashion, driven by strong marketing campaigns emphasizing wellness and self-care.

- Europe (Germany, U.K., France, Italy): A technologically advanced market focusing heavily on premium fashion, technical sportswear, and stringent sustainability standards. European consumers demonstrate high demand for seamless underwear and shapewear, often favoring quality and durability over low cost. Germany and Italy are significant manufacturing hubs, housing specialized knitting expertise and high-end machinery, which supports both regional and global supply chains with a focus on high-gauge, fine-knitted seamless products.

- Asia Pacific (APAC) (China, India, Japan, South Korea): Fastest-growing region driven by massive textile manufacturing capabilities, increasing domestic disposable incomes, and the rising participation in fitness and sports activities across urban centers. China is the undisputed global manufacturing powerhouse for seamless garments, offering high volume and competitive pricing, while consumer markets in India and Southeast Asia are witnessing rapid growth in basic seamless intimate wear and mass-market athleisure adoption. Japanese and South Korean markets focus on highly technical, fashion-forward seamless designs.

- Latin America (LATAM): Emerging market showing steady growth, particularly in Brazil and Mexico, fueled by expanding manufacturing sectors and local demand for activewear and basic undergarments. Growth is often concentrated in affordable seamless product lines, though premium segments are developing in metropolitan areas as urbanization progresses and international brands expand their presence.

- Middle East and Africa (MEA): A nascent but high-potential market. Demand is currently concentrated in luxury and international brand imports, especially in the UAE and Saudi Arabia, focusing on functional sportswear and premium, modest seamless apparel. The African region holds future potential, tied to improving infrastructure and increasing access to global supply chains, though local manufacturing capacity remains limited compared to APAC.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Seamless Garments Market, encompassing specialized manufacturers, leading global apparel brands, and key raw material innovators.- Hanesbrands Inc.

- Nike, Inc.

- Adidas AG

- Lululemon Athletica Inc.

- Under Armour, Inc.

- Tefron Ltd.

- Delta Galil Industries Ltd.

- MAS Holdings

- Jockey International, Inc.

- PUMA SE

- Triumph International

- Victoria's Secret & Co.

- Seamless Apparel Manufacturing Co.

- Unifi Inc. (Yarn supplier)

- Lonati Group (Machinery manufacturer)

- Santoni S.p.A. (Machinery manufacturer)

- Gildan Activewear Inc.

- Spanx, LLC

- Intimissimi (Calzedonia Group)

- Marks & Spencer Group plc

Frequently Asked Questions

Analyze common user questions about the Seamless Garments market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary technology used to manufacture seamless garments?

The primary technology is advanced circular knitting, utilizing specialized machines from companies like Santoni. These machines knit the entire garment body in a tubular, three-dimensional fashion, eliminating the need for traditional side seams, which is the foundational characteristic defining seamless apparel manufacturing.

Which application segment drives the highest demand in the seamless garments market?

Activewear, encompassing sportswear and athleisure, drives the highest demand. This segment relies heavily on seamless technology to provide essential performance features such as targeted compression, superior stretch, moisture-wicking properties, and reduced chafing, all critical for intense physical activity and everyday comfort.

How does the seamless process contribute to sustainability in the textile industry?

Seamless knitting significantly contributes to sustainability by operating a "zero-waste" or "near-zero-waste" production model. Since garments are knitted to size without the need for cutting excess fabric from flat panels, the process drastically minimizes textile scrap material compared to traditional cut-and-sew methods, reducing environmental footprint.

What are the main restraints hindering the growth of the seamless garments market?

The main restraints include the extremely high initial capital investment required for specialized, high-gauge seamless knitting machinery and the complexity associated with quality control and programming intricate patterns. These factors create high barriers to entry for smaller manufacturers and necessitate specialized technical labor.

How is AI expected to influence the future of seamless garment production?

AI will revolutionize seamless production primarily through mass customization, utilizing 3D body scan data to generate hyper-personalized knitting patterns automatically. Additionally, AI optimizes supply chain logistics, improves quality detection, and enhances demand forecasting, leading to greater efficiency and minimal inventory waste.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager