Secondary Alkane Sulfonates Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 437195 | Date : Dec, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Secondary Alkane Sulfonates Market Size

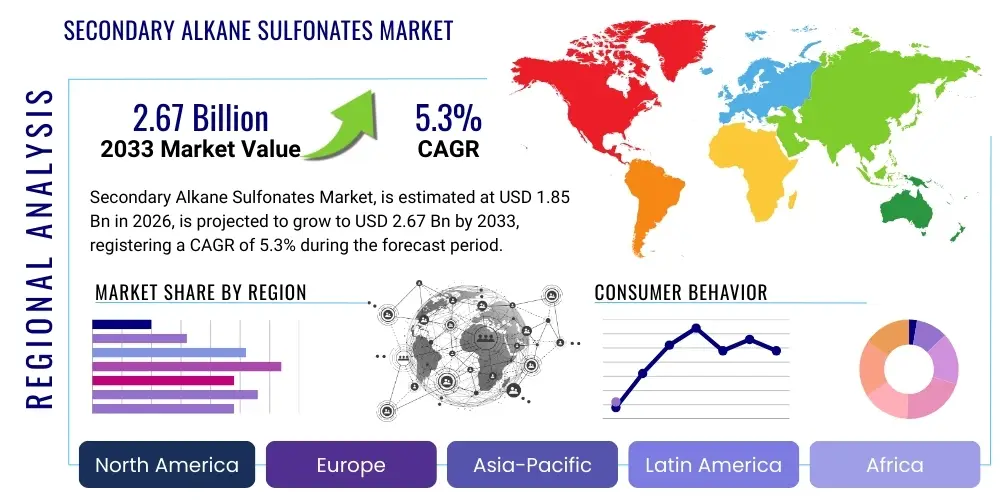

The Secondary Alkane Sulfonates Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.3% between 2026 and 2033. The market is estimated at USD 1.85 Billion in 2026 and is projected to reach USD 2.67 Billion by the end of the forecast period in 2033.

Secondary Alkane Sulfonates Market introduction

Secondary Alkane Sulfonates (SAS) are a class of versatile anionic surfactants widely utilized across numerous industrial and consumer applications due to their exceptional detergency, wetting properties, hard water stability, and relatively low toxicity profile. SAS are typically derived from paraffin oxidation and subsequent sulfonation, resulting in molecules that exhibit superior performance in cold water and high mineral content environments compared to some traditional alternatives like Linear Alkylbenzene Sulfonates (LAS). Their chemical structure, characterized by the sulfate group being attached to a secondary carbon atom on the alkyl chain, grants them unique performance characteristics critical for formulation stability and efficacy.

The primary applications for Secondary Alkane Sulfonates span household and institutional cleaning products, including laundry detergents, dishwashing liquids, and all-purpose cleaners, where their powerful emulsifying and dispersing capabilities are highly valued. Beyond consumer goods, SAS finds significant use in industrial processes such as textile processing, leather treatment, and emulsion polymerization. The growing emphasis on developing high-performance, concentrated detergent formulas that require surfactants capable of maintaining efficacy under varied conditions is a major proponent driving the demand for SAS globally. Furthermore, the inherent stability and rapid biodegradability of SAS position them favorably in markets increasingly prioritizing environmental compliance and green chemistry principles.

Key benefits driving the adoption of SAS include their excellent foaming properties, which are crucial in cleaning applications, and their ability to function effectively even at low concentrations, offering cost-effectiveness in formulation. The major driving factors for market expansion encompass the rapid urbanization and rising disposable incomes in emerging economies, leading to increased consumption of personal care and household cleaning products. Regulatory support favoring readily biodegradable surfactants over less environmentally friendly options also plays a pivotal role in accelerating the market penetration of Secondary Alkane Sulfonates across regions like Europe and North America.

Secondary Alkane Sulfonates Market Executive Summary

The Secondary Alkane Sulfonates (SAS) market demonstrates robust growth, primarily fueled by sustained demand from the household and laundry detergent sectors, especially in the Asia Pacific region due to expanding populations and improving sanitation standards. Business trends emphasize the shift toward concentrated liquid detergents and environmentally certified products, compelling manufacturers to invest in high-purity, biodegradable SAS variants. Strategic collaborations aimed at securing stable raw material supplies, specifically n-paraffins, and optimizing synthesis efficiency are common among key market players, highlighting a focus on operational excellence and competitive pricing in a largely commoditized segment of the specialty chemicals market. Investment in capacity expansion, particularly in high-growth manufacturing hubs, is a prevalent business strategy to meet the escalating global demand.

Regionally, Asia Pacific maintains its dominance in both production and consumption, driven by vast manufacturing bases in China and India serving both domestic needs and export markets. Europe and North America exhibit mature markets characterized by stringent regulatory environments, which favor SAS over traditional alternatives due to its superior environmental profile. These regions focus heavily on innovation, particularly the development of milder and bio-based derivatives suitable for sensitive skin applications or specialized industrial processes. Emerging markets in Latin America and the Middle East are experiencing accelerated market entry and increasing adoption, mirroring global trends in hygiene and cleaning product standardization.

Segmentation trends reveal that the liquid detergent application segment holds the largest market share, benefiting from consumer preference for easy-to-use liquid formulations. In terms of product type, C14-C17 chain length SAS are the most widely utilized due to their optimized balance of solubility, wetting power, and foaming characteristics. Looking ahead, the rise of industrial cleaning applications, particularly in the metals and machinery sectors requiring heavy-duty degreasing agents, represents a significant growth segment. The market continues to evolve through the introduction of specialized SAS grades tailored for specific textile or emulsification processes, indicating a move towards higher-value, performance-driven niche segments rather than solely bulk supply.

AI Impact Analysis on Secondary Alkane Sulfonates Market

Analysis of common user questions regarding the impact of Artificial Intelligence (AI) on the Secondary Alkane Sulfonates (SAS) market reveals a primary focus on operational efficiency, raw material sourcing optimization, and the acceleration of green chemistry development. Users frequently inquire about how AI can predict fluctuations in n-paraffin pricing and availability, optimize complex chemical reactions in the sulfonation process to maximize yield and purity, and assist in formulating novel, high-performing, and environmentally friendly surfactant blends. Key themes revolve around AI's potential to reduce waste, minimize energy consumption during synthesis, and ensure quality control in large-scale production, addressing the persistent industry challenge of margin pressure and sustainability compliance. Expectations are high regarding AI-driven predictive maintenance for expensive production equipment, ensuring consistent output and minimizing downtime.

The application of machine learning algorithms is increasingly anticipated in supply chain management for SAS, allowing companies to forecast demand volatility with greater accuracy and manage inventory more effectively, thereby reducing logistical costs and improving market responsiveness. Furthermore, AI tools are expected to revolutionize R&D by simulating molecular interactions, enabling the rapid screening of potential novel SAS derivatives or synergistic co-surfactants, reducing the time and cost associated with traditional laboratory experimentation. This predictive capability is particularly valuable in developing highly specialized SAS formulations required for demanding applications such as enhanced oil recovery (EOR) or high-speed textile processing, where performance tolerances are narrow. The integration of AI promises to transform SAS production from a conventional chemical process into a highly automated and optimized manufacturing operation.

While the direct displacement of SAS by AI-driven products is unlikely, the indirect impact involves making the production and deployment of SAS more sustainable and cost-competitive. AI-enhanced predictive analytics are critical for ensuring that SAS manufacturers maintain profitability amid fluctuating raw material costs and tightening environmental regulations. The adoption curve for sophisticated AI models in production facilities, however, remains dependent on initial investment capacity and the availability of specialized chemical engineering and data science expertise within the sector. Ultimately, AI serves as an enabler, driving optimization across the entire SAS value chain, from procurement to final application formulation.

- AI optimizes complex sulfonation reaction parameters, maximizing SAS yield and purity.

- Machine learning algorithms predict n-paraffin raw material price volatility, enhancing procurement strategies.

- Predictive maintenance minimizes operational downtime of high-pressure reactors and processing equipment.

- AI-driven simulation accelerates the R&D of novel, specialized, and bio-based SAS derivatives.

- Supply chain optimization through AI forecasts reduces inventory holding costs and improves delivery lead times.

- Enhanced quality control systems utilize computer vision and ML to detect impurities in real-time production streams.

DRO & Impact Forces Of Secondary Alkane Sulfonates Market

The Secondary Alkane Sulfonates (SAS) market is subject to a complex interplay of drivers, restraints, and opportunities that collectively shape its growth trajectory. Key drivers include the exponential increase in demand for premium and concentrated laundry detergents, especially in rapidly industrializing nations, where improved hygiene standards are becoming commonplace. The inherent environmental advantage of SAS—being readily biodegradable—is a powerful driver, pushing its adoption over traditional surfactants that face increasing regulatory scrutiny, particularly in developed economies. The versatility of SAS, allowing its use across a diverse range of applications from consumer goods to specialized industrial agents (e.g., metalworking fluids, oilfield chemicals), provides market resilience and diversification.

Conversely, the market faces significant restraints, primarily stemming from the volatility in the pricing and availability of its key petrochemical feedstock, n-paraffins, which ties the profitability of SAS production directly to crude oil market fluctuations. Furthermore, the market encounters stiff competition from established, lower-cost alternative surfactants, most notably Linear Alkylbenzene Sulfonates (LAS) and Fatty Alcohol Ethoxylates (FAE), which may dominate certain price-sensitive segments. Regulatory hurdles, although sometimes acting as a driver for sustainable products, can also impose costly compliance requirements related to manufacturing safety and waste management, particularly for new facility construction or expansion.

Opportunities for market growth are abundant, particularly through strategic product development focused on high-performance niche applications, such as enhanced oil recovery (EOR) agents, where SAS's exceptional stability and interfacial tension reduction capabilities are highly valued. Significant potential also exists in the development of "green" or partially bio-based SAS, utilizing renewable feedstocks where feasible, aligning with global sustainability mandates and attracting premium pricing. The market can capitalize on the trend towards high-efficiency, low-energy washing machine cycles, as SAS performs optimally in cold water, further solidifying its competitive edge over temperature-dependent alternatives. The overall impact forces suggest a market poised for steady growth, driven by technological adoption and sustainability mandates, counterbalanced by feedstock and competitive pressures.

Segmentation Analysis

The Secondary Alkane Sulfonates (SAS) market segmentation provides critical insights into the diverse end-use sectors and product variations influencing demand dynamics. The market is primarily segmented by application, which includes household detergents, industrial and institutional (I&I) cleaning, textile processing, and others such as construction chemicals and oilfield applications. The household detergent segment traditionally holds the largest volume share due to the daily use and high volume requirement for laundry and dishwashing products. Within this segment, there is a clear trend toward liquid concentrates, leveraging SAS's superior cold-water performance. Furthermore, segmentation by product type typically focuses on the alkyl chain length, with C14-C17 chain lengths dominating commercial production due to their balanced physicochemical properties essential for cleaning efficiency and mildness.

Segmentation by grade—high purity versus industrial grade—also plays a crucial role, determining the suitability for personal care versus heavy-duty industrial cleaning. High-purity SAS is often mandated for sensitive applications requiring excellent color and minimal odor, such as specialized cosmetic formulations or pharmaceutical cleaning. The geographic segmentation is vital, reflecting regional variations in manufacturing capacities, regulatory requirements, and consumer spending patterns. For instance, high growth in the APAC region is predominantly driven by bulk industrial and consumer grade SAS production, whereas North American and European markets prioritize premium, high-performance, and environmentally certified grades, reflecting different maturity levels and regulatory landscapes.

Understanding these segments allows market participants to tailor their offerings, optimize their distribution strategies, and focus R&D efforts on the most promising areas. For example, the increasing regulatory pressure on volatile organic compounds (VOCs) and non-biodegradable components in industrial fluids presents a distinct opportunity for high-stability SAS grades in the metalworking and lubricant sectors. The evolving nature of end-user requirements, particularly the global shift toward water-saving and energy-efficient practices in laundry, continues to reinforce the importance of SAS across nearly all key segments due to its inherent functional advantages.

- By Application:

- Household Detergents (Laundry, Dishwashing)

- Industrial and Institutional (I&I) Cleaning

- Textile and Leather Processing

- Personal Care Products

- Oilfield Chemicals (Enhanced Oil Recovery)

- Construction and Others (Emulsion Polymerization)

- By Type (Alkyl Chain Length):

- C10 - C13

- C14 - C17

- C18 - C20 and Above

- By Form:

- Liquid

- Powder (Granules)

- By Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America (LATAM)

- Middle East and Africa (MEA)

Value Chain Analysis For Secondary Alkane Sulfonates Market

The value chain for Secondary Alkane Sulfonates begins with the upstream segment, primarily involving the procurement and processing of raw materials. The crucial raw material is n-paraffin, which is derived from crude oil refining processes. This phase is characterized by intense price volatility, as n-paraffin availability and cost are intrinsically linked to global energy markets. Key upstream suppliers include major petrochemical companies and specialized paraffin refiners. Efficient supply chain management and securing long-term contracts are paramount in the upstream phase to mitigate commodity risk. The quality and purity of the n-paraffin feedstock directly impact the final SAS product quality, necessitating strict quality control measures at the supplier level.

The midstream segment involves the core manufacturing process, which includes the oxidation of n-paraffins followed by sulfonation, typically utilizing sulfur trioxide (SO3), and subsequent neutralization. This segment requires significant capital investment in specialized reaction vessels, sulfonation equipment, and sophisticated process control systems to ensure high yield and consistent product specification. Major SAS producers often integrate backward to secure feedstock stability or forward to formulate end-use products. Manufacturing efficiency, energy consumption minimization, and adherence to environmental discharge regulations are critical success factors in this processing stage, directly influencing the final cost competitiveness of SAS.

The downstream analysis focuses on the distribution and end-user consumption. Distribution channels are varied, involving direct sales to large Fast-Moving Consumer Goods (FMCG) corporations for household detergents, or through specialized chemical distributors who serve smaller industrial and institutional clients. Direct channels are common for high-volume transactions, offering better price control, while indirect channels leverage distributor networks for market penetration into diverse, localized industrial segments (e.g., textile auxiliaries, small batch specialty chemical formulators). The complexity in the downstream is handling the liquid form of SAS, requiring specialized storage and transport logistics. End-users evaluate SAS based on performance criteria such as biodegradability, concentration efficiency, and hard water tolerance, driving formulation adjustments and continuous dialogue between manufacturers and buyers.

Secondary Alkane Sulfonates Market Potential Customers

Potential customers for Secondary Alkane Sulfonates (SAS) are diverse, spanning multiple industrial and consumer sectors that require high-performance cleaning, wetting, and emulsifying agents. The largest segment of buyers comprises global and regional manufacturers of household cleaning products, including major consumer packaged goods (CPG) companies that require vast quantities of SAS for their laundry detergent, dishwashing liquid, and general surface cleaner lines. These buyers prioritize cost-effectiveness, consistency in supply, and compliance with local environmental standards, particularly regarding aquatic toxicity and biodegradability. Their procurement often involves large, multi-year contracts ensuring stable supply chains and competitive pricing due to the immense volumes required for mass-market distribution.

A second major group includes industrial and institutional (I&I) cleaning product manufacturers, who formulate specialized, heavy-duty cleaning agents for use in hospitals, food processing plants, commercial laundries, and industrial maintenance facilities. These customers seek SAS grades that offer superior stability under harsh conditions (e.g., high pH, high temperature) and powerful degreasing properties. Specialized industrial buyers also include textile processors who use SAS as wetting agents, dispersants, and leveling agents during dyeing and finishing, and leather processing plants utilizing them for fat-liquoring and preparation stages. For these industrial users, the unique chemical stability and performance characteristics of SAS are often non-negotiable requirements for achieving specific process outcomes.

Furthermore, niche markets represent lucrative customer segments, particularly companies operating in the oil and gas industry, where high-performance surfactants are vital for enhanced oil recovery (EOR) operations by reducing interfacial tension in the reservoir. Buyers in the construction chemicals sector also rely on SAS for use as air entrainers and dispersing agents in concrete and cement additives. The common trait among all these potential customers is the need for a surfactant that offers an optimal balance of effectiveness, environmental safety, and reliability across varied operational environments, making SAS a preferred choice over older, less environmentally acceptable alternatives.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.85 Billion |

| Market Forecast in 2033 | USD 2.67 Billion |

| Growth Rate | 5.3% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | BASF SE, Clariant AG, Lanxess AG, The Stepan Company, Galaxy Surfactants Ltd., Kao Corporation, Lion Specialty Chemicals Co., Ltd., AkzoNobel NV (Nouryon), Solvay S.A., Dow Chemical Company, Shell PLC, Huntsman Corporation, Sanyo Chemical Industries, Croda International PLC, Enaspol a.s., Wilmar International Ltd., Sinopec Corporation, Reliance Industries Limited, P&G Chemicals, Mitsubishi Chemical Corporation |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Secondary Alkane Sulfonates Market Key Technology Landscape

The core technology for producing Secondary Alkane Sulfonates (SAS) revolves around the sulfoxidation or chlorosulfonation processes of n-paraffins, followed by subsequent hydrolysis and neutralization. The modern technological landscape is heavily focused on process intensification and environmental sustainability. A critical technological trend is the optimization of continuous loop sulfonation reactors, which utilize sophisticated mixing and heat exchange mechanisms to ensure high conversion rates and uniform product quality while minimizing side reactions and energy input. Advanced techniques leverage precise temperature and pressure control, often managed by Supervisory Control and Data Acquisition (SCADA) systems, to maintain the desired reaction kinetics, thereby improving the efficiency and purity of the final SAS product, which is particularly important for high-end applications like personal care ingredients.

Another significant technological advancement involves mitigating environmental impact through improved separation and purification methods. Innovations in membrane filtration and advanced distillation techniques are being applied to effectively remove unreacted raw materials and undesirable byproducts, leading to ultra-pure SAS grades with negligible odor and color—features highly sought after by premium detergent and personal care formulators. Furthermore, there is an ongoing technological effort to explore alternative, potentially renewable feedstocks to partially replace petroleum-derived n-paraffins, aligning with the broader green chemistry movement. This research includes utilizing synthetic bio-paraffins or specialized Fischer-Tropsch derived waxes, although these alternatives currently face scalability and cost challenges.

Digitalization and automation technologies are rapidly being integrated into SAS production facilities, forming the basis of the technological competitive edge. This includes deploying multivariate statistical process control (MSPC) and AI-driven monitoring systems that analyze real-time data from hundreds of sensor points to predict process deviations and optimize catalyst usage, resulting in lower operational expenses and reduced waste. The emphasis on developing highly concentrated, flowable liquid SAS formulations also necessitates technological investments in specialized blending and stabilization equipment, ensuring long-term shelf stability and performance consistency for concentrated consumer products, which are gaining market share globally due to reduced packaging and transport costs.

Regional Highlights

The Secondary Alkane Sulfonates market exhibits distinct regional dynamics driven by varying levels of industrial development, regulatory frameworks, and consumer purchasing power. Asia Pacific (APAC) dominates the global market both in terms of consumption volume and production capacity. This supremacy is fueled by rapid urbanization, expanding middle-class populations, and the subsequent surge in demand for affordable household cleaning products across China, India, and Southeast Asian nations. Manufacturing facilities in APAC benefit from lower labor costs and less stringent environmental regulations (historically), making them the primary global supply hubs. However, the region is rapidly adopting global environmental standards, which further validates the choice of biodegradable surfactants like SAS over conventional non-biodegradable alternatives.

Europe represents a mature but highly influential market, distinguished by its rigorous regulatory landscape, especially under the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) framework. European markets prioritize high-performance, environmentally friendly, and certified sustainable chemical products, positioning SAS favorably due to its excellent biodegradability profile. Innovation in Europe is concentrated on developing specialized, high-purity SAS grades for sensitive applications and exploring alternatives to petroleum-based feedstocks. While consumption growth is moderate compared to APAC, the average selling price (ASP) of SAS in Europe is generally higher, reflecting the demand for specialized, compliant products.

North America, characterized by high consumer spending and sophisticated industrial sectors, maintains steady demand for SAS, driven by its robust household detergent and I&I cleaning markets. Similar to Europe, sustainability and product safety are key market drivers, compelling formulators to use performance surfactants that meet stringent regulatory criteria. The use of SAS in the burgeoning oilfield chemicals sector, particularly for EOR applications in major producing regions, provides an additional significant revenue stream. Latin America and the Middle East & Africa (MEA) are emerging markets showing accelerated growth, prompted by modernization efforts, increased foreign investment in manufacturing, and growing awareness regarding hygiene and sanitation standards. These regions are primarily demand-driven, relying heavily on imports or local blending operations supported by global suppliers.

- Asia Pacific (APAC): Dominates market share and production volume; high growth driven by China, India, and Southeast Asia due to expanding consumer base and rising detergent usage. Focus on bulk and industrial grades.

- Europe: High-value, mature market driven by stringent environmental regulations (REACH); strong demand for high-ppurity, biodegradable SAS in household and specialized industrial sectors.

- North America: Steady market growth fueled by concentrated liquid detergent adoption and significant use in enhanced oil recovery (EOR) operations; emphasis on sustainability and product performance.

- Latin America (LATAM): Emerging market with increasing demand, supported by economic development and urbanization; growing reliance on imported specialty surfactants.

- Middle East and Africa (MEA): Growth attributed to infrastructural development and increasing hygiene standards; focused demand in the I&I cleaning and oilfield chemical sectors.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Secondary Alkane Sulfonates Market.- BASF SE

- Clariant AG

- Lanxess AG

- The Stepan Company

- Galaxy Surfactants Ltd.

- Kao Corporation

- Lion Specialty Chemicals Co., Ltd.

- AkzoNobel NV (Nouryon)

- Solvay S.A.

- Dow Chemical Company

- Shell PLC

- Huntsman Corporation

- Sanyo Chemical Industries

- Croda International PLC

- Enaspol a.s.

- Wilmar International Ltd.

- Sinopec Corporation

- Reliance Industries Limited

- P&G Chemicals

- Mitsubishi Chemical Corporation

Frequently Asked Questions

Analyze common user questions about the Secondary Alkane Sulfonates market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary function of Secondary Alkane Sulfonates (SAS) in cleaning products?

SAS primarily functions as a high-performance anionic surfactant, offering excellent wetting, emulsifying, and detergency capabilities. It is highly valued for its stability and effectiveness in cold water and hard water conditions, making it superior for concentrated laundry and institutional cleaning formulations compared to conventional alternatives.

How does the biodegradability of SAS compare to other surfactants like LAS?

Secondary Alkane Sulfonates (SAS) exhibit rapid and excellent primary and ultimate biodegradability, often surpassing the performance of Linear Alkylbenzene Sulfonates (LAS) under similar environmental conditions. This favorable environmental profile is a key driver for its adoption in regions with strict regulatory standards concerning chemical runoff and aquatic toxicity.

Which application segment holds the largest share in the SAS Market?

The household detergents segment, particularly laundry and dishwashing liquids, accounts for the largest market share by volume. This dominance is driven by high consumer usage rates globally and the strong performance attributes of SAS in concentrated, low-temperature detergent formulas.

What are the key raw materials required for manufacturing Secondary Alkane Sulfonates?

The key raw material is n-paraffin (normal paraffin), typically sourced from crude oil refining. This feedstock undergoes complex sulfoxidation or chlorosulfonation processes using agents like sulfur trioxide (SO3) to yield the final SAS product. The price volatility of n-paraffin directly impacts the final manufacturing cost.

What is the growth outlook for the SAS Market in the Asia Pacific region?

The Asia Pacific region is expected to demonstrate the highest growth rate due to accelerating industrialization, increasing consumer awareness regarding hygiene, and large-scale manufacturing capacity expansion in countries such as China and India, making it the fastest-growing market globally for SAS consumption.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager