Shampoo Capsule and Dissolvable Laundry Condensate Beads Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 438590 | Date : Dec, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Shampoo Capsule and Dissolvable Laundry Condensate Beads Market Size

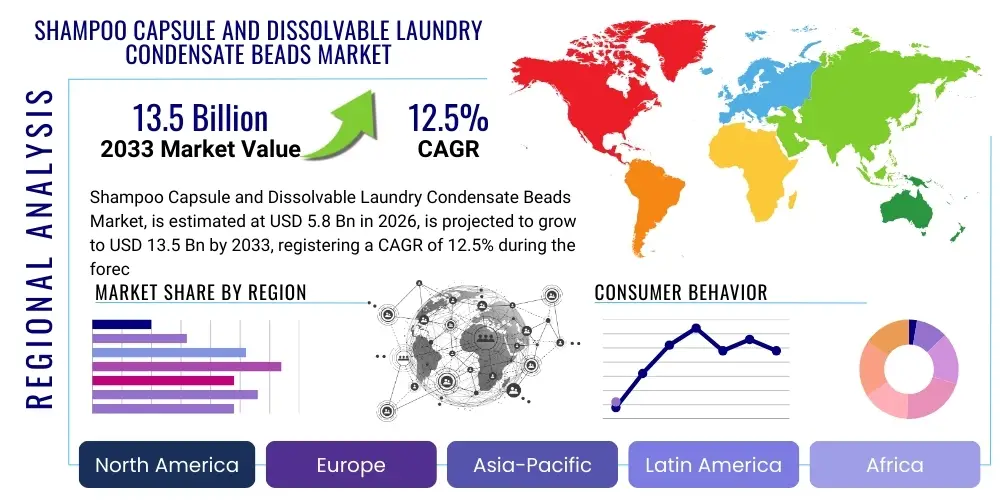

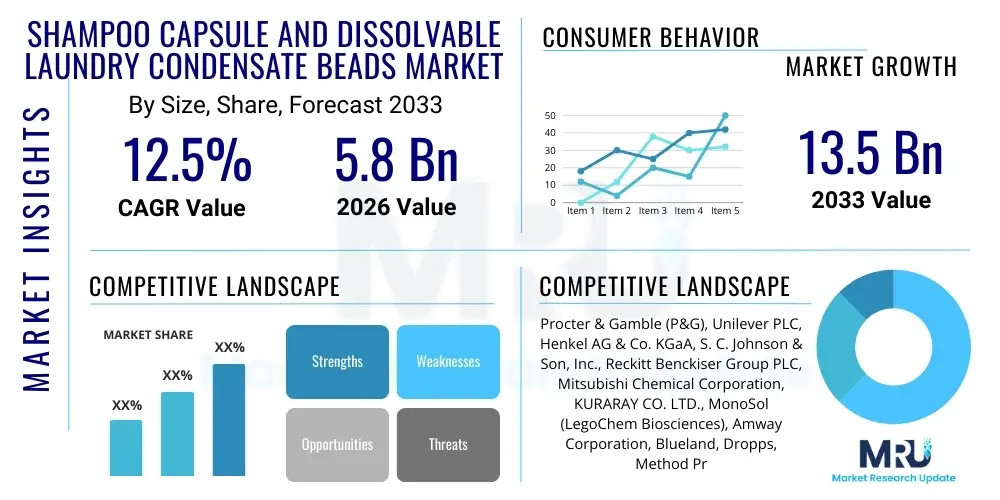

The Shampoo Capsule and Dissolvable Laundry Condensate Beads Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 12.5% between 2026 and 2033. The market is estimated at USD 5.8 Billion in 2026 and is projected to reach USD 13.5 Billion by the end of the forecast period in 2033. This significant expansion is primarily fueled by the accelerating global demand for sustainable and convenient household products, alongside advancements in water-soluble polymer technology, particularly Polyvinyl Alcohol (PVA) and specialized hydrocolloids, which facilitate the reliable and efficient delivery of concentrated cleaning agents. The shift away from traditional, bulky plastic packaging in mature economies like North America and Europe, coupled with the rapid urbanization and focus on space-saving solutions in the Asia Pacific region, are critical elements driving this impressive revenue forecast.

Shampoo Capsule and Dissolvable Laundry Condensate Beads Market introduction

The Shampoo Capsule and Dissolvable Laundry Condensate Beads Market represents a rapidly evolving segment within the broader personal care and household cleaning industries, characterized by innovative, pre-dosed, water-soluble product forms. Shampoo capsules typically contain highly concentrated liquid or powder shampoo formulations encased in a biodegradable or readily dissolvable film, often based on PVA, designed to reduce plastic waste and eliminate the need for traditional plastic bottles. Similarly, dissolvable laundry condensate beads—a term encompassing highly concentrated laundry detergent pods, packs, or beads—deliver precise quantities of detergent, fabric softener, or scent boosters, maximizing cleaning efficacy while ensuring minimal environmental impact through precise dosing and reduced transportation weight. These product formats cater directly to modern consumer priorities focusing on sustainability, convenience, and minimized clutter in residential spaces, positioning them as superior alternatives to conventional liquid or powder formulations.

Major applications of these innovative formats span both consumer and commercial domains, although the residential sector remains the primary revenue engine. Shampoo capsules are prominently utilized in daily personal hygiene routines, particularly appealing to travelers, fitness enthusiasts, and environmentally conscious consumers seeking zero-waste bathroom solutions. Dissolvable laundry condensate beads have found ubiquitous application across domestic washing machines, high-efficiency (HE) systems, and specialized commercial laundry operations, offering consistent performance and simplified usage that mitigates issues of spillage and inaccurate measurement common with bulk liquids. The fundamental benefit driving adoption is the unparalleled convenience of pre-measured doses, ensuring optimal product performance and preventing overuse, thereby reducing overall consumption costs and extending the life cycle of the product contents effectively.

The market growth is robustly driven by several macro and micro factors. Foremost among these is the escalating consumer awareness regarding plastic pollution and the corresponding regulatory pressures forcing Fast-Moving Consumer Goods (FMCG) giants to adopt sustainable packaging alternatives. The ease of use associated with these concentrated, single-dose formats appeals strongly to time-constrained modern consumers seeking efficiency in their routine tasks. Furthermore, continuous research and development efforts are focused on enhancing the stability, solubility, and shelf-life of the encapsulation materials, addressing previous concerns related to humidity sensitivity and dissolution rates in varying water temperatures. The compact nature of these products also significantly lowers shipping volume and weight, contributing to reduced logistics costs and a lower carbon footprint across the entire supply chain, making them economically and ecologically advantageous compared to their traditional counterparts.

Shampoo Capsule and Dissolvable Laundry Condensate Beads Market Executive Summary

The Shampoo Capsule and Dissolvable Laundry Condensate Beads Market is undergoing transformative growth, primarily powered by disruptive innovations in polymer chemistry and a global pivot toward sustainable consumption models. Key business trends indicate a strong focus on strategic partnerships between specialized polymer manufacturers and established consumer product companies to scale up production capacity and improve the efficacy of water-soluble films. Furthermore, the market is characterized by intense product differentiation centered around specialized ingredient delivery, such as capsules containing targeted hair treatments (e.g., keratin or argan oil) or laundry beads optimized for cold-water washing or sensitive skin. Companies are increasingly leveraging direct-to-consumer (DTC) subscription models, especially in the personal care segment, capitalizing on the compact size and lightweight nature of the products to offer customized, recurring delivery services that bolster customer loyalty and predictable revenue streams.

Regionally, the market dynamics show significant variation. North America and Europe remain the pioneers in terms of market maturity and sustainability-driven consumer adoption, commanding the largest initial market share due to stringent environmental regulations and high disposable incomes facilitating premium product purchases. However, the Asia Pacific (APAC) region is projected to register the highest Compound Annual Growth Rate (CAGR) over the forecast period, driven by expanding middle-class populations, rapid urbanization resulting in smaller living spaces where compact products are favored, and increasing governmental initiatives promoting biodegradable solutions. Specifically, countries like China and India are emerging as critical manufacturing hubs and massive consumption markets, necessitating localized product development that addresses regional water hardness and washing habits. Conversely, Latin America and the Middle East and Africa (MEA) are emerging markets, where growth is nascent but promising, contingent upon improving distribution infrastructure and enhanced consumer education regarding the cost-benefit analysis of concentrated products.

Segment-wise, the market is primarily segmented by product type (capsules vs. beads/pods), formulation type (liquid vs. powder), and application (personal care vs. household cleaning). The dissolvable laundry condensate beads segment currently holds the dominant market share due to widespread household adoption, established brand presence, and the higher volume usage associated with laundry cycles. Within the household segment, multi-chamber laundry pods offering combined detergent, stain remover, and color protection are leading the technological advancements. Meanwhile, the shampoo capsule segment, while smaller, is exhibiting faster proportional growth, fueled by its strong alignment with the zero-waste movement and specialized niche appeal, particularly targeting travel and hospitality sectors. Continuous innovation in sustainable packaging, moving beyond initial plastic components to fully compostable or zero-waste refill concepts, is expected to further refine and drive segment preferences throughout the forecast period.

- Business Trend: Increased investment in bio-based and compostable water-soluble polymer technologies to achieve full product sustainability compliance.

- Regional Trend: APAC projected to be the fastest-growing region, shifting the manufacturing and consumption focal points eastward, specifically toward China and Southeast Asia.

- Segment Trend: Accelerating preference for multi-chamber laundry pods that encapsulate diverse chemical components separately for maximum activation upon contact with water.

- Adoption Trend: Significant shift towards subscription-based and refill models leveraging the low logistical footprint of concentrated capsule and bead formats.

- Innovation Focus: Development of capsules with extended shelf life and higher stability against humidity without compromising dissolution speed.

AI Impact Analysis on Shampoo Capsule and Dissolvable Laundry Condensate Beads Market

User queries regarding the impact of Artificial Intelligence (AI) on the Shampoo Capsule and Dissolvable Laundry Condensate Beads Market frequently revolve around three core themes: optimization of manufacturing processes, enhancement of supply chain resilience, and personalized consumer engagement. Common questions include how AI can improve the precision of encapsulation processes, whether machine learning models can predict and mitigate PVA film degradation risks during storage, and how AI-driven analytics can tailor detergent formulations based on real-time data concerning regional water quality and consumer washing machine habits. Consumers also express interest in AI-powered recommendation engines that customize capsule counts and ingredients for individual hair or clothing care needs within subscription services. The underlying expectation is that AI will drive efficiency, reduce waste, and facilitate unprecedented levels of product customization in this highly technical FMCG niche.

The integration of AI technologies, particularly machine learning (ML) and computer vision, is poised to revolutionize the manufacturing precision and quality control of both capsules and beads. The delicate process of forming, filling, and sealing water-soluble films requires exceptional accuracy to ensure product integrity and consistent dissolution performance. AI algorithms are being deployed on manufacturing lines to monitor physical parameters—such as film thickness uniformity, filling volume consistency, and seal strength—in real-time, far exceeding human inspection capabilities. By analyzing massive datasets of production metrics, ML models can identify subtle process deviations that lead to defects, allowing for proactive adjustments, thereby minimizing material waste, improving yield rates, and ensuring regulatory compliance related to product safety and child resistance features inherent in specialized packaging design.

Furthermore, AI is fundamentally changing the market's engagement with consumers and optimizing inventory management. Predictive analytics, utilizing external factors like weather patterns, seasonality, and social media trends, enables highly accurate demand forecasting, mitigating the risk of stockouts or overstocking of specific capsule variants. For the end-user, AI-driven digital platforms are creating tailored experiences: for instance, a consumer can upload information about their hair type, lifestyle, or fabric care concerns, and an ML model will recommend the precise shampoo capsule formulation or laundry bead combination needed, enhancing perceived value and effectiveness. This personalization capability, coupled with AI-optimized logistical routes for compact, lightweight shipments, translates directly into enhanced operational profitability and a stronger competitive edge for adopting companies.

- Manufacturing Optimization: Utilization of computer vision and ML for real-time quality assurance of film encapsulation, significantly reducing defects and material waste.

- Supply Chain Efficiency: AI-driven predictive logistics for optimized inventory management and route planning, capitalizing on the compact size of capsules and beads to reduce transportation costs.

- Product Personalization: Implementation of machine learning recommendation engines to tailor specific formulation types (e.g., concentrated detergent, specialized shampoo) based on individual customer data and regional environmental factors.

- R&D Acceleration: AI simulations aiding in the rapid testing and optimization of novel water-soluble polymer formulations, speeding up the development cycle for biodegradable and high-performance films.

- Sustainability Tracking: Use of AI and blockchain to trace material origins and track the lifecycle impact of dissolvable products, enhancing transparency for environmentally conscious consumers.

DRO & Impact Forces Of Shampoo Capsule and Dissolvable Laundry Condensate Beads Market

The market is predominantly driven by powerful socio-economic trends focusing on environmental stewardship and lifestyle convenience, while simultaneously facing technical and regulatory restraints that necessitate continuous innovation. The primary driver is the global anti-plastic sentiment, which strongly favors concentrated, low-waste packaging formats. Opportunities arise from expanding into new geographical markets, particularly those with emerging regulatory frameworks favoring eco-friendly solutions, and through cross-segmentation, such as applying capsule technology to pet care products or specialized industrial cleaning agents. However, the market faces significant restraints, including the high cost and sensitivity of specialized water-soluble polymers (like PVA) to humidity and heat during storage and distribution, alongside regulatory complexities regarding child safety packaging standards for highly concentrated formulas. These dynamics create powerful impact forces, where the technological advancement in polymer science constantly counteracts the inherent logistical challenges of distributing sensitive, concentrated cleaning products globally.

Drivers: The dominant driver is the compelling consumer value proposition combining environmental responsibility with superior usage convenience. The pre-measured format eliminates guesswork, spillage, and product overuse, directly translating into cost savings and enhanced performance satisfaction for the end-user. Furthermore, the supportive regulatory environment in major developed markets, such as the European Union's focus on Extended Producer Responsibility (EPR) schemes and packaging waste reduction targets, actively incentivizes manufacturers to switch to these concentrated, low-material alternatives. The high efficacy of concentrated formulations, often providing enhanced cleaning power compared to their diluted liquid counterparts, further cements consumer loyalty and drives repeat purchases, solidifying the market's foundation.

Restraints: The most critical restraint is the technical challenge associated with the encapsulation material itself. The water-soluble films must be robust enough to withstand handling, humidity, and temperature fluctuations during transit and storage, yet dissolve completely and rapidly upon contact with water. Achieving this balance requires specialized, often patented polymer technology, leading to higher raw material costs compared to traditional packaging. Moreover, the industry faces continuous regulatory scrutiny regarding the bitterants or specialized safety mechanisms required on laundry pods to deter accidental ingestion by children, which adds complexity and cost to the manufacturing process and requires standardized global compliance that is difficult to achieve across diverse jurisdictions.

Opportunities: Significant growth opportunities exist in two main areas: product diversification and emerging market penetration. In diversification, the technology can be extended to include specialized functions like medical-grade disinfectants in capsule form or highly concentrated industrial fabric treatments. In terms of geography, developing robust, localized supply chains in high-growth regions like APAC and LATAM, coupled with aggressive consumer education campaigns demonstrating the cost-effectiveness and eco-benefits of condensation beads, provides a substantial avenue for market expansion. Furthermore, collaborating with hospitality and travel sectors to provide customized, single-use, sustainable personal care kits offers a high-margin niche opportunity.

Impact Forces: The interplay between drivers and restraints creates strong impact forces. The societal pressure for zero-waste solutions (a driver) compels material scientists to overcome the technical fragility of PVA and related polymers (a restraint). This leads to an accelerating cycle of innovation (an opportunity), focused on developing multi-layered films and hybrid biopolymers that offer superior barrier properties while maintaining biodegradability. The primary impact force is the intensification of material science research, pushing the boundaries of soluble film technology to meet both sustainability mandates and demanding logistical requirements, ultimately leading to a higher quality, albeit initially higher cost, product offering that sets a new standard for household product delivery.

Segmentation Analysis

The Shampoo Capsule and Dissolvable Laundry Condensate Beads Market is broadly segmented based on the core product category, the specific application area, the type of formulation encapsulated, and the distribution channel utilized for sales. Product segmentation distinguishes between the laundry-focused beads/pods, which dominate volumes, and the personal care capsules, which are rapidly gaining traction due to their high alignment with travel and sustainability trends. The application segmentation delineates household/residential use from commercial/institutional use (e.g., hotels, hospitals, industrial laundries). The formulation type is critical, covering liquid concentrates (requiring advanced film technology) and powder concentrates (simpler encapsulation but sometimes less potent). Analyzing these segments provides crucial insight into consumer behavior and manufacturer strategy, with significant emphasis placed on developing specialized formulas tailored for high-efficiency washing machines and specific hair/skin needs.

- By Product Type:

- Dissolvable Laundry Condensate Beads/Pods

- Shampoo Capsules/Tablets

- Other Personal Care Capsules (Conditioner, Body Wash)

- By Formulation Type:

- Liquid Concentrates

- Powder/Solid Concentrates

- Gel Concentrates

- By Application:

- Residential/Household Use

- Commercial/Institutional Use (Hospitality, Healthcare, Industrial Laundry)

- By Distribution Channel:

- Supermarkets and Hypermarkets

- E-commerce and Online Retail

- Specialty Stores

- Subscription Services (DTC)

- By End-Use Industry:

- Fabric Care

- Hair Care

- Surface Cleaning (Emerging)

Value Chain Analysis For Shampoo Capsule and Dissolvable Laundry Condensate Beads Market

The value chain for the Shampoo Capsule and Dissolvable Laundry Condensate Beads Market is complex, involving highly specialized material science and precision manufacturing, differentiating it significantly from traditional liquid FMCG production. Upstream analysis focuses heavily on the procurement of raw materials, particularly the specialized polymers (such as high-grade PVA, modified cellulose, or starch-based derivatives) required for the water-soluble films, and the high-purity surfactants, enzymes, and active ingredients necessary for the concentrated formulations. This stage requires rigorous quality control, as the integrity and dissolution properties of the final product are entirely dependent on the chemical consistency of these inputs. Key stakeholders at this stage include chemical processing companies and specialized polymer producers who hold significant intellectual property rights over the film technology, giving them considerable bargaining power and influence over manufacturing costs and supply stability.

Midstream activities encompass the sophisticated manufacturing processes: compounding the concentrated detergents or shampoos, followed by the highly precise encapsulation (Form-Fill-Seal or injection molding techniques) and final packaging. This stage is capital-intensive, requiring specialized, high-speed machinery capable of handling the sensitive water-soluble film material under controlled humidity and temperature conditions to prevent premature dissolution or degradation. Downstream analysis focuses on logistics, distribution, and retail, where the compact and lightweight nature of the products offers advantages in storage and transportation efficiency compared to bulky liquids. However, this advantage is moderated by the need for specialized secondary packaging (e.g., rigid, child-resistant containers) to protect the concentrated contents from external factors like moisture and to ensure compliance with stringent safety regulations globally.

Distribution channels are diversified, encompassing both traditional and modern retail pathways. Direct distribution involves large corporations managing their own dedicated sales forces supplying major supermarkets (Supermarkets and Hypermarkets) and bulk institutional buyers. Indirect distribution is dominated by e-commerce and subscription services, which are particularly effective for this product category due to their high density and ease of recurring shipment. Online retail penetration is rapidly increasing because consumers often seek out specialized, eco-friendly brands that leverage the DTC model for transparency and personalized service. The critical difference between direct and indirect channels is often the emphasis: indirect channels capitalize on the convenience factor (subscription, personalized delivery), while direct channels leverage massive shelf presence and impulse purchasing. The entire value chain is characterized by a high degree of integration between product formulation chemistry and packaging engineering to ensure both safety and consumer experience.

Shampoo Capsule and Dissolvable Laundry Condensate Beads Market Potential Customers

The core customer base for the Shampoo Capsule and Dissolvable Laundry Condensate Beads Market is broadly segmented into two primary groups: environmentally conscious, affluent consumers seeking sustainable lifestyle solutions, and convenience-driven urban dwellers and professionals valuing efficiency and space-saving products. Within the personal care segment (shampoo capsules), key end-users include frequent travelers, hotel chains aiming for sustainable and hygienic amenity offerings, and gym users who appreciate the leak-proof, single-use format. These customers prioritize product efficacy, aesthetic design, and clear environmental benefits, often being willing to pay a premium for certified biodegradable or zero-waste products that align with their ethical consumption values, driving the expansion of niche, high-value specialty brands.

For the dissolvable laundry condensate beads, the target audience is significantly larger, encompassing virtually all households with automatic washing machines. However, the most commercially important segment consists of young families and high-efficiency (HE) washing machine owners. Young families prioritize the child-safety features embedded in the packaging and the simplicity of pre-dosed measurements, which eliminate chemical handling risks. Owners of HE machines are crucial because these machines require low-sudsing, highly concentrated detergents to function optimally, a specification perfectly met by condensate beads. Furthermore, institutional buyers—including large commercial laundry facilities, hospitals requiring strict chemical protocols, and hotel chains seeking volume efficiency—represent a stable and high-volume segment that values consistent performance and simplified inventory management enabled by uniform dosing.

The market is also increasingly targeting renters and residents of smaller urban apartments where minimizing clutter and maximizing storage space is essential. The compact nature of both capsules and beads directly addresses this pain point, positioning them as essential modern household items. Future potential lies in expanding outreach to specialized industrial sectors that utilize high-capacity, automated cleaning systems, where the precision and measured control offered by concentrated beads can significantly reduce operational errors and chemical costs. The convergence of sustainability mandates, urban densification, and rising disposable income levels ensures a continuously expanding, diverse customer base spanning both premium specialty and mass market segments, provided that price parity relative to traditional liquids can be achieved through manufacturing scale efficiencies.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 5.8 Billion |

| Market Forecast in 2033 | USD 13.5 Billion |

| Growth Rate | 12.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Procter & Gamble (P&G), Unilever PLC, Henkel AG & Co. KGaA, S. C. Johnson & Son, Inc., Reckitt Benckiser Group PLC, Mitsubishi Chemical Corporation, KURARAY CO. LTD., MonoSol (LegoChem Biosciences), Amway Corporation, Blueland, Dropps, Method Products (Ecover), PUREOLOGY, Ethique, KAO Corporation, Colgate-Palmolive Company, The Clorox Company, Church & Dwight Co., Inc., The Honest Company, Melaleuca. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Shampoo Capsule and Dissolvable Laundry Condensate Beads Market Key Technology Landscape

The technological core of the Shampoo Capsule and Dissolvable Laundry Condensate Beads Market lies in specialized polymer science, particularly centered around Polyvinyl Alcohol (PVA) and its advanced derivatives, which form the film material. PVA is favored for its excellent water solubility, film-forming capability, and non-toxicity, yet continuous innovation is required to overcome its major weakness: sensitivity to moisture and temperature variation. Key advancements involve modifying PVA films to achieve multi-layer structures that offer improved barrier properties against humidity during storage while maintaining rapid dissolution kinetics in cold water. Researchers are also heavily focused on incorporating bio-based polymers, such as modified starch or cellulose derivatives, to improve the ultimate biodegradability profile of the capsules, addressing consumer concerns about PVA’s persistence in certain wastewater treatment scenarios. Furthermore, the development of precise dosing technologies, often utilizing advanced liquid handling and sealed-chamber equipment, ensures the accurate filling of highly concentrated, chemically sensitive ingredients within the films.

In addition to film technology, the formulation chemistry within the capsules and beads represents another critical technological frontier. Modern detergent beads utilize highly concentrated surfactant systems, sequestering agents, and enzymes optimized for low water volumes typical of high-efficiency washing machines. Multi-chamber pod technology is a major technical achievement, allowing incompatible ingredients—such as bleach activators and enzymes—to be isolated until contact with water, maximizing their efficacy and preventing premature degradation. This requires specialized sealing techniques and polymer chemistry that dictates the sequential dissolution rates of the different chambers. For shampoo capsules, the focus is on microencapsulation of active hair care ingredients (e.g., vitamins, essential oils) within the formulation itself, ensuring their stability and controlled release upon washing, maximizing consumer perceived benefits.

Manufacturing process technology is also rapidly evolving, driven by the need for higher throughput and better quality control. High-speed thermoforming and rotary vacuum forming are standard methods, but specialized high-precision Form-Fill-Seal (FFS) machines are increasingly incorporating automated visual inspection systems (often AI-enhanced) to verify seal integrity and dosing accuracy at speeds necessary for mass market production. The implementation of robust moisture control and humidity regulation systems within manufacturing environments is non-negotiable, given the hygroscopic nature of the PVA film. Furthermore, the development of compliant child-resistant closures (CRCs) for the outer packaging, utilizing materials that meet stringent global safety standards while remaining cost-effective for high-volume consumer goods, is an ongoing engineering challenge critical to market acceptance and regulatory clearance. The convergence of material science, process automation, and formulation innovation defines the competitive landscape.

Regional Highlights

- North America: This region holds a significant market share, driven by high consumer adoption of convenience products and the established presence of major FMCG market leaders like P&G and Henkel. Market growth is robust, largely fueled by strong household penetration of laundry pods and a rapidly developing market for premium, eco-friendly shampoo capsules sold through DTC subscription models. Stringent regulations regarding child-safe packaging for laundry detergents necessitate continuous innovation in packaging design.

- Europe: Characterized by the most aggressive regulatory environment promoting sustainability and plastic reduction (e.g., the EU Packaging and Packaging Waste Regulation), Europe is a pivotal region. The emphasis here is heavily on certified biodegradability and zero-waste claims, pushing manufacturers to invest in non-PVA or fully compostable polymer alternatives. Germany, the UK, and France are the key revenue drivers, showing high acceptance of concentrated products across both personal care and laundry segments.

- Asia Pacific (APAC): Projected to be the fastest-growing region, APAC is driven by rapid urbanization, increasing disposable incomes, and the preference for space-saving products in dense cities like Shanghai, Mumbai, and Tokyo. While price sensitivity remains a factor, the shift towards branded, convenient cleaning solutions is accelerating. Local manufacturing hubs in China and India are crucial, both for domestic supply and global export, necessitating investments in scalable, cost-effective encapsulation technology adapted to regional humidity levels.

- Latin America (LATAM): This is an emerging market where growth is concentrated in economically stable countries like Brazil and Mexico. The market penetration of laundry beads is gradually increasing, often positioning them as premium or high-efficacy products. Challenges include navigating complex distribution networks and competing against well-established, lower-cost traditional liquid detergent brands, requiring focused consumer education on the long-term value of concentrated formats.

- Middle East and Africa (MEA): Currently the smallest but showing potential in urbanized centers, particularly in the UAE and Saudi Arabia. Market uptake is generally limited to premium imported brands focusing on the high-end consumer segment and the hospitality sector. Future growth is dependent on improved logistics infrastructure and alignment with governmental sustainability initiatives that are still in early phases of development.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Shampoo Capsule and Dissolvable Laundry Condensate Beads Market.- Procter & Gamble (P&G)

- Unilever PLC

- Henkel AG & Co. KGaA

- S. C. Johnson & Son, Inc.

- Reckitt Benckiser Group PLC

- Mitsubishi Chemical Corporation

- KURARAY CO. LTD.

- MonoSol (A division of Kuraray)

- Amway Corporation

- Blueland

- Dropps

- Method Products (Ecover)

- PUREOLOGY (L'Oréal Group)

- Ethique

- KAO Corporation

- Colgate-Palmolive Company

- The Clorox Company

- Church & Dwight Co., Inc.

- The Honest Company

- Melaleuca

Frequently Asked Questions

Analyze common user questions about the Shampoo Capsule and Dissolvable Laundry Condensate Beads market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary material used for dissolvable packaging and is it truly biodegradable?

The primary material is Polyvinyl Alcohol (PVA), a synthetic polymer that is water-soluble. While PVA dissolves readily in water and is generally considered biodegradable under aerobic conditions in modern wastewater treatment plants, its ultimate environmental fate and degradation rate are subject to ongoing research and debate, driving innovation towards bio-based alternatives.

How do Shampoo Capsules and Laundry Condensate Beads contribute to sustainability?

These concentrated formats significantly reduce plastic waste by eliminating the need for bulky traditional bottles. They also minimize the carbon footprint associated with transportation, as they are lightweight and compact, requiring less fuel and storage space throughout the supply chain compared to transporting diluted liquid products.

Are dissolvable laundry beads safe, particularly concerning child ingestion risks?

Manufacturers adhere to strict regulatory standards, incorporating child-resistant outer packaging and specialized bitterants on the film surface. These measures are mandated by regulatory bodies globally to deter accidental ingestion of the highly concentrated chemicals, which pose a safety risk if consumed.

What are the main advantages of using concentrated capsules over traditional liquid detergents?

The main advantages include convenience due to pre-measured dosing, prevention of product spillage or overuse, superior cleaning efficacy in high-efficiency (HE) machines, and significantly reduced plastic packaging and storage space requirements, aligning with modern consumer preferences for efficiency.

Which geographical region is expected to show the highest growth rate for this market?

The Asia Pacific (APAC) region is projected to register the highest Compound Annual Growth Rate (CAGR). This acceleration is driven by rapid urbanization, increasing middle-class disposable income, and growing consumer awareness regarding sustainable and space-efficient household solutions across key markets like China and India.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager