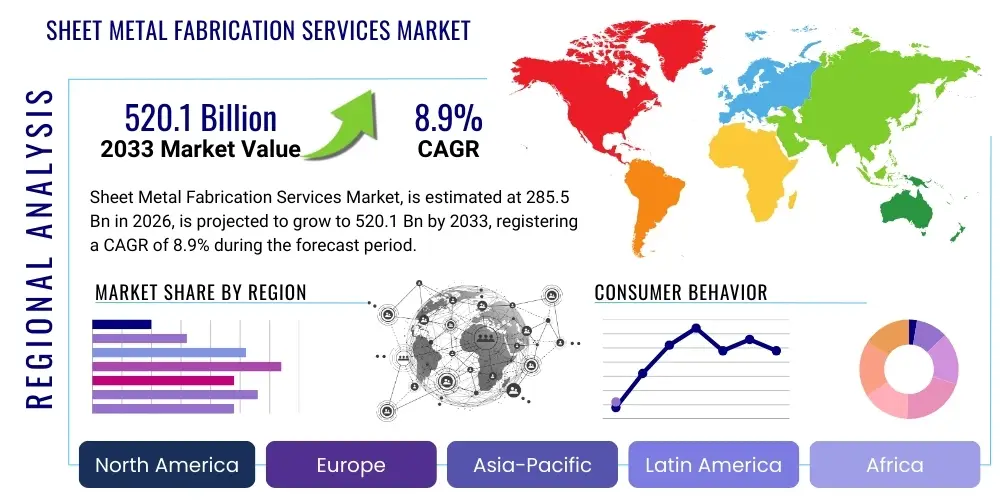

Sheet Metal Fabrication Services Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439450 | Date : Jan, 2026 | Pages : 258 | Region : Global | Publisher : MRU

Sheet Metal Fabrication Services Market Size

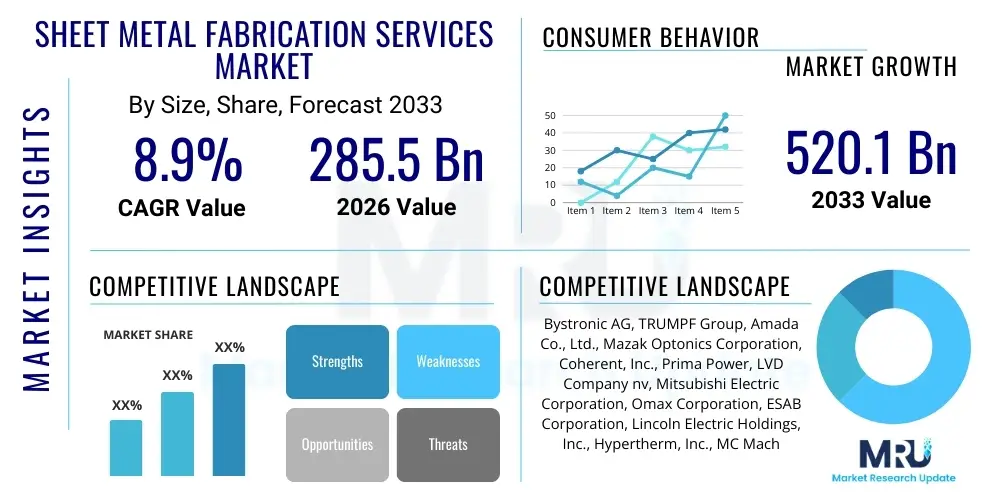

The Sheet Metal Fabrication Services Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.9% between 2026 and 2033. This robust growth trajectory underscores the increasing reliance of diverse industries on specialized metal processing capabilities for advanced manufacturing. The market is estimated at USD 285.5 Billion in 2026, reflecting its substantial current footprint and critical role in global industrial production. By the end of the forecast period in 2033, the market is projected to reach an impressive USD 520.1 Billion, driven by consistent innovation, expanding applications, and burgeoning industrial output across both developed and emerging economies. This significant expansion highlights the sustained demand for high-precision, custom-fabricated metal components essential for a wide array of end-use sectors, ranging from automotive and aerospace to construction and electronics, signifying a dynamic and evolving market landscape.

Sheet Metal Fabrication Services Market introduction

The Sheet Metal Fabrication Services Market encompasses a wide array of specialized processes that transform flat metal sheets into precision-engineered components and intricate structures. These indispensable services, foundational to modern manufacturing, involve a sequence of operations including precise cutting, versatile bending, complex forming, and robust assembly. From initial design to final finishing, fabrication services deliver custom metal solutions meeting the exacting specifications of various industries. The intrinsic value of sheet metal fabrication lies in its ability to produce highly durable, strong, and customizable parts from diverse metal alloys, ensuring structural integrity and functional performance. This market’s continuous evolution is critical for supporting global industrial output, facilitating technological innovation, and responding to dynamic shifts in product design and material science demands.

At the core of sheet metal fabrication lies a diverse suite of advanced techniques, including sophisticated laser, plasma, and waterjet cutting, along with precise shearing. Forming operations leverage powerful press brakes for acute bends, roll bending for curved profiles, and stamping or deep drawing for complex three-dimensional shapes. Joining processes employ various welding methods such as MIG/MAG, TIG, spot, and laser welding, ensuring strong, clean, and durable bonds. Post-fabrication services often include grinding, polishing, coating, and assembly to deliver a complete, ready-to-integrate product. These comprehensive capabilities enable the production of components ranging from intricate chassis and protective enclosures for electronics, to robust structural elements for construction, lightweight body panels for automotive and aerospace, and precision parts for sophisticated medical devices and industrial machinery.

The profound benefits of professional sheet metal fabrication services are multifaceted, extending from significant cost efficiencies through optimized material utilization and minimized waste, to accelerated product development facilitated by rapid prototyping and efficient mass production. Inherent customizability allows for tailored solutions that perfectly match unique project requirements, ensuring optimal performance and aesthetic integration. Moreover, these services produce components exhibiting exceptional strength-to-weight ratios and high resistance to environmental stressors, contributing to product longevity. Market growth is primarily propelled by persistent global industrialization, particularly in emerging economies, coupled with escalating worldwide demand for bespoke, high-performance, and technologically advanced metal components that meet stringent industry standards and design complexities across critical sectors.

Sheet Metal Fabrication Services Market Executive Summary

The executive summary highlights the dynamic landscape of the Sheet Metal Fabrication Services Market, characterized by robust growth driven by accelerating industrial output, advancements in automation, and strong global demand for custom metal components. Business trends are centered on the adoption of Industry 4.0 technologies, including robotics, IoT, and advanced analytics, which enhance operational efficiencies, improve precision, and enable more complex designs. Manufacturers are investing in sophisticated CNC machinery and integrated software to streamline production, reduce lead times, and optimize material utilization. Sustainability initiatives are influencing material choices and process optimizations, with a growing emphasis on waste reduction and energy efficiency in fabrication operations, signaling a shift towards more environmentally responsible practices.

Regional trends indicate significant expansion in Asia Pacific, propelled by large-scale infrastructure projects, burgeoning automotive production, and a rapidly expanding electronics manufacturing base. North America and Europe maintain strong market presence, driven by high-value aerospace and defense sectors, mature industrial bases, and a focus on advanced manufacturing techniques. These regions also lead in the adoption of automation and digitalization. Emerging markets in Latin America and the Middle East & Africa are witnessing steady growth, spurred by diversification efforts, urbanization, and increasing investments in industrial and energy sectors, creating new demand avenues for sophisticated sheet metal solutions, contributing to global market resilience.

Segmentation trends reveal a strong inclination towards advanced processing techniques such as laser cutting, precision CNC machining, and robotic welding, driven by the need for higher precision, faster turnaround, and consistent quality. Materials like stainless steel and aluminum continue to dominate due to versatile properties and broad application, with demand for lightweight materials growing in automotive and aerospace. End-use industries such as automotive, aerospace, and construction remain primary consumers, continuously pushing boundaries for innovative, durable, and cost-effective fabricated parts. The market also observes a shift towards integrated service offerings, where fabrication companies provide end-to-end solutions from design to final assembly, catering to the comprehensive needs of diverse clientele.

AI Impact Analysis on Sheet Metal Fabrication Services Market

The integration of Artificial Intelligence (AI) into the Sheet Metal Fabrication Services Market represents a transformative force, directly addressing and often exceeding common user expectations regarding enhanced efficiency, accuracy, and operational intelligence. Users frequently inquire about how AI can strategically optimize design processes, minimize material waste, accurately predict equipment failures, automate quality control, and streamline complex production schedules. While initial concerns often gravitate towards upfront investment costs, the requirement for specialized skills to manage AI systems, and potential impacts on workforce dynamics, the overwhelming consensus projects a future where AI will unlock unprecedented levels of precision, accelerate production speeds, and enable highly sophisticated customization capabilities. Successful adoption of these cutting-edge AI technologies is expected to lead to significant cost reductions, improved resource utilization, and a robust competitive advantage for fabrication service providers.

- Enhanced Design and Prototyping: AI algorithms use generative design to optimize part geometries for strength, weight, and material usage, reducing design iterations, accelerating prototyping, and enabling intricate components otherwise unfeasible.

- Advanced Predictive Maintenance: AI-driven analytics monitor machine performance in real-time, predicting potential failures of CNC machines, laser cutters, and press brakes. This minimizes unscheduled downtime, extends equipment lifespan, and optimizes maintenance schedules.

- Automated Quality Control: AI-powered vision systems detect microscopic defects, dimensional inaccuracies, and surface imperfections with high precision and speed, surpassing human capabilities. This ensures consistent quality and significantly reduces costly reworks or product recalls.

- Optimized Production Efficiency: AI analyzes vast production datasets to optimize cutting paths, bending sequences, and welding parameters. This leads to substantial reductions in cycle times, lower energy consumption, and minimized material scrap, fostering lean and sustainable production.

- Intelligent Supply Chain Management: AI-powered tools enhance inventory forecasting, demand prediction, and logistics. This ensures timely procurement of raw materials, minimizes stockouts, guarantees efficient delivery, and mitigates disruptions, fostering resilience.

- Integration with Robotics and Automation: AI provides intelligence for sophisticated robotic systems, enabling adaptive performance in material handling, welding, and assembly. This increases throughput, consistency, and worker safety by delegating hazardous or repetitive tasks.

DRO & Impact Forces Of Sheet Metal Fabrication Services Market

The Sheet Metal Fabrication Services Market operates within a dynamic environment significantly influenced by a complex interplay of Drivers, Restraints, Opportunities (DRO), and broader external Impact Forces. Key drivers include escalating demand from diverse end-use industries like automotive, aerospace, construction, and electronics, all requiring precise and durable metal components. This demand is amplified by continuous technological advancements in manufacturing, including widespread adoption of automation and advanced CNC machinery, enhancing efficiency, accuracy, and production capabilities. The growing imperative for customization and rapid prototyping across industries further fuels demand for flexible and responsive fabrication services, delivering bespoke solutions with reduced lead times and unparalleled precision.

However, the market's growth momentum is tempered by several significant restraints. A primary obstacle is the substantial capital investment required for acquiring and maintaining state-of-the-art fabrication equipment, which can be prohibitive for smaller enterprises. Another critical restraint is the persistent shortage of skilled labor—experienced welders, machine operators, and CAD/CAM specialists—essential for sophisticated machinery. Volatility in raw material prices, particularly for metals like steel and aluminum, directly impacts production costs and profit margins, creating financial uncertainty. Additionally, navigating intricate regulatory complexities and adhering to increasingly stringent environmental compliance standards adds layers of cost and operational burden.

Despite these challenges, numerous promising opportunities exist for substantial expansion and innovation. The integration of additive manufacturing (3D printing) with traditional fabrication pioneers new avenues for hybrid processes, enabling intricate designs and prototypes previously unachievable. Industry 4.0 initiatives, encompassing IoT, AI, and big data analytics, present unparalleled opportunities for dramatic operational efficiencies, predictive maintenance, and smart factory environments. Furthermore, escalating global demand for lightweight and high-strength materials, especially in automotive and aerospace, encourages R&D into novel alloys and fabrication techniques. Extensive infrastructure development projects in emerging economies globally represent vast untapped market potential for advanced sheet metal fabrication services.

Segmentation Analysis

The Sheet Metal Fabrication Services Market is meticulously segmented to provide a granular understanding of its diverse components, catering to varied industrial requirements and technological applications. This detailed segmentation allows stakeholders to analyze market dynamics based on the specific type of service offered, the materials utilized, the end-use industries served, and the underlying fabrication processes employed. Such an intricate breakdown helps in identifying niche markets, understanding competitive landscapes, and formulating targeted strategies for growth and innovation within this multifaceted industry. This approach ensures market players can tailor offerings, optimize resource allocation, and anticipate future trends, driving informed business decisions and fostering a responsive market environment.

- By Type: Categorizes services by primary operation.

- Cutting: Processes for separating parts.

- Laser Cutting: High-precision, intricate cuts with minimal deformation.

- Plasma Cutting: Fast cutting of thicker, electrically conductive metals.

- Waterjet Cutting: Clean cuts on heat-sensitive materials and thicker sheets.

- Shearing: Mechanical straight-line cuts for flat parts.

- Bending: Forming metal along a linear axis.

- Press Brake Bending: Precisely bends sheets to specific angles.

- Roll Bending: Forms metal into cylindrical or conical shapes.

- Forming: Changes metal shape without material removal.

- Stamping: Uses die and press for high-volume, complex parts.

- Deep Drawing: Creates 3D hollow shapes from flat sheets.

- Welding: Joins metal pieces permanently.

- MIG/MAG Welding: Versatile, fast, and easy for various metals.

- TIG Welding: High-quality, precise welds for thin materials and superior finish.

- Spot Welding: Resistance method for joining overlapping sheets.

- Laser Welding: Concentrated laser beam for strong, narrow welds with minimal distortion.

- Finishing: Post-fabrication treatments for surface quality or function.

- Grinding: Removes excess material, smooths edges.

- Polishing: Achieves smooth, reflective surface.

- Coating: Applies protective or decorative layers (e.g., powder coating).

- Deburring: Removes sharp edges for safety and integrity.

- Assembly: Joining multiple fabricated components into sub-assemblies or finished products.

- Cutting: Processes for separating parts.

- By Material: Classifies services by metal type.

- Steel: Fundamental material, high strength, versatile.

- Stainless Steel: Corrosion resistance, aesthetic appeal.

- Carbon Steel: Cost-effective, general structural applications.

- Alloy Steel: Enhanced strength, hardness, or corrosion resistance.

- Aluminum: Lightweight, corrosion-resistant, ductile; aerospace, automotive.

- Copper: Excellent electrical/thermal conductivity; electrical, heat exchangers.

- Brass: Workability, corrosion resistance; decorative, electrical fittings.

- Titanium: Exceptional strength-to-weight, corrosion resistance; aerospace, medical.

- Others: Specialized metals (e.g., Galvanized Iron, Nickel Alloys) for specific applications.

- Steel: Fundamental material, high strength, versatile.

- By End-Use Industry: Market based on primary sector utilizing components.

- Automotive: Vehicle bodies, chassis, engines, interiors; EV growth.

- Aerospace & Defense: High-precision, lightweight components; aircraft, defense systems.

- Construction: Structural elements, roofing, facades, HVAC; commercial, residential.

- Electronics & Electrical: Enclosures, brackets, chassis; protecting sensitive components.

- Industrial Machinery: Components for heavy equipment, agricultural machinery; robustness.

- Medical Devices: Precision parts for diagnostic equipment, surgical tools; biocompatible.

- Energy: Components for power generation, pipelines, solar/wind structures.

- Consumer Goods: Parts for appliances, furniture; aesthetics, function.

- Telecommunications: Enclosures for network equipment, server racks.

- Agriculture: Farming machinery, storage, irrigation.

- Mining: Robust components for heavy-duty equipment.

- Others: Marine, railway, artistic installations, custom projects.

- By Process: Focuses on the specific manufacturing method.

- CNC Machining: Automated, precise cutting, drilling, shaping.

- Punching: Rapidly creates holes or shapes using a punch press.

- Stamping: High-volume forming using dies.

- Welding: Various methods for permanent metal joining.

- Shearing: Mechanical cutting of flat metal along a straight line.

- Bending: Forming metal along an axis with tools like press brakes.

- Roll Forming: Continuous bending of metal strip into profile.

- Hydroforming: Uses hydraulic fluid for complex shapes, fewer parts.

- Spinning: Rotating sheet metal disc shaped over a mandrel.

- Prototyping: Creation of initial models for testing and validation.

- Others: Laser engraving, etching, specialized assembly.

Value Chain Analysis For Sheet Metal Fabrication Services Market

A comprehensive value chain analysis for the Sheet Metal Fabrication Services Market details the entire journey from raw material sourcing to final product integration, identifying critical activities and key participants. The upstream segment involves procurement of essential raw materials and specialized machinery. Raw material suppliers provide diverse metal sheets (steel, aluminum, copper, alloys), crucial inputs whose quality, availability, and cost profoundly impact downstream operations. Equipment manufacturers, another vital upstream component, supply advanced CNC machines, laser cutters, press brakes, and welding robots. Innovations in this segment, such as more efficient and precise machinery, directly impact the capabilities and competitive edge of fabrication service providers, enabling enhanced productivity and quality.

The core of the value chain is occupied by fabrication service providers, who transform raw metal sheets into finished or semi-finished components. This stage encompasses design, engineering, cutting, bending, forming, welding, and finishing processes, often leveraging sophisticated CAD/CAM software and automated systems. After fabrication, components may undergo further assembly, quality inspection, and packaging. The downstream segment involves end-use industries that integrate these fabricated components into their final products, such as automotive, aerospace, construction, and electronics manufacturers. Efficient logistics and robust supply chain management are paramount to ensure timely delivery and seamless integration into these complex manufacturing pipelines, maintaining project timelines and operational flow.

Distribution channels in the sheet metal fabrication market include both direct and indirect models. Direct distribution involves fabrication companies engaging directly with end-use customers, often through dedicated sales teams and long-term contracts for custom orders. This fosters strong client relationships and tailored solutions. Indirect distribution may involve working with intermediaries such as industrial distributors, brokers, or large-scale procurement platforms, particularly for standardized parts or broader customer reach. The choice of distribution channel depends on the complexity of parts, order volume, geographical reach, and strategic objectives, ensuring efficient product delivery to diverse customers while optimizing market access.

Sheet Metal Fabrication Services Market Potential Customers

The Sheet Metal Fabrication Services Market serves a broad and diverse customer base across nearly every industrial sector, reflecting the ubiquitous need for custom metal components. Potential customers encompass multinational corporations, small and medium-sized enterprises (SMEs), and individual entrepreneurs requiring specialized parts. The automotive industry stands as a cornerstone, demanding fabricated parts for vehicle chassis, body panels, engine components, and interior structures, driven by evolving design trends, safety standards, and the transition to electric vehicles. The aerospace and defense sectors are also critical customers, requiring extremely precise, lightweight, and high-strength components for aircraft frames, missile systems, and specialized equipment, where quality and reliability are paramount.

The construction industry is another significant end-user, utilizing fabricated sheet metal for roofing, structural elements, facades, HVAC systems, and architectural features in both commercial and residential projects. The electronics and electrical industries rely heavily on sheet metal fabrication for enclosures, chassis, brackets, and cabinets that house sensitive electronic components, providing protection and aesthetic appeal. In the industrial machinery sector, fabricated parts are essential for manufacturing equipment, agricultural machinery, and various heavy-duty industrial applications, where robust and durable components are crucial for operational longevity and performance under demanding conditions.

Beyond these major sectors, the medical devices industry is an increasingly important customer, demanding precision-fabricated enclosures for diagnostic equipment, surgical tools, and patient care systems, often requiring biocompatible materials and sterile finishes. The energy sector, including traditional oil and gas as well as renewable energy, requires fabricated parts for power generation equipment, pipelines, and structural supports. Furthermore, consumer goods manufacturers, telecommunications companies, and even artistic and custom design markets represent valuable customer segments, underscoring the universal applicability and essential nature of sheet metal fabrication services across the modern industrial landscape.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 285.5 Billion |

| Market Forecast in 2033 | USD 520.1 Billion |

| Growth Rate | 8.9% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Bystronic AG, TRUMPF Group, Amada Co., Ltd., Mazak Optonics Corporation, Coherent, Inc., Prima Power, LVD Company nv, Mitsubishi Electric Corporation, Omax Corporation, ESAB Corporation, Lincoln Electric Holdings, Inc., Hypertherm, Inc., MC Machinery Systems, Salvagnini Group, Accurpress, Haas Automation, Inc., FANUC Corporation, Yaskawa Electric Corporation, KUKA AG, ABB Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Sheet Metal Fabrication Services Market Key Technology Landscape

The Sheet Metal Fabrication Services Market is characterized by a rapidly evolving technological landscape, driven by the relentless pursuit of higher precision, greater efficiency, increased automation, and enhanced material utilization. At the forefront are Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software suites, indispensable for designing complex parts, optimizing nesting patterns, and generating machine-readable instructions. These digital tools ensure seamless integration from design concept to final production, minimizing errors and accelerating the product development cycle. The widespread adoption of CNC (Computer Numerical Control) machining across various processes, including laser cutting, plasma cutting, punching, and bending, forms the backbone of modern fabrication, enabling highly repeatable and accurate operations with minimal human intervention.

Advanced cutting technologies, such as high-power fiber lasers, offer unparalleled speed and precision for intricate cuts across a wide range of metal thicknesses. Waterjet cutting provides a versatile solution for heat-sensitive materials and thicker sheets, while plasma cutting remains cost-effective for conductive metals. In forming and bending, sophisticated press brakes with multiple axes and robotic loading/unloading systems enhance productivity and safety. Robotic welding systems, often integrated with vision systems, provide consistent, high-quality welds, particularly for repetitive tasks and large production volumes, reducing labor costs and improving weld integrity. These technologies collectively contribute to faster turnaround times and superior product quality, meeting stringent demands.

Beyond core fabrication machinery, the market increasingly leverages the Internet of Things (IoT) for real-time monitoring of machine performance, predictive maintenance, and overall factory floor optimization. IoT sensors collect data on machine uptime, material flow, and energy consumption, which is analyzed to identify bottlenecks and improve efficiency. Additive manufacturing (3D printing) is also emerging as a complementary technology for rapid prototyping and complex geometries. Furthermore, artificial intelligence (AI) and machine learning (ML) algorithms are being deployed for process optimization, quality control, and generative design, pushing the boundaries of sheet metal fabrication and ushering in an era of smart, interconnected manufacturing facilities.

Regional Highlights

- North America: This region is characterized by a mature industrial base and significant demand from the automotive, aerospace, and defense sectors. High adoption rates of advanced manufacturing technologies, including automation and digital fabrication, drive market growth. A strong emphasis on innovation and high-value manufacturing keeps the region at the forefront of specialized sheet metal fabrication solutions.

- Europe: Europe represents a robust market, propelled by its strong automotive industry, precision engineering capabilities, and a growing focus on renewable energy projects. Countries like Germany, Italy, and France are key players, investing heavily in smart factory initiatives and sustainable fabrication practices. Strict regulatory standards often necessitate advanced and efficient fabrication solutions.

- Asia Pacific (APAC): APAC is projected to be the fastest-growing region, driven by rapid industrialization, urbanization, and large-scale infrastructure development, particularly in China, India, and Southeast Asian countries. The presence of a vast manufacturing base, increasing foreign direct investment, and a burgeoning electronics industry fuel the demand for diverse sheet metal fabrication services.

- Latin America: The market in Latin America is experiencing steady growth, supported by investments in automotive manufacturing, infrastructure development, and the expansion of industrial sectors in countries like Brazil and Mexico. Economic stabilization and increasing industrial output are creating new opportunities for fabrication service providers to establish or expand their presence.

- Middle East and Africa (MEA): This region is witnessing growth spurred by economic diversification efforts, significant investments in construction and infrastructure projects (e.g., Saudi Arabia's Vision 2030), and expanding oil and gas industries. A rising demand for advanced fabrication services to bolster local manufacturing capabilities and reduce import reliance is a key underlying trend.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Sheet Metal Fabrication Services Market.- Bystronic AG

- TRUMPF Group

- Amada Co., Ltd.

- Mazak Optonics Corporation

- Coherent, Inc.

- Prima Power

- LVD Company nv

- Mitsubishi Electric Corporation

- Omax Corporation

- ESAB Corporation

- Lincoln Electric Holdings, Inc.

- Hypertherm, Inc.

- MC Machinery Systems

- Salvagnini Group

- Accurpress

- Haas Automation, Inc.

- FANUC Corporation

- Yaskawa Electric Corporation

- KUKA AG

- ABB Ltd.

Frequently Asked Questions

Analyze common user questions about the Sheet Metal Fabrication Services market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary drivers for growth in the Sheet Metal Fabrication Services Market?

The market is primarily driven by escalating demand from diverse end-use industries like automotive, aerospace, and construction, coupled with continuous technological advancements in manufacturing processes and the increasing adoption of automation and robotics to enhance precision and efficiency across the industry.

How is AI impacting the sheet metal fabrication industry?

AI is profoundly transforming the industry by enabling enhanced design optimization, predictive maintenance for machinery, automated quality control, and streamlined process optimization. It also supports more intelligent robotics, contributing to higher precision, reduced waste, and improved overall operational intelligence and competitiveness for fabrication service providers.

What are the major challenges faced by sheet metal fabrication service providers?

Key challenges include high initial capital investment for advanced machinery, a persistent shortage of skilled labor, volatility in raw material prices, and the need to comply with evolving environmental and safety regulations. These factors can impact profitability, operational scalability, and market entry for new players.

Which regions are leading in the adoption of sheet metal fabrication services?

The Asia Pacific region is currently experiencing the fastest growth due to rapid industrialization and manufacturing expansion. North America and Europe maintain strong market shares, driven by established industries and significant investment in advanced manufacturing technologies, particularly in high-value sectors like aerospace and defense.

What are the emerging technologies shaping the future of sheet metal fabrication?

Emerging technologies include advanced fiber laser systems, integrated robotic automation, the Internet of Things (IoT) for real-time monitoring, AI/ML for process optimization and generative design, and the increasing integration of additive manufacturing (3D printing) for hybrid fabrication solutions, all contributing to a smarter, more efficient industry.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager