Ship Unloaders Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 432605 | Date : Dec, 2025 | Pages : 249 | Region : Global | Publisher : MRU

Ship Unloaders Market Size

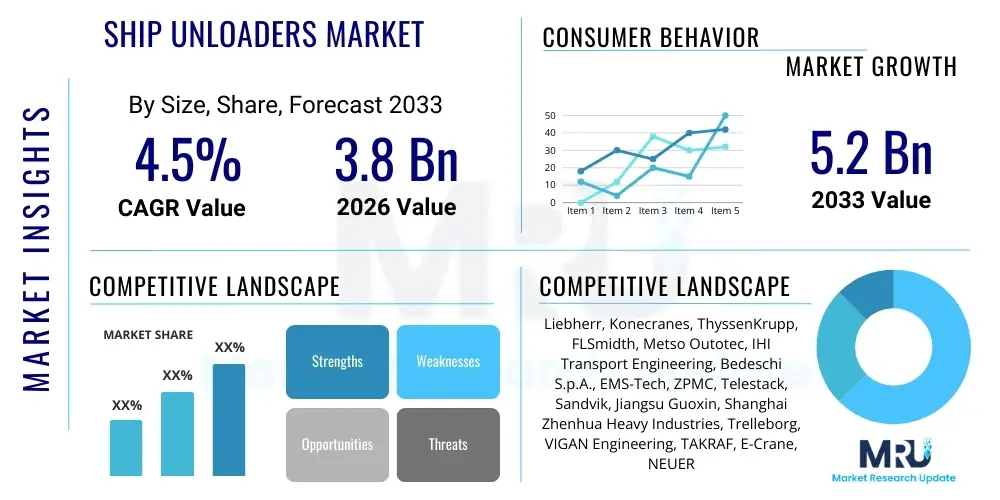

The Ship Unloaders Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.5% between 2026 and 2033. The market is estimated at USD 3.8 Billion in 2026 and is projected to reach USD 5.2 Billion by the end of the forecast period in 2033.

Ship Unloaders Market introduction

The Ship Unloaders Market encompasses highly specialized, heavy-duty machinery designed for the efficient, safe, and high-volume transfer of bulk and general cargo from maritime vessels to shore storage facilities or connecting transport systems. These systems are crucial components of modern port infrastructure, directly impacting global trade efficiency, logistics throughput, and material handling costs across various industries. Product descriptions primarily include Continuous Ship Unloaders (CSU), which use conveyors, bucket elevators, or screw mechanisms, and intermittent Grab Ship Unloaders (GSU), which utilize cable-operated or hydraulic grabs.

Major applications of ship unloaders span critical sectors, predominantly focused on handling bulk commodities such as iron ore, coal, grains, fertilizers, cement, and specialized mineral concentrates. The increasing global demand for energy resources and agricultural products drives the necessity for faster turnaround times at ports. Ship unloaders provide significant benefits, including reducing labor intensity, minimizing dust pollution (especially modern CSUs), improving operational safety through automation, and dramatically increasing the hourly unloading capacity compared to traditional methods, thereby optimizing vessel utilization.

Key driving factors accelerating market growth include rapid expansion and modernization of global port facilities, particularly in Asia Pacific; the growing size of bulk carrier vessels (Capesize and Valemax), necessitating larger and higher-capacity unloading equipment; and stringent environmental regulations promoting the adoption of enclosed, low-dust, and energy-efficient Continuous Ship Unloaders (CSU) over traditional Grab Ship Unloaders (GSU).

Ship Unloaders Market Executive Summary

The Ship Unloaders Market is characterized by strong regional differentiation and a persistent shift toward automated, environmentally compliant technology. Current business trends indicate heavy investment in high-capacity equipment capable of handling Ultra Large Ore Carriers (ULOCs) and similar mega-vessels, driving demand for rail-mounted gantry systems and specialized continuous unloaders. Consolidation among major original equipment manufacturers (OEMs) focusing on integrating smart sensors, predictive maintenance, and remote operation capabilities is also a defining trend, aiming to reduce total cost of ownership for port operators and bulk terminal managers.

Regionally, the Asia Pacific (APAC) dominates the market, fueled by massive infrastructure projects, industrial output, and high reliance on imported raw materials like iron ore and thermal coal, particularly in China and India. North America and Europe demonstrate mature markets, emphasizing retrofitting existing equipment with modern control systems and prioritizing eco-friendly solutions to comply with strict emission standards. Segments trends show that the Continuous Ship Unloaders (CSU) segment is experiencing faster growth than the Grab Ship Unloaders (GSU) segment due to superior efficiency and environmental performance, while the bulk cargo application segment, driven by metals and mining, remains the dominant revenue generator.

AI Impact Analysis on Ship Unloaders Market

User inquiries regarding AI's influence typically focus on how automation can improve operational throughput, reliability, and safety in heavy machinery environments. Common questions address the feasibility of fully autonomous ship unloading cycles, the role of machine learning in predictive maintenance (identifying component failures before they occur), and how computer vision can optimize grab trajectory and material flow detection in varied conditions. The key theme is the shift from remote-controlled operation toward intelligent, self-optimizing systems that reduce human error and maximize uptime. Concerns often revolve around the high initial capital investment required for AI integration and the necessity of skilled technicians capable of managing and troubleshooting complex software-driven machinery in harsh port environments.

- AI-driven optimization algorithms maximize unloading rates by dynamically adjusting trolley speeds, boom outreach, and grab patterns based on real-time ship hull geometry and cargo distribution.

- Predictive maintenance analytics, powered by machine learning (ML), utilize sensor data (vibration, temperature, power draw) to forecast equipment wear, drastically reducing unscheduled downtime and optimizing spare parts inventory management.

- Computer vision and sensor fusion enable highly accurate anti-collision systems and automated positioning, significantly enhancing safety during dense port operations and reducing structural damage risks.

- Autonomous operation capabilities allow unloaders to execute full cycles without human intervention, monitored remotely, thereby increasing operational efficiency, especially during overnight or low-staff periods.

- AI systems analyze environmental factors (wind, tide) and logistics bottlenecks (conveyor capacity, truck availability) to provide real-time suggestions for optimizing the terminal handling ecosystem.

DRO & Impact Forces Of Ship Unloaders Market

The dynamics of the Ship Unloaders Market are shaped by powerful factors driving demand, complex constraints limiting expansion, and lucrative opportunities emerging from technological evolution and regulatory changes. The primary drivers include the continuous growth in seaborne trade volumes, requiring faster port turnaround; the global trend toward larger vessel sizes, necessitating higher-capacity unloading systems; and supportive governmental investments in modernizing aging port infrastructure across emerging economies. These forces collectively push ports to adopt advanced, high-throughput unloading solutions to remain competitive on the global logistics stage.

Restraints, however, pose significant challenges to market proliferation. The high capital expenditure required for purchasing and installing heavy, complex ship unloader machinery acts as a barrier, particularly for smaller ports or terminals with limited funding. Furthermore, geopolitical instability and trade protectionism can introduce unpredictability in global commodity flows, leading port operators to postpone major equipment purchases. The intensive maintenance requirements and the need for highly specialized personnel to operate and service these complex mechanical, electrical, and control systems also constrain adoption rates in regions lacking sufficient technical expertise.

Opportunities for market players are substantial, stemming mainly from sustainability mandates and technological innovation. The transition toward green port initiatives is creating demand for electrically powered, dust-suppressing, and energy-regenerative Continuous Ship Unloaders (CSU), offering a niche for premium, high-tech solutions. The expanding application of robotics, Internet of Things (IoT), and digital twinning allows OEMs to offer sophisticated remote diagnostics, condition monitoring, and performance optimization services, transforming the revenue model from equipment sales alone to long-term service contracts, ensuring sustained growth and higher profit margins.

Segmentation Analysis

The Ship Unloaders Market segmentation is essential for understanding the varying needs of port operators, differentiating market dynamics based on operational efficiency, cargo type, and capacity. The market is primarily segmented by Unloader Type (Continuous Ship Unloaders vs. Grab Ship Unloaders), Operation Mode (Rail-Mounted vs. Rubber-Tired/Mobile), Cargo Type (Bulk vs. General), and Capacity. These segments reflect the technological maturity, specific commodity handled, and required throughput necessary for optimizing port logistics, heavily influenced by the size of the vessels serviced and local environmental regulations.

The dominance of bulk material handling, particularly for dry bulk commodities such as coal and iron ore, dictates the design requirements for capacity and durability. The ongoing regulatory pressure for environmental compliance favors Continuous Ship Unloaders (CSU), which offer enclosed material handling and superior dust control, impacting segment growth forecasts. Furthermore, geographical differences in port setup, ranging from dedicated dry bulk terminals to multi-purpose facilities, influence the choice between fixed, high-capacity rail-mounted units and more flexible, rubber-tired or mobile units.

- By Type

- Continuous Ship Unloaders (CSU)

- Grab Ship Unloaders (GSU)

- By Operation

- Rail-Mounted/Gantry

- Mobile/Rubber-Tired

- By Cargo Type

- Bulk Cargo (Coal, Iron Ore, Grain, Fertilizer, Cement)

- General Cargo (Limited Application)

- By Capacity (Tonnes per Hour - TPH)

- Low Capacity (< 1,000 TPH)

- Medium Capacity (1,000 - 3,000 TPH)

- High Capacity (> 3,000 TPH)

- By End User

- Port Authorities and Terminal Operators

- Power Generation Facilities (Coal Terminals)

- Mining and Metals Companies (Iron Ore Terminals)

- Agricultural Facilities (Grain Terminals)

Value Chain Analysis For Ship Unloaders Market

The value chain for Ship Unloaders is complex, beginning with upstream raw material suppliers and culminating in long-term maintenance and modernization services. Upstream analysis involves the procurement of high-grade steel, complex mechanical components (gearboxes, cables, bearings), specialized hydraulic systems, and sophisticated electrical and automation control systems. OEMs require strong relationships with specialized component manufacturers to ensure material quality, structural integrity, and reliability, crucial given the strenuous operating conditions of port machinery. Fluctuation in steel prices and supply chain reliability for specialized electronics often impacts the final manufacturing cost and lead times.

The manufacturing stage involves detailed engineering, precise fabrication of massive steel structures (booms, gantry frames), and complex assembly, often customized to specific port dimensions, tidal ranges, and vessel types. Distribution channels are typically direct, involving long-term contracts between the Original Equipment Manufacturers (OEMs) and the terminal operators or port authorities. Due to the high value and customized nature of the equipment, sales are usually consultative, incorporating site surveys, engineering design collaboration, and rigorous bidding processes, differentiating it significantly from standard industrial equipment sales.

Downstream activities are dominated by installation, commissioning, training, and, most critically, aftermarket services. The lifespan of a ship unloader often exceeds 30 years, making maintenance, spare parts supply, modernization, and control system upgrades highly lucrative long-term revenue streams for OEMs. Direct distribution ensures tight control over quality and installation, while indirect distribution may involve local agents or engineering firms specializing in installation and localized support, particularly in emerging markets. The shift toward digital services means remote diagnostics and condition monitoring are becoming integral parts of the downstream value proposition, enhancing equipment reliability and operator satisfaction.

Ship Unloaders Market Potential Customers

Potential customers for ship unloaders are organizations involved in large-scale logistics, commodity trading, and infrastructure management that require rapid and reliable material handling interfaces between maritime and land transport networks. These customers fall broadly into two main categories: governmental or municipal entities managing public ports and large private industrial corporations operating dedicated bulk terminals. Their purchase decisions are driven by throughput requirements, regulatory compliance, and optimization of vessel turnaround time, which directly impacts their profitability and global competitiveness.

Primary end-users include major international port authorities, which manage multi-purpose terminals handling diversified cargo, and private terminal operators specializing exclusively in specific commodities like iron ore (for mining giants) or grain (for agricultural corporations). Furthermore, utility companies operating large coal-fired power plants often maintain dedicated receiving terminals requiring high-capacity ship unloaders for continuous fuel supply. These buyers prioritize operational safety, longevity, and the availability of sophisticated automation features to minimize operational costs and maximize efficiency in their long-term infrastructure investments.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 3.8 Billion |

| Market Forecast in 2033 | USD 5.2 Billion |

| Growth Rate | 4.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Liebherr, Konecranes, ThyssenKrupp, FLSmidth, Metso Outotec, IHI Transport Engineering, Bedeschi S.p.A., EMS-Tech, ZPMC, Telestack, Sandvik, Jiangsu Guoxin, Shanghai Zhenhua Heavy Industries, Trelleborg, VIGAN Engineering, TAKRAF, E-Crane, NEUERO Industrietechnik, FAM Forderanlagen Magdeburg, Buhler Group |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Ship Unloaders Market Key Technology Landscape

The technology landscape of the Ship Unloaders Market is rapidly evolving, driven by the need for higher capacity, enhanced environmental compliance, and reduced operational expenditures through digitization. Modern ship unloaders leverage advanced structural engineering materials and designs to handle extreme loads and harsh marine environments, maximizing operational reach and durability. Key advancements center around the continuous flow mechanisms, particularly in Continuous Ship Unloaders (CSU), which utilize specialized belt conveyors, screw systems, or bucket elevators to achieve material transfer rates exceeding 5,000 tonnes per hour while significantly mitigating dust emissions compared to traditional grab systems.

The integration of advanced automation and control systems represents the most transformative technological shift. This includes sophisticated Programmable Logic Controllers (PLCs), Human-Machine Interfaces (HMIs), and precision sensor arrays providing real-time operational data. Many new systems feature remote diagnostics, digital twinning capabilities for simulating operational scenarios, and energy recuperation systems that capture kinetic energy during downward movements of the grab or trolley, increasing overall energy efficiency and reducing the carbon footprint of port operations.

Furthermore, technologies enabling true autonomous operation are becoming commonplace, utilizing advanced laser scanning, GPS, and machine learning to optimize the trajectory of the unloader cycle, especially for optimizing grab penetration and sweep-up operations inside the vessel hold. The shift is towards modular designs and standardized interfaces, facilitating easier maintenance, faster assembly, and future scalability. The incorporation of IoT devices allows for seamless data transmission to centralized terminal operating systems (TOS), enabling better resource planning and integration with inland transport logistics.

Regional Highlights

Regional dynamics play a crucial role in the Ship Unloaders Market, reflecting varied levels of port development, resource dependency, and regulatory environments. Asia Pacific (APAC) dominates global market share, driven primarily by China, India, and Southeast Asian nations. These countries are heavily dependent on imported raw materials (coal, iron ore) and are undertaking massive port expansion projects, requiring the installation of high-capacity, new-generation unloaders, often sourced from domestic manufacturers like ZPMC and Jiangsu Guoxin, which offer competitive pricing and government backing.

Europe and North America represent mature markets characterized by replacement demand and strict environmental regulations. Growth in these regions is less focused on capacity expansion and more on technological upgrades, such as replacing older GSU units with enclosed CSUs to meet stringent dust and noise limits. The emphasis here is on automation, energy efficiency, and retrofitting existing machinery with advanced PLCs and remote operational capabilities to enhance safety and labor productivity.

Latin America and the Middle East & Africa (MEA) are emerging growth regions. Latin American demand is cyclical, tied heavily to the global prices of agricultural products (Brazil, Argentina) and mining commodities, driving investment in dedicated grain and mineral terminals. The MEA region, particularly the Gulf Cooperation Council (GCC) countries and resource-rich areas in Africa, shows sustained long-term growth driven by diversification strategies that involve developing world-class logistics hubs and handling increasing volumes of imported essential commodities and materials for industrialization projects.

- Asia Pacific (APAC): Market leader due to intense infrastructure spending, high industrial output, and reliance on imported raw materials. Key markets include China, India, Australia, and Indonesia, focusing on high-capacity and durable systems for iron ore and coal handling.

- North America: Stable market driven by modernization and replacement cycles. Strong focus on environmental compliance, safety standards, and integration of automated systems into existing port infrastructure, particularly for grain and chemical handling along coastal ports and the Great Lakes.

- Europe: Characterized by regulatory pressure favoring eco-friendly solutions (low noise, minimal dust) and high levels of automation. Demand is centered around continuous unloader technology and sophisticated software integration to optimize terminal throughput efficiency.

- Latin America: Growth tied to global commodity cycles, strong demand for grain unloaders (especially in Brazil) and mineral handling equipment. Market volatility requires flexible purchasing models and robust, easily maintained machinery.

- Middle East and Africa (MEA): Rapidly developing market fueled by massive long-term investment in logistics hubs and diversification projects. Significant opportunity for high-throughput solutions as new deep-sea ports are commissioned to serve global trade routes and local industrial needs.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Ship Unloaders Market.- Liebherr

- Konecranes

- ThyssenKrupp

- FLSmidth

- Metso Outotec

- IHI Transport Engineering

- Bedeschi S.p.A.

- EMS-Tech

- ZPMC (Shanghai Zhenhua Heavy Industries)

- Telestack

- Sandvik

- Jiangsu Guoxin

- Trelleborg

- VIGAN Engineering

- TAKRAF

- E-Crane

- NEUERO Industrietechnik

- FAM Forderanlagen Magdeburg

- Buhler Group

- Kawasaki Heavy Industries

Frequently Asked Questions

Analyze common user questions about the Ship Unloaders market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between Continuous Ship Unloaders (CSU) and Grab Ship Unloaders (GSU)?

CSUs provide a continuous, high-volume flow of bulk material using screws or conveyor systems, offering superior dust control and efficiency for homogenous cargo. GSUs operate intermittently using a grab bucket, offering versatility to handle varied material types but typically generating more dust and requiring more precise operator control.

How are environmental regulations impacting investment in new ship unloading equipment?

Environmental mandates, particularly those addressing dust emissions and noise pollution, are strongly driving port operators globally to invest in CSUs, which are enclosed and cleaner. There is also increasing demand for electric and hybrid power systems to reduce carbon footprints and meet local air quality standards.

Which geographical region exhibits the fastest growth potential for ship unloaders?

Asia Pacific (APAC), particularly China, India, and Southeast Asia, demonstrates the highest growth potential due to ongoing port modernization, heavy reliance on seaborne imported commodities, and large-scale infrastructure development projects requiring new, high-capacity dry bulk terminals.

What are the key technological trends improving the efficiency of ship unloaders?

Key trends include advanced automation (using AI and machine learning for trajectory optimization), integration of IoT for real-time condition monitoring and predictive maintenance, and the adoption of energy recuperation systems to enhance power efficiency and reduce operational costs.

What is the estimated lifespan and maintenance challenge associated with ship unloaders?

Ship unloaders typically have a lifespan exceeding 30 years, often requiring major refurbishments every 10-15 years. The primary challenge involves managing maintenance under continuous operational stress, necessitating robust scheduled inspections, proactive replacement of high-wear components (cables, bearings), and specialized technical personnel.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager