Shower Bases and Pans Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 431421 | Date : Dec, 2025 | Pages : 248 | Region : Global | Publisher : MRU

Shower Bases and Pans Market Size

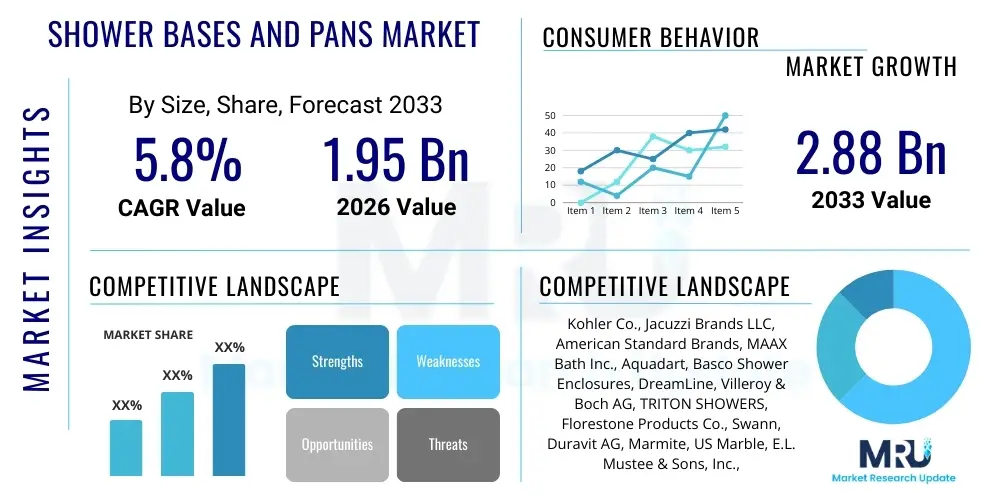

The Shower Bases and Pans Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.8% between 2026 and 2033. The market is estimated at USD 2.55 Billion in 2026 and is projected to reach USD 3.51 Billion by the end of the forecast period in 2033.

Shower Bases and Pans Market introduction

The Shower Bases and Pans Market encompasses the manufacturing, distribution, and sale of pre-formed foundational units installed beneath a shower enclosure to contain and drain water efficiently. These foundational elements, often referred to as shower receptors, are critical components in both residential and commercial wet room installations, providing a watertight and structurally sound surface. Products range significantly by material, including readily available options such as acrylic, fiberglass, and increasingly popular materials like cultured marble and composite stone, which offer enhanced durability and aesthetic appeal. The design evolution focuses on low-profile, barrier-free access (walk-in designs) to meet the growing demand for universal design principles and accessibility standards in modern architecture and renovation projects.

Major applications of shower bases and pans are primarily segmented across new residential construction, housing remodels, hospitality sectors (hotels and resorts), and healthcare facilities (hospitals and assisted living centers). The ease of installation inherent in pre-fabricated pans, compared to traditional tile and mortar applications, serves as a major benefit, reducing construction time and mitigating potential water leakage issues, which are costly to repair. Furthermore, advancements in material science have led to products that boast anti-microbial properties and improved slip resistance, appealing directly to consumers prioritizing hygiene and safety within bathroom environments, particularly relevant in multi-generational homes.

Key driving factors accelerating market expansion include the sustained growth in global urbanization, leading to increased residential and commercial construction activities, especially in emerging economies. Additionally, a strong trend towards bathroom modernization and luxury renovations in mature markets drives demand for high-end, custom-sized, and aesthetically superior shower pans, such as those made from solid surface materials that mimic natural stone. Regulatory mandates concerning water efficiency and accessibility (e.g., ADA compliance in the US) also necessitate the adoption of specific base types, further stimulating innovation in product design and drainage solutions, thus underpinning the projected market growth over the forecast period.

Shower Bases and Pans Market Executive Summary

The Shower Bases and Pans Market is characterized by robust growth fueled by shifting consumer preferences towards walk-in showers, an uptick in bathroom renovation projects, and significant technological advancements in material composition offering enhanced durability and reduced maintenance. Business trends indicate a strong move toward customization and premiumization, with manufacturers investing heavily in composite materials that allow for sleek, low-profile designs that are both visually appealing and highly functional. Furthermore, the market is experiencing consolidation among key players who are acquiring smaller specialized manufacturers to gain access to proprietary material technologies and expand their regional distribution networks, focusing on optimizing the supply chain for large-format base delivery.

Regional trends highlight that North America and Europe remain mature markets dominated by renovation activity, demonstrating high demand for ADA-compliant and sustainable recycled material options, driven by strict environmental regulations and aging demographics requiring accessible bathroom solutions. Conversely, the Asia Pacific (APAC) region is poised for the fastest growth, primarily due to rapid residential infrastructure development, burgeoning middle-class populations, and accelerated adoption of modern bathroom aesthetics, especially in China and India. This regional divergence necessitates distinct market strategies, focusing on logistical efficiency and mass-market pricing in APAC, versus premium branding and sustainable material certification in Western markets.

Segment trends reveal that the composite stone and solid surface segments are outpacing traditional acrylic and fiberglass in terms of revenue growth, commanding higher average selling prices due to superior aesthetic versatility and perceived longevity. The residential application segment maintains the dominant market share, but the commercial segment, particularly hospitality, is showing accelerated demand for heavy-duty, easily cleanable, and anti-slip shower pans that minimize maintenance downtime. Additionally, single-threshold pans are increasingly favored over multi-threshold designs, reflecting the industry-wide preference for seamless, contemporary wet room integration, which streamlines water flow management and enhances the overall user experience.

AI Impact Analysis on Shower Bases and Pans Market

User queries regarding AI's influence in the Shower Bases and Pans Market frequently revolve around optimizing manufacturing efficiency, personalization tools for custom designs, and leveraging predictive analytics for inventory management in variable construction environments. Consumers are keen on understanding how AI can facilitate the selection process, asking questions about AI-driven virtual fitting rooms (AR/VR) that map specific shower pan sizes and styles into existing bathroom layouts, thereby minimizing costly measurement errors and returns. Manufacturers, on the other hand, are focused on queries related to integrating machine learning (ML) models to predict material stress points during the molding process, ensuring zero-defect production runs, and using complex algorithms to manage the highly fragmented supply chains involving specialized polymers and stone aggregates, ensuring just-in-time delivery to volatile construction sites.

- AI-driven predictive maintenance optimizes molds and machinery, reducing unexpected downtime and enhancing overall equipment effectiveness (OEE) in manufacturing facilities.

- Machine learning algorithms analyze consumer aesthetic trends and purchasing data to guide R&D toward developing the most profitable color palettes, textures, and dimensions for new product lines, accelerating product introduction cycles.

- Generative design tools, powered by AI, enable instantaneous customization of shower pan dimensions and drainage positions based on complex contractor specifications, offering a tailored solution without manual engineering overhead.

- AI-enhanced quality control systems use computer vision to scan finished products for minute surface imperfections or dimensional deviations, ensuring every base meets stringent tolerance specifications before shipping.

- Predictive logistics models use real-time construction activity data to optimize inventory levels and distribution routes, minimizing warehousing costs and ensuring timely delivery of bulky shower bases to active job sites.

DRO & Impact Forces Of Shower Bases and Pans Market

The market dynamics are significantly influenced by a confluence of accelerating drivers such as the global momentum in residential renovation spurred by the desire for upgraded home aesthetics, alongside major restraints including the volatility of raw material prices, particularly petrochemicals used in polymer-based products. Opportunities are abundantly present in the burgeoning field of smart bathroom integration and the adoption of sustainably sourced, recyclable composite materials, positioning manufacturers who prioritize R&D in these areas for substantial competitive advantage. The interplay between these factors determines the market's trajectory, where robust housing market health acts as a powerful tailwind, while stringent regulatory hurdles related to water ingress and safety standards impose considerable developmental complexity and costs on new product introductions.

Impact forces currently shaping the competitive landscape are centered on the rapid shift in consumer perception, favoring durable and aesthetically pleasing solid surface options over traditional lightweight acrylic bases, creating pressure on legacy manufacturers to diversify their material portfolios. Furthermore, the increasing prevalence of e-commerce channels, particularly for DIY consumers and small-scale contractors, demands streamlined packaging and logistical optimization for bulky items, creating new distribution challenges and opportunities. The economic impact force is tied directly to interest rate fluctuations; higher rates can dampen new construction and large-scale renovation spending, slowing the adoption rate, while sustained low rates typically accelerate market activity and foster aggressive product expansion strategies, especially in the high-end customizable segments.

These forces mandate continuous innovation, particularly concerning ease of installation. Manufacturers are striving to simplify the installation process, offering click-and-lock systems or integrated leveling features, directly addressing the restraint imposed by skilled labor shortages in many mature markets. The overall market resilience, however, is bolstered by the non-discretionary nature of bathroom fixtures during home construction or essential remodeling, ensuring a stable baseline demand even during minor economic downturns, provided the cost of raw materials can be effectively managed through long-term supply agreements and diversified sourcing strategies.

Segmentation Analysis

The Shower Bases and Pans Market is intricately segmented based on material, type, application, and distribution channel, reflecting the diversity of consumer preferences and specific installation requirements across different construction environments. Material segmentation is crucial as it dictates the product's price point, durability, and aesthetic finish, with high-growth observed in engineered composites that merge the lightweight advantages of acrylic with the robust, luxurious feel of stone. Furthermore, the segmentation by type, specifically focusing on accessibility features like low-profile and barrier-free thresholds, is increasingly critical, catering to the demographic shift towards aging-in-place solutions and regulatory compliance in public spaces. Understanding these segments allows manufacturers to precisely target their product development and marketing efforts, ensuring relevance across the spectrum from budget-conscious residential renovations to high-specification commercial projects requiring industrial-grade longevity.

- By Material:

- Acrylic

- Fiberglass/FRP

- Composite Stone/Solid Surface

- Cultured Marble

- Cast Iron/Steel (Niche Applications)

- By Type:

- Single Threshold

- Double Threshold

- Neo-Angle

- Corner/Quadrant

- Barrier-Free/Walk-in

- By Application:

- Residential (New Construction and Renovation)

- Commercial (Hospitality, Healthcare, Education, Corporate)

- By Distribution Channel:

- Offline (Retail Stores, Wholesalers, Specialty Distributors)

- Online (E-commerce Platforms, Company Websites)

Value Chain Analysis For Shower Bases and Pans Market

The value chain for shower bases and pans begins upstream with the procurement of essential raw materials, including bulk petrochemicals (for acrylic and fiberglass resins), mineral fillers (e.g., bauxite, stone aggregates), and specialized pigments for coloration and surface finishes. This initial stage is highly sensitive to global commodity pricing and supply stability, directly impacting the final product cost and manufacturing margins. Key upstream activities involve quality testing of resins to ensure durability and adherence to fire and safety standards, followed by bulk processing and preparation for the molding stage, often involving proprietary mixing techniques for composite materials to achieve specific strength-to-weight ratios and non-slip textures demanded by the market.

The middle segment of the chain encompasses the manufacturing processes, which vary significantly based on material—from vacuum forming for acrylic bases to intricate casting and curing processes for solid surface and cultured marble products. Efficiency at this stage is crucial, utilizing advanced computer-numerical control (CNC) technology for precise trimming and finishing, alongside integrated quality assurance checks. Following manufacturing, products move to the distribution channel, which is complex due to the bulky and fragile nature of shower bases. Distribution relies heavily on specialized logistics, utilizing both direct sales channels to large home builders and indirect sales through extensive networks of plumbing wholesalers, general construction distributors, and major home improvement retailers (e.g., Lowe's, Home Depot).

Downstream activities center on installation and end-user consumption. Direct distribution often involves manufacturers supplying large volumes to construction sites or specialized renovation contractors who handle the final installation. Indirect channels involve the consumer purchasing the product through a retail intermediary, which requires robust retail support, detailed installation guides, and strong after-sales service and warranty provision. The channel strategy is influenced by product type; highly customized, luxury solid-surface bases are often sold through specialized showrooms or directly to interior designers, ensuring high-touch customer interaction, while mass-produced acrylic bases are predominantly moved through high-volume, cost-effective wholesale and e-commerce platforms, optimizing for reach and logistical efficiency across diverse geographical regions.

Shower Bases and Pans Market Potential Customers

The primary customer base for shower bases and pans spans several distinct categories, reflecting both the new construction boom and the persistent renovation cycle globally. The largest volume buyers are residential builders and contractors involved in mass housing projects, who prioritize cost-effectiveness, consistency, and ease of installation for standard-sized acrylic and fiberglass units. Equally significant are individual homeowners undertaking bathroom remodels; this segment drives demand for premium, customized, and aesthetically superior products, such as composite stone bases with integrated benches and customized drain locations, focusing on long-term value and design integration, often seeking products through designer showrooms or high-end retail channels.

A rapidly expanding segment involves the commercial sector, particularly the hospitality industry (hotels and resorts), which requires highly durable, easy-to-clean, and rapidly replaceable shower bases that can withstand intensive use and minimize room downtime. These customers often demand bases with superior slip resistance and specific certifications. Furthermore, the healthcare and institutional sectors, including hospitals, nursing homes, and assisted living facilities, represent critical end-users. These institutions have strict requirements for safety, demanding barrier-free, ADA-compliant, anti-microbial surfaces that facilitate wheelchair access and maintain the highest levels of hygiene, making them key targets for specialized, non-slip composite materials.

Finally, distributors and large retail chains act as crucial intermediaries, acquiring bulk inventory to service both professional contractors and the DIY market. Their purchasing decisions are driven by inventory turnover, logistical simplicity, and the manufacturer's ability to provide a wide range of sizes and materials promptly. Effectively targeting these diverse groups requires a multi-faceted marketing approach: technical specifications and volume pricing for commercial and construction customers, and aesthetic appeal and ease-of-maintenance messaging for the homeowner/retail segment, emphasizing the long-term hygienic and structural benefits of modern shower receptors over traditional tiled solutions.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 2.55 Billion |

| Market Forecast in 2033 | USD 3.51 Billion |

| Growth Rate | 4.8% ( Include CAGR Word with % Value ) |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Kohler Co., MAAX Bath Inc., Jacuzzi Brands LLC, American Standard Brands, E. I. du Pont de Nemours and Company (Corian), Villeroy & Boch AG, Duravit AG, Grohe AG, Jaquar Group, KUDOS Showers, TOTO Ltd., WEDI GmbH, Florestone Products Co., Fiora Bath, Sterling Plumbing (a subsidiary of Kohler Co.) |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Shower Bases and Pans Market Key Technology Landscape

The technology landscape in the Shower Bases and Pans Market is rapidly evolving, driven primarily by material science innovation aimed at enhancing durability, aesthetics, and hygiene. A significant trend involves the development of proprietary composite materials, often utilizing high-density polymer matrices reinforced with natural minerals or aggregates. These composites allow manufacturers to create shower bases that are exceptionally resistant to chipping, scratching, and fading, while maintaining a luxurious, heavy feel similar to cast materials, but with the added benefit of being customizable and typically easier to install due to optimized weight. Advanced manufacturing technologies, such as high-pressure injection molding and specialized vacuum forming, are instrumental in achieving precise tolerances, essential for seamless installation, particularly for large, custom-sized bases in luxury wet room designs.

Surface technology represents another critical area of innovation. Manufacturers are implementing nanotechnology-based surface treatments to achieve superior non-slip properties, exceeding current safety standards without compromising the ease of cleaning. These treatments often integrate anti-microbial properties directly into the gel coat or surface layer, inhibiting the growth of mold, mildew, and bacteria, which is a major selling point in both residential and high-traffic commercial applications like hospitals. Furthermore, smart drainage technology is gaining traction, featuring integrated linear drains that enhance water flow management and self-cleaning mechanisms, reducing maintenance efforts and the risk of blockages associated with traditional center-point drains, providing a highly efficient solution for modern, minimalist designs.

Finally, digital prototyping and design software, often incorporating augmented reality (AR) and virtual reality (VR), are revolutionizing the selection and customization process. This technology allows contractors and consumers to virtually place different base models within their specific bathroom dimensions, ensuring perfect fit and aesthetic alignment before purchase, significantly reducing the industry's historical problem of measurement errors and returns. The shift toward digitally enabled design facilitates the mass customization model, allowing manufacturers to quickly scale production for unique shapes and specifications demanded by complex architectural projects while maintaining strict quality control through automated inspection systems throughout the production line.

Regional Highlights

The global Shower Bases and Pans Market exhibits distinct growth patterns and material preferences across major geographic regions, necessitating tailored marketing and distribution strategies.

- North America: Characterized by high replacement and renovation demand, driven by an aging population prioritizing accessibility (barrier-free and ADA-compliant bases) and premiumization trends. The U.S. remains the dominant revenue contributor, showing strong preference for solid surface and composite materials due to their perceived quality and aesthetic versatility in high-end remodels. Regulatory compliance regarding building codes and water management heavily influences product design and materials selection in this region.

- Europe: The European market, particularly in Western countries (Germany, UK, France), is highly focused on sustainability and water conservation. There is a robust demand for bases made from recycled materials and those certified for low environmental impact. Minimalist design aesthetics, favoring low-profile, walk-in, and flush-to-floor installations, are standard, alongside stringent requirements for non-slip safety features, driven by national health and safety standards.

- Asia Pacific (APAC): This is the fastest-growing region, fueled by massive new residential construction projects and rapid urbanization, particularly in developing economies like China, India, and Southeast Asia. The market here is volume-driven, with strong demand for cost-effective, durable materials like acrylic and fiberglass, although the luxury segment in metropolitan areas is increasingly adopting cultured marble and composite stone. Logistical efficiency and scaling production capacity are key competitive advantages in APAC.

- Latin America (LATAM): Growth in LATAM is closely tied to economic stability and infrastructure investment. The market shows diverse demand, with emerging interest in mid-range composite materials offering better longevity than traditional ceramics, aiming to balance cost and durability in new housing developments. Brazil and Mexico represent the largest markets, driven by localized manufacturing capabilities and growing consumer desire for modern bathroom aesthetics.

- Middle East and Africa (MEA): The MEA market is highly bifurcated, with Gulf Cooperation Council (GCC) countries showing strong demand for high-end, luxury composite and custom-made bases due to significant investments in high-profile commercial projects (hotels, luxury residences). The rest of the region shows a preference for entry-level, resilient materials, with market growth heavily dependent on governmental expenditure on housing and tourism infrastructure development.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Shower Bases and Pans Market.- Kohler Co.

- MAAX Bath Inc.

- Jacuzzi Brands LLC

- American Standard Brands

- E. I. du Pont de Nemours and Company (Corian)

- Villeroy & Boch AG

- Duravit AG

- Grohe AG

- Jaquar Group

- KUDOS Showers

- TOTO Ltd.

- WEDI GmbH

- Florestone Products Co.

- Fiora Bath

- Sterling Plumbing (a subsidiary of Kohler Co.)

- DreamLine

- Basco Manufacturing Co.

- Clarion Bathware

- Swan Corporation

- Mustee Corp.

Frequently Asked Questions

Analyze common user questions about the Shower Bases and Pans market and generate a concise list of summarized FAQs reflecting key topics and concerns.Which material is superior for shower bases: Acrylic or Composite Stone?

Composite stone bases are generally considered superior for durability, aesthetic appeal, and resistance to scratches and chipping, offering a premium, solid feel. However, acrylic is significantly more cost-effective, lightweight, and easier to install, making it the preferred choice for budget-conscious residential projects and quick installations.

What are the key benefits of choosing a barrier-free or low-profile shower pan design?

Barrier-free designs, also known as walk-in or zero-threshold, significantly enhance accessibility and safety, particularly for the elderly or individuals with mobility challenges, aligning with universal design principles. They also create a modern, seamless aesthetic, making the bathroom appear larger and more integrated with the surrounding flooring.

How does the shift towards smart bathrooms impact the shower pan market?

The shift towards smart bathrooms drives innovation in shower pan design by increasing demand for integrated, hidden drainage systems and materials that support advanced sensors (e.g., for floor heating or water leak detection). This trend accelerates the adoption of custom-fitted, solid-surface bases that can seamlessly house sophisticated technology.

What factors primarily drive the high growth rate projected for the Asia Pacific (APAC) market?

The high growth in APAC is primarily driven by extensive residential and commercial infrastructure development, rapid urbanization, and rising disposable incomes leading to increased spending on modern home construction and remodeling. This creates massive volume demand for both standard and mid-range shower base products.

What is the typical lifespan of a high-quality composite shower pan compared to fiberglass?

A high-quality composite or solid surface shower pan can typically last 15 to 25 years or more with proper care, offering excellent resistance to wear and tear. Fiberglass, while cost-effective, often has a shorter lifespan, potentially lasting 10 to 15 years before showing signs of flexing, cracking, or surface deterioration due to its less rigid structure.

Are anti-slip surfaces standard on modern shower bases, and how are they achieved?

Anti-slip surfaces are becoming an industry standard, particularly in commercial and high-end residential segments, driven by safety regulations. These properties are often achieved either through integrated textures in the mold during manufacturing or by applying specialized, durable, nanotechnology-enhanced coatings that increase the coefficient of friction without feeling abrasive or rough.

How crucial is the distribution channel for the Shower Bases and Pans Market?

Distribution is extremely crucial due to the bulky, dimension-specific, and sometimes fragile nature of the products. Manufacturers rely heavily on established plumbing wholesalers and specialty distributors for business-to-business sales (contractors) and major big-box retailers/e-commerce platforms for business-to-consumer sales, requiring robust logistics to handle large-format shipping effectively.

What is the most significant restraint challenging market growth over the forecast period?

The most significant restraint is the volatility and rising cost of raw materials, especially petrochemical derivatives used in acrylic and fiberglass production. These fluctuations directly impact manufacturing margins and necessitate price increases, potentially dampening volume growth in the highly price-sensitive segments of the market.

Do advancements in 3D printing technology play a role in the future of shower base manufacturing?

Yes, while not yet fully scalable for mass production of large bases, 3D printing is significantly influencing rapid prototyping and the creation of highly complex or customized mold tooling. This allows manufacturers to test new designs, integrated drainage features, and unique dimensions much faster and cheaper, accelerating product development cycles for niche or bespoke architectural projects.

What are neo-angle shower bases, and where are they most commonly used?

Neo-angle shower bases are typically five-sided, designed specifically for corner installations where space optimization is critical. They are commonly used in smaller residential bathrooms or ensuite bathrooms where a standard square or rectangular enclosure would consume too much floor space, providing an efficient yet aesthetically pleasing solution.

How are environmental sustainability concerns addressed by manufacturers in this market?

Manufacturers are addressing sustainability by increasing the use of recycled materials in composite bases, reducing volatile organic compound (VOC) emissions during production, optimizing packaging to minimize waste, and designing products that are lighter and more durable, thereby extending the product lifecycle and reducing the frequency of replacement and associated waste.

Is customization a major market trend, and for which segments is it most popular?

Yes, customization is a major market trend, driven by the luxury and high-end residential renovation segments, particularly for solid surface and cultured marble bases. Customers demand specific colors, custom sizes, integrated seating, and personalized drain placements to match unique architectural bathroom designs and layouts.

What role does the hospitality sector play in driving commercial demand for shower pans?

The hospitality sector (hotels and resorts) is a major driver, demanding shower pans that offer extreme durability, rapid installation (to minimize room downtime), ease of deep cleaning, and superior anti-slip properties to ensure guest safety. They typically favor heavy-duty composite materials that maintain a high-quality appearance under frequent, heavy use.

How does AI contribute to improving the manufacturing quality of shower bases?

AI contributes through advanced computer vision systems integrated into the production line. These systems automatically scan newly formed bases, detecting micro-cracks, surface pitting, or dimensional irregularities with far greater accuracy and speed than human inspectors, ensuring that only zero-defect products proceed to curing and packaging.

What distinguishes cultured marble from composite stone bases in terms of composition and price?

Cultured marble is a blend of marble dust and polyester resin, often resulting in a glossy, uniform finish. Composite stone (or solid surface) is typically a blend of mineral fillers (like bauxite) and acrylic/polyester resins, often providing a matte, less porous, and highly customizable texture, generally commanding a slightly higher price point due to enhanced durability and resistance to thermal shock.

Are metal shower bases (cast iron or steel) still relevant in the market?

Metal bases, particularly cast iron or enameled steel, occupy a shrinking, niche market. They are valued for their extreme durability and classic aesthetics but are heavy, difficult to install, and susceptible to chipping, limiting their use primarily to older home restorations or specific high-durability institutional settings where weight is not a constraint.

What is the impact of changing residential construction standards on shower base design?

Changing standards, particularly around water proofing and accessibility (ADA requirements), compel manufacturers to design bases with integrated tiling flanges, precise slopes for drainage, and mandatory low-threshold options, ensuring compliance and reducing the liability associated with water ingress and slip hazards during use.

How important are distribution relationships with plumbing wholesalers for market penetration?

Plumbing wholesalers are immensely important as they serve as the primary conduit between manufacturers and professional plumbing contractors who perform the vast majority of new construction and remodel installations. Strong relationships guarantee consistent inventory movement and technical support outreach to the professional installer base.

What considerations are critical for installing a shower base on an uneven subfloor?

For uneven subfloors, installers must select bases that offer robust support or integrated leveling systems (such as adjustable feet). Alternatively, a mortar bed must be meticulously prepared prior to setting the pan, ensuring full support across the base's entire footprint to prevent flexing and cracking over time, which is particularly critical for fiberglass or acrylic units.

In which region is the demand for fiberglass shower bases expected to decline most significantly?

Demand for fiberglass bases is expected to decline most significantly in mature European markets and high-end North American segments, where stricter environmental standards and consumer preference for premium, sustainable, and rigid composite materials are pushing fiberglass towards lower-end, highly price-sensitive new construction projects only.

What distinguishes a single-threshold from a double-threshold shower base?

A single-threshold base allows entry from only one side, designed for three-wall alcove installations. A double-threshold base allows entry from two adjacent sides, typically used for corner installations where two walls meet, requiring thresholds on the remaining two exposed sides for water containment.

What are the key advantages of integrated drainage systems in modern shower pans?

Integrated drainage systems, often linear drains concealed beneath a removable cover, offer a sleek, minimalist look, facilitate better water removal efficiency, and simplify installation by incorporating all necessary plumbing connections directly into the base structure, reducing the complexity of subfloor preparation.

How do manufacturers ensure the chemical resistance of their shower base materials?

Manufacturers achieve chemical resistance by using high-grade, cross-linked polymer resins (like marine-grade resins) and specialized gel coats, particularly for acrylic and fiberglass. For composite stone, the non-porous nature of the solid surface material inherently resists staining and degradation from common household cleaning agents and bath products.

Which application segment—Residential or Commercial—currently holds the largest market share?

The Residential segment (encompassing both new construction and extensive remodeling projects) currently holds the largest market share globally due to the sheer volume of housing units and the ongoing cycle of homeowner renovations, though the Commercial segment exhibits higher average per-unit quality and faster growth in specific luxury sub-sectors.

What impact does the trend of 'aging-in-place' have on product development for shower bases?

The 'aging-in-place' trend necessitates the development of products focused on safety and accessibility, driving innovation towards ultra-low-profile or zero-entry bases, integrated seating/benches, enhanced anti-slip surfaces, and highly durable materials designed to support mobility assistance devices without compromising the structure or finish.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Shower Bases and Pans Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- Shower Bases and Pans Market Size Report By Type (Acrylic, Others), By Application (Commercial Enterprises, Household, Government Academic Institutions, Others), By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Share, Trends, Outlook and Forecast 2025-2032

- Shower Bases and Pans Market Size, Share, Trends, & Covid-19 Impact Analysis By Type (Acrylic, Fiberglass, Solid Surface, Others), By Application (Hotel, Household, Others), By Region - North America, Latin America, Europe, Asia Pacific, Middle East, and Africa | In-depth Analysis of all factors and Forecast 2023-2030

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager