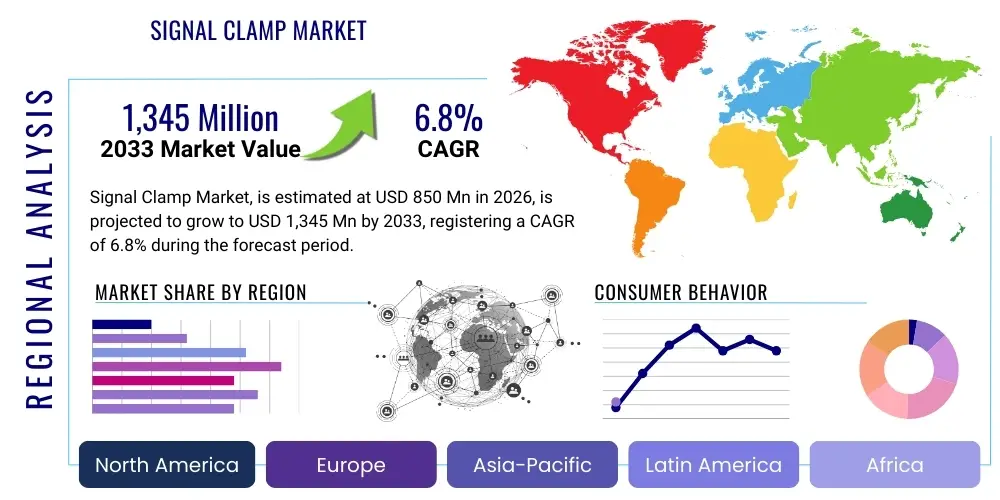

Signal Clamp Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 435874 | Date : Dec, 2025 | Pages : 257 | Region : Global | Publisher : MRU

Signal Clamp Market Size

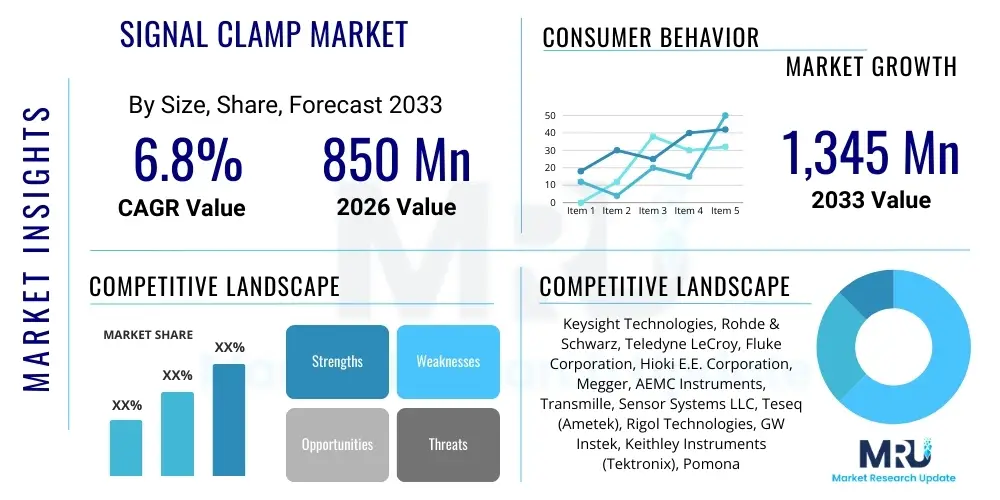

The Signal Clamp Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at $850 Million in 2026 and is projected to reach $1,345 Million by the end of the forecast period in 2033. This substantial growth is fundamentally driven by the escalating demand for electromagnetic compatibility (EMC) testing across diverse industrial sectors, particularly in advanced electronics manufacturing and the rapidly evolving automotive industry, which increasingly relies on complex sensor networks.

The valuation reflects the increasing complexity of electronic devices and the stringent regulatory requirements imposed globally concerning electromagnetic interference (EMI) and radio frequency (RF) emissions. Signal clamps, essential tools for precise current measurement without interrupting the circuit, are critical for diagnostics, signal integrity analysis, and compliance verification. The consistent rise in data rates and operating frequencies necessitates highly accurate, specialized clamping technology capable of handling transient and high-bandwidth signals, thereby sustaining premium pricing and market expansion.

Signal Clamp Market introduction

The Signal Clamp Market encompasses devices specifically engineered to inductively measure current flow and associated signals within electrical conductors and cable harnesses, typically without galvanic contact. These instruments are pivotal for non-intrusive current sensing, providing crucial data for diagnostics, performance verification, and regulatory compliance. Signal clamps are widely utilized in applications ranging from routine maintenance and troubleshooting to highly sensitive electromagnetic compatibility (EMC) pre-compliance and full compliance testing, ensuring that electronic equipment meets international standards regarding radiated emissions and immunity.

Major applications of signal clamps span telecommunications infrastructure, where they assess signal quality and noise levels; the automotive sector, critical for measuring parasitic loads and diagnosing complex vehicle electronic control units (ECUs); and industrial automation, where reliable current monitoring is paramount for equipment safety and efficiency. The primary benefit these devices offer is the ability to obtain accurate, real-time current measurements in live circuits, drastically reducing downtime and the risk of circuit damage. Furthermore, advancements in clamp design, particularly concerning frequency response and shielding, are expanding their utility into high-speed digital electronics and aerospace applications.

Key driving factors accelerating market adoption include the proliferation of connected devices (IoT), the increasing electrification of vehicles (EVs), and the global implementation of stricter EMC standards (such as CISPR and FCC regulations). The transition towards higher power density and faster switching frequencies in power electronics also mandates the use of highly reliable signal clamps for ensuring thermal stability and operational integrity. Manufacturers are continuously innovating to deliver clamps with better isolation characteristics, wider dynamic ranges, and enhanced frequency capabilities to meet these demanding industrial requirements.

Signal Clamp Market Executive Summary

The Signal Clamp Market exhibits strong growth momentum, propelled by robust business trends centered on digitization and regulatory harmonization. Key business trends include the shift toward active signal clamping technologies offering superior bandwidth and lower noise floor compared to traditional passive designs. Furthermore, strategic alliances between clamp manufacturers and test and measurement equipment providers are creating bundled solutions that offer enhanced integration and usability, especially appealing to complex testing environments such like high-speed data centers and 5G network deployments. The focus remains on miniaturization and ergonomic design, allowing technicians easier access to constrained testing points in modern electronic systems.

Regional trends indicate that Asia Pacific (APAC) is emerging as the fastest-growing market due to the massive scale of electronics manufacturing in countries like China, South Korea, and Taiwan, coupled with rapidly expanding automotive and telecommunications infrastructure across the region. North America and Europe, while mature, maintain dominance in high-precision and high-frequency segments, driven by stringent aerospace & defense standards and advanced R&D activities in new energy technologies. Segment trends highlight that the application segment of EMI/EMC testing remains the largest revenue contributor, although automotive diagnostics is experiencing the highest proportional growth, reflecting the explosive adoption of electric vehicles and ADAS (Advanced Driver-Assistance Systems).

Overall, the market structure is moderately consolidated, with major players competing primarily on technological superiority, frequency range capability, and calibration precision. The market is characterized by continuous product lifecycles, with manufacturers frequently releasing clamps tailored for specific regulatory standards or niche applications, such as specialized current probes for pulsed power systems. Sustainability and efficiency concerns are also subtly influencing product design, favoring components that offer high longevity and simplified calibration procedures, thus minimizing operational expenditure for end-users.

AI Impact Analysis on Signal Clamp Market

User queries regarding the intersection of AI and signal clamp technology often revolve around the automation of complex testing workflows, the use of machine learning for real-time noise pattern identification, and the potential for AI-driven predictive maintenance enabled by continuous signal monitoring. Key themes include the shift from manual, technician-driven signal analysis to automated data interpretation, concerns about the required integration standards between analog clamping hardware and sophisticated digital AI platforms, and expectations regarding enhanced fault detection capabilities that surpass traditional threshold analysis. Users are keenly interested in whether AI can reduce the time and cost associated with achieving full regulatory compliance in highly noisy environments.

The core influence of Artificial Intelligence on the Signal Clamp Market lies in augmenting the analysis capabilities downstream of the measurement. AI and Machine Learning (ML) algorithms are increasingly being used to process the vast amounts of time-domain and frequency-domain data collected by high-performance clamps. This enables automated anomaly detection, classification of noise sources (e.g., differentiating between broadband noise and specific switching harmonics), and prediction of potential system failures before they occur. This shift transforms the signal clamp from a purely measurement tool into a critical data acquisition component feeding advanced analytical systems, thereby increasing the value proposition of high-fidelity clamp outputs.

Furthermore, AI is instrumental in optimizing the measurement setup itself, especially in complex EMC testing where optimal clamp placement and orientation significantly affect measurement accuracy. ML models trained on simulation data and historical test results can recommend ideal configurations, minimizing human error and variability. This technological synergy enhances test repeatability and significantly accelerates the product development cycle by providing quicker, more reliable feedback on electromagnetic signatures, which is vital for industries operating under tight time-to-market constraints, such as consumer electronics and 5G hardware manufacturing.

- AI enables automated signal anomaly detection and noise source classification.

- Machine Learning optimizes clamp placement and testing parameters for improved accuracy.

- Predictive maintenance using continuously monitored signal data gathered via clamps.

- AI-driven analysis accelerates EMC pre-compliance and full compliance testing cycles.

- Facilitates integration of signal measurements into large-scale smart factory monitoring systems.

- Improves real-time transient analysis and classification of intermittent fault signals.

DRO & Impact Forces Of Signal Clamp Market

The Signal Clamp Market is significantly influenced by a confluence of accelerating drivers and constraining factors, creating complex impact forces. The primary driver is the pervasive adoption of high-speed digital communications and power electronics, demanding specialized tools for measuring fast-switching currents and maintaining signal integrity in increasingly dense electronic environments. Concurrently, rigorous global regulatory mandates for EMI/EMC compliance, enforced across consumer, medical, and industrial sectors, necessitate accurate and certifiable current measurement, securing a baseline demand for high-quality clamps. However, market growth is often restrained by the high initial cost associated with high-frequency, wide-bandwidth clamps, particularly those required for advanced applications like automotive Ethernet and complex aerospace avionics, which can deter smaller enterprises or R&D labs with constrained budgets.

Opportunities for expansion are predominantly centered around the rapid global rollout of 5G infrastructure, which requires extensive field testing and maintenance using precision RF signal clamps, and the massive ongoing investment in electric vehicle (EV) battery and powertrain diagnostics. EVs utilize high-voltage DC and high-frequency AC systems, demanding clamps with superior isolation and transient handling capabilities. These opportunities often intersect with impact forces such as supply chain volatility for specialized materials (e.g., ferrite cores) and the need for standardized calibration methodologies across diverse manufacturers, which directly affects product reliability and market trust.

The market also faces the indirect impact force stemming from technological substitution, where alternative non-contact sensing methods (like fiber optic current sensors for extreme isolation or Hall effect sensors integrated into monitoring systems) could potentially displace traditional inductive clamps in niche high-voltage or high-isolation environments. Despite this, the unique combination of portability, bandwidth, and proven reliability of inductive signal clamps ensures their sustained relevance in diagnostics and field testing. The competitive force is high, forcing continuous innovation in material science and electronic design to improve measurement fidelity and reduce size while adhering to stringent performance criteria necessary for future high-frequency applications.

Segmentation Analysis

The Signal Clamp Market is extensively segmented based on key attributes including product type, operational frequency, application area, and the specific end-use industry, reflecting the diverse technical requirements across the user base. Segmentation is crucial for market participants as it dictates the required technological capabilities—for instance, clamps designed for high-frequency EMI testing require different ferrite compositions and shielding compared to those used for low-frequency DC current monitoring in industrial settings. The dynamic expansion of high-speed data transmission technologies is consistently driving demand toward segments offering wider frequency ranges and lower phase shift errors, pushing manufacturers to continuously refine coil design and material characteristics to maintain measurement accuracy in demanding environments.

Analysis by application clearly illustrates the market's dependence on regulatory compliance, with EMI/EMC testing constituting the largest revenue share due to mandatory certification processes globally. However, the fastest growth is observed in highly specialized fields such as signal integrity analysis for semiconductor manufacturing and the detailed current measurement required for complex automotive diagnostics, particularly related to battery management systems (BMS) in hybrid and electric vehicles. Understanding these segments allows companies to prioritize R&D investments toward areas yielding the highest return, focusing on integration capabilities, software compatibility, and robustness for harsh field use.

- By Type: Passive Signal Clamps, Active Signal Clamps, High-Frequency Clamps, Low-Frequency Clamps.

- By Application: EMI/EMC Testing, Signal Integrity Testing, Automotive Diagnostics, Telecommunications Maintenance, Aerospace & Defense, Industrial Monitoring, Research & Development.

- By End-Use Industry: Electronics Manufacturing, Automotive Sector, Telecom & IT, Utilities/Power Generation, Medical Devices, Industrial Automation, Military & Government.

- By Frequency Range: Below 1 GHz, 1 GHz to 5 GHz, Above 5 GHz (High Bandwidth).

Value Chain Analysis For Signal Clamp Market

The value chain for the Signal Clamp Market begins with the upstream raw material suppliers, predominantly specializing in high-permeability magnetic materials such as advanced ferrites, specialized alloys, and shielding materials critical for performance. High quality and consistency in these materials are paramount, as they directly determine the clamp's frequency response, insertion loss, and noise immunity. Key upstream activities also involve the design and fabrication of complex custom coils and high-precision mechanical enclosures, often requiring specialized machining capabilities to achieve the necessary ergonomic and shielding characteristics, particularly for high-end active clamps.

Midstream activities involve the core manufacturing and integration processes, where the coil assemblies, shielding, and electronic components (for active clamps, including internal amplifiers and power conditioning circuitry) are integrated and rigorously calibrated. Calibration is a critical value-add step, requiring traceability to national standards and often involving specialized anechoic or semi-anechoic chambers for accurate frequency response characterization. Distribution channels are varied: direct sales are common for highly specialized, high-value clamps sold directly to large R&D labs or military customers, while indirect channels, relying heavily on specialized distributors and resellers of test and measurement equipment, dominate sales to smaller industrial maintenance groups and general electronics manufacturers. These distributors provide essential technical support and local inventory.

Downstream analysis focuses on the end-users—the engineering teams, field technicians, and compliance laboratories—who utilize the clamps for diagnostics, monitoring, and certification. After-market services, including mandatory periodic recalibration, repair services, and firmware updates (for smart clamps), form a crucial part of the downstream value capture. The market increasingly values comprehensive service contracts and high levels of technical support, as downtime associated with sophisticated testing equipment can be highly costly. Efficiency across the value chain is increasingly sought through vertical integration or strong supplier partnerships to mitigate supply chain risks associated with unique, high-performance magnetic components.

Signal Clamp Market Potential Customers

The primary consumers and end-users of signal clamps are entities requiring non-intrusive current measurement for validation, diagnostics, or compliance purposes, spanning across highly regulated and technically advanced industries. EMC compliance laboratories, both independent and corporate, represent a significant segment, using clamps daily to verify that new electronic products meet legal limits on radiated and conducted emissions before market release. Automotive Original Equipment Manufacturers (OEMs) and Tier 1 suppliers are also major buyers, utilizing clamps extensively for diagnosing complex wiring harnesses, measuring current draw in various vehicle states (e.g., sleep mode current), and validating the performance and safety of high-voltage battery systems in electrified powertrains.

Furthermore, telecommunication companies, particularly those involved in setting up and maintaining 5G base stations and fiber infrastructure, rely on specialized high-frequency clamps to ensure signal integrity and diagnose common mode current issues that degrade performance. The aerospace and defense sector represents a high-value, low-volume customer base, demanding extremely robust and highly accurate clamps certified for use in mission-critical environments, often requiring specialized MIL-SPEC ratings and extended temperature ranges. In the industrial sector, utilities and power generation facilities use clamps for fault isolation and load balancing, while industrial automation relies on them for monitoring machine health and troubleshooting control systems.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $850 Million |

| Market Forecast in 2033 | $1,345 Million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Keysight Technologies, Rohde & Schwarz, Teledyne LeCroy, Fluke Corporation, Hioki E.E. Corporation, Megger, AEMC Instruments, Transmille, Sensor Systems LLC, Teseq (Ametek), Rigol Technologies, GW Instek, Keithley Instruments (Tektronix), Pomona Electronics, Pico Technology, Hameg (Rohde & Schwarz), Kyoritsu Electrical Instruments Works, ZES ZIMMER. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Signal Clamp Market Key Technology Landscape

The Signal Clamp Market is characterized by continuous technological refinement focused primarily on improving measurement bandwidth, reducing noise floor, and enhancing immunity to external fields. A core technological trend involves the transition from purely passive clamps, which rely on the conductor current to generate a measurable output voltage, to active signal clamps. Active clamps incorporate internal low-noise amplifiers and sophisticated compensation circuits (often utilizing magnetic or electronic feedback loops) to significantly extend the measurable frequency range, often reaching several gigahertz, which is crucial for modern high-speed digital buses and RF applications like 5G and Wi-Fi 6E testing. This active approach minimizes the effect of input impedance changes, providing a more reliable and flat frequency response across the spectrum.

Material science innovation is equally vital, particularly in the development of specialized ferrite core compositions that exhibit high permeability and low loss characteristics over extreme frequency ranges and operating temperatures. Advances in core gap technology and improved shielding techniques are being deployed to minimize errors caused by fringing fields and external common-mode noise, enhancing the accuracy, especially in highly transient environments like automotive power systems. Furthermore, the integration of advanced digital signal processing (DSP) capabilities directly into the clamps or associated instrumentation is becoming standard. DSP allows for real-time signal conditioning, correction for known clamp characteristics (such as phase shift), and improved rejection of unwanted noise components, leading to cleaner and more trustworthy measurement data outputs.

Another crucial element of the technology landscape is the increasing emphasis on miniaturization and ergonomic design. High-density electronics and complex cable harnesses in modern vehicles and aerospace systems often restrict access, requiring thinner, lighter, and more flexible clamp designs. Smart features, such as automatic zero-offset calibration, enhanced connectivity via USB or Ethernet, and integrated memory for data logging, are defining the next generation of professional signal clamps. The collaboration between manufacturers and calibration labs is also driving the adoption of standardized measurement methods (e.g., injection clamps used in BCI testing) to ensure repeatability and inter-device correlation, further legitimizing high-end technology investment.

Regional Highlights

Market dynamics for signal clamps vary significantly across key geographical regions, reflecting differences in manufacturing activity, regulatory standards, and technological adoption rates. North America remains a crucial market, particularly due to its leadership in advanced R&D, aerospace, and defense electronics. The region has stringent requirements for signal integrity and EMC compliance, driving demand for the highest-performance, wide-bandwidth active clamps. Major testing houses and the massive presence of technology giants utilizing complex data center architectures contribute significantly to sustained demand in this region.

Europe demonstrates high demand fueled by the automotive sector’s aggressive transition to electric and hybrid vehicles, alongside strong adherence to EU-mandated EMC directives (e.g., CE marking requirements). Countries like Germany and France, with strong industrial automation and precision engineering bases, drive the need for reliable, calibrated clamps for both manufacturing quality control and field service. European regulatory frameworks often require continuous monitoring, promoting the use of permanent or semi-permanent installations of sensor technologies derived from signal clamp principles.

Asia Pacific (APAC) is characterized by explosive market expansion, largely driven by high-volume electronics manufacturing in East Asia (China, Korea, Japan) and rapid infrastructure development across Southeast Asia. The region is the global hub for consumer electronics, necessitating enormous volumes of clamps for mandatory pre-compliance and final certification testing. Furthermore, APAC is leading the global deployment of 5G networks, demanding specialized RF clamps for commissioning and maintenance, positioning it as the primary growth engine for the forecast period. Investment in local R&D capabilities and the growing presence of local test and measurement equipment manufacturers further solidify the region's importance.

- North America: Dominant in high-frequency, precision applications; strong demand from Aerospace & Defense and advanced R&D labs.

- Europe: High growth driven by electric vehicle adoption and strict adherence to industrial and automotive EMC regulations (CE).

- Asia Pacific (APAC): Fastest growing market due to high-volume electronics manufacturing, 5G rollout, and automotive electrification investments.

- Latin America (LATAM): Emerging market, primarily driven by utilities infrastructure modernization and expanding telecommunications networks.

- Middle East and Africa (MEA): Growth concentrated in energy sector monitoring and new smart city infrastructure projects requiring reliable industrial clamps.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Signal Clamp Market.- Keysight Technologies

- Rohde & Schwarz

- Teledyne LeCroy

- Fluke Corporation

- Hioki E.E. Corporation

- Megger

- AEMC Instruments

- Transmille

- Sensor Systems LLC

- Teseq (Ametek)

- Rigol Technologies

- GW Instek

- Keithley Instruments (Tektronix)

- Pomona Electronics

- Pico Technology

- Kyoritsu Electrical Instruments Works

- CHAUVIN ARNOUX

- ZES ZIMMER Electronic Systems GmbH

- Doble Engineering Company

- Hameg (Rohde & Schwarz)

Frequently Asked Questions

Analyze common user questions about the Signal Clamp market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between passive and active signal clamps?

Passive signal clamps generate an output voltage proportional to the measured current without requiring external power, but typically have limited bandwidth and lower sensitivity. Active signal clamps incorporate internal amplification and conditioning circuitry, requiring external power, but offering significantly higher bandwidth (up to GHz ranges) and better linearity across a wider dynamic range, crucial for high-speed testing.

How do global EMC regulations impact the demand for signal clamps?

Strict global electromagnetic compatibility (EMC) regulations, such as CISPR 25 for automotive and various FCC standards, mandate pre-compliance and full compliance testing. Signal clamps are essential tools for these processes, used to accurately measure conducted and radiated emissions, thus directly increasing market demand as products become electronically complex and ubiquitous.

Which specific technology advancements are driving the high-frequency segment?

The high-frequency segment is driven by advancements in low-loss, wide-band ferrite materials, improved magnetic shielding techniques, and the integration of highly stable internal amplifiers (active clamps). These innovations allow clamps to maintain flat frequency responses and minimal phase shift errors necessary for accurately capturing signals in the multi-gigahertz range, vital for 5G and signal integrity testing.

What role do signal clamps play in the growing Electric Vehicle (EV) industry?

Signal clamps are fundamental in the EV industry for diagnosing high-voltage battery systems, monitoring transient current spikes in power electronics (inverters/converters), and assessing parasitic loads in the vehicle's electrical system when powered off. They ensure safety, optimize battery performance, and aid in complying with stringent automotive electrical standards.

What challenges exist regarding the calibration and accuracy of signal clamps?

The main challenges involve maintaining traceable calibration across wide frequency ranges, especially for high-bandwidth devices, and ensuring consistency between different clamp units. Environmental factors like temperature and external magnetic fields can introduce errors, necessitating frequent, standardized calibration procedures performed by accredited laboratories to guarantee measurement accuracy.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager