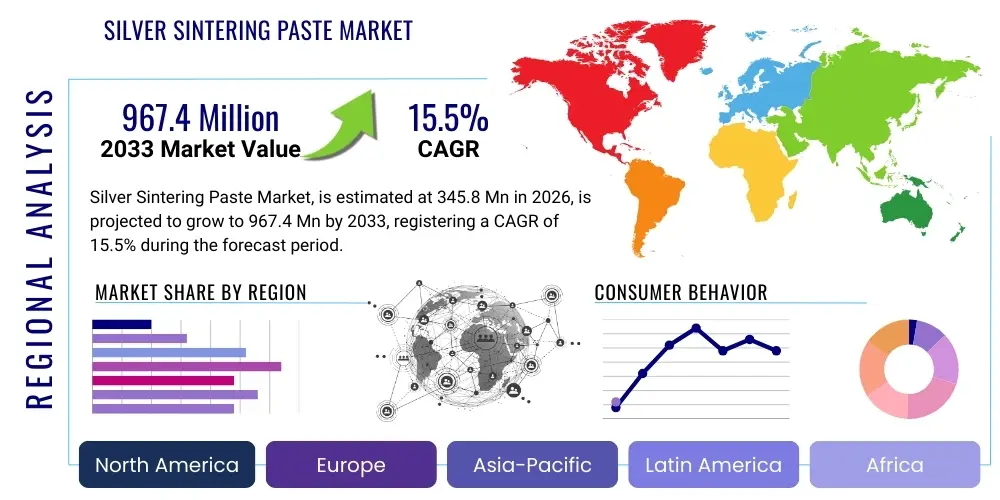

Silver Sintering Paste Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439816 | Date : Jan, 2026 | Pages : 251 | Region : Global | Publisher : MRU

Silver Sintering Paste Market Size

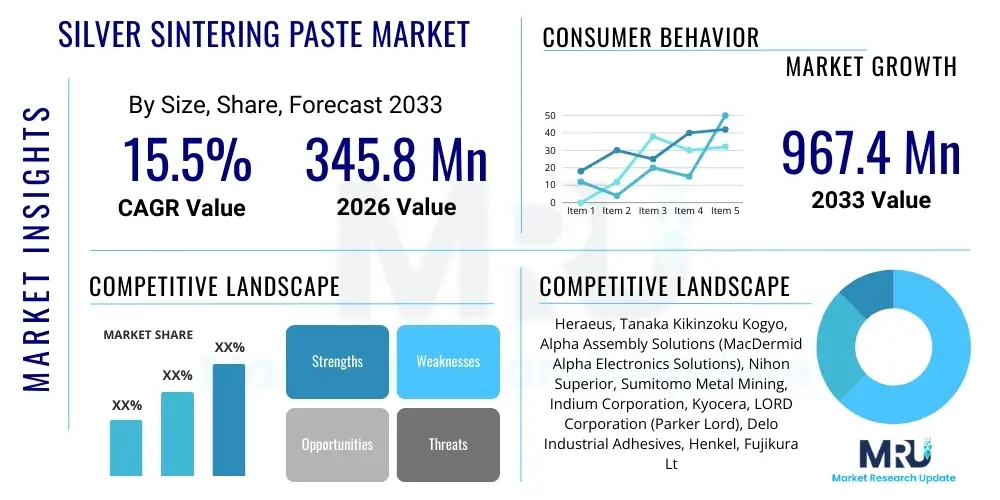

The Silver Sintering Paste Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 15.5% between 2026 and 2033. The market is estimated at USD 345.8 Million in 2026 and is projected to reach USD 967.4 Million by the end of the forecast period in 2033.

Silver Sintering Paste Market introduction

Silver sintering paste represents a critical advanced material solution, primarily utilized in high-performance power electronic packaging. It functions as a robust die-attach material, offering superior thermal and electrical conductivity compared to traditional solders. This material is typically composed of micron or nano-sized silver particles dispersed in an organic vehicle, designed to form a solid silver bond at temperatures significantly lower than the melting point of bulk silver, through a process known as sintering.

Major applications for silver sintering paste span across various demanding industries, including automotive electronics, particularly for electric vehicles (EVs) and hybrid electric vehicles (HEVs), where high power density and reliable thermal management are paramount. It is also extensively used in renewable energy systems, such as solar inverters, and in high-power LEDs, consumer electronics, and aerospace and defense applications. The primary benefits include excellent high-temperature reliability, superior thermal management capabilities, and enhanced electrical performance, making it an ideal choice for power modules like IGBTs and MOSFETs that operate under extreme conditions.

Driving factors for the Silver Sintering Paste Market include the escalating global demand for high-performance electronic devices, especially within the burgeoning EV market which necessitates robust power modules. The continuous push for miniaturization of electronic components, coupled with the need for higher power density and improved thermal dissipation in advanced packaging, further propels market expansion. Additionally, stringent environmental regulations urging the phase-out of lead-based solders have accelerated the adoption of lead-free alternatives like silver sintering paste, solidifying its position as a preferred bonding solution in modern electronics manufacturing.

Silver Sintering Paste Market Executive Summary

The Silver Sintering Paste Market is undergoing transformative growth, primarily fueled by significant advancements in power electronics and the automotive industry's electrification trend. Business trends indicate a strong focus on research and development by key players to enhance paste formulations, focusing on lower processing temperatures, pressureless sintering capabilities, and improved long-term reliability. Strategic collaborations between material suppliers and semiconductor manufacturers are becoming more prevalent, aimed at developing application-specific solutions that cater to increasingly stringent performance requirements. Furthermore, the market is witnessing an expansion in manufacturing capacities to meet the rising demand, particularly from the Asia Pacific region.

Regional trends highlight Asia Pacific as the dominant market, driven by its robust electronics manufacturing base, particularly in China, Japan, South Korea, and Taiwan, which are leading producers of power semiconductors and automotive electronics. North America and Europe are also experiencing substantial growth, attributed to significant investments in electric vehicle production and advanced industrial power applications, along with stringent regulatory pushes for lead-free solutions. These regions are characterized by strong innovation ecosystems and a high demand for premium, high-reliability electronic components, fostering the adoption of silver sintering paste in mission-critical applications.

Segment trends reveal a pronounced shift towards pressureless sintering paste technologies, offering greater flexibility in manufacturing processes and enabling broader adoption across diverse applications. The automotive electronics segment, particularly for IGBT and power module die attach in EVs/HEVs, continues to be the largest and fastest-growing application area due to the critical need for thermal stability and power cycling reliability. The market is also experiencing growth in segments such as high-power LEDs and renewable energy inverters, indicating a diversified demand landscape for silver sintering solutions that promise enhanced performance and durability across high-stress environments.

AI Impact Analysis on Silver Sintering Paste Market

User inquiries concerning the impact of Artificial Intelligence on the Silver Sintering Paste Market frequently revolve around optimizing material properties, enhancing manufacturing efficiency, and predicting market dynamics. Common questions explore how AI could accelerate the discovery of novel paste formulations with improved thermal or electrical performance, how it might revolutionize quality control and yield rates in production, and its potential in forecasting demand for critical raw materials like silver amidst global supply chain uncertainties. There is a clear user expectation that AI will lead to more intelligent process control, reducing defects and energy consumption, while also providing predictive insights into application trends and competitive landscapes, ultimately driving innovation and cost-effectiveness within the industry.

- AI-driven material discovery and optimization for novel silver sintering paste formulations.

- Predictive maintenance for manufacturing equipment, minimizing downtime and increasing throughput.

- Real-time process control and quality assurance, leading to enhanced product consistency and reduced waste.

- Optimized supply chain management for silver particles and organic vehicles, mitigating volatility.

- Advanced demand forecasting for various end-use applications, informing production planning and inventory.

- Simulation and modeling of sintering processes to accelerate R&D cycles and improve performance.

DRO & Impact Forces Of Silver Sintering Paste Market

The Silver Sintering Paste Market is profoundly influenced by a complex interplay of drivers, restraints, and opportunities, collectively shaped by various impact forces. A primary driver is the relentless demand for high-performance and high-reliability power electronics across industries such as automotive, industrial, and consumer electronics, which increasingly require superior thermal management and robust die-attach solutions for components like IGBTs and MOSFETs. The global shift towards electric vehicles (EVs) and hybrid electric vehicles (HEVs) stands as a significant catalyst, as these platforms heavily rely on advanced power modules that benefit immensely from the thermal and electrical performance characteristics of silver sintering paste, ensuring extended operational lifespans and efficiency under demanding conditions. Furthermore, the growing trend of miniaturization in electronic devices necessitates innovative packaging solutions that can dissipate heat effectively from smaller footprints, thereby enhancing component density without compromising reliability. This miniaturization, coupled with the industry's continuous pursuit of higher power density, positions silver sintering paste as an indispensable material.

However, several restraints temper the market's growth trajectory. The relatively high cost of silver, which is a primary raw material, poses a significant barrier, especially when compared to more traditional and less expensive solder alternatives. This cost factor can impact the overall bill of materials for electronic components, making it a crucial consideration for manufacturers, particularly in price-sensitive markets. Additionally, the complex manufacturing processes associated with silver sintering, including specific temperature profiles, pressure requirements (for pressure sintering), and precise paste application techniques, demand specialized equipment and expertise, which can deter some potential adopters. The competition from alternative die-attach technologies, such as advanced epoxy resins, transient liquid phase (TLP) bonding, and copper sintering, also presents a challenge, as these alternatives continue to evolve and offer competitive performance in specific applications. These factors necessitate continuous innovation to justify the premium cost and complexity of silver sintering solutions.

Despite these challenges, the market is brimming with opportunities. The rapid expansion of 5G infrastructure and data centers, which require high-power and high-frequency components with efficient thermal management, offers a lucrative growth avenue. The development of advanced packaging technologies, such as wide bandgap (WBG) semiconductors (e.g., SiC and GaN), significantly benefits from silver sintering paste due to their ability to operate at higher temperatures and frequencies, demanding superior thermal interfaces. Moreover, the increasing adoption of renewable energy systems, including solar inverters and wind turbine converters, presents a substantial opportunity as these systems require highly reliable and thermally stable power electronics. The ongoing research and development efforts aimed at reducing processing temperatures, developing pressureless sintering capabilities, and improving material cost-effectiveness are expected to unlock new application areas and broaden market adoption. These technological advancements, combined with the increasing regulatory pressure to eliminate lead from electronic components, collectively create a compelling landscape for sustained innovation and market expansion for silver sintering paste.

Segmentation Analysis

The Silver Sintering Paste Market is meticulously segmented to provide a granular understanding of its diverse landscape, enabling stakeholders to identify specific growth areas and target audiences. These segmentations are critical for analyzing market dynamics, competitive positioning, and strategic planning, reflecting the various forms, applications, end-use industries, and geographical distributions of this advanced material. Each segment offers unique insights into the demand drivers and technological requirements shaping the market's evolution, underscoring the material's versatility and specialized utility across modern electronics. This structured approach allows for a detailed assessment of where value is created and consumed throughout the market ecosystem.

- By Type

- Pressure Sintering Paste

- Pressureless Sintering Paste

- Hybrid Sintering Paste

- By Application

- Power Modules (IGBT, MOSFET, SiC, GaN)

- LED Lighting

- Automotive Electronics (EV/HEV Inverters, Converters)

- Photovoltaic (Solar Inverters)

- Consumer Electronics (High-Performance Processors)

- Industrial Power Devices

- Aerospace and Defense

- Medical Devices

- By End-Use Industry

- Automotive

- Consumer Electronics

- Industrial

- Aerospace & Defense

- Energy (Renewable Energy, Power Grids)

- Telecommunications

- Medical

- By Region

- North America (U.S., Canada, Mexico)

- Europe (Germany, UK, France, Italy, Spain, Rest of Europe)

- Asia Pacific (China, Japan, South Korea, India, Southeast Asia, Rest of APAC)

- Latin America (Brazil, Argentina, Rest of Latin America)

- Middle East & Africa (UAE, Saudi Arabia, South Africa, Rest of MEA)

Value Chain Analysis For Silver Sintering Paste Market

The value chain for the Silver Sintering Paste Market begins with the upstream analysis, which primarily focuses on the sourcing and processing of raw materials. This segment involves suppliers of ultra-high purity silver powder, typically in micron or nano-sized particles, and manufacturers of organic vehicles, binders, and solvents that form the paste matrix. Key activities here include refining silver, synthesizing specialized organic compounds, and ensuring the quality and consistency of these foundational components. The efficiency and cost-effectiveness at this stage are critical, as the price volatility of silver and the specialized nature of organic additives directly influence the final product cost and performance, making supplier relationships and material innovation pivotal.

Following raw material procurement, the value chain moves into the manufacturing of silver sintering paste. This midstream segment involves specialized chemical companies and material science firms that formulate the paste by precisely mixing silver powder with the organic vehicle, often incorporating proprietary additives to achieve desired rheological properties, printability, and sintering characteristics. Quality control, R&D for new formulations (e.g., low-temperature sintering, pressureless sintering), and scaling production are central activities here. This stage is highly technology-intensive, requiring deep expertise in material science and process engineering to ensure the paste meets the stringent performance requirements of high-reliability electronics.

The downstream analysis encompasses the distribution channels and end-user applications. Distribution involves direct sales from manufacturers to large-scale electronics assemblers, semiconductor packaging houses, and power module producers, as well as indirect channels through specialized distributors who cater to smaller manufacturers or offer technical support. The final end-users are primarily concentrated in industries such as automotive (for EV/HEV power modules), consumer electronics (high-performance CPUs/GPUs), industrial power systems, renewable energy (solar inverters), and aerospace & defense. The effectiveness of the distribution network, coupled with robust technical support and application engineering, is crucial for market penetration and customer satisfaction, ensuring that the specialized needs of diverse industries are met with tailored solutions.

Silver Sintering Paste Market Potential Customers

The primary potential customers and end-users of silver sintering paste are diverse and concentrated within industries demanding high-performance, thermally stable, and reliable electronic components. These include manufacturers of power semiconductor modules such as Insulated Gate Bipolar Transistors (IGBTs), MOSFETs, and emerging wide bandgap (WBG) devices like Silicon Carbide (SiC) and Gallium Nitride (GaN) power devices, which operate at higher temperatures and power densities than traditional silicon-based components. These companies seek robust die-attach solutions that can withstand extreme thermal cycling and provide superior thermal dissipation, ensuring the longevity and efficiency of their products, particularly in high-voltage and high-current applications.

Furthermore, a significant segment of potential customers resides within the automotive industry, specifically manufacturers involved in the production of electric vehicles (EVs) and hybrid electric vehicles (HEVs). This includes suppliers of inverters, converters, on-board chargers, and other critical power electronics for EV powertrains. The stringent reliability requirements, high operating temperatures, and long lifespan expectations for automotive components make silver sintering paste an ideal material for ensuring the performance and safety of these advanced vehicle systems, replacing conventional solders that may not meet the durability standards under severe automotive conditions. The rapid global electrification of vehicles continues to expand this customer base.

Beyond automotive, other key customer segments include manufacturers of high-power LED lighting systems, where efficient heat dissipation is crucial for luminaire lifespan and performance, as well as companies producing photovoltaic inverters for solar energy systems, which require reliable thermal management under varying environmental conditions. Industrial power supply manufacturers, developers of aerospace and defense electronics, and even producers of high-performance consumer electronics (e.g., advanced computing processors) also represent vital customer groups. These industries prioritize silver sintering paste for its ability to deliver enhanced thermal conductivity, electrical stability, and high-temperature operational reliability, thereby enabling the next generation of electronic devices that are smaller, more powerful, and more dependable.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 345.8 Million |

| Market Forecast in 2033 | USD 967.4 Million |

| Growth Rate | 15.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Heraeus, Tanaka Kikinzoku Kogyo, Alpha Assembly Solutions (MacDermid Alpha Electronics Solutions), Nihon Superior, Sumitomo Metal Mining, Indium Corporation, Kyocera, LORD Corporation (Parker Lord), Delo Industrial Adhesives, Henkel, Fujikura Ltd., DuPont, Mitsui Mining & Smelting, Shin-Etsu Chemical, Namics, Shoei Chemical, Advanced Silver Technologies, BASF SE, Hitachi Chemical (Showa Denko Materials), Sumitomo Electric Industries |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Silver Sintering Paste Market Key Technology Landscape

The Silver Sintering Paste Market is characterized by a dynamic and evolving technology landscape, continuously driven by the demand for enhanced performance, reliability, and manufacturability in high-power electronic applications. At its core, the technology relies on advanced material science, particularly the precise formulation of silver nanoparticles or micro-particles with specific size distributions and morphologies. These particles are combined with a complex organic vehicle, comprising binders, solvents, and rheology modifiers, which dictates the paste's printability, dispensability, and stability. Innovations in particle synthesis, such as advanced milling techniques and chemical precipitation methods, are crucial for controlling particle size and surface chemistry, directly impacting sintering kinetics and bond strength. Furthermore, the development of specialized organic systems that fully evaporate or decompose during sintering without leaving harmful residues is paramount for achieving high purity silver bonds.

A significant technological advancement in the market is the shift towards pressureless sintering paste, which eliminates the need for external pressure during the sintering process. This innovation simplifies manufacturing, reduces equipment costs, and broadens the applicability of silver sintering to a wider range of substrates and device geometries. Pressureless sintering pastes achieve densification and bonding through optimized particle-to-particle contact and surface energy driven consolidation at lower temperatures, making them highly attractive for high-volume production and complex packaging designs. Concurrently, hybrid sintering technologies are emerging, which combine the benefits of both pressure and pressureless approaches or integrate elements of other bonding mechanisms to achieve specific performance profiles, such as improved shear strength or enhanced thermal cycling reliability, catering to highly specialized application requirements.

Moreover, the technological landscape includes advancements in process optimization and characterization techniques. Advanced rheological measurements and thermal analysis methods are employed to precisely understand paste behavior during application and sintering. High-resolution imaging techniques, such as scanning electron microscopy (SEM) and X-ray diffraction (XRD), are critical for analyzing the microstructure of the sintered silver bond, assessing porosity, and ensuring optimal interconnect quality. Developments in automated dispensing and printing technologies, including stencil printing and jetting, are also integral, enabling high-precision deposition and throughput for mass production. These technological refinements across material formulation, processing methods, and analytical tools collectively contribute to the continuous improvement of silver sintering paste, addressing the escalating demands of next-generation power electronics and packaging solutions.

Regional Highlights

- Asia Pacific: Dominates the market due to a robust electronics manufacturing base, significant investments in automotive electronics (especially EVs in China, Japan, South Korea), and a burgeoning semiconductor industry. China, in particular, leads in both production and consumption.

- North America: Experiences substantial growth driven by advanced research and development in power electronics, increasing demand from the aerospace and defense sectors, and a strong focus on high-performance computing and renewable energy technologies.

- Europe: A key region for automotive innovation, particularly in Germany for luxury and electric vehicles, alongside a strong industrial electronics sector. Strict environmental regulations also accelerate the adoption of lead-free sintering solutions.

- Latin America: Emerging market with increasing industrialization and growing electronics assembly activities, though currently a smaller share, it presents future growth potential as manufacturing capabilities expand.

- Middle East & Africa (MEA): Growing demand from developing infrastructure projects, telecommunications, and a nascent but expanding automotive and electronics manufacturing sector, particularly in countries like UAE and South Africa.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Silver Sintering Paste Market.- Heraeus

- Tanaka Kikinzoku Kogyo

- Alpha Assembly Solutions (MacDermid Alpha Electronics Solutions)

- Nihon Superior

- Sumitomo Metal Mining

- Indium Corporation

- Kyocera

- LORD Corporation (Parker Lord)

- Delo Industrial Adhesives

- Henkel

- Fujikura Ltd.

- DuPont

- Mitsui Mining & Smelting

- Shin-Etsu Chemical

- Namics

- Shoei Chemical

- Advanced Silver Technologies

- BASF SE

- Hitachi Chemical (Showa Denko Materials)

- Sumitomo Electric Industries

Frequently Asked Questions

What is silver sintering paste and why is it used?

Silver sintering paste is an advanced die-attach material composed of silver particles in an organic vehicle, used to form a strong, highly conductive silver bond at relatively low temperatures. It is primarily used in high-performance electronics for superior thermal and electrical conductivity, high-temperature reliability, and as a lead-free alternative to traditional solders.

What are the primary applications of silver sintering paste?

The main applications include power modules for electric vehicles (EVs) and hybrid electric vehicles (HEVs), high-power LEDs, industrial power devices, photovoltaic inverters, and high-performance consumer electronics, where excellent thermal management and long-term reliability are crucial.

How does silver sintering paste differ from traditional solder?

Unlike traditional solder, silver sintering paste forms a pure silver bond through solid-state diffusion, offering significantly higher melting temperatures (above 960°C for silver vs. ~200-300°C for solder), superior thermal and electrical conductivity, and enhanced reliability under extreme thermal cycling and high-temperature operation, while being lead-free.

What are the key drivers for the growth of the silver sintering paste market?

Key drivers include the rapid expansion of the electric vehicle market, the increasing demand for high-performance and miniaturized power electronics, the continuous push for higher power density and thermal management solutions, and the global regulatory shift towards lead-free electronic components.

What are the main types of silver sintering paste available?

The market primarily offers two types: pressure sintering paste, which requires external pressure during the bonding process to achieve densification, and pressureless sintering paste, which can form a robust bond without external pressure, simplifying manufacturing and expanding application versatility.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager