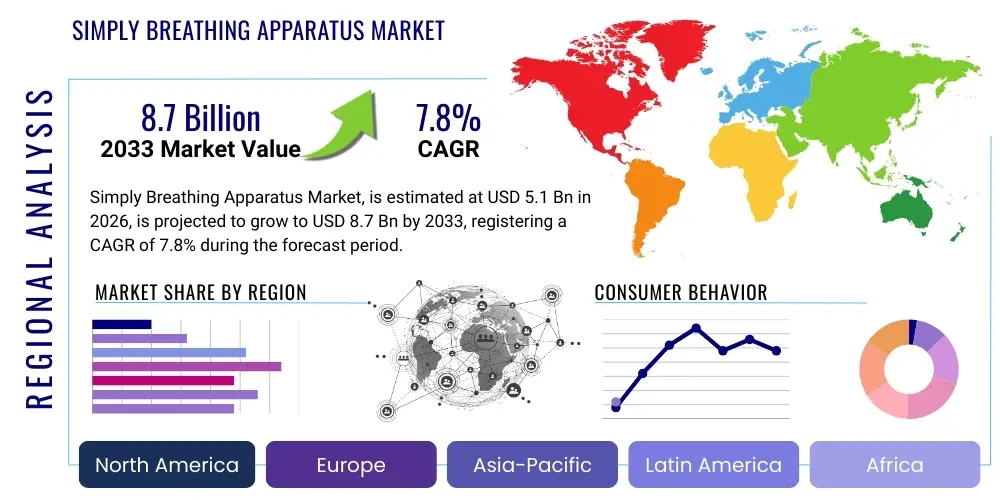

Simply Breathing Apparatus Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 437051 | Date : Dec, 2025 | Pages : 255 | Region : Global | Publisher : MRU

Simply Breathing Apparatus Market Size

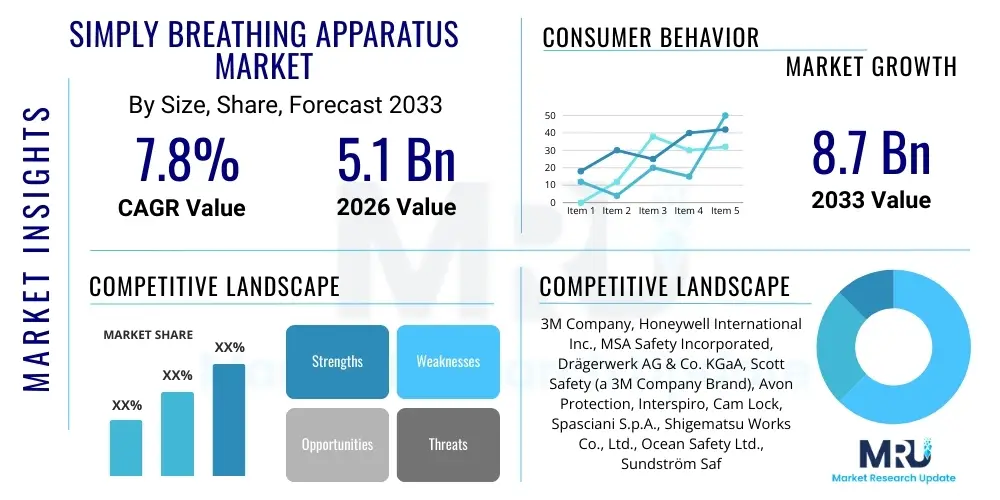

The Simply Breathing Apparatus Market, which includes a range of devices from basic filtering face pieces to sophisticated emergency escape breathing devices (EEBDs) used primarily in industrial safety, emergency services, and healthcare settings, is undergoing robust expansion driven by stringent safety regulations globally and heightened awareness of occupational respiratory hazards. This market is projected to grow at a strong Compound Annual Growth Rate (CAGR) of 7.8% between 2026 and 2033. The market is estimated at USD 5.1 Billion in 2026, benefiting from mandatory safety upgrades across legacy industrial infrastructure and increased defense spending on specialized protection gear. Based on current procurement trends and anticipated technological advancements, the market is projected to reach USD 8.7 Billion by the end of the forecast period in 2033, reflecting increased demand for personal protective equipment (PPE) and rapid industrialization in emerging economies, alongside a consistent replacement cycle in mature markets.

Simply Breathing Apparatus Market introduction

The Simply Breathing Apparatus (SBA) Market encompasses essential life support and safety equipment designed to provide breathable air in environments where the ambient atmosphere is toxic, oxygen-deficient, or otherwise immediately dangerous to life or health (IDLH). This equipment category is fundamentally crucial for maintaining human safety in high-risk operational settings. Products range widely, covering complex systems like self-contained breathing apparatus (SCBA) used by firefighters, semi-mobile supplied air respirators (SAR) utilized in chemical plants, basic filtering devices for dust and particulate matter, and specialized medical breathing systems essential in anesthesia delivery and non-invasive ventilation (NIV). These apparatuses are deployed where atmospheric contaminants or lack of oxygen pose an immediate threat, making them vital tools mandated by international labor organizations and national occupational safety regulatory bodies worldwide. The core function of SBA is to either filter harmful substances from ambient air or provide an independent supply of clean, pressurized air, ensuring operational continuity and protecting the health of the wearer.

Modern SBA systems are defined by their integration of advanced materials and digital technologies. Key technological focuses include improving the portability and duration of air supply through the use of carbon fiber composite cylinders, enhancing communication through integrated radio systems, and increasing user safety via electronic monitoring capabilities. Standard product features must meet rigorous international certification standards, such as those set by the European Committee for Standardization (CEN) or the National Institute for Occupational Safety and Health (NIOSH) in the US, ensuring reliability under extreme conditions like high heat, corrosive exposure, or deep water immersion. Major applications span critical sectors: industrial hazard mitigation, particularly in confined spaces and areas prone to chemical leaks; emergency response, providing critical air to first responders in smoke-filled or toxic environments; and specialized applications, including military decontamination procedures and advanced medical oxygen therapy in tertiary care facilities. The demand profile is highly correlated with capital expenditure in infrastructure and adherence to health and safety audits across all global manufacturing hubs.

The primary benefits driving the robust growth of the market include the significant reduction in occupational fatalities and long-term respiratory illnesses, achieving mandated regulatory compliance—a critical factor for international industrial operations—and enabling operational access to highly hazardous zones, thus minimizing downtime following incidents. Major driving factors include heightened global awareness regarding air quality, particularly post-pandemic, which has driven investment in high-efficiency particulate air (HEPA) filtering apparatuses, and accelerated infrastructural development in rapidly expanding economies, which inherently increases industrial risk exposure. Furthermore, continuous product innovation, particularly the development of lighter, more comfortable equipment that encourages consistent usage, coupled with mandatory equipment replacement cycles stipulated by regulatory bodies (e.g., replacement of air cylinders every 15 years), guarantees sustained market momentum. The inherent necessity of reliable respiratory protection in environments designated as Immediately Dangerous to Life or Health (IDLH) ensures that demand for certified, high-quality SBA solutions remains inelastic relative to broader economic fluctuations, solidifying the market's trajectory.

Simply Breathing Apparatus Market Executive Summary

The Simply Breathing Apparatus Market is exhibiting dynamic growth, underpinned by a confluence of rigorous global safety legislation, advancements in material science, and the pervasive adoption of smart technology. Key business trends underscore a strategic shift towards providing comprehensive safety solutions rather than just hardware. This includes offering bundled packages comprising hardware, predictive maintenance subscriptions, and specialized training programs, significantly enhancing revenue streams post-sale. Manufacturers are increasingly prioritizing supply chain resilience following recent global disruptions, focusing on regionalizing manufacturing and sourcing critical components like specialized regulators and composite prepregs. Furthermore, mergers and acquisitions remain a viable strategy for market leaders seeking to acquire niche technologies, such as advanced gas detection integration or superior mask sealing patents, thereby consolidating market share and achieving economies of scale in R&D and global distribution capabilities. The transition to digital monitoring is reshaping competitive dynamics, requiring players to invest heavily in software development and data security.

Regionally, the market displays a dual growth trajectory. Mature regions like North America and Western Europe maintain their dominance in terms of market value due to established regulatory enforcement, stable public safety budgets, and higher average selling prices for advanced equipment featuring digital telemetry and lightweight carbon fiber components. However, the Asia Pacific (APAC) region is demonstrating unparalleled Compound Annual Growth Rate (CAGR) expansion. This acceleration is driven by the massive scale of infrastructure investment, particularly the construction of new petrochemical complexes and coal/metal mines in countries like Indonesia, Vietnam, and India, which are rapidly transitioning from reliance on basic safety gear to internationally certified, high-performance breathing apparatuses. Investment in safety infrastructure in the Middle East, propelled by national energy sector strategies focused on sour gas processing and large-scale industrial park development, also contributes significantly to global demand, particularly for highly specialized self-contained and supplied air protection equipment.

Analysis of segment trends highlights the enduring centrality of the Self-Contained Breathing Apparatus (SCBA) segment, which commands the largest revenue share, reflecting its critical application in life-or-death scenarios where mobility and independent air supply are paramount. Within the SCBA segment, the sub-segment utilizing carbon fiber composite cylinders is witnessing the fastest adoption rate, reflecting the industry’s willingness to pay a premium for reduced weight and enhanced operational duration, especially in fire and rescue services. Conversely, the growth in Supplied Air Respirator (SAR) systems is robust in heavy manufacturing sectors requiring long duration, non-mobile protection against less concentrated hazards. By application, the Firefighting and Emergency Response category is characterized by demand for highly sophisticated, high-feature equipment that integrates seamlessly with command structures, while the broader Industrial sector remains the volume leader, necessitating a diverse range of apparatus types tailored for tasks ranging from routine maintenance to major chemical spill mitigation. The trend toward modularity and interchangeability of components across product lines is a key strategy for market players to reduce inventory burden for large-fleet customers.

AI Impact Analysis on Simply Breathing Apparatus Market

User inquiries about the integration of Artificial Intelligence (AI) often center on transforming the "Simply Breathing Apparatus" from a passive safety tool into an active, intelligent situational awareness platform. The most frequently asked questions relate to the practical application of AI in minimizing human error and enhancing data-driven decision-making during emergencies. Specifically, users are keen to understand how AI can process complex, multi-modal data streams—including telemetry from multiple SCBA units, ambient environmental sensor readings, and geographic coordinates—to create a unified, real-time operational map for incident commanders. This summarized understanding reveals a critical market expectation: AI should augment the human decision-maker, allowing for rapid resource allocation, predictive risk mapping within hazardous zones, and immediate, automated alerts that go beyond basic low-air warnings, thereby dramatically reducing response times and improving victim location probability and overall safety margins. The demand is not just for data, but for processed, actionable intelligence.

The influence of AI extends deeply into the maintenance and lifecycle management of these critical assets, creating significant operational efficiencies. Users are seeking solutions where AI algorithms can analyze historical usage data, environmental exposure logs, pressure cycle data, and maintenance records to predict the optimal service interval for individual, high-stress components, such as high-pressure regulators or safety relief valves, which are prone to subtle material fatigue and wear. This fundamental shift from time-based, scheduled maintenance to condition-based, predictive maintenance (PdM) is highly anticipated as it promises to reduce unnecessary servicing costs, minimize equipment downtime, and, most importantly, maximize equipment reliability, which is non-negotiable in life-support safety applications. OEMs are rapidly developing proprietary AI platforms to manage these service contracts, locking in long-term customer relationships and optimizing their global spare parts logistics.

Furthermore, AI is crucial in developing next-generation SBA training simulators, moving beyond pre-programmed scenarios to dynamically adapting training exercises based on real-time trainee performance, physiological feedback, and complex historical incident data. This capability ensures that personnel are better equipped to handle novel emergency conditions that require complex judgment and quick analysis of conflicting sensor data. AI systems are also being deployed to analyze voice communications within the apparatus, utilizing noise cancellation and language processing to ensure clear, unambiguous communication between team members and command, a crucial factor often compromised in high-stress, high-noise operational environments. This push towards "intelligent protection" is rapidly becoming a core differentiator in the high-end breathing apparatus market segment.

- AI-driven predictive maintenance modeling utilizing sophisticated sensor data to forecast potential failures in air regulators and valves, optimizing service schedules and significantly minimizing unexpected equipment downtime.

- Real-time anomaly detection in air consumption rates and physiological patterns of users via integrated wearables, instantly flagging potential physical distress, overexertion, or breathing apparatus integrity failures.

- Integration of machine learning algorithms to process multi-modal environmental sensor inputs (thermal, chemical plume tracking, pressure fluctuations), automating the accurate classification and dynamic predictive mapping of IDLH environments for faster, more informed command decisions.

- Optimization of complex air cascade system logistics, cylinder inventory, and refilling schedules based on predicted operational demand, historical usage spikes, and geographically dispersed incident probability models.

- Enhanced hands-free voice command processing and interpretation within the facepiece communications system, powered by deep neural network algorithms to filter out extreme background noise and ensure crystal-clear communication fidelity.

- Development of AI-powered data fusion platforms that seamlessly merge SCBA telemetry (air supply, location) with external data sources like building blueprints, drone surveillance feeds, and thermal imaging for comprehensive, three-dimensional incident mapping and asset tracking.

- Automated post-incident report generation and regulatory compliance verification based on recorded apparatus usage logs, pressure profiles, and performance metrics analyzed and summarized efficiently by AI systems, streamlining administrative burden.

DRO & Impact Forces Of Simply Breathing Apparatus Market

The Simply Breathing Apparatus market is structurally fortified by powerful, non-negotiable drivers stemming from global regulatory mandates and inherent industrial risks. Foremost among these drivers is the increasing global harmonization and rigorous enforcement of occupational safety standards, particularly those governing confined spaces, hazardous material handling, and fire protection. Organizations such as the International Labour Organization (ILO) and national bodies like OSHA (US) and HSE (UK) continuously update and strengthen requirements for respiratory protection, guaranteeing baseline demand and mandatory upgrade cycles. Furthermore, the accelerating pace of global industrialization, especially the construction of mega-projects in energy, chemical processing, and infrastructure sectors across Asia and the Middle East, directly translates into mandatory procurement of certified breathing equipment for massive fleet deployments. Continuous product improvement, offering lighter weight, longer duration, greater durability, and enhanced connectivity, serves as an intrinsic market stimulant, encouraging voluntary and early upgrades even before mandatory replacement cycles occur, driven by end-user desire for superior operational comfort.

Despite the inherent, resilient demand, the market faces significant constraining forces that temper explosive growth potential. The single largest restraint is the substantial initial capital outlay required for high-end SCBA units, which incorporate advanced carbon fiber cylinders and complex, digitally integrated electronic systems. This high barrier to entry disproportionately affects small and medium-sized enterprises (SMEs) in developing regions, who may opt for lower-cost, less-certified alternatives or delay critical procurement, creating a safety gap. Additionally, the operational complexity associated with maintaining specialized, high-pressure equipment, including mandatory annual flow testing, regulator calibration, and the high infrastructure cost of maintaining high-pressure air charging stations, demands significant ongoing investment in specialized training and certified infrastructure. Finally, the fragmented nature of international safety certifications—where a device certified in the US (NIOSH) may require expensive re-certification, adaptation, or even redesign for sale in Europe (CE/EN) or Australia (AS/NZS)—creates substantial inventory management hurdles and cost complexity for global suppliers.

Opportunities for exponential growth are concentrated in two primary areas: technological advancement and geographical expansion into developing regulatory regimes. The pervasive integration of Internet of Things (IoT) capabilities, particularly comprehensive telemetry systems allowing incident commanders to monitor user vitals and air supply remotely, represents a major value-add opportunity, creating a rapidly growing premium market segment focused on data-driven safety management and operational efficiency. Geographically, the maturation and rigorous enforcement of regulatory practices in large, previously underserved markets, such as India, Indonesia, and parts of Latin America and Africa, offer vast potential for market penetration. The key impact forces dictating market behavior include the persistent pressure from insurance and liability groups to adopt the highest safety standards (often exceeding minimum regulatory requirements), which indirectly accelerates the purchase of superior, smarter equipment. Secondly, the competitive force of innovation ensures a rapid obsolescence cycle for older, heavier, non-telemetry apparatuses, pushing consistent R&D investment aimed at achieving maximum lightness and duration for optimal user performance and long-term asset value.

Segmentation Analysis

The comprehensive analysis of the Simply Breathing Apparatus market by segmentation reveals distinct consumer behaviors and technological preferences across various application environments and regional safety cultures. Segmentation by product type clearly delineates the market utility: SCBA dominates critical response (firefighting, rescue), SAR systems serve extended work duration in fixed locations (chemical plants, paint booths) due to their limitless air supply potential, and EEBDs fulfill mandatory emergency escape requirements across the maritime and confined space industrial platforms. The differentiation by component materials, particularly the sustained shift from traditional Steel/Aluminum cylinders to advanced Composite Cylinders (Carbon Fiber wrapped), reflects a fundamental market trend favoring mobility, driven by end-user demands across almost all high-risk sectors. This detailed segmentation allows manufacturers to tailor product specifications—such as harness durability, regulator complexity, and electronic component robustness—precisely to the regulatory and operational needs of specific industries, optimizing the product-market fit and pricing strategy.

- By Product Type:

- Self-Contained Breathing Apparatus (SCBA)

- Open Circuit SCBA (Positive Pressure)

- Closed Circuit SCBA (Rebreathers, specialized for long duration)

- Supplied Air Respirators (SAR)

- Airline Respirators (Continuous Flow or Pressure Demand)

- Hose Masks (Less Common, Non-IDLH only)

- Emergency Escape Breathing Devices (EEBD)

- Hood Type EEBD (Simplified, Quick Donning)

- Cylinder Type EEBD (Compressed Air, Short Duration)

- Air Purifying Respirators (APR)

- Powered Air Purifying Respirators (PAPR) (High volume airflow)

- Non-Powered Filtering Facepiece Respirators (Disposable or Reusable)

- Self-Contained Breathing Apparatus (SCBA)

- By Component:

- Cylinders

- Composite Cylinders (Carbon Fiber/Kevlar wrapped)

- Steel and Aluminum Cylinders (Traditional, Lower Cost)

- Regulators and Valves (First and Second Stage High-Pressure Reduction)

- Face Masks and Hoods (Full Facepiece, Half Mask, Specialized Hoods)

- Harnesses, Backplates, and Carrying Systems (Ergonomic Support)

- Electronic Monitoring Systems (Telemetry, HUDs, PASS Devices, Distress Alarms)

- Hoses, Couplings, and Connectors

- Cylinders

- By End-User Industry:

- Oil and Gas (Upstream, Midstream, Downstream, Offshore Platforms)

- Mining (Underground and Surface Operations, Mine Rescue)

- Chemical and Petrochemical Processing (Hazardous Material Response)

- Firefighting and Emergency Response (Municipal and Industrial Brigades, HAZMAT Teams)

- Healthcare and Pharmaceutical (Sterile Environments, Biological/Infectious Agents Protection)

- Construction and Manufacturing (Heavy Fabrication, Tunneling, Welding Fume Mitigation)

- Defense and Maritime (Naval Operations, Submarine Escape, Shipboard Safety)

- Utilities (Power Generation, Confined Space Entry in Water/Wastewater Treatment)

- By Geography:

- North America (US, Canada, Mexico)

- Europe (Germany, UK, France, Italy, Nordic Countries, Rest of Europe)

- Asia Pacific (APAC) (China, India, Japan, South Korea, Australia, Southeast Asia)

- Latin America (LATAM) (Brazil, Argentina, Chile, Rest of LATAM)

- Middle East and Africa (MEA) (GCC Countries, South Africa, Nigeria)

Value Chain Analysis For Simply Breathing Apparatus Market

The value chain for the Simply Breathing Apparatus market is structurally complex, characterized by stringent safety compliance and reliance on highly technical, specialized component manufacturing at the upstream level. Upstream analysis focuses heavily on the procurement of highly regulated raw materials. This includes aerospace-grade carbon fiber filaments and specialized resins for composite cylinders, high-purity aluminum or corrosion-resistant steel alloys for liners and valves, and medical-grade, highly durable polymers for masks and mouthpieces. Suppliers of these core raw materials must adhere to exceptional quality control standards and maintain meticulous traceability, as any material inconsistency can compromise the integrity of life-support equipment. Critical intellectual property resides in the design and precision manufacturing of the high-pressure regulator, which must reliably and consistently reduce tank pressure from extreme levels (up to 6000 psi in some systems) down to breathable levels, demanding specialized machining tolerances that represent a significant barrier to entry for potential competitors. Strategic partnerships with key material suppliers are essential for managing input costs and ensuring supply chain security.

The mid-stream segment involves core manufacturing processes, including the intricate filament winding of composite cylinders, the sterile-environment assembly of high-pressure regulators, and the complex integration of electronic monitoring components and communication modules. This stage is dominated by manufacturers who must implement rigorous quality assurance protocols, as every assembled unit is required to pass hydrostatic testing, heat exposure tests, and functional performance checks mandated by certifying bodies such as ISO, NIOSH, or CEN. Distribution channels are highly structured and typically bifurcated to serve the diverse customer base: Direct distribution is favored for large, complex government, military, or major industrial contracts, often involving highly technical sales engineers who provide customized solutions and comprehensive training packages. This allows manufacturers maximum margin capture and precise control over product deployment and initial service onboarding. Indirect distribution, conversely, relies on a dense network of specialized safety equipment dealers, authorized stocking distributors, and industrial wholesalers. These partners provide localized access, manage smaller volume sales to SMEs, and offer crucial regional after-sales support, including mandatory service and air charging capabilities.

Downstream analysis highlights the critical, high-margin role of after-market services, which often generate stable, long-term revenue streams essential for market participants. This includes mandatory annual maintenance, periodic major overhaul (MRO), hydrostatic testing of cylinders (required every three to five years), and the provision of certified, recurrent training programs for end-users to ensure competency. The distribution network must therefore include a robust network of certified service centers equipped with specialized calibration tools, test benches, and highly trained, OEM-certified personnel to handle crucial calibration and repair tasks. The increasing sophistication of SBA through IoT telemetry integration also necessitates significant investment in the downstream segment in secure data handling infrastructure, cloud services, and integration specialists capable of linking apparatus data with the customer's existing safety and facility management systems. The profitability and competitive longevity in this market are intrinsically linked to the ability to provide reliable, compliant, and pervasive after-sales service and support throughout the apparatus's multi-decade service life.

Simply Breathing Apparatus Market Potential Customers

The customer base for Simply Breathing Apparatus is broadly segmented by operational risk exposure and regulatory compliance requirements, leading to highly differentiated demands for product features and performance metrics. The largest volume purchasers are centralized industrial entities in the Chemical, Petrochemical, and Oil & Gas sectors, particularly those managing large refineries, exploration sites, offshore platforms, and manufacturing sites with continuous exposure to corrosive, volatile, or highly toxic atmospheres. These customers operate under strict international Process Safety Management (PSM) guidelines and require extensive fleets of standardized SCBA, EEBD, and specialized SAR systems for both routine maintenance entries and major emergency response preparedness. Their purchasing decisions are critically influenced by the total cost of ownership (TCO), material durability against harsh environments, cylinder longevity, and ease of seamless integration into existing plant safety management systems, often prioritizing comprehensive, long-term service agreements with original equipment manufacturers (OEMs) to ensure uninterrupted operational readiness and regulatory adherence.

A second, high-value, and technologically demanding customer segment comprises public sector entities, specifically municipal, regional, and national firefighting, HAZMAT, and disaster relief agencies. These clients operate under the most extreme conditions and consequently demand the absolute highest performance standards, uncompromising reliability, and advanced digital integration capabilities. They frequently specify the lightest available carbon fiber composite cylinders, advanced digital telemetry systems (Heads-Up Displays, integrated radio, GPS tracking), and rapid-donning harness systems. Procurement in this sector is characterized by lengthy, highly competitive governmental tender processes where compliance with stringent national and international standards (e.g., NFPA 1981, EN 137) is mandatory. Winning these large, often multi-year contracts requires demonstrating not only superior product performance but also robust, nationwide service support networks, guaranteed spare parts logistics, and accredited training academies capable of certifying large numbers of personnel on the specialized, life-saving equipment.

Emerging and specialized customer segments, representing significant growth vectors, include the global maritime industry, driven by mandatory safety regulations (IMO/SOLAS) requiring EEBDs and basic SCBA on all commercial vessels, cruise ships, and offshore drilling units. Furthermore, the healthcare and pharmaceutical sector, particularly R&D labs and specialized hospital isolation units, increasingly require high-performance Air Purifying Respirators (PAPR) and supplied air systems to protect workers from specific particulates, biological agents, and sterile environment requirements. The defense and military sector is a stable, high-specification customer for closed-circuit rebreathers and specialized hazard protection gear. These diverse customers prioritize equipment certified for specific hazard classes, demanding transparency in filtration effectiveness, robust user training support, and ergonomic design optimized for specific tasks, ranging from confined space inspection to extended clean-room operations without compromising air quality delivery.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 5.1 Billion |

| Market Forecast in 2033 | USD 8.7 Billion |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | 3M Company, Honeywell International Inc., MSA Safety Incorporated, Drägerwerk AG & Co. KGaA, Scott Safety (a 3M Company Brand), Avon Protection, Interspiro, Cam Lock, Spasciani S.p.A., Shigematsu Works Co., Ltd., Ocean Safety Ltd., Sundström Safety AB, CMC Rescue Inc., RAE Systems (Honeywell), S-Gard SafetyTex, AirBoss of America Corp., Vortex Technologies, Survitec Group Ltd., Respirator Protection UK Ltd., Jiangsu Huayi Technology Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Simply Breathing Apparatus Market Key Technology Landscape

The core technological evolution in the Simply Breathing Apparatus market revolves around enhancing three critical performance vectors: mobility, communication, and intelligence, ensuring that equipment is safer, easier to use, and provides actionable data. The transition to advanced Composite Cylinder Technology remains the paramount material science innovation. Carbon fiber composite cylinders, meticulously engineered through automated filament winding techniques over lightweight liners (typically aluminum or polymer), offer up to a 70% weight reduction compared to older steel cylinders while safely operating at higher pressure ratings (up to 450 bar/6600 psi). This substantial weight reduction directly contributes to improved ergonomic performance, extended wear time tolerance, and dramatically reduced physical strain on rescue and industrial personnel, which is paramount for maximizing operational effectiveness and endurance during high-stress operations. Manufacturers are continually refining the composite matrix and the liner material to further enhance resistance to impact damage, thermal shock, and aggressive chemical corrosion, ensuring a stable and reliable service life mandated by rigorous inspection requirements such as DOT or TPED standards.

The most significant disruptive technology is the ubiquitous integration of Digital and Smart SCBA Systems, leveraging the power of IoT (Internet of Things) connectivity and micro-sensor technology. These modern systems incorporate multi-sensor packs, robust microprocessors, and secure wireless transmission modules (often using specialized radio protocols) to monitor apparatus status, ambient environment conditions, and critical user health metrics. Key user interfaces include Heads-Up Displays (HUDs) integrated within the mask, which utilize visual cues (e.g., colored LEDs, projected digital readouts) to continuously inform the user of remaining air pressure, estimated time of egress based on current consumption, and high-temperature or low-battery warnings. Furthermore, advanced telemetry functionality enables real-time accountability tracking by centralized incident commanders, providing critical data on time spent in the hazardous zone, precise geographic location, and the status of the device’s integrated PASS (Personal Alert Safety System) alarm. This digital transformation elevates the SBA from a purely mechanical protection device to a crucial, interconnected safety and tactical support node within a larger emergency response network, enabling proactive risk mitigation.

Beyond air supply and digital monitoring, ongoing innovations in Facepiece Ergonomics and Regulator Precision are vital for improving user acceptance, minimizing air leakage, and ensuring reliability. Modern face masks utilize advanced optical coatings and high-durability, scratch-resistant polycarbonate materials for visors, incorporating design elements that reduce peripheral vision obstruction and resist fogging even in high-humidity environments. Regulator technology is advancing to include improved pressure redundancy systems, often utilizing dual-stage mechanisms, and integrated voice amplifiers (AVAs) for clear communication despite the muffling effect of the facepiece. For specialized applications like rebreathers (Closed Circuit SCBA), technological focus is intensely dedicated to extending duration (potentially multiple hours) through highly efficient CO2 scrubbers (often lithium hydroxide or sodalime compounds) and sophisticated electronic controls that precisely manage oxygen injection and mixture delivery, which is essential for specialized mine rescue, long-duration maintenance, or deep-sea diving operations. Continuous R&D into long-life, intrinsically safe battery technology and the development of non-proprietary communication interfaces are also crucial technological efforts, aimed at ensuring digital safety features remain functional throughout the mandated operational period and interoperate seamlessly with other industrial safety equipment.

Regional Highlights

- North America: This region consistently dominates the market in terms of value, primarily due to the stringent adherence to institutionalized safety standards (NFPA, NIOSH, OSHA) and high regulatory oversight across industrial and public safety sectors. The US market, driven significantly by mandatory equipment replacement cycles for municipal fire departments, large government contracts, and substantial capital expenditures in the refining and chemical sectors, exhibits a high propensity for adopting premium, digitally-integrated SCBA systems. Technological adoption is rapid, favoring lightweight composite cylinders and sophisticated data management platforms for compliance reporting and post-incident analysis, setting a global benchmark for safety technology implementation.

- Europe: Characterized by highly standardized, pan-European compliance stemming from the EU's comprehensive PPE Regulation and stringent national bodies (e.g., Germany's DGUV, UK's HSE), Europe maintains a mature, steady demand driven by strict maintenance requirements. The market here places a strong emphasis on modularity, high efficiency, ease of field servicing, and sustainability, leading to demand for apparatuses with long service lives and easily replaceable, recyclable components. Western European countries are major technology exporters in safety and filtering apparatus, fostering strong R&D in specialized filtering and supplied air systems often utilized in pharmaceutical, clean-room, and chemical manufacturing environments.

- Asia Pacific (APAC): APAC is designated as the engine of future market growth, anticipated to record the highest CAGR. This accelerated expansion is driven by both massive industrial scale-up (construction, manufacturing, mining) and the rapidly increasing governmental adoption and rigorous enforcement of international occupational safety standards across key economies like China, India, and Southeast Asia. The market demand profile is shifting from basic safety gear toward certified, mid-to-high-range SCBA and SAR systems, resulting in vast fleet expansion requirements. While price sensitivity exists, the critical need for compliance in major export-oriented industries is forcing rapid investment in superior respiratory protection.

- Latin America (LATAM): Market expansion in LATAM is closely correlated with the performance of resource extraction industries, particularly high-altitude mining (Andean countries) and complex deep-water oil exploration (Brazil, Mexico). Demand is predominantly driven by multinational companies operating locally and enforcing global safety standards. The market faces challenges related to economic volatility and inconsistent local safety enforcement across smaller enterprises, leading to varied and often project-dependent demand patterns. However, the long-term outlook remains strong due to increasing governmental focus on industrial accountability, worker protection mandates, and large-scale infrastructure projects requiring confined space protection.

- Middle East and Africa (MEA): Demand is robust and consistently high within the Gulf Cooperation Council (GCC) countries, specifically driven by the massive investment in hydrocarbon processing, desalination plants, and specialized export terminals, which require high-specification breathing equipment resistant to high heat, dust, and toxic H2S exposure. Procurement is typically large-scale, centralized, and managed by state-owned enterprises, valuing high performance, guaranteed durability, and robust local service contracts. Africa's market growth is slower but steady, primarily focused on mining safety and infrastructure projects, often depending on foreign investment to procure certified, internationally compliant safety equipment fleets.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Simply Breathing Apparatus Market.- 3M Company (through Scott Safety and other respiratory divisions)

- Honeywell International Inc. (including RAE Systems and other safety brands)

- MSA Safety Incorporated

- Drägerwerk AG & Co. KGaA

- Avon Protection

- Interspiro

- Cam Lock

- Spasciani S.p.A.

- Shigematsu Works Co., Ltd.

- Ocean Safety Ltd.

- Sundström Safety AB

- CMC Rescue Inc.

- AirBoss of America Corp.

- Vortex Technologies

- Survitec Group Ltd.

- Respirator Protection UK Ltd.

- Jiangsu Huayi Technology Co., Ltd.

- Techno-Fira Srl

- Bulldog Safety Equipment

- GEC Corporation

Frequently Asked Questions

Analyze common user questions about the Simply Breathing Apparatus market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between SCBA and SAR systems?

SCBA (Self-Contained Breathing Apparatus) provides air from a portable high-pressure cylinder carried by the user, granting complete mobility essential for emergency entry into IDLH (Immediately Dangerous to Life or Health) zones. SAR (Supplied Air Respirator) delivers air from a fixed, remote compressor or bank via a long hose, offering unlimited duration for extended work but restricting user movement to the hose length and necessitating a reliable non-IDLH emergency escape provision.

How do carbon fiber composite cylinders enhance safety and operational efficiency?

Composite cylinders significantly reduce the apparatus weight (up to 70% lighter than traditional steel), which minimizes user fatigue, improves mobility, and extends the operational endurance of personnel during critical tasks. Their reduced weight and higher pressure ratings allow for longer duration air supplies in a more ergonomic package, directly correlating with enhanced safety compliance and effectiveness.

What technological feature is considered the most critical advancement in modern SCBA?

The most critical advancement is the integration of telemetry systems and Heads-Up Displays (HUDs). These smart features provide real-time digital monitoring of remaining air supply, location, and user status to both the wearer and the incident commander simultaneously. This capability enables immediate, data-driven resource allocation and drastically improves accountability tracking and coordination in complex, low-visibility emergency environments.

Which geographical region is expected to experience the highest growth rate and why?

The Asia Pacific (APAC) region is forecasted to exhibit the highest Compound Annual Growth Rate (CAGR). This expansion is fundamentally driven by the enormous scale of industrialization, infrastructure development, and the accelerating trend of governments in countries like China, India, and Indonesia adopting and enforcing international occupational safety standards, leading to massive fleet procurement mandates.

What is the role of AI in maintaining the reliability of breathing apparatus equipment?

AI is crucial in enabling predictive maintenance (PdM) programs. By analyzing historical usage data, pressure cycles, and operational logs, AI algorithms can accurately predict when specific high-stress components, such as high-pressure valves or regulators, are likely to fail due to fatigue, allowing safety managers to schedule proactive maintenance and replacement, thus maximizing equipment uptime and guaranteeing life-saving reliability.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager