Single Dose Laundry Detergent Cap Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440047 | Date : Jan, 2026 | Pages : 253 | Region : Global | Publisher : MRU

Single Dose Laundry Detergent Cap Market Size

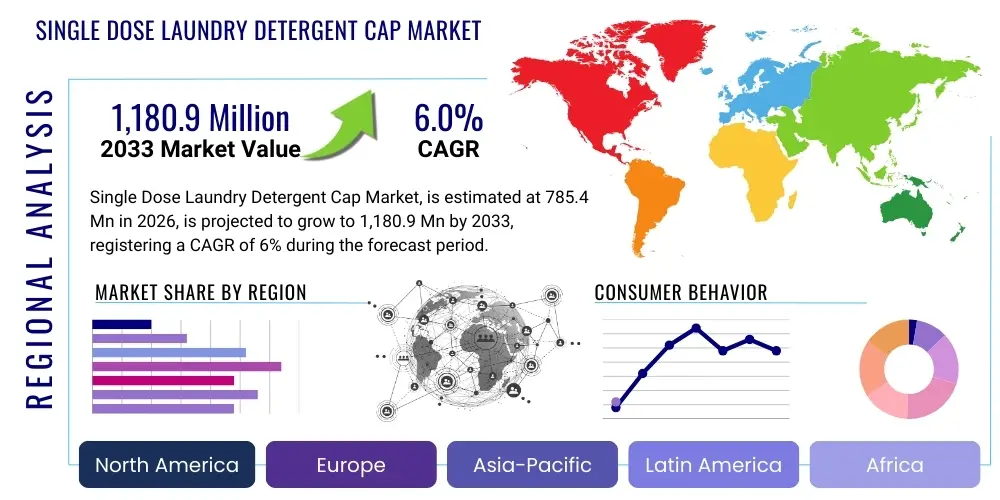

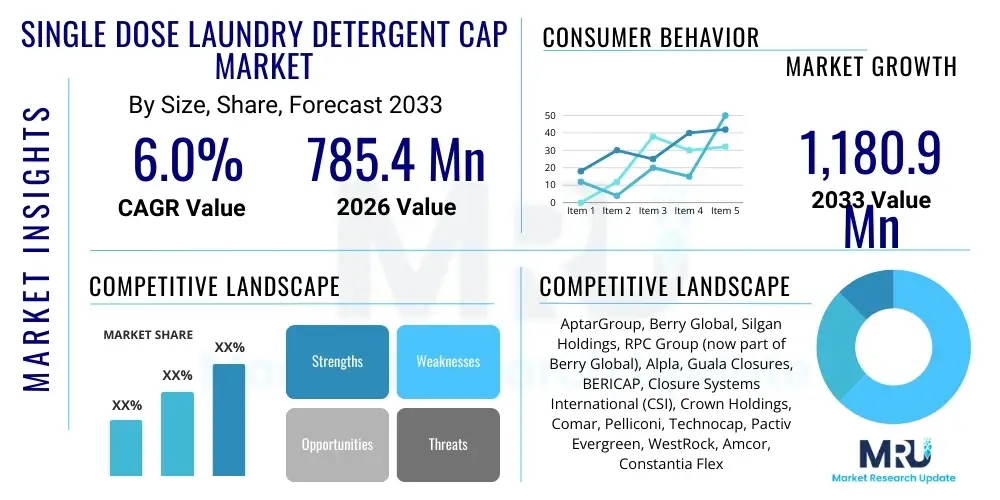

The Single Dose Laundry Detergent Cap Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.0% between 2026 and 2033. The market is estimated at USD 785.4 million in 2026 and is projected to reach USD 1,180.9 million by the end of the forecast period in 2033.

Single Dose Laundry Detergent Cap Market introduction

The Single Dose Laundry Detergent Cap Market is an integral and rapidly evolving segment within the broader consumer packaging industry, specifically catering to the growing popularity of pre-measured laundry detergent formats. These caps are not merely closures but represent a critical component in the convenience, safety, and efficacy of single-dose laundry pods, packs, or tablets. The product description encompasses a range of designs, materials, and functionalities, from child-resistant features and precise dosing mechanisms to aesthetically pleasing and eco-friendly options. Major applications primarily involve household laundry care, but also extend to institutional and commercial laundering where precise dosage and ease of use are paramount.

The inherent benefits of single-dose laundry detergent caps include enhanced user convenience by eliminating the need for measuring, reduced spillage and waste, and improved safety, particularly with child-resistant closures. They contribute significantly to brand differentiation through innovative design and material choices, aligning with consumer preferences for simplicity and efficiency in their daily routines. Driving factors for this market's expansion are multifaceted, encompassing rising consumer demand for convenience products due to busy lifestyles, the continuous innovation in detergent formulations that benefit from precise dosing, and growing awareness around sustainability driving demand for lightweight and recyclable packaging solutions.

Furthermore, advancements in manufacturing technologies allow for more complex and functional cap designs, addressing specific challenges such as moisture protection and chemical compatibility. Regulatory pressures for child safety features, particularly in regions like North America and Europe, also play a significant role in shaping product development and market growth. The increasing penetration of automatic washing machines globally, coupled with a shift towards premium and specialized laundry products, further propels the adoption of single-dose formats, making the cap market a critical enabler of these trends.

Single Dose Laundry Detergent Cap Market Executive Summary

The Executive Summary for the Single Dose Laundry Detergent Cap Market highlights robust business trends driven by consumer preference for convenience and innovation in packaging. The market is experiencing significant growth fueled by the widespread adoption of single-dose laundry detergents globally, which necessitates specialized, high-performance caps. Key business trends include a strong focus on sustainable materials, such as post-consumer recycled (PCR) plastics and bio-based polymers, to meet corporate social responsibility goals and consumer environmental demands. Manufacturers are also investing in advanced molding technologies and automation to improve production efficiency and reduce costs, while simultaneously enhancing product functionality, such as improved child-resistant mechanisms and tamper-evident features. Strategic partnerships between cap manufacturers and detergent brands are becoming more common, fostering collaborative innovation and faster market entry for new cap designs.

Regional trends indicate North America and Europe as mature markets with high penetration of single-dose detergents, driving demand for advanced and safety-compliant caps. These regions are characterized by stringent regulatory frameworks for child safety, pushing innovation in closure design. Asia Pacific, particularly emerging economies like China and India, presents the fastest growth opportunities due to increasing disposable incomes, urbanization, and a burgeoning middle class adopting modern convenience products. Latin America and the Middle East & Africa are also showing steady growth, albeit from a smaller base, as global detergent brands expand their presence and introduce single-dose options. Regional variations in consumer preferences, climate, and regulatory landscapes significantly influence cap material choices, design aesthetics, and functional requirements, creating diverse market demands.

Segments trends reveal a significant shift towards innovative materials, with polypropylene (PP) and high-density polyethylene (HDPE) remaining dominant due to their excellent chemical resistance and cost-effectiveness, but with a growing inclination towards sustainable alternatives. Child-resistant caps continue to be a primary segment, driven by regulatory mandates and parental concerns, with ongoing advancements in user-friendly yet secure designs. The market is also seeing segmentation based on aesthetic appeal and customizability, allowing brands to differentiate their products on crowded retail shelves. Furthermore, the increasing adoption of e-commerce platforms is influencing packaging design, requiring robust and spill-proof caps that can withstand the rigors of shipping. The interplay of these trends underscores a dynamic market focused on safety, sustainability, and consumer convenience, driving continuous innovation across all segments.

AI Impact Analysis on Single Dose Laundry Detergent Cap Market

User inquiries regarding the impact of Artificial Intelligence on the Single Dose Laundry Detergent Cap Market frequently center on themes of manufacturing efficiency, supply chain optimization, and product innovation. Consumers and industry professionals are keen to understand how AI can enhance the production process, from predictive maintenance in molding operations to intelligent quality control systems that detect microscopic defects in caps. There is also significant interest in AI's role in streamlining global supply chains, forecasting demand more accurately, and optimizing logistics for cap distribution to detergent manufacturers. Expectations include AI leading to more cost-effective production, faster time-to-market for new designs, and ultimately, a more reliable and consistent product for end-users. Concerns often revolve around the initial investment costs, the need for specialized skills, and data privacy implications associated with AI implementation in manufacturing and supply chain management.

- AI-driven predictive maintenance for injection molding machines, reducing downtime and improving production efficiency.

- Enhanced quality control systems utilizing computer vision and machine learning to detect cap defects at higher speeds and accuracy than traditional methods.

- Optimized supply chain logistics and inventory management through AI algorithms that forecast demand, manage raw material procurement, and streamline distribution.

- Accelerated material research and development by simulating new polymer compositions and cap designs, leading to more sustainable or functional materials.

- Personalized product development insights derived from AI analysis of consumer feedback and market trends, guiding the creation of caps with desired features.

- Automation of repetitive tasks in cap assembly and packaging, leading to increased output and reduced labor costs.

- Improved energy efficiency in manufacturing processes through AI monitoring and optimization of machinery operations.

- Risk assessment and mitigation in the supply chain, identifying potential disruptions and suggesting alternative strategies proactively.

DRO & Impact Forces Of Single Dose Laundry Detergent Cap Market

The Single Dose Laundry Detergent Cap Market is significantly shaped by a confluence of drivers, restraints, opportunities, and broader impact forces. Key drivers include the escalating global demand for convenience products, fueled by urbanization and hectic lifestyles, making single-dose detergents an attractive option for consumers seeking efficiency. The inherent benefits of precise dosing, which minimizes product waste and ensures optimal cleaning performance, also contribute to their appeal. Furthermore, stringent regulatory mandates for child-resistant packaging in many regions necessitate advanced cap designs, thereby stimulating innovation and growth in this specialized segment. Brand differentiation through unique cap functionalities and aesthetic appeal also serves as a strong driver, as manufacturers strive to capture market share.

However, the market faces several restraints. The relatively higher cost of production for specialized caps, especially those with child-resistant or complex dispensing mechanisms, can be a deterrent for some manufacturers, potentially impacting overall product affordability. Material price volatility, particularly for plastics, can also squeeze profit margins. Environmental concerns related to plastic waste and the growing pressure to adopt sustainable packaging solutions pose a challenge, requiring significant R&D investment in eco-friendly materials that maintain performance integrity. The complexity of designing caps that are both child-resistant and adult-friendly presents a continuous engineering hurdle, as balancing these two often conflicting requirements is critical for market acceptance.

Opportunities within the market are vast and promising. The ongoing shift towards sustainable and recyclable packaging materials, including PCR (post-consumer recycled) content and bio-based plastics, offers a significant avenue for innovation and market expansion. Emerging markets, particularly in Asia Pacific and Latin America, present substantial untapped potential as disposable incomes rise and modern retail formats proliferate, increasing the adoption of single-dose laundry products. Furthermore, advancements in smart packaging technologies, such as NFC/RFID enabled caps for product authentication or usage tracking, could unlock new value propositions. The continuous evolution of detergent formulations, which may require novel cap designs for optimal dispensing and preservation, also presents ongoing opportunities for specialized cap manufacturers.

Impact forces acting on this market include evolving consumer preferences towards eco-friendly and safe products, which directly influence cap material selection and design. Technological advancements in molding and manufacturing processes allow for greater design complexity and efficiency, impacting production costs and speed. Global supply chain disruptions, as witnessed recently, highlight the need for resilient and diversified sourcing strategies. Furthermore, the competitive landscape, characterized by both large established players and agile niche manufacturers, drives continuous innovation and competitive pricing. The interplay of these forces mandates a dynamic and adaptive strategy for companies operating within the Single Dose Laundry Detergent Cap Market to ensure long-term sustainability and growth.

Segmentation Analysis

The Single Dose Laundry Detergent Cap Market is extensively segmented to reflect the diverse needs of detergent manufacturers and the varied preferences of end-users. These segmentations provide a granular view of the market, allowing for targeted product development and strategic marketing efforts. Key segmentation criteria include the type of material used for manufacturing, the specific closure mechanism employed, the end-user application, and the geographical distribution. Each segment plays a crucial role in defining the market's dynamics, influencing pricing strategies, technological innovation, and competitive positioning. Understanding these distinct segments is essential for stakeholders to identify growth opportunities and address specific market demands effectively.

- By Material Type:

- Polypropylene (PP): Dominant due to excellent chemical resistance, durability, and cost-effectiveness.

- High-Density Polyethylene (HDPE): Offers good stiffness, impact resistance, and barrier properties.

- Low-Density Polyethylene (LDPE): Known for flexibility and ease of processing.

- Bio-based Plastics: Emerging segment driven by sustainability goals, including PLA, PHA.

- Recycled Plastics (PCR): Growing in demand for environmental responsibility.

- Other Polymers: Including specialty plastics for specific barrier or aesthetic requirements.

- By Closure Type:

- Child-Resistant Closures (CRCs): Mandated in many regions for safety, often push-and-turn or squeeze-and-turn designs.

- Flip-Top Caps: Offer convenience for easy opening and closing.

- Screw Caps: Traditional and secure closure type, widely used.

- Snap-On Caps: Quick and easy to apply, often used for smaller packs.

- Specialty/Dispensing Caps: Includes caps with integrated measuring features or unique dispensing mechanisms.

- By Application:

- Laundry Pods/Packs: Primary application, requiring precise sealing and often child-resistant features.

- Laundry Tablets/Tablets: For solid detergent forms, requiring moisture protection.

- Liquid Detergent Sachets (with small caps): For single-use liquid portions, common in some developing markets.

- By End-Use Industry:

- Household: Represents the largest share, driven by consumer laundry needs.

- Commercial/Industrial: For laundromats, hotels, hospitals, and other large-scale operations.

Value Chain Analysis For Single Dose Laundry Detergent Cap Market

The value chain for the Single Dose Laundry Detergent Cap Market is a complex network involving multiple stages from raw material sourcing to final product consumption, emphasizing the critical interplay between upstream and downstream activities. Upstream analysis focuses on the procurement of primary raw materials, predominantly various types of plastic resins such as polypropylene (PP), high-density polyethylene (HDPE), and polyethylene terephthalate (PET). This stage involves chemical manufacturers and polymer suppliers who convert crude oil or natural gas into plastic pellets. The quality, availability, and cost fluctuations of these raw materials directly impact the manufacturing efficiency and pricing strategy of cap producers. Sustainability initiatives are increasingly influencing this stage, driving demand for recycled and bio-based polymers, which requires specialized sourcing and processing capabilities.

Midstream activities involve the manufacturing of the caps themselves. This typically includes processes like injection molding, compression molding, or blow molding, where specialized machinery shapes the plastic resins into the desired cap forms. Cap manufacturers invest significantly in tooling, automation, and quality control systems to produce caps that meet stringent specifications for size, fit, chemical resistance, and safety features like child-resistance. This stage also includes post-molding processes such as lining insertion, printing, and assembly of multi-component caps. Innovation in this segment is driven by the need for faster cycle times, reduced waste, and the production of increasingly complex and functional designs, often requiring sophisticated engineering and material science expertise.

Downstream analysis in the value chain centers on the distribution channels and the ultimate integration of these caps into the final single-dose laundry detergent products. Once manufactured, caps are typically transported to detergent producers, who then fill and package their single-dose products (pods, packs, tablets). Distribution channels for caps can be direct, where cap manufacturers supply directly to large detergent companies, or indirect, involving distributors and wholesalers who serve smaller and medium-sized detergent brands. The choice of channel often depends on the scale of operations, geographical reach, and specific logistical requirements. The success of this downstream integration relies heavily on seamless collaboration, precise specifications, and timely delivery, as caps are a critical component of the finished detergent product's marketability and safety. This entire chain from raw material extraction to final product integration defines the market dynamics and influences overall efficiency and cost-effectiveness.

Single Dose Laundry Detergent Cap Market Potential Customers

The potential customers for the Single Dose Laundry Detergent Cap Market are primarily the manufacturers of laundry detergents, particularly those specializing in or expanding into single-dose formats such as pods, packs, and tablets. These end-users or buyers are a diverse group ranging from multinational consumer goods conglomerates with extensive global distribution networks to regional and niche detergent brands focusing on specific market segments. Their demand for caps is driven by several factors, including the need for packaging that ensures product integrity, enhances user convenience, meets safety regulations (especially child-resistance), and provides aesthetic appeal to differentiate their products on competitive retail shelves. These customers value reliability, consistency, and innovation in cap design, seeking partners who can offer scalable production, quality assurance, and often, customized solutions.

Large multinational corporations, such as Procter & Gamble, Unilever, Henkel, and Church & Dwight, represent a significant portion of the potential customer base due to their massive production volumes and global reach. These companies often require highly specialized caps that integrate seamlessly with their automated filling lines and adhere to stringent safety standards across various international markets. They frequently seek long-term supply agreements and partners capable of continuous innovation in materials and design to support their brand strategies. Their purchasing decisions are influenced by factors like cost-efficiency, supply chain reliability, regulatory compliance, and the ability of cap manufacturers to contribute to their sustainability goals, such as by offering caps made from recycled or bio-based materials.

Beyond these industry giants, there is a growing segment of smaller and medium-sized enterprises (SMEs) and private label brands that are increasingly entering the single-dose laundry detergent market. These customers may have different needs, potentially requiring more flexible order quantities, lower minimum order values, and greater assistance with design and material selection. They often rely on distributors or indirect channels for sourcing caps. Furthermore, contract manufacturers who produce detergents for various brands also constitute a key customer segment, as they need a versatile range of caps to cater to their diverse client portfolios. The dynamic landscape of detergent innovation, including the emergence of eco-friendly and specialized laundry solutions, continually expands the pool of potential customers seeking advanced and sustainable cap solutions.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 785.4 Million |

| Market Forecast in 2033 | USD 1,180.9 Million |

| Growth Rate | 6.0% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | AptarGroup, Berry Global, Silgan Holdings, RPC Group (now part of Berry Global), Alpla, Guala Closures, BERICAP, Closure Systems International (CSI), Crown Holdings, Comar, Pelliconi, Technocap, Pactiv Evergreen, WestRock, Amcor, Constantia Flexibles, Gerresheimer, Graham Packaging Company, DWK Life Sciences, Weener Plastics |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Single Dose Laundry Detergent Cap Market Key Technology Landscape

The Single Dose Laundry Detergent Cap Market is characterized by a dynamic and evolving technology landscape, primarily driven by innovations in material science, manufacturing processes, and smart packaging solutions. The core technology revolves around advanced plastic injection molding and compression molding techniques, which enable the high-volume production of complex cap geometries with precision and consistency. Manufacturers utilize multi-cavity molds and high-speed automation to achieve economies of scale and meet the demand for millions of caps annually. Developments in tooling and mold design are crucial for creating intricate features such as child-resistant mechanisms, tamper-evident seals, and integrated measuring elements, which require tight tolerances and superior surface finishes. The integration of in-mold labeling (IML) technology is also gaining traction, allowing for high-quality graphics and branding directly onto the cap during the molding process, enhancing aesthetic appeal and durability.

Beyond basic molding, the technology landscape includes significant advancements in material formulation. There is a growing emphasis on developing and utilizing sustainable polymers, including post-consumer recycled (PCR) content, bio-based plastics like polylactic acid (PLA) and polyhydroxyalkanoates (PHA), and biodegradable polymers. This requires specialized compounding and processing technologies to ensure that the recycled or bio-based materials maintain the necessary mechanical properties, chemical resistance, and barrier performance for detergent caps. Furthermore, research into additive manufacturing (3D printing) is exploring its potential for rapid prototyping of new cap designs, allowing for quicker iteration and testing phases before committing to expensive production tooling. Functional coatings and additives are also being developed to enhance properties like UV resistance, anti-static properties, or even antimicrobial protection.

The rise of Industry 4.0 concepts is profoundly impacting cap manufacturing, with the integration of sensors, IoT devices, and data analytics. This enables real-time monitoring of production lines, predictive maintenance for machinery, and AI-driven quality control systems that can detect minute defects with high accuracy. Automation and robotics are increasingly being employed for cap assembly, particularly for multi-component child-resistant caps, improving efficiency and reducing human error. Moreover, the emergence of smart packaging technologies, though still nascent in this specific market, holds future potential. This includes embedding NFC or RFID tags within caps for supply chain traceability, anti-counterfeiting measures, or even providing consumer information and usage instructions via a smartphone scan. These technological advancements collectively contribute to safer, more efficient, and more sustainable single-dose laundry detergent caps, shaping the future trajectory of the market.

Regional Highlights

- North America: This region stands as a dominant force in the Single Dose Laundry Detergent Cap Market, driven by high consumer adoption of convenience products and stringent safety regulations, particularly concerning child-resistant packaging. The United States and Canada lead in innovation and market maturity, with a strong focus on sustainable packaging solutions and advanced functional designs. The presence of major detergent manufacturers and a well-established retail infrastructure contribute significantly to market expansion. Consumers in this region prioritize both convenience and safety, fostering a competitive landscape for cap manufacturers to continuously develop high-performance and compliant products.

- Europe: Europe represents another key market, characterized by mature consumer preferences for single-dose detergents and robust regulatory frameworks, especially related to environmental standards and child safety. Countries like Germany, the UK, and France are at the forefront, pushing for eco-friendly packaging materials such as PCR plastics and bio-based polymers. Innovation in lightweighting and recyclability of caps is a strong regional trend. The region's emphasis on sustainability and product safety drives demand for high-quality, technically advanced caps that meet both consumer expectations and regulatory requirements.

- Asia Pacific (APAC): The APAC region is projected to exhibit the highest growth rate, fueled by rapid urbanization, increasing disposable incomes, and the growing penetration of modern retail channels in countries like China, India, and Southeast Asian nations. The expanding middle class in these economies is increasingly adopting convenience-oriented laundry solutions, thereby boosting the demand for single-dose detergents and their corresponding caps. While cost-effectiveness remains a key factor, there is a rising awareness regarding product safety and environmental impact, leading to a gradual shift towards more sophisticated and sustainable cap solutions.

- Latin America: This region shows steady growth, with Brazil and Mexico being the leading markets. The rising penetration of automatic washing machines and the increasing availability of single-dose laundry detergents from global and local brands are driving demand. Economic stability and increasing consumer awareness about modern household products contribute to the market's upward trajectory. While convenience is a major driver, affordability often plays a critical role in purchasing decisions, influencing material choices and cap designs.

- Middle East and Africa (MEA): The MEA market is experiencing nascent but growing demand for single-dose laundry detergent caps. Economic development, changing consumer lifestyles, and the expansion of international retail chains are contributing to market growth. Countries in the GCC region and South Africa are notable contributors. As the preference for modern laundry solutions grows, so does the demand for packaging components like specialized caps, with an increasing focus on product integrity and user convenience.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Single Dose Laundry Detergent Cap Market.- AptarGroup

- Berry Global

- Silgan Holdings

- Alpla

- Guala Closures

- BERICAP

- Closure Systems International (CSI)

- Crown Holdings

- Comar

- Pelliconi

- Technocap

- Pactiv Evergreen

- WestRock

- Amcor

- Constantia Flexibles

- Gerresheimer

- Graham Packaging Company

- DWK Life Sciences

- Weener Plastics

- Resilux

Frequently Asked Questions

Analyze common user questions about the Single Dose Laundry Detergent Cap market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary drivers of growth for the Single Dose Laundry Detergent Cap Market?

The market is primarily driven by increasing consumer demand for convenience in laundry care, stringent safety regulations mandating child-resistant packaging, the benefits of precise detergent dosing, and continuous innovation in cap design for brand differentiation and sustainability.

What types of materials are commonly used in manufacturing single-dose laundry detergent caps?

Common materials include polypropylene (PP) and high-density polyethylene (HDPE) due to their chemical resistance and durability. There is a growing trend towards sustainable options like post-consumer recycled (PCR) plastics and bio-based polymers to meet environmental demands.

How do child-resistant closures (CRCs) impact the market?

CRCs are a significant market segment, driven by regulatory mandates in many regions to enhance product safety and prevent accidental ingestion by children. This necessitates continuous innovation in design to ensure both security and ease of use for adults, influencing manufacturing complexity and costs.

What role does sustainability play in the development of single-dose laundry detergent caps?

Sustainability is a crucial factor, pushing manufacturers to adopt eco-friendly materials such as PCR content and bio-based plastics. The focus is on creating lightweight, recyclable, and environmentally responsible caps to meet consumer demand and corporate sustainability goals, reducing the overall environmental footprint.

Which geographical regions are key growth areas for this market?

North America and Europe are mature markets with high adoption and stringent regulations. Asia Pacific, particularly countries like China and India, is the fastest-growing region due to urbanization, rising disposable incomes, and increasing adoption of convenience products. Latin America and MEA also show steady growth.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager