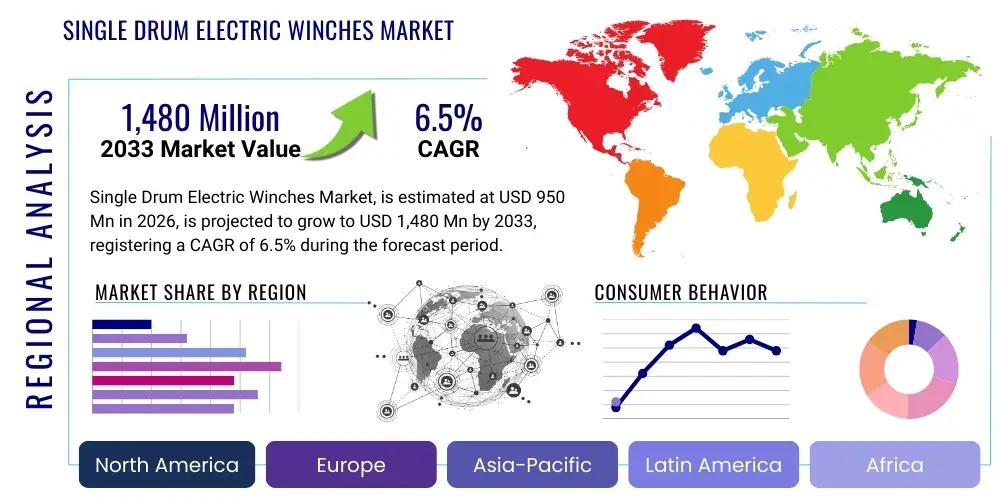

Single Drum Electric Winches Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 438585 | Date : Dec, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Single Drum Electric Winches Market Size

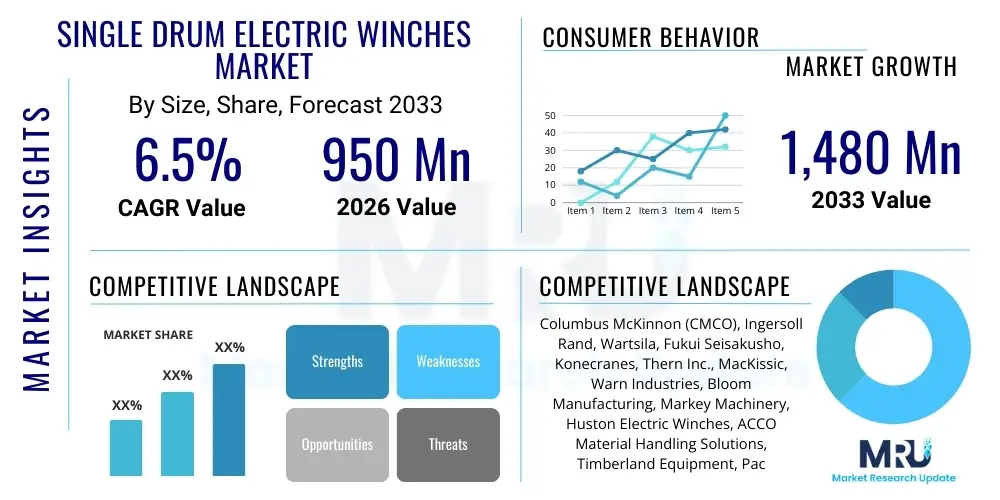

The Single Drum Electric Winches Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2026 and 2033. The market is estimated at USD 950 million in 2026 and is projected to reach USD 1,480 million by the end of the forecast period in 2033.

Single Drum Electric Winches Market introduction

The Single Drum Electric Winches Market encompasses machinery specifically designed for heavy-duty pulling, hoisting, or positioning applications, utilizing a single revolving drum to spool wire rope or cable driven by an electric motor. These winches are vital components across numerous heavy industries due to their reliability, high torque capacity, and precision control. Key product attributes include variable speed control (often through Variable Frequency Drives or VFDs), dynamic braking systems, and robust structural designs capable of withstanding harsh operational environments, such as marine, mining, and construction sites. The standardization of these systems, coupled with increased demands for efficiency and operational safety, underpins the market's stability and consistent expansion.

Major applications of single drum electric winches are concentrated in the infrastructure and energy sectors. In construction, they are essential for lifting structural steel, managing material hoists, and positioning heavy modules. Within the marine sector, applications span mooring, anchor handling, and deep-sea towing operations, requiring specialized corrosion resistance and IP ratings. Furthermore, the oil and gas industry utilizes these winches extensively for pipe laying, riser deployment, and subsea equipment retrieval, where precision handling capabilities are paramount. The versatility of electric winches, offering cleaner operation and reduced maintenance compared to hydraulic or pneumatic counterparts, is a significant driver of their adoption across these high-stakes applications.

The primary benefit driving market expansion is the enhanced operational efficiency and stringent safety standards mandated globally. Modern electric winches incorporate advanced features such as automatic load limiting, emergency stop functionality, and real-time diagnostic monitoring, significantly reducing the risk of accidents and equipment failure. Furthermore, the rising global investment in renewable energy infrastructure, particularly the construction of large offshore wind farms and associated foundation installation, mandates the use of high-capacity, reliable electric winches for assembly and deployment tasks. These factors, combined with the general trend towards automation in material handling processes, ensure sustained growth for the Single Drum Electric Winches Market throughout the forecast period.

Single Drum Electric Winches Market Executive Summary

The Single Drum Electric Winches Market is experiencing dynamic shifts characterized by technological integration and increasing demand from rapidly industrializing regions. Current business trends indicate a strong move toward developing smart winches featuring integrated IoT capabilities, allowing for remote diagnostics, predictive maintenance scheduling, and optimization of operational cycles. Manufacturers are focusing heavily on energy efficiency, integrating permanent magnet synchronous motors (PMSM) and advanced VFD technology to minimize power consumption while maintaining superior lifting capacities. Consolidations among key players and strategic partnerships aimed at geographic expansion, especially into high-growth Asian markets, define the competitive landscape, emphasizing the delivery of custom-engineered solutions tailored to specific project requirements in sectors like deep-sea exploration and specialized heavy lifting.

Regionally, the Asia Pacific (APAC) stands as the undisputed leader in market expansion, driven primarily by massive governmental investments in infrastructure projects, urbanization, and burgeoning shipbuilding activities in China, India, and Southeast Asian nations. North America and Europe, while mature, exhibit demand concentrated on replacing older hydraulic systems with modern, energy-efficient electric variants that comply with stricter environmental and occupational safety regulations. The Middle East and Africa (MEA) are showing robust growth, fueled by sustained activity in the oil and gas sector and significant investments in port development and large-scale utility construction, necessitating reliable, high-capacity lifting equipment.

Segmentation trends highlight a substantial preference for medium to heavy-duty capacity winches (above 10 tons) driven by the scale of modern construction and marine operations. The application segment dominated by construction and industrial use is anticipated to retain the largest market share, though the marine segment, particularly related to offshore operations and specialized vessel handling, is projected to register the highest CAGR. Furthermore, the market for winches incorporating advanced control systems, such as proprietary software for automated spooling and tension control, is growing rapidly, reflecting the industry's commitment to precision and safety across diverse operational environments.

AI Impact Analysis on Single Drum Electric Winches Market

User queries regarding AI in the Single Drum Electric Winches Market frequently center on predictive failure prevention, optimization of lifting sequences, and achieving autonomous operation. Stakeholders are keen to understand how AI algorithms can leverage sensor data (tension, vibration, temperature) to anticipate component failure, specifically in critical areas like the gearbox, motor windings, and wire rope integrity, thereby maximizing uptime and reducing catastrophic risks. Key themes also include the use of machine learning to dynamically adjust winch speed and torque based on real-time load conditions and environmental factors (e.g., wave motion in marine applications), leading to improved efficiency and reduced energy consumption. Concerns often revolve around the cybersecurity risks associated with IoT-enabled, AI-controlled winches and the necessity for robust, redundant control systems capable of safe manual override, ensuring that AI integration enhances, rather than compromises, operational safety.

- Predictive Maintenance: AI algorithms analyze sensor data (load, temperature, vibration) to forecast component degradation, enabling just-in-time maintenance and minimizing unscheduled downtime.

- Automated Load Management: Machine learning optimizes spooling patterns and tension control, reducing cable wear and preventing hazardous slack conditions, particularly in deep-water applications.

- Operational Efficiency: AI dynamically adjusts motor output and speed based on the load profile and energy tariffs, significantly reducing operational energy costs.

- Safety Enhancement: Real-time anomaly detection flags unusual operating parameters, triggering immediate alerts or controlled shutdowns before critical failure occurs.

- Remote Diagnostics and Fleet Management: AI facilitates centralized monitoring of multiple winches across various locations, streamlining fleet performance analysis and resource allocation.

DRO & Impact Forces Of Single Drum Electric Winches Market

The Single Drum Electric Winches Market is shaped by a confluence of accelerating drivers, critical restraints, and significant opportunities. A primary driver is the accelerating pace of global infrastructure development, including large-scale urban projects, port modernization, and the expansion of heavy industrial facilities, which inherently require reliable, high-capacity lifting apparatus. Coupled with this is the increasing global emphasis on occupational safety, driving demand for electric winches that comply with stringent international standards (like ASME B30.7 and ISO regulations) and feature advanced safety mechanisms such as integrated load monitoring and redundant braking systems. The efficiency of electric motors compared to hydraulic alternatives, particularly their lower environmental footprint and reduced maintenance complexity, further reinforces their market dominance.

However, the market faces notable restraints. The initial capital investment for high-capacity, specialized electric winches, especially those incorporating VFDs and advanced sensors, remains substantially high, posing a barrier to entry for smaller enterprises and regional operators. Furthermore, the complexity involved in custom engineering winches for highly specialized environments (e.g., deep-sea drilling, explosive atmospheres) requires specialized technical expertise and compliance certification, which can lengthen project timelines and increase overall costs. Fluctuations in raw material prices, particularly steel and copper, essential for drum construction and motor windings, also introduce volatility into the manufacturing cost structure, impacting final product pricing and market stability.

Opportunities for market expansion are abundant, particularly through technological innovation and geographic penetration. The development of fully automated, remote-controlled winches utilizing 5G connectivity presents a significant growth avenue, allowing for safer operations in hazardous environments. Furthermore, emerging applications in niche markets such as space component handling, specialized rescue operations, and the nascent floating offshore solar segment require custom-built, precision electric winches, offering high-margin specialization opportunities for market players. The global push for digitalization and the implementation of Industry 4.0 standards across manufacturing and construction sectors provide fertile ground for integrating smart winch solutions, offering optimized operational intelligence and enhanced system lifespan.

Segmentation Analysis

The Single Drum Electric Winches Market segmentation is critical for understanding varied end-user requirements and market dynamics, primarily categorized by capacity, application, and power source configuration. Capacity segmentation (light-duty <5 tons, medium-duty 5–20 tons, heavy-duty >20 tons) reflects the specific weight management needs of diverse industries, with heavy-duty winches seeing high demand in specialized mining and marine projects. Application-based segmentation highlights the dominant sectors of usage, including construction, maritime, industrial manufacturing, and mining, each requiring specialized features related to speed, durability, and corrosion resistance. Furthermore, distinctions based on power source characteristics, such as AC power systems versus specialized DC battery-powered mobile units, offer insights into portability and specific environment suitability.

- By Capacity:

- Light-Duty (Below 5 Tons)

- Medium-Duty (5 Tons - 20 Tons)

- Heavy-Duty (Above 20 Tons)

- By Application:

- Construction and Infrastructure

- Marine and Offshore (Mooring, Anchor Handling, Towing)

- Mining and Material Handling

- Industrial Manufacturing and Utilities

- By Power Source/Configuration:

- AC Powered Winches

- DC Powered Winches (often used in smaller, portable units)

- VFD Controlled Winches

Value Chain Analysis For Single Drum Electric Winches Market

The value chain for the Single Drum Electric Winches Market begins with the upstream acquisition of critical raw materials, primarily high-grade steel alloys (for the drum and frame), copper (for motor windings), and specialized components like gearboxes, braking systems, and advanced electronic controls (VFDs, PLCs, sensors). The efficiency of sourcing and managing these specialized inputs directly influences the final product cost and manufacturing lead times. Manufacturers focus on strategic partnerships with specialized suppliers to ensure quality control and maintain compliance with metallurgy standards necessary for demanding applications like marine environments where corrosion resistance is paramount. This initial stage requires significant capital investment in precision machining and fabrication facilities.

The core manufacturing stage involves complex processes, including welding, machining of the drum and gear assemblies, motor integration, and rigorous testing. This stage adds significant value through proprietary engineering and quality assurance protocols, ensuring the winches meet stringent load ratings and safety standards. Distribution, or the downstream analysis, is multi-faceted. It typically involves a blend of direct sales channels for large, custom-engineered projects (especially in marine and oil & gas) and indirect channels utilizing regional distributors, specialized equipment rental companies, and certified service providers for standard commercial units. Direct engagement ensures that technical specifications and installation requirements are precisely met, while indirect channels provide broader market penetration and easier access to spare parts and localized maintenance support.

The post-sale phase, which includes installation, commissioning, maintenance contracts, and technical support, is increasingly vital. Service providers add considerable value by offering predictive maintenance solutions (often leveraging IoT and AI) and specialized training for operators. The direct channel benefits key manufacturers by maintaining a direct relationship with high-value end-users, facilitating quicker product evolution based on field feedback. Overall, the market rewards manufacturers who can effectively manage component supply, offer superior customized engineering, and provide robust, long-term technical support, thereby reducing the total cost of ownership for the end-user throughout the product lifecycle.

Single Drum Electric Winches Market Potential Customers

The potential customer base for Single Drum Electric Winches is broad, encompassing heavy industries where repetitive, high-force pulling and lifting operations are indispensable. The largest segment of buyers includes large-scale civil engineering and construction conglomerates responsible for developing major infrastructure projects such as bridges, dams, high-rise buildings, and industrial complexes. These entities demand winches with high capacity, precise control, and high operational duty cycles, often requiring VFD-controlled systems for soft starts and regulated lifting speeds to manage valuable materials accurately and safely, making reliability and compliance essential purchasing criteria.

Another major segment consists of the maritime and offshore industries, including shipbuilding yards, port authorities, offshore energy providers (oil, gas, and wind), and specialized vessel operators (tugs, dredgers). These buyers necessitate winches designed for extreme operational environments, prioritizing anti-corrosion features, robust sealing (high IP ratings), and specialized control systems for dynamic loading, such as anchor handling winches or deep-sea research deployment systems. Their procurement decisions are heavily influenced by regulatory compliance (e.g., classification society requirements like ABS, DNV) and the winch's mean time between failures (MTBF) in harsh saltwater environments.

Furthermore, the mining sector and industrial utility providers (power plants, heavy manufacturing plants) represent steady customer bases. Mining operations require durable winches for incline hoisting, ventilation management, and material transport, often demanding explosion-proof (EX) rated motors and controls. Utility providers utilize these systems for equipment maintenance, turbine repair, and complex machinery installation. These customers typically prioritize robustness, ease of maintenance, and the ability to operate reliably in thermally challenging or particulate-heavy conditions, seeking long-term operational guarantees and readily available local service support.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 950 Million |

| Market Forecast in 2033 | USD 1,480 Million |

| Growth Rate | 6.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Columbus McKinnon (CMCO), Ingersoll Rand, Wartsila, Fukui Seisakusho, Konecranes, Thern Inc., MacKissic, Warn Industries, Bloom Manufacturing, Markey Machinery, Huston Electric Winches, ACCO Material Handling Solutions, Timberland Equipment, Paccar Winch Division, Zhejiang Liming Industry Co., Ltd., Zhejiang Hengya Electric Co., Ltd., J.D. Neuhaus, Rolls-Royce Marine, Demag Cranes & Components. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Single Drum Electric Winches Market Key Technology Landscape

The technological evolution within the Single Drum Electric Winches Market is centered on enhancing precision, operational safety, and connectivity. A foundational advancement is the widespread adoption of Variable Frequency Drives (VFDs) and sophisticated motor control systems. VFDs allow for precise speed and torque adjustment, minimizing mechanical stress during start-up and stopping phases, which is crucial for handling fragile or valuable cargo. This technological integration not only increases the lifespan of the mechanical components but also drastically improves energy efficiency, enabling the winch system to draw only the necessary power relative to the instantaneous load and speed requirements, thereby aligning with modern sustainability goals and reducing operating expenses for end-users.

Furthermore, the integration of robust sensors and IoT technology is transforming winches into intelligent assets. Modern winches are often equipped with load cells, temperature sensors, vibration analyzers, and encoders that relay real-time operational data back to a central monitoring system. This allows for predictive maintenance, proactive detection of anomalies, and accurate documentation of lifting operations, which is essential for audit trails in highly regulated sectors like marine and oil & gas. Data connectivity, often facilitated through proprietary software platforms and cloud infrastructure, ensures that fleet managers can optimize utilization rates and schedule necessary service intervals based on actual usage rather than arbitrary timelines, maximizing operational availability.

Material science and safety mechanisms are also key technological focus areas. Manufacturers are increasingly utilizing advanced corrosion-resistant coatings and specialized materials (e.g., stainless steel components for marine environments) to prolong equipment life and reduce maintenance requirements in harsh weather conditions. Safety innovation includes dynamic braking systems, which operate independently of the electric motor, providing redundant safety layers. Automated spooling mechanisms, controlled by sophisticated algorithms that monitor the tension and layering of the wire rope on the drum, prevent tangling and damage, which is a common failure point, significantly improving both safety and the longevity of the rope.

Regional Highlights

Regional dynamics significantly influence the Single Drum Electric Winches Market, driven by differing rates of infrastructure investment and regulatory environments. Asia Pacific (APAC) holds the leading position in terms of market size and growth trajectory. This dominance is attributed to the unprecedented scale of infrastructure development, including high-speed rail networks, massive port expansions, and industrial zone creation, particularly in China, India, and Southeast Asia. The region’s burgeoning shipbuilding industry and increased demand for customized winches in local mining and construction projects fuel sustained, high-volume growth. Furthermore, the lower manufacturing costs in certain APAC nations support a competitive export market for electric winches.

North America (NA) and Europe represent mature, high-value markets characterized by a strong emphasis on regulatory compliance and the adoption of technologically advanced, high-specification equipment. In North America, demand is often driven by the replacement of aging equipment with modern, safer, and IoT-enabled electric systems, especially in the oil and gas (onshore drilling) and structural steel construction sectors. European demand is bolstered by stringent safety and environmental mandates, pushing users toward highly efficient VFD-controlled systems and supporting the significant growth in offshore wind turbine installation, which requires specialized, high-capacity winches designed for extreme reliability.

The Middle East and Africa (MEA) region is emerging as a critical growth center, heavily reliant on investments in oil and gas exploration, utility infrastructure, and commercial real estate development, particularly in the GCC countries. The requirement for robust, reliable lifting equipment capable of operating in high-temperature, arid conditions dictates product specifications. Latin America (LATAM) shows steady demand, primarily centered around mining activities in countries like Chile and Peru, and ongoing port and logistics infrastructure upgrades, where reliable industrial winches are essential components of heavy material handling operations.

- Asia Pacific (APAC): Market leader due to infrastructure boom (ports, construction, energy), rapid urbanization, and massive government investment in heavy industries.

- North America (NA): High demand for technology upgrades, safety compliance, and specialized winches for offshore energy projects and automated industrial facilities.

- Europe: Focus on energy efficiency, stringent environmental standards, and strong investment in the offshore renewable energy sector (wind and wave power).

- Middle East and Africa (MEA): Growth driven by persistent oil and gas projects, large-scale construction, and port modernization initiatives.

- Latin America (LATAM): Steady growth linked to expansion of mining operations and necessary upgrades to regional logistics and transport infrastructure.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Single Drum Electric Winches Market.- Columbus McKinnon (CMCO)

- Ingersoll Rand

- Wartsila

- Fukui Seisakusho

- Konecranes

- Thern Inc.

- MacKissic

- Warn Industries

- Bloom Manufacturing

- Markey Machinery

- Huston Electric Winches

- ACCO Material Handling Solutions

- Timberland Equipment

- Paccar Winch Division

- Zhejiang Liming Industry Co., Ltd.

- Zhejiang Hengya Electric Co., Ltd.

- J.D. Neuhaus

- Rolls-Royce Marine

- Demag Cranes & Components

- Kawasaki Heavy Industries (Marine Machinery Division)

Frequently Asked Questions

Analyze common user questions about the Single Drum Electric Winches market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the projected CAGR for the Single Drum Electric Winches Market through 2033?

The market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2026 and 2033, driven by global infrastructure expansion and safety regulations.

Which application segment drives the highest demand for electric winches?

The Construction and Infrastructure segment currently accounts for the largest market share, though the Marine and Offshore segment, particularly deep-sea operations, is expected to exhibit the highest growth rate.

How does technological integration, like VFDs, benefit winch operation?

Variable Frequency Drives (VFDs) provide precise speed and torque control, which enhances operational efficiency, reduces mechanical wear, and significantly improves energy consumption compared to fixed-speed systems.

What are the primary restraints affecting the growth of this market?

Key restraints include the high initial capital investment required for specialized, high-capacity electric winches and the inherent complexity and time needed for custom engineering solutions for niche applications.

Which geographical region is the most dominant in the market?

The Asia Pacific (APAC) region currently holds the highest market share and is projected to maintain its dominance due to extensive government-led infrastructure investments and robust growth in the shipbuilding industry.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager