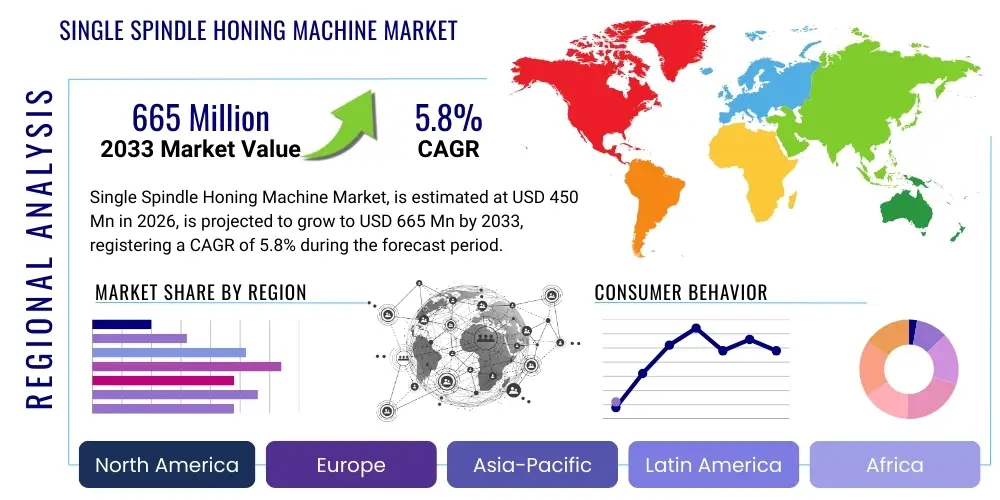

Single Spindle Honing Machine Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 436422 | Date : Dec, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Single Spindle Honing Machine Market Size

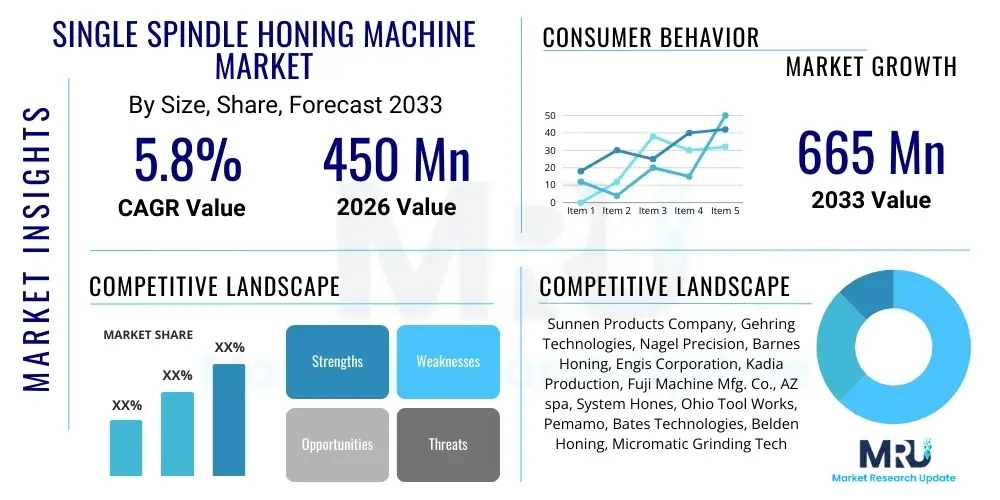

The Single Spindle Honing Machine Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 450 Million in 2026 and is projected to reach USD 665 Million by the end of the forecast period in 2033. This growth is fundamentally driven by the escalating demand for precision components across high-stakes industries, including automotive engine manufacturing, aerospace hydraulic systems, and specialized medical device production. Single spindle machines are highly valued for their ability to achieve superior surface finish, excellent geometric accuracy, and tight tolerance control on bores and internal cylindrical surfaces, making them indispensable in quality-critical machining processes. The increasing production volumes of internal combustion engines, coupled with the rising requirement for efficiency improvements in industrial machinery, serve as primary catalysts for market expansion.

Market expansion is significantly bolstered by ongoing technological advancements focused on integrating sophisticated control systems, automated loading/unloading mechanisms, and real-time monitoring capabilities into single spindle honing platforms. These technological innovations enhance operational efficiency, reduce cycle times, and minimize reliance on highly skilled labor, thereby improving overall cost-effectiveness for end-users. Furthermore, the adoption of specialized abrasive tooling, such as superabrasives (diamond and CBN), is contributing to enhanced machining longevity and performance, allowing single spindle machines to process harder materials with greater precision and speed. The shift towards higher-performance materials in critical applications, such as high-strength steel and advanced ceramics, necessitates the reliability and accuracy offered by dedicated single spindle honing solutions.

While the market demonstrates robust growth potential, it remains susceptible to fluctuations in global capital expenditure, particularly within the automotive and oil and gas sectors. Nevertheless, the continuous emphasis on miniaturization and high-tolerance manufacturing in emerging economies, coupled with significant investments in infrastructure and industrial automation in regions like Asia Pacific, ensures a stable demand pipeline for these precision instruments. The replacement cycle of aging conventional honing equipment with modern, CNC-controlled single spindle machines further reinforces the positive market trajectory, emphasizing efficiency and adherence to stringent modern manufacturing quality standards.

Single Spindle Honing Machine Market introduction

Single Spindle Honing Machines represent a crucial segment within the precision finishing equipment industry, designed specifically for the meticulous internal finishing of cylindrical bores. These machines utilize a single rotating and reciprocating tool assembly (the honing head) equipped with abrasive stones or sticks to remove minimal amounts of material, refining the surface texture, correcting errors in geometry (straightness, roundness, taper), and achieving exceptionally tight dimensional tolerances. The primary product description centers around high rigidity, thermal stability, and the integration of sophisticated control systems, often CNC-based, to manage stroke length, expansion pressure, rotational speed, and coolant delivery precisely. Single spindle units are generally preferred for mid-to-high volume production runs involving components where internal diameter finishing is critical, such as engine cylinder blocks, connecting rods, hydraulic valve sleeves, gear bores, and compressor components. The fundamental benefit of employing single spindle honing lies in its unparalleled ability to produce a controlled cross-hatch pattern on the internal surface, which is essential for oil retention and optimal performance in friction-critical applications. Driving factors include the stringent regulatory requirements for efficiency and emissions in the automotive sector, demanding finer tolerances in engine components, and the continuous industrial expansion requiring highly reliable hydraulic and pneumatic systems across various heavy machinery and manufacturing processes. The inherent reliability and precision offered by these machines ensure component longevity and operational efficiency across critical industrial applications, underpinning their stable market relevance.

Single Spindle Honing Machine Market Executive Summary

The Single Spindle Honing Machine Market Executive Summary highlights robust growth anchored by escalating global demands for precision manufacturing, particularly in the automotive, aerospace, and heavy machinery industries. Current business trends indicate a strong inclination towards digitalization, with leading manufacturers integrating Industry 4.0 principles, including IoT connectivity, predictive maintenance algorithms, and advanced CNC interfaces, to optimize production lines and minimize downtime. Key regional trends show that the Asia Pacific (APAC) region, driven primarily by China and India, maintains the highest market share and growth rate due to massive investments in local automotive production capacity and expanding manufacturing bases for industrial equipment. North America and Europe remain crucial markets, characterized by high adoption rates of advanced, automated honing systems focused on specialized, high-mix, low-volume aerospace and medical applications. Segment trends emphasize the dominance of CNC/Automatic operation types over manual systems, reflecting the industry-wide push for automation and repeatability. Furthermore, the automotive application segment continues to be the largest consumer, although significant growth is being observed in the hydraulics and oil & gas sectors where bore quality directly dictates system reliability and performance integrity. The overall market environment is competitive, with technological differentiation in abrasive technology and software control emerging as the key strategy for market leadership, ensuring stable and repeatable growth across the forecast period.

AI Impact Analysis on Single Spindle Honing Machine Market

User inquiries regarding the integration of Artificial Intelligence (AI) and machine learning (ML) into the Single Spindle Honing Machine Market predominantly revolve around optimizing process parameters, predicting tool wear, and achieving zero-defect production through enhanced quality control. Common questions address how AI can dynamically adjust variables such as stone pressure, feed rate, and lubrication flow in real-time to compensate for material inconsistencies or thermal expansion during the honing process. Users also express interest in AI-driven predictive maintenance models that utilize sensor data (vibration, temperature, current draw) to forecast potential component failures or abrasive stone replacement needs, thereby drastically reducing unplanned downtime. The underlying expectation is that AI will move honing from a deterministic, parameter-set process to an adaptive, self-optimizing system capable of consistently delivering ultra-precise finishes regardless of minor operational variables, solidifying the transition toward fully autonomous machining cells within the precision component manufacturing ecosystem.

- AI-driven optimization of honing parameters: Real-time adjustment of feed rates, pressure, and speed based on acoustic emission and torque feedback to maintain optimal surface finish and geometry.

- Predictive Maintenance (PdM): Utilization of ML algorithms analyzing machine sensor data (vibration, thermal imaging) to accurately forecast tool wear and potential mechanical failures, maximizing machine uptime.

- Automated Quality Control (AQC): Integration of computer vision and deep learning models to inspect honed surfaces for defects (e.g., chatter marks, tearing) immediately after the cycle, reducing reliance on manual inspection.

- Process Diagnostics and Anomaly Detection: AI identifies subtle deviations in the honing signature indicative of impending issues, ensuring consistent quality across high-volume batches.

- Generative Design for Tooling: AI assists in designing specialized honing tools and fixtures for complex geometries, minimizing setup time and improving overall process stability.

- Energy Efficiency Optimization: ML models analyze historical operational data to optimize motor performance and coolant pump usage, reducing overall energy consumption during the honing cycle.

DRO & Impact Forces Of Single Spindle Honing Machine Market

The Single Spindle Honing Machine Market is primarily driven by the relentless pursuit of high-precision components in sectors like automotive, aerospace, and medical devices (Drivers). However, it faces significant challenges, notably the high initial capital investment required for advanced CNC honing systems and the scarcity of highly trained technicians necessary to operate and maintain these sophisticated machines (Restraints). Opportunities abound through the development of specialized micro-honing techniques tailored for miniaturized components, particularly in the electronics and medical implant sectors (Opportunities). The market is heavily influenced by four key impact forces: technological advancements leading to faster cycle times and enhanced surface quality; stringent quality regulations (ISO standards) mandating tight tolerances; economic volatility impacting capital expenditure decisions; and competitive dynamics characterized by the emergence of cost-effective automation solutions from Asian manufacturers. These forces collectively shape the investment priorities of end-users and the product development strategies of equipment suppliers, demanding continuous innovation to maintain relevance and competitive pricing strategies in the global market.

Segmentation Analysis

The Single Spindle Honing Machine Market is systematically segmented based on Type, Operation, and Application, providing a granular view of demand patterns and technological preferences across various industrial ecosystems. Segmentation by Type differentiates between Vertical Single Spindle Honing Machines, which are typically preferred for larger, heavier components like engine blocks due to gravity assisting fixturing and chip removal, and Horizontal Single Spindle Honing Machines, which are more suited for longer workpieces such as rifle barrels, transmission shafts, or specialized hydraulic cylinders. The operational segmentation highlights the significant industry shift from manual or semi-automatic conventional systems toward highly repeatable and flexible CNC or fully automatic honing centers. Application segmentation demonstrates the market's reliance on the Automotive sector for volume consumption, contrasted by the high-value, stringent demands originating from Aerospace and Medical industries. This structure allows both suppliers and stakeholders to tailor product offerings and marketing strategies to specific, high-growth niche areas while also serving large-scale established segments effectively.

- By Type:

- Vertical Single Spindle Honing Machines

- Horizontal Single Spindle Honing Machines

- By Operation:

- Manual/Semi-Automatic Honing Machines

- CNC/Automatic Honing Machines

- By Application:

- Automotive (Engine Blocks, Connecting Rods, Transmission Components)

- Aerospace and Defense (Landing Gear Components, Hydraulic Actuators)

- Hydraulics & Pneumatics (Valve Bodies, Cylinders, Housings)

- Oil & Gas (Downhole Tools, Pump Liners)

- Medical Devices and Precision Instruments

- General Machinery Manufacturing

- By Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America (LATAM)

- Middle East and Africa (MEA)

Value Chain Analysis For Single Spindle Honing Machine Market

The value chain for the Single Spindle Honing Machine Market begins with Upstream Activities, involving the sourcing of highly specialized raw materials and complex components, including high-grade steel alloys for machine structures, advanced CNC controllers (Siemens, Fanuc), and critical hydraulic and electrical systems. Key upstream suppliers include manufacturers of precision bearings, servo motors, and advanced sensor technologies essential for maintaining the machine's precision and dynamic control capabilities. The core manufacturing stage involves complex assembly, software integration, and rigorous testing of the honing equipment, where intellectual property related to machine kinematics and abrasive management is the primary value generator. Distribution channels, both Direct and Indirect, form the crucial link between manufacturers and end-users. Direct channels are typically used for large, customized, or high-value CNC systems, providing bespoke installation, training, and maintenance contracts. Indirect channels leverage specialized local distributors and integrators, particularly in geographically dispersed markets, who offer regional support and handle standard machine sales. Downstream analysis focuses on the end-user applications—specifically the automotive and aerospace tiers—where the honing machine's performance directly affects the quality and functional longevity of critical finished components, making comprehensive aftermarket support and abrasive consumable supply vital components of sustained value delivery.

Single Spindle Honing Machine Market Potential Customers

Potential customers for Single Spindle Honing Machines are predominantly entities engaged in the large-scale production or specialized finishing of cylindrical components requiring high degrees of geometric accuracy and superior surface integrity. The largest segment of End-Users/Buyers comprises major Automotive OEMs and their Tier 1 suppliers, who utilize these machines extensively for finishing internal bores in engine components (cylinder liners, connecting rods) and transmission parts, where friction reduction and wear resistance are paramount. Another critical customer base is the Hydraulics and Pneumatics industry, including manufacturers of pumps, valves, and actuators, where precision bore sizing is essential to prevent leakage and ensure system responsiveness in heavy machinery and industrial automation systems. Aerospace and Defense contractors represent a high-value customer segment, focusing on low-volume, high-precision finishing for critical flight control actuators, landing gear components, and complex turbine parts, demanding specialized machines capable of handling exotic materials. Furthermore, precision job shops and specialized machinery manufacturers also serve as potential buyers, investing in flexible single spindle honing solutions to meet the diverse and stringent specifications of multiple industrial clients, emphasizing versatility and reliable performance across various materials and tolerance requirements.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450 Million |

| Market Forecast in 2033 | USD 665 Million |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Sunnen Products Company, Gehring Technologies, Nagel Precision, Barnes Honing, Engis Corporation, Kadia Production, Fuji Machine Mfg. Co., AZ spa, System Hones, Ohio Tool Works, Pemamo, Bates Technologies, Belden Honing, Micromatic Grinding Technologies, Premier Honing Machines, Delapena Group, Kros Honing, Honingtec, Ningbo Hongye Honing, Wenzhou Jingsheng Machine, Beijing Precision Machinery, Mitsui Grinding Technology, Stähli Läpp-Technik. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Single Spindle Honing Machine Market Key Technology Landscape

The technology landscape of the Single Spindle Honing Machine Market is defined by the convergence of mechanical precision engineering with advanced digital control and sensing technologies. A crucial technological element is the continuous development of abrasive materials, moving significantly towards superabrasives, specifically cubic boron nitride (CBN) and synthetic diamond stones, which offer superior wear resistance, faster material removal rates, and enhanced thermal stability compared to traditional aluminum oxide or silicon carbide. This shift allows manufacturers to hone increasingly hard materials common in high-performance applications. The control systems utilize sophisticated Computer Numerical Control (CNC) architectures that enable dynamic, real-time control over critical parameters, including spindle speed synchronization with stroking frequency, precise abrasive expansion control (pressure honing), and complex bore size measurement integration, often employing in-process air gauging or laser measurement systems to ensure zero-defect output and automatic cycle compensation. The reliability and flexibility of these advanced CNC systems are central to maintaining the competitive edge in precision finishing.

Further technological advancements center on optimizing machine rigidity and thermal management, critical factors for maintaining accuracy during prolonged, high-speed operation. Modern single spindle machines incorporate advanced machine foundations, often utilizing polymer concrete bases or heavy cast iron structures, to minimize vibration and enhance dampening characteristics. Additionally, closed-loop thermal control systems manage the temperature of the coolant and hydraulic oil, preventing thermal distortion that could compromise the geometric precision of the workpiece. Automated features, such as robotic part loading/unloading and integrated washing stations, are becoming standard, positioning these machines as essential components of fully integrated, automated manufacturing cells. The ongoing trend toward high-speed production necessitates continuous innovation in coolant filtration and delivery systems to effectively manage the fine swarf generated during superabrasive honing, ensuring the clean operation required for micro-finish specifications.

The latest generation of single spindle honing machines also heavily integrates connectivity features relevant to Industry 4.0. This includes built-in sensors for measuring torque, acoustic emissions, and vibration analysis, feeding data into cloud-based platforms for real-time performance monitoring and predictive analytics. This data accessibility allows manufacturers to remotely diagnose issues, optimize tool life, and validate process parameters against global standards. Specialized tooling technology, such as mandate systems designed for specific component geometries (e.g., blind holes, splined bores), continues to evolve, improving the machine's versatility and ability to tackle complex finishing challenges with uncompromising accuracy. The focus remains on reducing the overall cost per piece by maximizing uptime, increasing production speed, and consistently meeting the highest standards of bore quality.

Regional Highlights

Regional dynamics significantly influence the Single Spindle Honing Machine Market, reflecting disparities in manufacturing scale, technological adoption, and regulatory environment across global geographies. The Asia Pacific (APAC) region is indisputably the largest and fastest-growing market, primarily fueled by the presence of major automotive manufacturing hubs in China, India, Japan, and South Korea. These nations are experiencing substantial infrastructural investments and a robust expansion of their local manufacturing capacity, demanding high-volume, reliable honing solutions for engine and hydraulic component production. Competitive local manufacturing of affordable honing equipment also contributes to the market volume in APAC, although high-end precision requirements still rely on specialized European and North American suppliers. The focus in APAC is often on efficiency, speed, and cost-effective automation to meet mass-market demand.

North America and Europe represent mature markets characterized by stringent quality standards and a high degree of technological sophistication. These regions drive demand for advanced, fully automated, CNC-controlled single spindle machines designed for highly specialized applications, particularly in the aerospace, medical implant, and high-performance automotive (motorsport) sectors. European manufacturers, particularly in Germany and Switzerland, are global leaders in developing and supplying ultra-precision honing technology, focusing on complex material processing and the integration of advanced measurement and AI capabilities. The North American market emphasizes reduced cycle times and machine flexibility to cater to varied customer specifications and shorter production runs common in defense and advanced manufacturing.

The Middle East and Africa (MEA) and Latin America (LATAM) regions are emerging markets for single spindle honing equipment. Growth in MEA is largely concentrated in the Oil & Gas sector, where honing is crucial for pump liners, valves, and downhole tools to ensure sealing integrity and operational reliability under extreme conditions. The LATAM market, led by Brazil and Mexico, demonstrates growth linked to regional automotive production and expanding agricultural and construction machinery industries. While these regions currently represent a smaller market share, infrastructure development and industrialization initiatives are expected to steadily increase the demand for precision machining capabilities, driving future market penetration for single spindle honing solutions.

- Asia Pacific (APAC): Dominates the market share due to rapid industrialization, massive automotive production capacities, and high government investment in manufacturing infrastructure (China, India).

- North America: Focuses on high-value, high-precision applications in aerospace, defense, and specialized medical manufacturing, driving demand for automated, technologically advanced CNC machines.

- Europe: A technology hub for precision honing, characterized by stringent quality requirements and leading innovation in superabrasives and integrated measuring systems, particularly strong in Germany and Italy.

- Latin America (LATAM): Growth driven by regional automotive assembly plants and expanding heavy equipment manufacturing (Brazil, Mexico).

- Middle East and Africa (MEA): Demand heavily concentrated in the Oil & Gas industry for reliable high-pressure components, requiring robust and durable honing solutions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Single Spindle Honing Machine Market.- Sunnen Products Company

- Gehring Technologies

- Nagel Precision

- Barnes Honing

- Engis Corporation

- Kadia Production

- Fuji Machine Mfg. Co.

- AZ spa

- System Hones

- Ohio Tool Works

- Pemamo

- Bates Technologies

- Belden Honing

- Micromatic Grinding Technologies

- Premier Honing Machines

- Delapena Group

- Kros Honing

- Honingtec

- Ningbo Hongye Honing

- Wenzhou Jingsheng Machine

- Beijing Precision Machinery

- Mitsui Grinding Technology

- Stähli Läpp-Technik

- Taiyo Koki Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the Single Spindle Honing Machine market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between single spindle and multi-spindle honing machines?

Single spindle honing machines are optimized for high precision, repeatability, and superior geometric accuracy on one bore at a time, making them ideal for specialized, critical components. Multi-spindle machines are designed for mass production, honing multiple bores simultaneously to maximize throughput, often sacrificing slight degrees of ultimate precision for speed and volume.

Which industries are the major end-users driving the demand for Single Spindle Honing Machines?

The primary demand driver is the Automotive industry, particularly for engine and transmission components requiring strict surface finish control. Significant demand also stems from Aerospace for hydraulic systems, the Hydraulics & Pneumatics sector for critical valve bodies, and the Medical industry for precision instrument components.

How is CNC technology impacting the operational efficiency of single spindle honing?

CNC technology provides precise, automated control over all operational variables, including abrasive expansion pressure, stroking speed, and tool feed, enabling repeatable, sub-micron accuracy. This reduces operator error, shortens cycle times, and allows for automatic compensation adjustments based on in-process gauging, vastly improving overall operational efficiency and reducing scrap rates.

What role do superabrasives like CBN and Diamond play in modern honing processes?

Superabrasives (Cubic Boron Nitride and Diamond) are essential for modern honing as they offer significantly higher hardness and wear resistance, allowing machines to effectively process difficult-to-machine materials (e.g., hardened steel, ceramics) at higher speeds, leading to improved material removal rates, longer tool life, and superior surface integrity compared to conventional abrasives.

What is the current market outlook for Single Spindle Honing Machine adoption in the Asia Pacific region?

The Asia Pacific region, led by China and India, exhibits the highest growth rate due to massive investments in local manufacturing and high-volume automotive production. The market outlook is highly positive, driven by the continuous need to upgrade older equipment and meet increasing regional quality standards for precision components.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager