Sintered Stone Furniture Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 433967 | Date : Dec, 2025 | Pages : 249 | Region : Global | Publisher : MRU

Sintered Stone Furniture Market Size

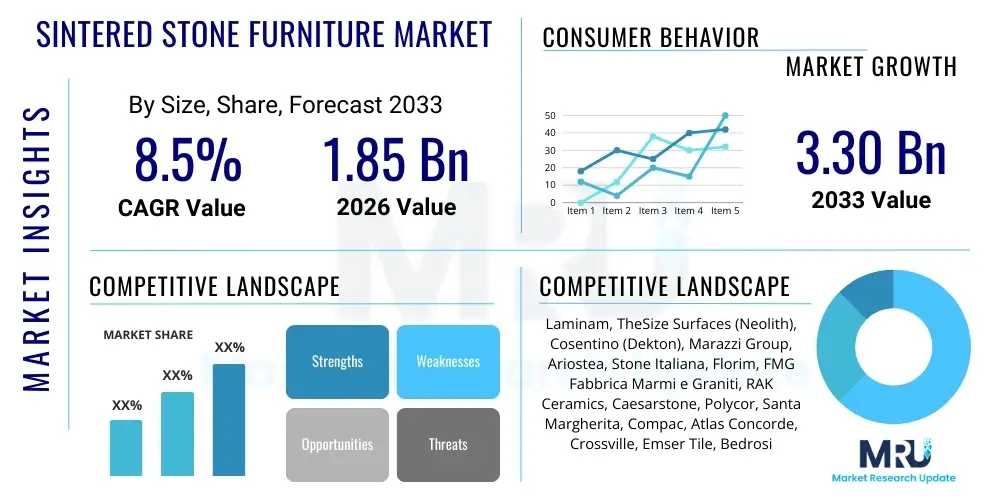

The Sintered Stone Furniture Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.5% between 2026 and 2033. The market is estimated at $1.85 Billion in 2026 and is projected to reach $3.30 Billion by the end of the forecast period in 2033.

Sintered Stone Furniture Market introduction

The Sintered Stone Furniture Market encompasses high-end furniture and architectural surfaces manufactured from sintered stone, an engineered material produced by subjecting natural minerals, silica, clay, and inorganic pigments to extreme heat and pressure, mimicking the natural formation process of metamorphic rock over thousands of years but accelerated to hours. This process results in a material that is exceptionally durable, non-porous, and highly resistant to scratching, UV exposure, chemical corrosion, and thermal shock, making it superior to traditional natural stones or engineered quartz in many functional applications.

Sintered stone furniture, including dining tables, countertops, outdoor seating elements, and bespoke cabinetry surfaces, has witnessed rapid adoption across both residential and commercial sectors. Major applications span modern kitchens, luxury bathrooms, high-traffic commercial spaces like hotels and restaurants, and increasingly, premium outdoor living areas due to the material's weather resistance. The primary benefits driving market expansion include its robust nature, ease of maintenance (hygiene), and the ability to replicate the aesthetic appeal of natural marble or wood without the associated vulnerability to staining or etching.

Key driving factors propelling the market forward include the global trend toward premium, durable, and low-maintenance home furnishings, particularly in densely populated urban environments where longevity and aesthetics are paramount. Furthermore, stringent hygienic requirements in hospitality and healthcare settings favor non-porous surfaces like sintered stone. Continuous advancements in digital printing and manufacturing technologies allow producers to offer diverse textures, colors, and designs, catering to evolving interior design trends and sophisticated consumer demands for personalized, long-lasting furniture solutions.

Sintered Stone Furniture Market Executive Summary

The Sintered Stone Furniture Market is experiencing robust expansion, fundamentally driven by shifts in consumer preferences towards highly durable and aesthetically versatile materials. Business trends indicate a strong focus on enhancing manufacturing efficiency, particularly reducing the high energy consumption associated with the sintering process, and expanding customization capabilities through advanced digital printing techniques. Major manufacturers are investing heavily in establishing strong global distribution networks, capitalizing on the increasing demand for high-performance surfaces in high-end renovation and new construction projects worldwide. The market is increasingly characterized by strategic partnerships between sintered stone producers and large-scale furniture designers and architectural firms to secure lucrative commercial contracts.

Regionally, the Asia Pacific (APAC) market stands out as the primary growth engine, fueled by rapid urbanization, substantial investment in infrastructure, and a burgeoning affluent population driving demand for luxury interiors, particularly in countries like China and India. North America and Europe maintain significant market share, characterized by high adoption rates in residential remodeling and a steady flow of demand from the hospitality sector. These established regions focus heavily on innovation in sustainable production practices and the integration of smart features into sintered stone designs, such as invisible charging capabilities embedded within tabletops.

Segment trends reveal that the Tables and Countertops segment holds the dominant market share due to the direct utility of sintered stone’s scratch and heat resistance in kitchen and dining environments. Simultaneously, the application of sintered stone in outdoor furniture is projected to show the fastest growth rate, benefiting from the material's exceptional resistance to weathering and UV degradation. The residential sector remains the largest end-user segment, although the commercial sector is rapidly accelerating its adoption for high-traffic public spaces where material resilience translates directly into lower long-term maintenance costs. The overall trend emphasizes larger format slabs and thinner profiles, optimizing both aesthetic appeal and logistical efficiency.

AI Impact Analysis on Sintered Stone Furniture Market

User inquiries regarding AI's influence in the Sintered Stone Furniture Market primarily center on three areas: design optimization, manufacturing quality control, and customer experience personalization. Users frequently ask how AI can help predict aesthetic trends, optimize slab cutting to minimize waste (a high-cost factor in production), and automate defect detection in the sintering process. There is significant interest in using AI algorithms to analyze architectural trends and consumer purchasing patterns to inform the creation of new patterns and colors that resonate instantly with the market, thus reducing the lead time for new product introductions.

AI's primary role is emerging in enhancing operational efficiency and tailoring product offerings. Machine learning models are being deployed to predict equipment failure in sintering kilns, ensuring optimal temperature profiles and reducing costly downtime. Furthermore, advanced vision systems coupled with deep learning are revolutionizing quality control by scanning manufactured slabs at high resolution, identifying subtle imperfections, cracks, or color inconsistencies far beyond human capability, ensuring adherence to stringent quality standards demanded by the luxury furniture segment. This precision is critical, given the high value of finished sintered stone products.

On the consumer front, AI is utilized through augmented reality (AR) applications that allow potential buyers to visualize sintered stone furniture in their own spaces, and through recommendation engines that suggest complementary stone patterns, textures, and furniture styles based on existing home decor or historical purchasing data. This focus on personalized digital design consultation significantly enhances the buying journey, bridging the gap between digital exploration and physical material selection, thereby driving sales and improving customer satisfaction in this highly visual and design-intensive market segment.

- AI-driven optimization of slab cutting patterns, minimizing raw material waste and improving yield rates.

- Predictive maintenance analytics for high-temperature sintering equipment, reducing operational downtime and energy costs.

- Advanced visual inspection systems utilizing machine learning for automated defect detection (e.g., micro-cracks, color variations).

- Generative design tools assisting R&D teams in creating novel and market-relevant stone patterns and textures.

- Personalized customer experience via AI-powered visualization (AR/VR) and intelligent product recommendation engines.

- Supply chain forecasting and demand planning optimization to manage inventory of high-value raw materials and finished goods.

DRO & Impact Forces Of Sintered Stone Furniture Market

The market dynamics of sintered stone furniture are dictated by a compelling set of drivers, balanced by material-specific restraints, and characterized by substantial growth opportunities, all governed by underlying external impact forces. The dominant drivers stem from the material's superior performance characteristics, notably its extreme durability, resistance to high temperatures, non-porosity ensuring hygiene, and UV resistance, which makes it ideal for both sophisticated indoor and exposed outdoor applications. The desire among consumers for long-lasting, investment-grade furniture that mirrors the luxury aesthetic of marble or granite without the maintenance liabilities strongly fuels demand across global markets.

However, the market faces significant restraints, primarily revolving around the high initial production cost associated with the energy-intensive sintering process and the high precision required for manufacturing large format slabs. Furthermore, specialized installation expertise is often required due to the weight and inherent rigidity of the material, presenting a barrier in less developed construction markets. The market also contends with fierce competition from established, cheaper alternatives such as traditional quartz, natural stone (marble and granite), and advanced laminate surfaces, which constantly seek to close the performance gap through continuous technological improvements.

Opportunities for expansion are largely concentrated in the residential renovation boom, particularly the upgrading of kitchen and bathroom spaces, and the exponential growth potential in the outdoor furniture sector, where sintered stone's weather resilience offers a distinct advantage over competing materials. Significant scope exists for technological advancements to reduce manufacturing costs, possibly through innovations in lower-temperature sintering processes or more efficient kiln designs. Impact forces, such as fluctuating energy prices globally, directly affect production costs, while changing trade policies influence material sourcing and global distribution costs, compelling manufacturers to focus on localized production or robust supply chain diversification.

Segmentation Analysis

The Sintered Stone Furniture Market is comprehensively segmented based on product type, application, and distribution channel, providing a granular view of market dynamics and consumer preferences across different usage scenarios. Analysis by product type shows the dominance of large format applications, reflecting the material’s utility in creating seamless, luxurious surfaces. The segmentation analysis helps manufacturers tailor their production volumes and aesthetic designs to target the most profitable and fastest-growing end-user segments, ensuring product development aligns with specific market demands, such as thin profiles for cabinetry or extremely thick slabs for robust dining table bases.

The market is predominantly driven by residential usage, specifically new construction and extensive remodeling, where durability and aesthetic uniformity are highly valued. However, the commercial sector, encompassing hospitality (hotels, restaurants), corporate offices, and institutional spaces, is demonstrating a quicker adoption trajectory. The commercial segment appreciates the material's ability to withstand high foot traffic and intensive cleaning protocols, directly contributing to lower lifecycle costs compared to softer natural stones. Understanding these segmental dynamics is critical for strategic marketing efforts and optimizing global supply chain logistics.

- By Product Type:

- Tables (Dining Tables, Coffee Tables, Side Tables)

- Countertops and Vanity Tops (Kitchen Countertops, Bathroom Vanities)

- Shelving and Storage Units

- Cabinets and Wall Cladding

- Outdoor Furniture (Patio Sets, Benches)

- By Application:

- Residential (Homes, Apartments, Villas)

- Commercial (Hotels, Restaurants, Retail Stores, Offices)

- Institutional (Hospitals, Educational Facilities)

- By Distribution Channel:

- Offline (Specialty Stores, Furniture Showrooms, Construction Supply Distributors)

- Online (E-commerce Platforms, Direct-to-Consumer Websites)

Value Chain Analysis For Sintered Stone Furniture Market

The Sintered Stone Furniture Value Chain begins with the upstream segment, which involves the sourcing and preparation of high-purity raw materials, including natural minerals, feldspar, clay, silica, and inorganic pigments necessary for achieving desired colors and textures. This stage is crucial, as the quality and consistency of these materials directly impact the final product’s structural integrity and aesthetic fidelity. Specialized suppliers provide these finely milled components, often requiring rigorous quality checks before they enter the manufacturing process, which is characterized by high energy costs due to the required extreme pressure and high-temperature firing (sintering).

The core manufacturing process transforms these raw powders into large format slabs, utilizing advanced machinery for pressing, digital printing, and firing. Midstream activities also include cutting, polishing, and specialized finishing required to convert the raw slab into furniture components—such as table tops, structural elements, or cladding panels. Efficiency in this stage, particularly minimizing slab breakage and optimizing material usage, is vital for cost control. Logistics and warehousing follow, focusing on the safe and efficient transportation of large, fragile slabs to regional processing centers or direct project sites.

The downstream segment involves complex distribution channels. Direct distribution (B2B) often targets large commercial and hospitality projects, where manufacturers deal directly with architects, interior designers, and general contractors, offering customized solutions and bulk pricing. Indirect distribution relies heavily on regional distributors, specialized stone fabricators, and high-end furniture retailers and showrooms (B2C). These indirect channels provide the necessary fabrication, installation services, and personalized customer interaction crucial for residential sales. The final stage involves installation and after-sales support, emphasizing the specialized skills required to handle sintered stone, which adds significant value to the overall product offering.

Sintered Stone Furniture Market Potential Customers

Potential customers for the Sintered Stone Furniture Market span a diverse range of buyers who prioritize longevity, premium aesthetics, and minimal maintenance in their furnishing decisions. The primary end-users are affluent homeowners and high-net-worth individuals engaged in luxury residential remodeling or building custom homes, seeking durable kitchen countertops, luxurious bathroom vanities, and high-performance outdoor entertainment areas. These consumers view sintered stone furniture as an investment that enhances both the value and functionality of their property, demanding high customization and design sophistication.

The second major category includes the commercial and hospitality sectors. Hotel chains, luxury resorts, upscale restaurants, and high-end retail boutiques are crucial buyers. These entities require materials that can withstand high traffic, frequent cleaning with industrial agents, and maintain pristine appearance over years of intensive use. Sintered stone, with its hygienic, scratch-resistant, and non-porous properties, perfectly meets the demanding specifications for lobbies, dining surfaces, bars, and public restrooms, where material failure translates directly into operational disruption and high replacement costs.

Furthermore, architectural firms, interior designers, and bespoke furniture manufacturers constitute a substantial indirect customer base, acting as gatekeepers and specifiers who integrate sintered stone into large-scale projects. They require reliable supply chains, detailed technical specifications, and a broad range of color/texture options to fulfill diverse client visions. Lastly, specialized segments such as yacht builders and healthcare facility developers represent niche, high-value opportunities due to the material's structural performance and hygienic superiority in constrained or regulated environments.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $1.85 Billion |

| Market Forecast in 2033 | $3.30 Billion |

| Growth Rate | 8.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Laminam, TheSize Surfaces (Neolith), Cosentino (Dekton), Marazzi Group, Ariostea, Stone Italiana, Florim, FMG Fabbrica Marmi e Graniti, RAK Ceramics, Caesarstone, Polycor, Santa Margherita, Compac, Atlas Concorde, Crossville, Emser Tile, Bedrosians Tile & Stone, Walker Zanger, MSI, Daltile. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Sintered Stone Furniture Market Key Technology Landscape

The manufacturing process of sintered stone relies on several core technological advancements to achieve its material superiority. Central to the process is the use of high-pressure pressing technology, often employing hydraulic presses exceeding 15,000 tons, which compact the raw material mixture (minerals, feldspar, clay) into dense, large format slabs. This mechanical compaction minimizes residual porosity, a key differentiator from traditional ceramics or natural stone. Following compaction, the slabs undergo sophisticated sintering in specialized kilns, where they are fired at temperatures often exceeding 1,200 degrees Celsius, initiating a vitrification process that bonds the particles without the use of resins or chemical binders, yielding a homogenous and ultra-durable final product.

A second critical technology is high-definition digital printing, which allows manufacturers to achieve hyper-realistic aesthetic reproductions of natural materials such as marble, wood, or concrete. Using advanced inkjet technology and reactive inks, detailed graphics and textures are printed onto the surface of the unfired slab, penetrating the material slightly before sintering. This technology allows for unparalleled customization, aesthetic range, and consistency across batches, directly addressing the demand for unique, high-end design finishes in the furniture market.

Furthermore, continuous innovation in surface treatment and post-processing technologies is essential. This includes specialized polishing and texturing equipment that can replicate various finishes, from ultra-glossy to deep matte and textured natural surfaces. Robotics and advanced cutting technologies, such as waterjet and CNC cutting, are integral for precise fabrication required for furniture components, ensuring edges are perfectly finished and complex designs can be executed accurately. The market also sees emerging technologies focused on sustainability, such as closed-loop water usage and energy recovery systems within the kilns, aimed at mitigating the high energy footprint of the production process.

Regional Highlights

- Asia Pacific (APAC): APAC is the largest and fastest-growing regional market, primarily driven by explosive growth in residential construction, rapid urbanization, and increasing disposable incomes in key economies like China, India, and Southeast Asian nations. The region’s preference for modern, sleek, and minimalist furniture designs aligns perfectly with the aesthetic and functional characteristics of sintered stone. Furthermore, high population density necessitates materials that offer longevity and low maintenance in apartment living, fueling demand for sintered stone in kitchen and bathroom applications.

- North America: North America represents a mature, high-value market, heavily influenced by the robust home renovation and remodeling sector. Demand is concentrated among affluent consumers who prioritize premium, imported European-style materials. The region sees strong adoption in high-end commercial projects, particularly hospitality and corporate spaces, where durability and aesthetic continuity across large areas are crucial. Market growth is sustained by a willingness to invest in materials that offer superior scratch, stain, and heat resistance over conventional engineered stones.

- Europe: Europe holds a historical significance in high-quality surface materials and furniture design. The region, particularly Italy and Spain, houses many of the world's leading sintered stone manufacturers. Market growth is driven by a strong focus on sustainable and eco-friendly manufacturing practices (AEO focus on green building certifications), combined with high consumer standards for design innovation and material longevity. The residential market, especially in Western European countries, continues to exhibit steady demand for modern, durable interior solutions.

- Latin America (LATAM): The LATAM market is characterized by increasing foreign investment in real estate and the expansion of the middle class, leading to rising demand for durable, aspirational building materials. Growth is steady but faces challenges related to economic volatility and reliance on imported products. Key growth areas include luxury residential developments in major metropolitan hubs like São Paulo and Mexico City.

- Middle East and Africa (MEA): The MEA market is undergoing significant expansion, propelled by large-scale infrastructure projects, mega-city developments (e.g., NEOM in Saudi Arabia), and a burgeoning luxury residential sector. Sintered stone is particularly valued here for its UV resistance, crucial in the harsh, high-sun environments, and its ability to maintain aesthetics in upscale hotel and commercial projects across the Gulf Cooperation Council (GCC) countries.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Sintered Stone Furniture Market.- Laminam S.p.A.

- TheSize Surfaces (Neolith)

- Cosentino S.A. (Dekton)

- Marazzi Group S.r.l.

- Ariostea S.p.A.

- Stone Italiana S.p.A.

- Florim Ceramiche S.p.A.

- FMG Fabbrica Marmi e Graniti

- RAK Ceramics PJSC

- Caesarstone Ltd.

- Polycor Inc.

- Santa Margherita S.p.A.

- Compac Technological Surfaces

- Atlas Concorde S.p.A.

- Crossville Inc.

- Emser Tile

- Bedrosians Tile & Stone

- Walker Zanger

- MS International, Inc. (MSI)

- Daltile (Mohawk Industries)

Frequently Asked Questions

Analyze common user questions about the Sintered Stone Furniture market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is sintered stone and how does it compare to quartz or granite?

Sintered stone is an engineered surface created by sintering (high pressure and heat) natural minerals, resulting in an ultra-compact, non-porous material. It is significantly more resistant to scratching, etching, heat, and UV rays than traditional engineered quartz (which contains resin) and natural granite, making it ideal for both indoor and outdoor furniture applications.

What are the primary applications and benefits of choosing sintered stone for furniture?

Primary applications include high-end dining tables, kitchen countertops, and robust outdoor furniture. The key benefits are exceptional durability, hygienic non-porous surface (preventing stain absorption), minimal maintenance requirements, and full resistance to UV fading, ensuring longevity and preserved aesthetics.

How is the global market for sintered stone furniture segmented, and which region is leading growth?

The market is segmented by product type (Tables, Countertops), application (Residential, Commercial), and distribution channel (Online, Offline). The Asia Pacific (APAC) region currently leads market growth, driven by rapid urbanization and high demand for durable, luxurious interior materials in new construction projects.

Are there significant cost or installation challenges associated with sintered stone furniture?

Yes, significant restraints include the high initial material cost due to the energy-intensive manufacturing process and the specialized installation required. Sintered stone is dense and rigid, necessitating experienced fabricators and precise handling during cutting and mounting to prevent breakage.

What role does technology, specifically AI and digital printing, play in the manufacturing of modern sintered stone?

Advanced digital printing technology enables manufacturers to produce hyper-realistic, customizable textures (like marble or wood grain) with high consistency. AI is increasingly used for optimizing material usage (slab cutting optimization) and automated quality control to detect defects, thereby enhancing production efficiency and product quality.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager