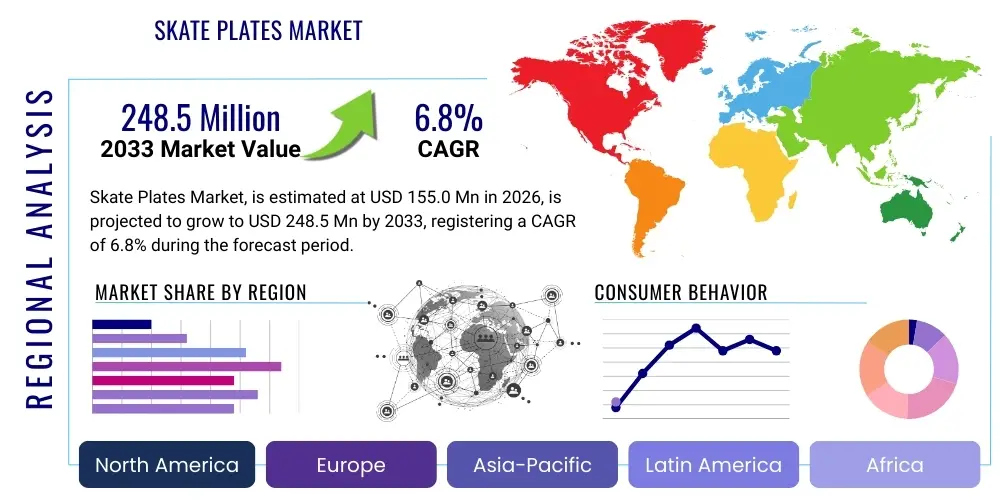

Skate Plates Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 434577 | Date : Dec, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Skate Plates Market Size

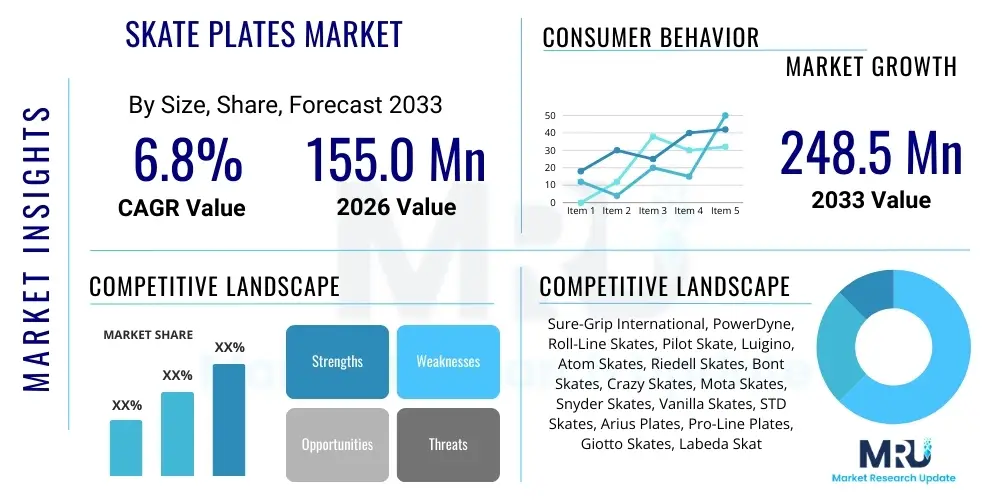

The Skate Plates Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 155.0 Million in 2026 and is projected to reach USD 248.5 Million by the end of the forecast period in 2033.

Skate Plates Market introduction

The Skate Plates Market encompasses the manufacturing, distribution, and sale of the foundational chassis component connecting the boot and the wheels in quad roller skates, crucial for performance and structural integrity. These plates are typically precision-engineered from materials such as aircraft-grade aluminum, durable nylon composites, or increasingly, lightweight carbon fiber. The primary function of a skate plate is to provide a rigid, responsive platform that translates the skater’s movements into steering via the trucks and cushions (bushings), directly influencing speed, agility, and control. Product descriptions often highlight key attributes like plate angle, truck mechanism design (e.g., standard kingpin or adjustable pivot), and overall weight reduction, catering to specific skating disciplines.

Major applications for skate plates span across professional and recreational skating sectors, prominently including roller derby, which demands high impact resistance and quick maneuverability; speed skating, where lightweight rigidity is paramount for efficient power transfer; and artistic skating, necessitating precise control and specialized pivot mechanisms for executing complex figures and jumps. The benefits derived from high-quality skate plates include enhanced durability, superior responsiveness, reduced foot fatigue due to optimized weight distribution, and significant customization potential through interchangeable components. Modern plates offer increasingly complex adjustment features, allowing skaters to fine-tune steering responsiveness based on individual style and floor conditions, leading to improved athletic performance and safety.

Driving factors stimulating market expansion include the sustained global resurgence of roller skating as both a recreational activity and a competitive sport, particularly the robust growth of roller derby leagues worldwide and the increased popularity of outdoor recreational skating during the post-pandemic period. Furthermore, continuous material innovation, focusing on achieving optimal strength-to-weight ratios through advanced composites and specialized metal alloys, allows manufacturers to introduce premium products commanding higher price points. The market is also heavily influenced by social media trends and the increasing consumer demand for personalized and high-performance sports equipment, driving frequent upgrades and component replacements among dedicated skaters seeking marginal gains in performance and aesthetic appeal.

Skate Plates Market Executive Summary

The Skate Plates Market Executive Summary highlights robust growth driven primarily by a convergence of sports participation trends and advancements in material science. Business trends indicate a strong move toward customization and modular designs, where companies are offering plates with varying truck angles (e.g., 10-degree, 45-degree) and adjustable components to cater to highly specialized skating needs, moving away from one-size-fits-all solutions. The competitive landscape is characterized by established specialty manufacturers maintaining market dominance through quality and brand legacy, alongside emerging innovative companies leveraging 3D printing and carbon fiber to disrupt traditional aluminum plate production. Strategic alliances between plate manufacturers and boot producers are becoming common, offering integrated, high-performance skate packages to consumers, simplifying the purchasing decision and ensuring component compatibility.

Regional trends demonstrate North America’s persistent leadership in market revenue, largely attributed to the deeply entrenched roller derby culture and a large, mature recreational skating community with high disposable income willing to invest in premium equipment. Europe follows closely, driven by a strong presence in artistic skating and a growing awareness of high-performance speed skating plates, particularly in countries like Italy and Germany. The Asia Pacific (APAC) region is projected to be the fastest-growing market segment, fueled by rising disposable incomes, rapid urbanization leading to increased interest in urban and recreational sports, and targeted marketing campaigns by major skate brands expanding into emerging economies like China and India. Local manufacturing capabilities are also increasing in APAC, contributing to lower supply chain costs and faster market response times in the region.

Segment trends reveal that the Material segment is undergoing a significant shift, with high-performance aluminum plates (such as 7075 series aluminum) retaining market share due to their proven durability, but carbon fiber and high-grade composite materials are gaining traction, especially in the high-end speed and artistic skating sectors, where minimizing weight is critical. Conversely, entry-level and recreational segments remain loyal to durable, cost-effective nylon/composite plates. Application-wise, Roller Derby continues to be the largest revenue generator due to the high wear-and-tear nature of the sport necessitating frequent component replacement, while the Recreational segment provides the volume growth base, introducing new consumers to the market and encouraging incremental upgrades over time.

AI Impact Analysis on Skate Plates Market

User questions regarding the impact of AI on the Skate Plates Market primarily revolve around how artificial intelligence can optimize the design and manufacturing processes, enhance product durability, and personalize the consumer experience. Common concerns focus on the potential for AI-driven design to reduce material waste, predict structural failures under specific stresses (e.g., jump landings in artistic skating or heavy lateral pressure in roller derby), and automate complex CNC machining paths for exotic materials. Users are also interested in AI's role in retail, specifically using machine learning to analyze skating style, body metrics, and preference data to recommend the optimal plate model, size, and kingpin angle for individual skaters, thereby solving the complexity often associated with component selection. The overarching expectation is that AI will lead to lighter, stronger, and more accurately customized skate plates, drastically cutting down development cycles and improving user performance outcomes.

AI's primary influence is seen in the iterative design phase, where Generative Design algorithms can rapidly produce thousands of optimized plate geometries that satisfy specific performance metrics—such as maximum torsional stiffness while minimizing weight—a task impossible for traditional human designers. By inputting constraints related to material properties, manufacturing costs, and desired load bearing capacity, AI outputs designs that often utilize lattice structures or unconventional shapes, significantly reducing material mass while maintaining or even increasing strength. Furthermore, AI-powered simulations allow manufacturers to predict the long-term fatigue life of different alloys or composites under real-world skating stresses, moving product testing from physical prototypes to virtual environments, accelerating time-to-market for new models.

In manufacturing and supply chain management, AI algorithms are critical for predictive maintenance of high-precision CNC machines used to mill aluminum plates, anticipating tool wear or calibration drift to ensure consistent quality control, which is essential for components requiring micron-level accuracy. On the consumer side, AI is integrated into specialized online fitting tools that use complex algorithms to match a skater's foot length, stance width, discipline, and historical purchase data to the most suitable plate and mounting configuration. This personalized recommendation system improves customer satisfaction, reduces returns due to incorrect sizing or component incompatibility, and provides manufacturers with valuable, granular data on performance preferences, further fueling AI-driven design improvements.

- AI-driven Generative Design optimizes plate geometry for superior strength-to-weight ratios.

- Machine learning improves quality control and precision in CNC machining processes.

- Predictive modeling simulates stress and fatigue life, reducing physical prototyping requirements.

- AI-powered fitting tools offer highly personalized component recommendations to consumers.

- Supply chain AI enhances inventory management and predicts material cost fluctuations.

DRO & Impact Forces Of Skate Plates Market

The Skate Plates Market is characterized by dynamic interplay between demand resurgence, material constraints, innovation opportunities, and competitive impact forces. Key drivers include the revitalization of competitive roller sports, particularly roller derby, coupled with a significant surge in recreational and fitness skating globally, creating a high-volume demand base for replacement and upgrade components. Restraints primarily involve the volatility of raw material costs, particularly high-grade aluminum and specialized resins for composites, which directly impact manufacturing margins, alongside the challenge of maintaining high precision in production to meet stringent performance standards required by professional skaters. Opportunities arise from expanding into emerging global markets, developing sustainable, bio-based composite plates, and capitalizing on the burgeoning demand for highly customizable and aesthetically diverse products, leveraging advanced manufacturing techniques like 3D printing for low-volume, high-value components. The impact forces are defined by intense competition leading to aggressive pricing strategies in the mid-range segment, and consumer preference shifting strongly toward lighter, more responsive plates, forcing manufacturers to continuously invest in research and development to maintain relevance and competitive advantage.

Drivers contributing to market growth are deeply rooted in demographic shifts and cultural trends. The increasing adoption of roller skating as a core fitness activity, especially among younger demographics and adults seeking retro-inspired physical hobbies, has broadened the consumer base significantly beyond traditional competitive circles. Furthermore, professional sports leagues and global competitive events are elevating the profile of skating, driving demand for premium, high-specification equipment that offers marginal performance improvements. The growing availability of specialized coaching and training facilities also encourages skaters to invest in high-quality plates tailored to specific technical requirements, such as plates designed for aggressive slides or rapid acceleration, fueling product diversification and premiumization across all major skating disciplines.

Restraints impose tangible barriers to unfettered growth, most notably concerning supply chain reliability and material scarcity. Dependence on specialized, aerospace-grade aluminum alloys (like 7075 T6) means that manufacturers are susceptible to global metal market fluctuations and geopolitical instability affecting mineral sourcing. Additionally, technical expertise required for the precise assembly and alignment of skate plates—especially high-end models with complex adjustable pivots and multiple cushion hardness settings—represents a skill barrier that limits the scalability of consistent, high-quality production across all potential manufacturing sites. Counterfeit products, particularly in online marketplaces, pose another restraint, undermining consumer trust and the perceived value of premium branded plates, necessitating significant investment in brand protection and authentication technologies by leading industry players.

Opportunities are strongly linked to technological integration and market segment expansion. The adoption of advanced simulation software allows companies to rapidly prototype and test new designs, optimizing component longevity and responsiveness without incurring extensive physical testing costs. Developing customizable software platforms that enable end-users to design or select specific aesthetic elements (colorways, custom logos) or functional elements (kingpin length, truck angle modifications) represents a high-margin opportunity for niche players. Furthermore, the push towards sustainability in sports equipment creates a significant niche for recycled materials and bio-composites, appealing to environmentally conscious consumers and offering a distinct marketing edge against competitors relying solely on traditional aluminum or plastic resins. The growing digital influence means that direct-to-consumer (D2C) channels and influencer marketing offer cost-effective routes to market expansion.

Segmentation Analysis

The Skate Plates Market segmentation analysis is critical for understanding varying consumer needs and market dynamics across different product specifications and end-user applications. The market is fundamentally segmented by Material Type, Application, and Distribution Channel, reflecting the diverse performance requirements ranging from casual sidewalk skating to intense professional competition like roller derby and artistic skating. Material type is a primary differentiator, directly correlating with price point, durability, and weight—key factors influencing purchasing decisions. Composite (Nylon/Plastic) plates dominate the entry-level and recreational segments due to their cost-effectiveness and inherent dampening properties, while high-grade aluminum and emerging carbon fiber plates target the professional and enthusiast demographics willing to pay a premium for maximized power transfer and minimal weight.

Application-based segmentation divides the market based on the specific mechanical demands placed on the plate. Roller Derby plates emphasize robust construction and specific truck geometry for rapid side-to-side movement and impact absorption, making them a high-replacement segment. Artistic skating plates require extremely precise, often adjustable, pivot actions for tight turns and spins, justifying specialized engineering. Speed skating mandates plates designed for maximum rigidity and optimal wheelbase length to ensure straight-line speed and efficient power conversion from the boot to the wheel. This divergence in requirements dictates distinct product lines and marketing strategies, ensuring that manufacturers effectively meet the specialized needs of each sub-market while capitalizing on the high loyalty often seen within these focused skating communities.

The segmentation by Distribution Channel highlights the increasing importance of e-commerce and specialized retail outlets. While traditional brick-and-mortar specialty skate shops remain vital for expert advice, fitting, and custom mounting services—which are critical for premium plates—online retail has rapidly grown to capture market share, offering convenience, wider product selections, and competitive pricing, particularly for standard, non-customized plates and replacement parts. Mass merchandisers, though carrying limited, generally entry-level composite plates, introduce the product category to broader consumers. Understanding these channels is crucial for market penetration and optimizing supply chain logistics to ensure product availability across diverse geographic regions and consumer purchasing preferences, from informed professionals to impulse recreational buyers.

- Material Type: Aluminum, Nylon/Composite, Carbon Fiber.

- Application: Roller Derby, Speed Skating, Artistic Skating, Recreational/Fitness Skating.

- Distribution Channel: Online Retail (E-commerce), Specialty Skate Shops, Mass Merchandisers.

Value Chain Analysis For Skate Plates Market

The value chain for the Skate Plates Market begins with upstream activities focused heavily on raw material sourcing and primary processing. For aluminum plates, this involves acquiring specialized aluminum ingots (often 6061 or 7075 alloys) known for their strength and machinability. Upstream analysis also includes the procurement of high-density nylon resins, fiberglass reinforcement, and increasingly, prepreg carbon fiber sheets for composite plates. Suppliers must meet stringent quality and specification standards, as material integrity directly dictates the final product's performance and safety profile. Primary processing involves casting or forging the initial aluminum blanks or molding the composite components, often outsourced to specialized fabrication facilities, demanding tight quality control to minimize structural defects and ensure uniform density across batches. Reliable, long-term relationships with material suppliers are paramount given the specialized nature of the alloys and resins required.

The midstream segment involves the core manufacturing process, where high-precision engineering takes place. This typically includes advanced CNC machining for aluminum plates to achieve precise dimensions, kingpin angles, and mounting specifications; specialized tooling and injection molding for composite plates; and sophisticated layering and curing processes for carbon fiber plates. Post-processing activities include surface treatments such as anodization for durability and color, assembly of components like kingpins, trucks, and cushions, and meticulous quality assurance testing, often involving simulated stress tests and dimensional checks. Manufacturing efficiency and minimizing material waste are crucial competitive factors in this stage. Distribution channels then link the finished product to the end-consumer, utilizing both direct and indirect routes.

The downstream analysis focuses on market delivery and consumer interaction. Direct channels include manufacturers' own e-commerce platforms and official branded retail stores, offering maximized margins and direct customer feedback loops. Indirect channels rely heavily on specialized sports distributors who manage regional warehousing and logistics, feeding products into specialty skate shops and large online retailers. Specialty skate shops play a vital role, especially for premium plates, providing crucial expert advice, professional installation, and after-sales support, bridging the knowledge gap for complex performance equipment. Mass merchandisers handle high-volume, lower-margin composite plates. Effective channel management requires balancing quick fulfillment across e-commerce with the specialized technical support offered by dedicated brick-and-mortar outlets, ensuring broad market access while maintaining high service quality for technical products.

Skate Plates Market Potential Customers

The potential customer base for the Skate Plates Market is segmented into distinct groups defined by their skating discipline, skill level, and frequency of equipment use, encompassing professional athletes, dedicated amateur competitors, serious recreational enthusiasts, and casual fitness skaters. Professional and high-level amateur skaters, particularly in roller derby, artistic skating, and speed skating, represent the highest value customers. These buyers prioritize peak performance, durability, and lightweight construction, demanding premium aluminum or carbon fiber plates that offer minute adjustability and superior responsiveness. They view skate plates as critical performance tools and are frequently replacing components due to intense wear, driving demand for the most technologically advanced and highest-priced products on the market. Their purchasing decisions are heavily influenced by sponsor affiliations, competitive regulations, and direct peer recommendations from their respective competitive communities.

A significant volume driver comes from the serious recreational enthusiast and fitness skating segment. These customers are primarily focused on quality, comfort, and reliability for regular, non-competitive use, such as urban skating, trail skating, or general rink use. They typically seek mid-range products, often high-grade nylon composites or solid, mid-tier aluminum plates that balance performance benefits with affordability and longevity. Their purchasing decisions are influenced by ease of maintenance, overall weight, and the plate's compatibility with standard boots and components. This group often upgrades their plates after initial experience with entry-level skates, representing a stable segment for growth as they seek incremental improvements in their skating experience without necessarily targeting professional-grade features.

The entry-level market consists of new skaters, casual hobbyists, and renters who prioritize cost-effectiveness and ease of use. This segment is dominated by basic nylon or plastic composite plates pre-mounted on entry-level boots. While their individual purchase value is low, this segment provides essential volume and acts as a pipeline for future upgrades as skaters become more committed to the sport. Institutions such as skate rinks and school programs also constitute bulk buyers, purchasing durable, standardized plates for rental fleets. Targeting these potential customers requires marketing strategies focused on safety, reliability, and value proposition, often utilizing mass market distribution channels and accessible price points to capture initial market entry, ensuring accessibility to the sport.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 155.0 Million |

| Market Forecast in 2033 | USD 248.5 Million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Sure-Grip International, PowerDyne, Roll-Line Skates, Pilot Skate, Luigino, Atom Skates, Riedell Skates, Bont Skates, Crazy Skates, Mota Skates, Snyder Skates, Vanilla Skates, STD Skates, Arius Plates, Pro-Line Plates, Giotto Skates, Labeda Skates, Radar Wheels, Pacer Skates, Fila Skates |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Skate Plates Market Key Technology Landscape

The technological landscape of the Skate Plates Market is rapidly evolving, driven by the imperative to reduce weight while maximizing structural rigidity and control responsiveness. Core manufacturing technologies remain centered around high-precision Computer Numerical Control (CNC) machining, particularly for premium aluminum plates. CNC allows for the milling of complex geometries with extremely tight tolerances, which is crucial for the precise alignment of kingpins and pivot points that dictate steering response. Advanced CNC techniques, including multi-axis milling, are employed to create intricate hollowed-out or truss structures within the plate body, successfully reducing mass without compromising the critical load-bearing areas, maximizing the strength-to-weight ratio which is highly valued by performance skaters. Furthermore, specialized heat treatment processes, such as T6 tempering for aluminum alloys, are utilized to significantly enhance the tensile strength and fatigue resistance of the metal plates, ensuring longevity under high stress.

Material innovation represents a second major technological pillar. The transition towards advanced composites, including carbon fiber reinforced polymers (CFRP) and sophisticated fiberglass-nylon blends, is defining the high-end lightweight segment. Carbon fiber technology leverages aerospace-grade materials and complex lay-up schedules to create plates that are significantly lighter than their aluminum counterparts while offering exceptional vibration dampening and torsional stiffness. The use of injection molding technologies for high-volume composite plates has also advanced, utilizing improved fiber orientation control within the resin matrix to enhance mechanical properties previously associated only with metal. This technology enables the mass production of durable, lightweight plates suitable for recreational and entry-level competitive use, often featuring integrated mounting points and specialized resin formulations to improve impact absorption.

A third crucial technological area is the integration of customization and rapid prototyping. Additive Manufacturing (3D Printing) is increasingly employed, primarily for developing functional prototypes rapidly, allowing designers to test fit and structural integrity of new geometries before committing to expensive tooling for mass production. In a few niche applications, 3D printing is also used for producing highly customized, low-volume components or even entire plates from high-strength polymers or metal powders, catering to specialized athletes with unique dimensional or stiffness requirements. Furthermore, plate design is increasingly incorporating advanced finite element analysis (FEA) software during the digital design phase. FEA allows engineers to virtually simulate the stresses and strains a plate will endure during jumping, landing, and lateral pushing, optimizing material distribution across the plate surface to prevent failure points and ensuring that new models are structurally sound before production commences, significantly enhancing product safety and reliability.

Regional Highlights

Regional dynamics play a crucial role in shaping the Skate Plates Market, driven by cultural skating preferences, competitive infrastructure, and regional economic stability. The market is broadly divided into mature markets like North America and Europe, and rapidly emerging markets like Asia Pacific (APAC).

- North America: This region holds the largest market share, predominantly fueled by the strong competitive environment surrounding roller derby leagues (WFTDA, MRDA) and a large, established recreational skating community. The high disposable income and strong consumer preference for performance-oriented, premium-priced aluminum and carbon fiber plates drive revenue. The region is a key hub for innovation and distribution, with many major manufacturers headquartered here, facilitating quick market response to consumer demands and trends.

- Europe: Europe is a mature market characterized by robust participation in artistic skating (especially in Southern Europe) and significant historical interest in speed skating. Demand here is highly segmented, with artistic skaters driving demand for highly specialized, often adjustable, Italian-made Roll-Line and other precision plates, while general fitness skaters favor durable mid-range products. Regulatory standards related to sports equipment safety also influence product design and marketing strategies across the European Union.

- Asia Pacific (APAC): APAC is projected to exhibit the highest Compound Annual Growth Rate (CAGR) due to increasing urbanization, rising middle-class disposable income, and growing adoption of Western recreational sports culture. Key markets like China, Japan, and Australia are showing increased interest in urban and recreational skating. The market here is highly price-sensitive in the entry-level segment, but the professional markets in Australia and Japan show strong demand for imported, high-performance gear. Local manufacturing capabilities are expanding, potentially disrupting established import distribution networks.

- Latin America (LATAM) and Middle East & Africa (MEA): These regions represent emerging opportunities. Growth is steady, driven by local competitive leagues and recreational participation. Market penetration is often focused on durable, cost-effective composite plates, although premium brands are making inroads in economically stronger urban centers where dedicated skating clubs exist. Infrastructure development for skating facilities is a key factor influencing future growth potential in these regions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Skate Plates Market.- Sure-Grip International

- PowerDyne (Riedell Skates subsidiary)

- Roll-Line Skates

- Pilot Skate

- Luigino

- Atom Skates

- Riedell Skates

- Bont Skates

- Crazy Skates

- Mota Skates

- Snyder Skates

- Vanilla Skates

- STD Skates

- Arius Plates

- Pro-Line Plates

- Giotto Skates

- Labeda Skates

- Radar Wheels (Component division)

- Pacer Skates

- Fila Skates

Frequently Asked Questions

Analyze common user questions about the Skate Plates market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between aluminum and nylon skate plates?

Aluminum plates (typically 7075 or 6061 alloy) offer superior rigidity, strength, and power transfer, making them ideal for high-performance and competitive skating. Nylon or composite plates are significantly lighter and more affordable, providing inherent shock absorption, best suited for recreational skaters and beginners who prioritize comfort and budget over ultimate performance responsiveness.

How does the kingpin angle impact skate plate performance?

The kingpin angle dictates the responsiveness and stability of the skate. Plates with steeper angles (e.g., 45 degrees) provide quick, sharp turning and maximum maneuverability, preferred in roller derby. Shallower angles (e.g., 10 or 15 degrees) offer greater stability at high speeds, making them the standard choice for speed skating and general fitness skating.

Is the Skate Plates Market experiencing growth due to roller derby?

Yes, roller derby is a major growth driver for the Skate Plates Market. The high-impact, demanding nature of roller derby necessitates durable, responsive plates, often leading to frequent upgrades and replacements, thereby sustaining consistent demand for mid-to-high-end aluminum and specialized composite plates across North America and Europe.

What factors should influence the choice between a carbon fiber and an aluminum plate?

Choose carbon fiber if minimizing weight is the absolute priority, such as in highly competitive artistic or speed skating, and if budget is not a constraint. Choose high-grade aluminum if maximum durability, resilience to impact, and a proven, rigid feel are required, offering a better balance of performance and longevity for most competitive uses.

Where is the fastest growth anticipated for skate plates?

The Asia Pacific (APAC) region is projected to experience the fastest growth rate, driven by increasing participation in recreational sports, rising disposable incomes, and urbanization that supports the development of new skating facilities and consumer access to premium international brands.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager