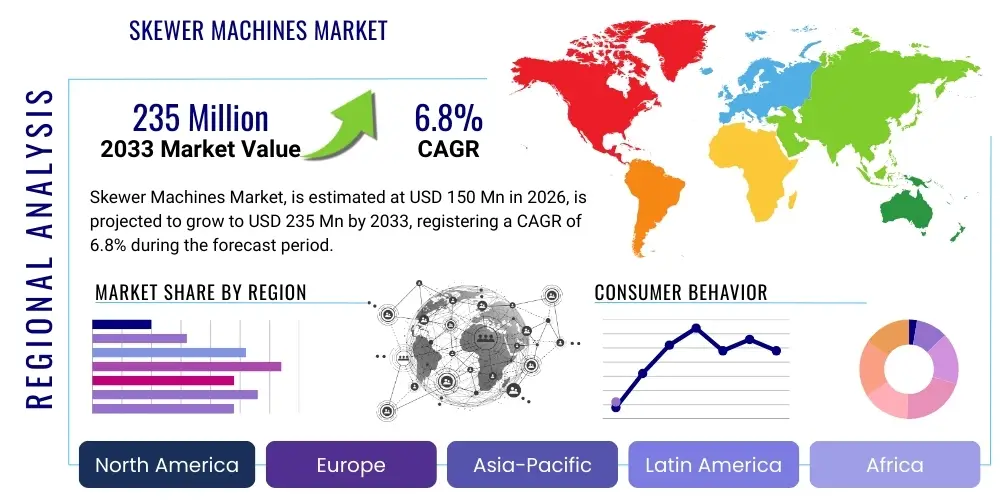

Skewer Machines Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 438022 | Date : Dec, 2025 | Pages : 257 | Region : Global | Publisher : MRU

Skewer Machines Market Size

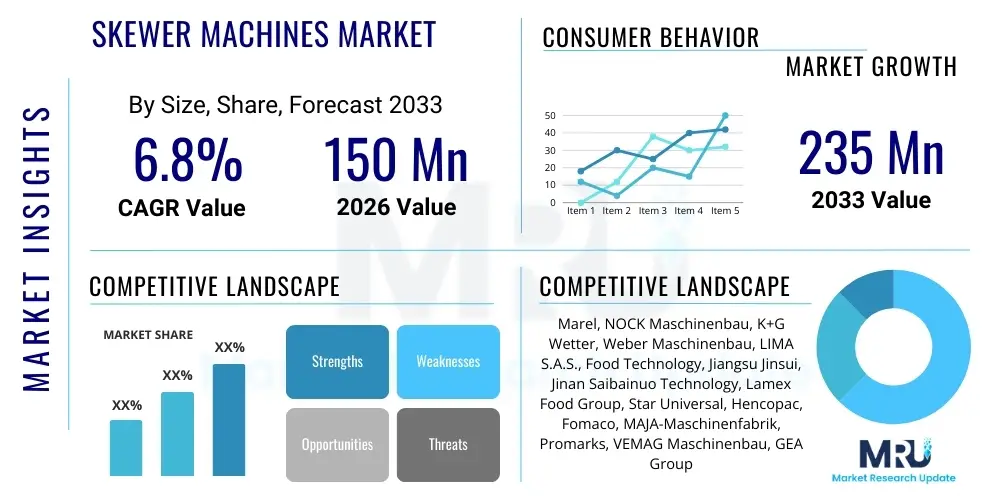

The Skewer Machines Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 150 Million in 2026 and is projected to reach USD 235 Million by the end of the forecast period in 2033.

Skewer Machines Market introduction

Skewer machine technology represents a crucial advancement in the food service and processing industries, offering sophisticated automation capabilities designed to significantly enhance operational efficiency and maintain stringent hygiene standards across various culinary environments. These specialized apparatuses are indispensable for large-scale production facilities, quick-service restaurants (QSRs), and specialized catering operations where consistent product quality and high throughput are paramount concerns. The integration of advanced mechanics and precise control systems allows these machines to handle diverse materials, ranging from various meats and vegetables to fruits and confectionery items, ensuring uniform skewering results that human labor often struggles to consistently achieve, thereby minimizing material waste and maximizing resource utilization.

The primary applications of skewer machines span commercial kitchens, meat processing plants, poultry factories, and specialized street food preparation units. Key benefits include dramatically reduced labor costs, increased production speed, improved food safety due to reduced human handling, and enhanced product aesthetics. Driving factors propelling this market growth include the global expansion of the ready-to-eat and processed food sectors, the increasing demand for standardized fast food products, and the persistent labor shortage challenges faced by the food service industry worldwide. Furthermore, continuous innovations in machine design, focusing on modularity, ease of cleaning (CIP – Clean-in-Place compatibility), and versatility in handling different skewer types (bamboo, metal) and product textures, are further cementing their market relevance.

Skewer Machines Market Executive Summary

The Skewer Machines Market exhibits robust growth driven primarily by accelerating automation trends within the global food processing and QSR sectors. Business trends indicate a strong move toward high-capacity, fully automated systems capable of continuous operation, particularly in Asia Pacific and North America, regions experiencing rapid urbanization and changing dietary habits favoring convenience foods. Manufacturers are increasingly focusing on developing smart, IoT-enabled machines that allow for remote monitoring and predictive maintenance, enhancing overall equipment effectiveness (OEE). Competitive intensity remains high, with established players leveraging their distribution networks and intellectual property in precision engineering, while emerging companies introduce cost-effective, smaller-scale solutions targeting independent restaurants and specialized food retailers.

Regionally, Asia Pacific is projected to lead market expansion, fueled by massive investment in modernizing food manufacturing infrastructure in countries like China and India, coupled with the immense popularity of skewered foods (such as satay and kebabs) as staples. North America and Europe maintain stable growth, characterized by demand for sophisticated, high-end machines that comply with stringent regulatory standards regarding sanitation and worker safety. Segment trends highlight the dominance of the Automatic Skewer Machines segment due to superior throughput, while the Meat and Poultry segment maintains the largest market share by application, reflecting the global consumption patterns of grilled and roasted protein products. However, the vegetable and fruit skewering segment is showing above-average growth, responding to healthier eating trends and the rise of vegan and vegetarian processed foods.

AI Impact Analysis on Skewer Machines Market

User inquiries regarding the impact of Artificial Intelligence (AI) on the Skewer Machines Market frequently center on whether AI can optimize the complex loading, sorting, and cutting processes, and how predictive maintenance driven by machine learning (ML) can minimize costly downtime. Key themes reveal user expectations for AI integration in visual quality control, enabling machines to instantly detect improperly placed ingredients or damaged skewers, thereby ensuring product consistency that exceeds human capabilities. Furthermore, there is significant interest in AI’s role in supply chain synchronization, allowing machines to adjust production rates dynamically based on real-time inventory and demand forecasts, moving the industry toward truly intelligent food production systems where efficiency is maximized and material waste is negligible.

- AI-driven visual inspection systems enhance quality control, identifying defective product placements or ingredient variations with high precision.

- Machine Learning algorithms enable predictive maintenance, analyzing sensor data (vibration, temperature, current draw) to forecast equipment failure before it occurs, minimizing unexpected downtime.

- Optimization of ingredient sorting and placement: AI helps robots select and orient ingredients (e.g., unevenly shaped meat chunks) to maximize skewer density and aesthetic appeal.

- Dynamic production scheduling: Integration with ERP systems allows AI to adjust machine throughput based on real-time order flow and inventory levels, optimizing energy consumption and labor allocation.

- Enhanced food safety compliance through data logging and anomaly detection, immediately flagging any operational deviation that could compromise hygiene standards.

DRO & Impact Forces Of Skewer Machines Market

The Skewer Machines Market is significantly influenced by a confluence of accelerating drivers, stringent restraints, and substantial opportunities, collectively shaping the competitive landscape. Key drivers include the exponential growth of the global QSR industry and the necessity for industrial food processors to achieve economies of scale through automation, directly reducing reliance on manual labor, which is increasingly expensive and prone to inconsistency. Opportunities are primarily centered on geographical expansion into emerging economies where traditional skewering methods are labor-intensive, and technological advancements such as the deployment of robotics and IoT integration into skewer machinery for remote diagnostics and performance optimization. However, the high initial capital investment required for automated systems, particularly for small and medium-sized enterprises (SMEs), acts as a substantial restraint, alongside the complexity of maintaining and repairing these specialized pieces of equipment. The immediate impact forces are dominated by intense market competition and rapidly evolving sanitation regulations, compelling manufacturers to continuously innovate their designs while maintaining cost competitiveness.

Segmentation Analysis

The Skewer Machines Market is broadly segmented based on Operational Mode, Application, Skewering Capacity, and Distribution Channel, allowing for precise targeting of diverse customer needs across the food industry. Understanding these segments is crucial for stakeholders to tailor their product offerings, whether focusing on high-volume, fully automatic industrial solutions or compact, semi-automatic machines suitable for specialized retail use. The complexity in segmentation arises from the varied requirements concerning ingredient handling (meat, vegetables, fruit), skewer material (bamboo, metal), and the requisite level of sanitation, which differs significantly between industrial processing plants and local QSR outlets. The segmentation analysis provides a granular view of market dynamics, highlighting areas of rapid growth and technological maturity across different usage scenarios.

- Operational Mode:

- Automatic Skewer Machines

- Semi-Automatic Skewer Machines

- Manual/Handheld Skewer Devices (for specialized niche)

- Application:

- Meat and Poultry Processing

- Seafood Skewering

- Vegetable and Fruit Skewering

- Confectionery and Snack Skewering

- Skewering Capacity:

- Low Capacity (Under 500 skewers/hour)

- Medium Capacity (500-2000 skewers/hour)

- High Capacity (Above 2000 skewers/hour)

- Distribution Channel:

- Direct Sales (Manufacturer to Processor)

- Distributors/Dealers

- Online Retail/E-commerce

- End-User:

- Industrial Food Processors

- Quick Service Restaurants (QSRs)

- Hotels, Restaurants, and Cafes (HoReCa)

- Catering Services

Value Chain Analysis For Skewer Machines Market

The value chain for the Skewer Machines Market begins with upstream activities involving raw material procurement, predominantly encompassing specialized stainless steel, industrial-grade plastics, and complex electronic components necessary for constructing durable and hygienic machinery. Suppliers of precision motors, sensors, and programmable logic controllers (PLCs) form a critical part of the upstream segment, dictating the quality and technological sophistication of the final product. Manufacturers then engage in design, assembly, and rigorous testing, focusing heavily on certifications related to food safety (e.g., FDA, CE compliance) and operational efficiency, thereby adding significant value through advanced engineering and proprietary software integration.

Midstream activities involve the distribution channel, which is highly specialized. Direct sales are common for high-capacity, custom industrial machinery, enabling personalized installation, training, and long-term maintenance contracts. Conversely, standard or semi-automatic models often flow through regional distributors and specialized equipment dealers who offer local support and faster deployment. The efficiency of the distribution network directly influences market penetration and the availability of prompt aftermarket service, which is crucial given the complexity of the machines and their importance in continuous food production lines.

Downstream, the value chain culminates with installation, end-user operation, and maintenance. Customer segments, primarily industrial food processors and large QSR chains, focus on maximizing machine uptime and return on investment. The value derived at this stage relies heavily on reliable servicing, supply of specialized spare parts, and ongoing software updates provided by manufacturers or authorized service partners. This after-sales support ecosystem is a critical competitive differentiator, ensuring sustained client satisfaction and loyalty within a high-stakes, operational environment.

Skewer Machines Market Potential Customers

The primary customer base for Skewer Machines is extensive and segmented by scale of operation and required output capacity, spanning from multinational food corporations to independent culinary entrepreneurs. Industrial food processors, including large meat and poultry packing houses and seafood processors, constitute the most significant segment, requiring fully automated, high-throughput systems capable of running twenty-four hours a day while adhering to the strictest hygiene protocols. These customers prioritize speed, consistency, and integration capabilities with existing processing lines, often necessitating customized machine configurations to handle specific product dimensions and textures.

A rapidly growing segment comprises Quick Service Restaurants (QSRs) and large-scale catering operations, which seek semi-automatic or medium-capacity automatic machines that balance automation benefits with operational flexibility. These end-users are primarily focused on maintaining product standardization across multiple outlets and reducing the high costs associated with manual labor in repetitive tasks. Furthermore, specialized food manufacturers focusing on ethnic or regional skewered products (e.g., yakitori, souvlaki) also represent key buyers, demanding machines that can replicate traditional preparation quality with industrial consistency.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 150 Million |

| Market Forecast in 2033 | USD 235 Million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Marel, NOCK Maschinenbau, K+G Wetter, Weber Maschinenbau, LIMA S.A.S., Food Technology, Jiangsu Jinsui, Jinan Saibainuo Technology, Lamex Food Group, Star Universal, Hencopac, Fomaco, MAJA-Maschinenfabrik, Promarks, VEMAG Maschinenbau, GEA Group, Handtmann, Risco S.p.A., Provisur Technologies, Metalbud NOWICKI |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Skewer Machines Market Key Technology Landscape

The technological landscape of the Skewer Machines Market is defined by a shift toward enhanced precision engineering and digital integration, primarily focused on improving efficiency, safety, and versatility. Core technologies revolve around sophisticated control systems, particularly the use of Programmable Logic Controllers (PLCs) and Human-Machine Interfaces (HMIs), which allow operators to precisely manage skewering parameters, ingredient sequencing, and cleaning cycles. Modern machines utilize servo motors and pneumatic actuators to achieve high-speed, repeatable movements necessary for high-volume production, ensuring minimal damage to delicate food products and maximum consistency in ingredient spacing and weight distribution.

A critical innovation is the integration of advanced sensor technology and vision systems. High-resolution cameras and optical sensors are increasingly used to gauge ingredient size and shape, allowing the machine's internal software to dynamically adjust the skewering process for irregularly shaped items. This level of adaptability significantly reduces raw material preparation time and decreases overall waste. Furthermore, food safety technologies, such as full stainless steel construction, quick-disassembly mechanisms for cleaning, and integrated Clean-in-Place (CIP) functionalities, are now standard features, responding to rigorous global health regulations and end-user demand for simplified sanitation protocols that prevent cross-contamination.

Looking forward, the adoption of Industry 4.0 principles is shaping the next generation of skewer machinery. This includes IoT connectivity for real-time performance monitoring, remote diagnostics, and data analytics that inform process optimization. Robotics, especially collaborative robots (cobots), are starting to be employed in the pre-loading stages, such as ingredient preparation and staging, working alongside human operators in a safe and flexible manner. This technological trajectory is aimed at creating fully autonomous production lines where human interaction is limited to supervision and maintenance, further driving efficiency improvements across the entire manufacturing pipeline.

Regional Highlights

The global demand for skewer machines demonstrates distinct patterns across major geographic regions, primarily influenced by local dietary preferences, the maturity of the food processing infrastructure, and prevailing labor costs. North America and Europe represent mature markets characterized by high labor costs and stringent regulatory requirements, driving demand predominantly for fully automated, high-end machines equipped with advanced sanitation features and IoT connectivity. In these regions, the focus is on maximizing efficiency and quality control to maintain competitive advantages in a highly capitalized food service sector. The high penetration of large QSR chains and industrial meat processors dictates a sustained requirement for replacement and upgrade cycles of existing machinery, keeping market growth stable and focused on technological refinement rather than sheer volume expansion.

Asia Pacific (APAC) is projected to be the engine of market growth throughout the forecast period. This acceleration is attributed to rapid urbanization, increasing disposable incomes, and the modernization of food manufacturing facilities, particularly in populous countries such as China, India, and Southeast Asian nations where skewered foods are culinary staples. The APAC market shows immense demand for both medium-capacity, semi-automatic machines catering to local businesses and high-capacity automatic systems for massive export-oriented processing plants. Government initiatives supporting the automation of the food industry to ensure hygiene and efficiency further bolster market penetration across this diverse region.

Latin America and the Middle East & Africa (MEA) are emerging markets experiencing nascent growth. Labor costs are generally lower in these regions, making the transition to full automation slower; however, the rising awareness of food safety standards and the increasing establishment of international fast-food franchises are beginning to drive the adoption of entry-level and semi-automatic skewer machines. In the MEA region, the significant trade in meat products and the cultural relevance of kebabs and similar dishes provide a solid foundation for future market expansion, contingent upon local infrastructure investment and stable economic conditions.

- Asia Pacific (APAC): Highest growth trajectory driven by rapid industrialization, large population base consuming skewered foods, and strong government push for food processing modernization in countries like China and India.

- North America: Market stability maintained by high automation necessity, stringent food safety standards, and continuous demand for high-capacity, technologically advanced machinery in commercial food production.

- Europe: Focus on premium, customized, and highly efficient machines complying with complex European Union (EU) health and safety directives, particularly strong demand in poultry and vegetable processing segments.

- Latin America: Developing market with potential driven by expansion of international food chains and need for improved efficiency in local meatpacking operations.

- Middle East and Africa (MEA): Emerging demand fueled by increasing tourism, rising consumer wealth, and high consumption of traditional skewered meat dishes, creating opportunities for mid-range automation solutions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Skewer Machines Market.- Marel

- NOCK Maschinenbau GmbH

- K+G Wetter GmbH

- Weber Maschinenbau GmbH

- LIMA S.A.S.

- Food Technology Co., Ltd.

- Jiangsu Jinsui Machinery Manufacturing Co., Ltd.

- Jinan Saibainuo Technology Development Co., Ltd.

- Lamex Food Group Limited

- Star Universal Co., Ltd.

- Hencopac A/S

- Fomaco A/S

- MAJA-Maschinenfabrik Hermann Schill GmbH & Co. KG

- Promarks, Inc.

- VEMAG Maschinenbau GmbH

- GEA Group Aktiengesellschaft

- Handtmann A-Punkt Automation GmbH

- Risco S.p.A.

- Provisur Technologies, Inc.

- Metalbud NOWICKI Sp. z o.o.

Frequently Asked Questions

Analyze common user questions about the Skewer Machines market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the projected Compound Annual Growth Rate (CAGR) for the Skewer Machines Market?

The Skewer Machines Market is anticipated to grow at a CAGR of 6.8% between 2026 and 2033, driven primarily by global food automation trends and expanding QSR infrastructure.

Which operational mode dominates the Skewer Machines Market and why?

Automatic Skewer Machines hold the dominant market share due to their superior throughput capacity, high level of consistency, and ability to drastically reduce labor reliance in large-scale industrial food processing environments.

What is the primary constraint limiting the adoption of advanced skewer machinery?

The high initial capital investment required for fully automated and high-capacity skewer machines often acts as the primary restraint, particularly impacting small and medium-sized enterprises (SMEs) seeking to modernize.

How is AI impacting quality control within skewer machine operations?

AI is integrated through advanced vision systems and machine learning to perform real-time, high-precision quality checks, identifying misplaced ingredients or structural defects far more accurately and quickly than manual inspection, thus ensuring superior product standardization.

Which geographical region is expected to demonstrate the fastest growth in the Skewer Machines Market?

The Asia Pacific (APAC) region is forecasted to exhibit the fastest growth, propelled by significant infrastructure investment, rising consumer demand for convenient foods, and the necessity to automate traditional, labor-intensive food preparation methods.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager