Skin Protective Equipment Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 433382 | Date : Dec, 2025 | Pages : 245 | Region : Global | Publisher : MRU

Skin Protective Equipment Market Size

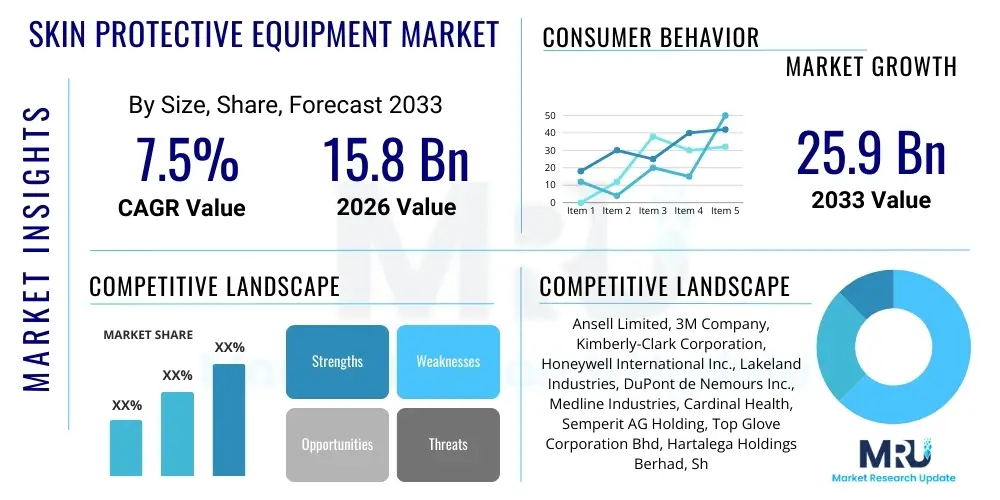

The Skin Protective Equipment Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.5% between 2026 and 2033. The market is estimated at USD 15.8 Billion in 2026 and is projected to reach USD 25.9 Billion by the end of the forecast period in 2033.

Skin Protective Equipment Market introduction

The Skin Protective Equipment (SPE) market encompasses a wide range of products designed to safeguard the dermal layer of workers against environmental, chemical, mechanical, biological, and thermal hazards encountered across various industrial and occupational settings. This critical segment of the Personal Protective Equipment (PPE) industry includes items such as protective gloves, specialized skin creams, lotions, barrier films, and protective clothing designed specifically to cover and shield the skin. The fundamental objective of SPE is to prevent occupational dermatitis, chemical burns, infections, and chronic skin diseases that arise from prolonged exposure to harmful substances or conditions, thereby ensuring worker health and safety compliance.

Major applications of SPE are prevalent in high-risk sectors including chemical manufacturing, healthcare and pharmaceuticals, oil and gas exploration, construction, and heavy manufacturing. In chemical handling, barrier gloves and specialized anti-solvent creams are indispensable, while in the healthcare sector, sterile surgical gloves and examination gloves are essential for preventing cross-contamination and protecting staff from biological hazards. The growing awareness regarding the long-term consequences of occupational exposure, coupled with stringent government mandates concerning workplace safety, significantly drives the demand for high-quality, specialized skin protective solutions that offer superior protection without compromising dexterity or comfort.

Key benefits derived from the widespread adoption of robust SPE include reduced incidence of workplace injuries, lower absenteeism rates, improved productivity, and adherence to global safety standards set by bodies like OSHA and the European Agency for Safety and Health at Work (EU-OSHA). Furthermore, advancements in material science, leading to the development of highly impermeable, ergonomic, and hypoallergenic materials, are continuously expanding the functional efficacy and adoption rate of skin protective gear across emerging economies undergoing rapid industrialization.

Skin Protective Equipment Market Executive Summary

The Skin Protective Equipment market is experiencing robust growth fueled by intensifying regulatory oversight concerning worker safety and a surge in industrial activities across developing nations. Current business trends indicate a strong shift towards advanced, multi-hazard protection solutions, including smart gloves equipped with sensor technology and dermatologically tested protective creams that offer superior barrier functions. The increasing focus on disposable skin protective products, particularly in the healthcare and food processing industries post-pandemic, continues to dominate the revenue landscape, although the durable segment is gaining traction due to demands for cost-effective, long-life protective apparel in heavy industry settings. Strategic mergers and acquisitions aimed at consolidating market share and enhancing specialized product portfolios are defining the competitive landscape.

Regionally, the Asia Pacific (APAC) stands out as the fastest-growing market, primarily driven by rapid industrial expansion in countries like China, India, and Southeast Asian nations, coupled with increasing government emphasis on implementing standardized safety protocols in manufacturing and construction sectors. North America and Europe, while mature markets, maintain significant market share due to the strict enforcement of occupational health and safety laws and the high adoption rate of premium, technologically advanced protective gear. These established regions focus heavily on innovation, particularly in sustainable and environmentally friendly protective equipment materials.

Segment trends highlight the dominance of the protective gloves category, which is essential for hand protection against chemical and mechanical risks, followed closely by protective clothing and specialized dermatological protection products like skin cleaners and moisturizers, which address post-exposure contamination and skin health maintenance. The end-user analysis shows that the healthcare and manufacturing industries are the primary consumers, but the demand from the chemical and oil & gas sectors for high-resistance, chemical-impermeable SPE remains a critical driver for market value expansion. Sustainability and material innovation, such as the use of nitrile and biodegradable polymers, are core themes shaping future segment dynamics.

AI Impact Analysis on Skin Protective Equipment Market

Common user inquiries regarding the impact of Artificial Intelligence (AI) on the Skin Protective Equipment market center on several crucial themes: how AI can enhance predictive maintenance of PPE integrity, optimize inventory and supply chain resilience for highly demanded protective gear, and whether AI-driven analytics can personalize safety recommendations based on individual worker exposure levels. Users are keen to understand if AI tools, integrated with wearable technology, can detect material degradation in gloves or protective apparel before failure occurs, moving safety management from reactive compliance to proactive risk mitigation. The underlying concern often relates to data privacy when monitoring worker exposure and the cost-effectiveness of implementing complex AI infrastructures in traditional industrial settings.

The consensus of user expectations suggests that AI will revolutionize the SPE supply chain by predicting demand fluctuations, particularly for single-use items, mitigating the severe shortages experienced during global health crises. Furthermore, AI analytics applied to incident reports and exposure data will allow safety managers to tailor the choice of SPE—for instance, recommending specific barrier creams or glove types based on precise chemical mixtures handled or ambient environmental factors. This level of precision safety management, facilitated by machine learning algorithms processing real-time environmental and usage data, promises substantial reductions in occupational skin injuries.

Ultimately, the impact of AI is viewed as transformative, shifting the SPE market focus from simply manufacturing compliant products to delivering intelligent, customized protective solutions. While implementation faces hurdles related to sensor integration, data governance, and standardization of data inputs from diverse industrial environments, AI is expected to become indispensable for complex risk assessment, ensuring the right protection is available at the right time and maintained optimally throughout its service life, thus maximizing worker safety and operational efficiency.

- AI-driven predictive analytics optimize SPE replacement schedules by assessing material stress and degradation in real-time.

- Machine learning algorithms enhance inventory management and forecasting accuracy for highly consumable skin protection products, preventing supply chain disruptions.

- AI integrates with smart wearable SPE (e.g., sensor-embedded gloves) to monitor worker exposure levels to specific toxins or UV radiation.

- Natural Language Processing (NLP) tools analyze global safety regulations and incident reports to rapidly update SPE design and usage guidelines for improved compliance.

- Robotics and AI-vision systems ensure quality control and defect detection during the high-volume manufacturing of protective gloves and clothing.

DRO & Impact Forces Of Skin Protective Equipment Market

The Skin Protective Equipment market is fundamentally driven by stringent occupational safety regulations globally, particularly in industrialized nations where non-compliance results in severe financial penalties and legal repercussions. The increasing incidence of occupational dermatitis and chronic skin conditions, especially in sectors dealing with hazardous chemicals or prolonged wet work (e.g., food processing, cleaning services), acts as a primary catalyst for market expansion. Key restraints include the high cost associated with advanced, specialized SPE materials (such as high-performance nitrile or anti-cut fabrics) and the persistent challenge of user non-compliance, often stemming from discomfort, poor fit, or reduced dexterity offered by protective gear.

Significant opportunities arise from the rapid technological evolution of protective materials, including the incorporation of nanotechnology for enhanced barrier properties and the development of sustainable, biodegradable SPE solutions catering to the growing environmental consciousness of large corporations. Furthermore, the expansion of the market into emerging applications, such as specialized protective gear for photovoltaic panel installation and electric vehicle manufacturing (which involves unique chemical exposures), presents lucrative avenues for manufacturers specializing in advanced protective films and coatings. The rise of sophisticated dermatological barrier creams and post-exposure skin care products also represents an untapped segment focusing on holistic skin health management in the workplace.

The major impact forces governing the market trajectory are twofold: regulatory pressure and technological disruption. Regulatory bodies continually update standards, requiring manufacturers to innovate and certify products against increasingly rigorous criteria for chemical permeation, tear resistance, and comfort. Technologically, the shift towards connected and smart PPE—integrating IoT sensors to track usage and exposure—is changing procurement decisions, favoring providers who offer integrated safety management systems rather than just standalone products. Economic volatility, particularly affecting the cost of crude oil derivatives (key components in synthetic rubber and plastics used for gloves), also exerts a direct impact on raw material pricing and overall market stability.

Segmentation Analysis

The Skin Protective Equipment market is comprehensively segmented based on product type, material composition, hazard application, and the specific end-use industry, reflecting the diverse requirements for dermal protection across global occupational environments. This structured analysis allows manufacturers to target niche safety requirements, such as specialized protection against carcinogenic dust in construction or highly corrosive substances in laboratories. The segmentation by product reveals the dominant share held by protective gloves, essential for preventing direct contact injuries, while segmentation by material underscores the transition towards synthetic, high-performance polymers like nitrile and neoprene due to concerns over latex allergies and superior chemical resistance.

- Product Type:

- Protective Gloves (Disposable, Durable)

- Protective Clothing (Aprons, Sleeves, Coveralls specific to skin protection)

- Dermatological Skin Care Products (Barrier Creams, Hand Sanitizers, Cleansers, Moisturizers)

- Foot Protection (Specific boots/coverings for fluid/chemical splash protection)

- Material Type:

- Natural Rubber Latex

- Nitrile

- Neoprene

- Vinyl (PVC)

- Polyethylene (PE)

- Specialty Fabrics (e.g., Tyvek, GORE-TEX, Chemical-resistant laminates)

- Hazard Application:

- Chemical Protection

- Mechanical Protection (Abrasions, Cuts)

- Biological Protection (Infectious agents, Pathogens)

- Thermal Protection (Heat/Cold contact)

- UV/Radiation Protection

- End-Use Industry:

- Manufacturing (Automotive, Machinery)

- Healthcare and Pharmaceuticals

- Chemical and Material Processing

- Oil and Gas

- Construction

- Food Processing

- Mining

Value Chain Analysis For Skin Protective Equipment Market

The value chain for the Skin Protective Equipment market begins with the upstream procurement and processing of specialized raw materials, primarily focusing on synthetic polymers like nitrile butadiene rubber (NBR), neoprene, and various plastic resins such as PVC and polyethylene, alongside specialized fabrics for protective apparel. The efficiency and reliability of these upstream suppliers are critical, as fluctuating commodity prices and the need for medical-grade purity significantly impact manufacturing costs and product quality. Manufacturers invest heavily in R&D to enhance barrier technology and incorporate antimicrobial or flame-resistant properties into these base materials, ensuring compliance with diverse international safety standards and maximizing the protective lifespan of the equipment.

The midstream stage involves the core manufacturing processes, which are increasingly automated and specialized. For gloves, this includes dipping, curing, and chlorination processes, demanding high capital investment in state-of-the-art machinery capable of maintaining sterility and uniform thickness. For protective clothing and barrier creams, manufacturing focuses on formulation precision, weaving, lamination, and quality assurance testing (e.g., permeation testing against a standardized panel of chemicals). Effective quality control at this stage is paramount, as failure in skin protective gear can lead to severe occupational health issues and liability for the producer.

Downstream analysis highlights complex distribution channels serving disparate end-user industries. Distribution relies heavily on specialized industrial safety distributors and regional PPE wholesalers who maintain large inventories and provide essential technical support regarding product selection and proper usage protocols. Direct distribution is common for high-volume, institutional buyers like major hospital chains or large petrochemical companies seeking custom-engineered solutions. Indirect channels, including safety equipment retailers and growing e-commerce platforms specializing in industrial supplies, cater effectively to small and medium enterprises (SMEs), emphasizing convenience, breadth of product offering, and immediate availability. The final stage involves the end-user training and responsible disposal of hazardous waste SPE, particularly crucial for biologically or chemically contaminated items.

Skin Protective Equipment Market Potential Customers

Potential customers for Skin Protective Equipment span virtually all industries where workers encounter hazards that can compromise skin integrity, ranging from physical abrasions and cuts to severe chemical or biological contamination. The largest purchasing segments are systematically found within highly regulated environments such as healthcare and pharmaceuticals, where stringent hygiene and contamination control mandates necessitate the constant use of disposable gloves, gowns, and specialized skin barrier products to protect both patients and personnel from infectious agents and cytotoxic drugs. Manufacturing, encompassing automotive, aerospace, and general industrial assembly, represents another major customer base, primarily requiring protection against solvents, lubricants, heavy metals, and mechanical hazards.

The chemical and petrochemical industries constitute a premium customer segment, demanding highly specialized, often multi-layered protective equipment capable of resisting specific corrosive acids, bases, and organic solvents. These buyers prioritize technical specifications, permeation breakthrough time, and certified compliance (e.g., EN 374 standards) over cost, leading to lucrative contracts for high-performance SPE manufacturers. Furthermore, the food processing sector, encompassing meatpacking, dairy, and beverage production, is a rapidly expanding customer base driven by the need for waterproof and chemical-resistant SPE to prevent contamination risks and protect workers from extended exposure to water, detergents, and sanitizers during extensive cleaning cycles.

Emerging potential customers include the renewable energy sector, specifically those involved in battery manufacturing and solar panel fabrication, which involve handling novel, sometimes volatile chemicals and materials requiring tailored skin protection solutions. Construction and mining, while traditional users of PPE, are increasing their demand for dermatological products (creams, cleansers) to manage exposure to cement dust, UV radiation, and skin dryness associated with harsh working conditions. These sectors represent a growing opportunity for holistic skin health management product offerings designed to complement traditional protective apparel.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 15.8 Billion |

| Market Forecast in 2033 | USD 25.9 Billion |

| Growth Rate | 7.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Ansell Limited, 3M Company, Kimberly-Clark Corporation, Honeywell International Inc., Lakeland Industries, DuPont de Nemours Inc., Medline Industries, Cardinal Health, Semperit AG Holding, Top Glove Corporation Bhd, Hartalega Holdings Berhad, Showa Group, Supermax Corporation Berhad, Kossan Rubber Industries Bhd, MSA Safety Inc., Uvex Group, Dynarex Corporation, Superior Glove Works Ltd., Radians Inc., Riverstone Holdings Limited. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Skin Protective Equipment Market Key Technology Landscape

The technological landscape of the Skin Protective Equipment market is characterized by significant innovation aimed at improving barrier integrity, enhancing user comfort, and ensuring sustainability. A primary focus is on advanced polymer science, specifically the development of thin-gauge, high-performance nitrile formulations that offer superior puncture and chemical resistance while maintaining tactile sensitivity, a critical requirement in precision-based industries like surgery and electronics assembly. Nanotechnology is emerging as a critical differentiator, allowing manufacturers to embed nanoparticles into fabric or polymer matrices to create enhanced chemical barriers or self-cleaning surfaces, significantly extending the effective protection life of the equipment.

Another crucial technological advancement involves the integration of smart textiles and Internet of Things (IoT) capabilities into protective clothing and gloves. This includes the development of sensor-embedded gear that monitors physical parameters such as temperature, humidity, chemical saturation, and UV exposure. These smart SPE solutions can provide real-time alerts to the worker and safety management system if the protective barrier is compromised or if exposure limits are exceeded. Such technological integration shifts the utility of SPE from passive barrier protection to active, data-driven safety management tools, necessitating expertise in microelectronics and data analytics alongside traditional textile engineering.

Furthermore, sustainability-driven innovations are reshaping material choices. There is growing research into developing high-quality, protective materials derived from bio-based or biodegradable polymers to address the massive waste generation associated with disposable SPE, particularly gloves and medical apparel. Manufacturers are also implementing advanced manufacturing techniques, such as precision additive manufacturing (3D printing) for specialized fittings and rapid prototyping of ergonomic designs, which ensure better fit and consequently higher rates of user compliance and superior protection. Permeation testing methods are also becoming more sophisticated, incorporating artificial skin models to accurately simulate real-world exposure scenarios.

Regional Highlights

- North America: This region holds a substantial market share, driven primarily by highly stringent regulatory environments enforced by OSHA and the CDC, which mandate the use of high-quality, certified SPE across healthcare, manufacturing, and construction sectors. The U.S. and Canada are early adopters of innovative, premium protective gear, including smart PPE and specialized barrier creams. High labor costs necessitate investments in reducing workplace injuries, positioning safety and injury prevention as a major operational priority.

- Europe: The European market is characterized by robust regulatory harmonization through EU directives, demanding CE marking and adherence to rigorous standards (e.g., EN 374, EN 407). Growth is steady, focused heavily on sustainability, leading to strong demand for environmentally friendly and recyclable protective materials. Germany, France, and the UK are key markets, with particular strength in chemical resistance and high-end thermal protection required by their sophisticated manufacturing and chemical industries.

- Asia Pacific (APAC): APAC is projected to exhibit the highest Compound Annual Growth Rate (CAGR) due to rapid industrialization, massive infrastructure development, and increasing foreign investment in manufacturing facilities across China, India, and Southeast Asia. While regulatory enforcement historically lagged behind, governments are increasingly adopting and enforcing international safety standards, dramatically boosting the demand for basic and intermediate-level SPE, especially disposable gloves for industrial and healthcare applications.

- Latin America (LATAM): The market in LATAM is driven by growth in the oil and gas sector, mining operations, and burgeoning manufacturing industries, particularly in Brazil and Mexico. Market growth is often volatile, influenced by economic conditions and varying degrees of enforcement of occupational safety laws. There is a strong preference for cost-effective, durable equipment, though regulatory convergence is slowly pushing adoption towards higher-grade international standards.

- Middle East and Africa (MEA): Growth in MEA is primarily concentrated in the Gulf Cooperation Council (GCC) countries, fueled by massive projects in the oil and gas, construction, and petrochemical sectors. Demand focuses on SPE suitable for extreme thermal conditions and specialized chemical exposure. Africa remains a nascent market, heavily dependent on imported goods, with adoption concentrated around major industrial hubs and international aid initiatives.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Skin Protective Equipment Market.- Ansell Limited

- 3M Company

- Kimberly-Clark Corporation

- Honeywell International Inc.

- DuPont de Nemours Inc.

- Lakeland Industries

- Medline Industries

- Cardinal Health

- Semperit AG Holding

- Top Glove Corporation Bhd

- Hartalega Holdings Berhad

- Showa Group

- Supermax Corporation Berhad

- Kossan Rubber Industries Bhd

- MSA Safety Inc.

- Uvex Group

- Dynarex Corporation

- Superior Glove Works Ltd.

- Radians Inc.

- Riverstone Holdings Limited

Frequently Asked Questions

Analyze common user questions about the Skin Protective Equipment market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary factors driving the growth of the Skin Protective Equipment Market?

Market growth is primarily driven by rigorous enforcement of occupational health and safety regulations worldwide, increasing industrial activity, and heightened awareness regarding the prevention of chronic occupational skin diseases like dermatitis and chemical burns.

How is sustainability impacting the selection and manufacturing of protective gloves?

Sustainability mandates are pushing manufacturers to invest in biodegradable polymers and bio-based materials (e.g., greener nitrile alternatives) to reduce the environmental footprint associated with the vast consumption of single-use disposable protective gloves across all industries.

Which end-use industry holds the largest market share for Skin Protective Equipment?

The healthcare and pharmaceutical sectors collectively hold the largest market share, driven by high-volume usage of disposable protective gloves and specialized surgical apparel critical for infection control and barrier protection against biological hazards and cytotoxic substances.

What role does smart technology play in the future of skin protective equipment?

Smart technology, including integrated IoT sensors, allows SPE to become proactive by monitoring material integrity, tracking worker exposure to harmful agents in real-time, and providing immediate alerts to both the wearer and safety management systems regarding potential breach or over-exposure.

What is the main challenge faced by manufacturers in the Skin Protective Equipment Market?

A significant challenge is ensuring high rates of user compliance; discomfort, reduced dexterity, poor fit, and high costs associated with premium, specialized materials often lead workers to avoid consistent or proper use of necessary skin protective gear, undermining safety objectives.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager