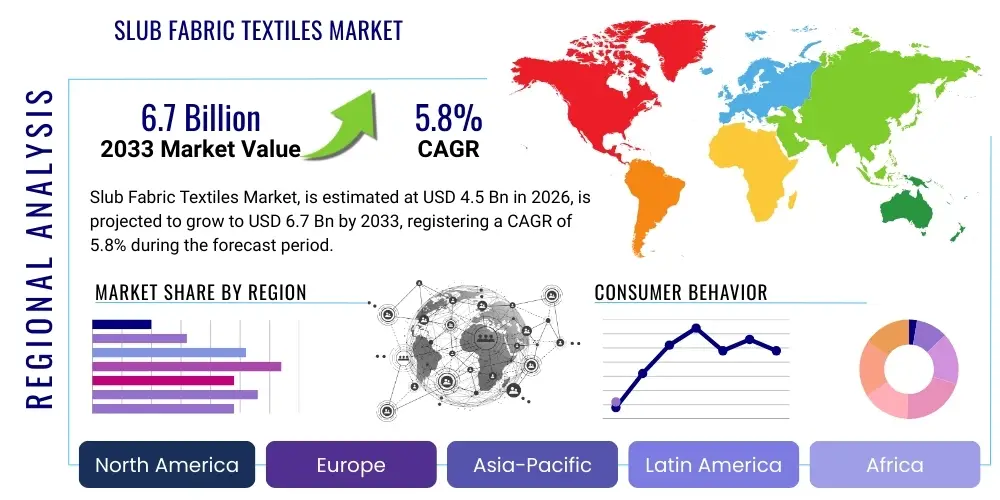

Slub Fabric Textiles Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 437331 | Date : Dec, 2025 | Pages : 255 | Region : Global | Publisher : MRU

Slub Fabric Textiles Market Size

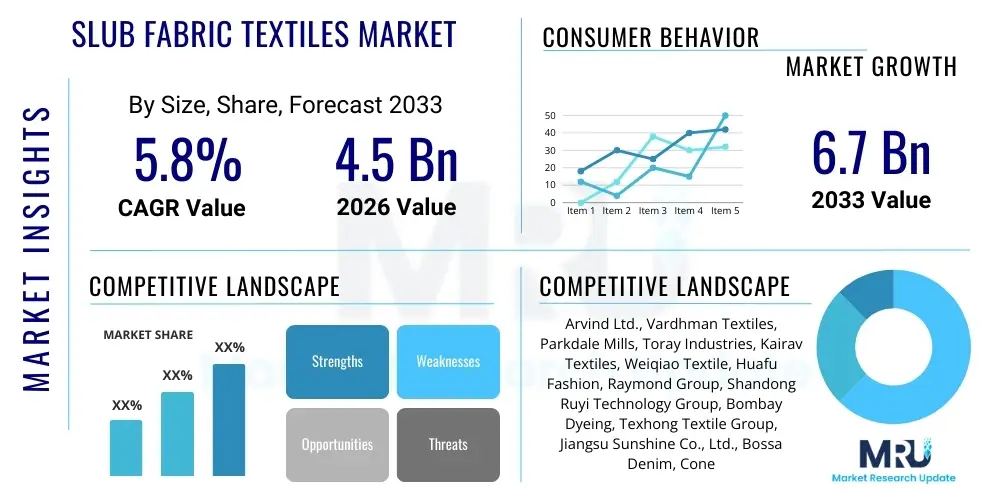

The Slub Fabric Textiles Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 4.5 Billion in 2026 and is projected to reach USD 6.7 Billion by the end of the forecast period in 2033.

Slub Fabric Textiles Market introduction

Slub fabric textiles are characterized by their intentional irregularities in yarn thickness, creating a texture featuring thicker, softer sections (slubs) alternating with finer, taut sections. This aesthetic quality provides garments and home furnishings with a desirable vintage, natural, or artisanal look, differentiating them significantly from uniformly woven materials. Historically associated primarily with cotton, slub effects are now successfully engineered using synthetic and blended fibers, expanding their application range and performance characteristics, such as moisture-wicking and wrinkle resistance. The primary application sectors include apparel, specifically casual wear, denim, and t-shirts, alongside home textiles like drapery, upholstery, and bedding, where the textured appearance adds depth and sophistication.

The global demand for slub textiles is heavily influenced by persistent consumer preferences for comfort, natural aesthetics, and unique surface textures in clothing. Key driving factors include the revival of sustainable fashion, where the uneven, natural look of slub cotton aligns well with eco-friendly narratives, and continuous innovation in manufacturing processes that allow for greater control over slub formation and fiber blending. The versatility of slub textiles, enabling their use across diverse price points—from mass-market casual apparel to high-end designer collections—bolsters market stability and growth potential. Furthermore, advances in weaving and knitting machinery are making slub production more efficient and cost-effective, improving supply chain scalability to meet fluctuating fashion trends.

The inherent benefits of slub fabric, such as enhanced breathability, softness, and a visually interesting drape, contribute directly to its sustained market penetration. The textural variance helps mask slight imperfections and enhances the perceived quality and uniqueness of the final product. Technological integration, particularly in dyeing and finishing processes, is enabling vibrant colors and novel finishes on slub surfaces without compromising the characteristic texture. This focus on performance and aesthetics ensures that slub fabrics remain a crucial component in both fast fashion cycles and long-term sustainable collections, solidifying its position in the broader textile industry landscape.

Slub Fabric Textiles Market Executive Summary

The Slub Fabric Textiles Market is experiencing robust growth driven primarily by shifting consumer demographics favoring textured and comfortable clothing, coupled with technological advancements in yarn production. Business trends highlight a strong movement towards customization and small-batch production, enabled by flexible modern weaving technologies that can quickly adapt slub patterns to current fashion demands. Sustainability initiatives are critical, with major manufacturers investing heavily in organic cotton and recycled synthetic fibers to produce slub yarns, addressing the increasing pressure from regulatory bodies and eco-conscious consumers. Strategic partnerships between yarn producers and apparel brands are becoming more common, focusing on supply chain transparency and traceability, which are crucial competitive differentiators in the modern textile industry.

Regionally, Asia Pacific maintains its dominance, serving as both the largest production hub and a rapidly expanding consumption market, fueled by burgeoning domestic apparel industries in countries like India, China, and Vietnam. North America and Europe remain high-value markets, characterized by demand for premium, performance-enhanced slub fabrics, particularly in the denim and activewear segments. The emerging markets in Latin America and the Middle East are showing significant potential, driven by rising disposable incomes and the internalization of global fashion trends. Regulatory environments regarding chemical usage and waste disposal in these regions are increasingly influencing production methods and sourcing decisions for international textile corporations operating within them.

In terms of segmentation, the Cotton segment continues to hold the largest market share due to cotton’s intrinsic characteristics that complement the slub effect, offering superior softness and breathability. However, the Blended Fibers segment is registering the fastest growth, propelled by the need for enhanced functionality, such as stretch, durability, and better moisture management, particularly in performance apparel. Application analysis reveals that the Apparel sector, especially casual tops and t-shirts, accounts for the majority of revenue, though the Home Textiles segment is expanding rapidly, leveraging the aesthetic appeal of slub texture for premium decorative and functional items, indicating diversified end-user penetration.

AI Impact Analysis on Slub Fabric Textiles Market

User inquiries regarding AI's influence on the Slub Fabric Textiles Market frequently center on three primary themes: how AI can optimize the inherent irregularity of slub yarn, its role in predicting volatile fashion trends, and its application in enhancing sustainability and supply chain efficiency. Users are particularly interested in whether machine learning algorithms can achieve 'controlled randomness,' optimizing the slub ratio for desired aesthetic outcomes while minimizing material waste. There are significant concerns about ensuring consistency across large production batches while maintaining the handmade feel that defines slub fabric. Expectations are high concerning predictive analytics, anticipating that AI can forecast the cyclical return of certain textures and colors, allowing manufacturers to reduce lead times and inventory risks associated with fashion seasonality.

The application of Artificial Intelligence is beginning to revolutionize the textile design and manufacturing phases of slub fabric production. AI systems are currently being deployed to analyze vast datasets relating to consumer preferences, social media trends, and historical sales patterns to generate highly accurate predictions regarding desired slub density, length, and fiber composition. This data-driven design process minimizes the reliance on subjective human judgment, leading to more commercially viable textile products. Furthermore, in the spinning stage, AI-powered quality control systems utilize computer vision and sensor technology to monitor yarn tension and feeding speed in real-time, allowing for precise adjustments to the slub formation mechanisms. This control enables manufacturers to produce bespoke slub effects with unprecedented repeatability, addressing the core challenge of balancing unique texture with mass production consistency.

The impact of AI extends significantly into supply chain management and sustainable sourcing within the slub fabric domain. Machine learning models optimize logistics, predict raw material price fluctuations, and identify the most sustainable suppliers of cotton and synthetic fibers. By integrating AI into inventory management, companies can accurately determine the optimal amount of textured fabric needed for seasonal collections, dramatically reducing overproduction and subsequent textile waste. Moreover, AI-driven sorting and blending of recycled fibers allow for the creation of new slub yarns with specified aesthetic outcomes from heterogeneous waste streams, directly furthering circular economy objectives within the uniquely textured textile sector.

- AI-driven Predictive Trend Analysis: Forecasting specific slub densities and color palettes to optimize design cycles and inventory levels.

- Enhanced Production Precision: Real-time monitoring of spinning equipment using computer vision for consistent, customized slub formation, improving yield and reducing defects.

- Sustainable Sourcing Optimization: Machine learning algorithms identify and verify ethical and organic raw material sources for slub cotton and blended alternatives.

- Supply Chain Efficiency: Automated demand forecasting reduces overstocking of textured materials and optimizes transportation logistics.

- Automated Quality Control: AI sensors detect subtle variations in fabric texture and composition instantly, ensuring adherence to strict aesthetic and functional specifications.

DRO & Impact Forces Of Slub Fabric Textiles Market

The Slub Fabric Textiles Market is dynamically influenced by a blend of strong drivers rooted in consumer demand and aesthetic preference, coupled with significant restraints related to manufacturing complexity and raw material volatility. The core driver is the persistent consumer desire for unique, comfortable, and visually textured textiles, particularly in the casual and sustainable apparel segments. However, the complexity inherent in manufacturing slub yarn, which requires specialized machinery and precise technical control to achieve desired irregularities consistently, acts as a primary restraint, leading to higher production costs compared to conventional smooth fabrics. Opportunities emerge from material science innovation, focusing on developing sustainable slub fibers and enhanced performance blends that offer wrinkle resistance or improved stretch, expanding the fabric’s utility beyond traditional casual wear. These forces collectively shape the competitive landscape and strategic investment decisions across the value chain.

Impact forces acting upon the market are largely centered around regulatory pressures and socioeconomic shifts. Environmental regulations increasingly impact the dyeing and finishing processes required for slub textiles, pushing manufacturers toward less toxic and water-intensive methods. The rising cost of high-quality raw materials, particularly long-staple cotton preferred for fine slub effects, poses a perpetual cost challenge. The market resilience is often tested by the rapid shifts in fashion trends; while slub is generally considered a timeless texture, specific application preferences can vary widely year-to-year, necessitating flexible and responsive manufacturing capabilities. Furthermore, the increasing prominence of digital retail platforms serves as a key accelerating force, allowing unique, textured products like slub textiles to be marketed globally to niche consumer segments who value craftsmanship and distinctive appearance.

A crucial factor determining market penetration is the ability of manufacturers to leverage advanced knitting and weaving technologies that can simulate slub effects using less expensive or recycled inputs without sacrificing aesthetic quality. This capability mitigates the restraint of high raw material costs and production complexity. The major opportunities lie in the expansion into non-apparel applications, such as high-end automotive interiors and specialized industrial textiles, where the texture and durability of engineered slub blends offer distinct advantages. Navigating the balance between maintaining the artisanal appeal of slub and achieving the efficiencies of mass production remains the paramount strategic challenge for market participants throughout the forecast period.

Segmentation Analysis

The Slub Fabric Textiles Market is segmented based on Material Type, Application, and Manufacturing Process, providing a detailed framework for understanding market dynamics and growth potential across various product categories. The segmentation by Material Type, including Cotton, Synthetic, and Blended Fibers, is fundamental as the material choice dictates the texture quality, performance features (e.g., stretch, durability), and sustainability profile of the final fabric. Application segmentation, spanning Apparel, Home Textiles, and Industrial Use, defines the primary demand drivers and end-user requirements, with Apparel typically dominating revenue due to high volume consumption in casual wear.

- By Material Type:

- Cotton Slub Fabric

- Synthetic Slub Fabric (Polyester, Rayon, Nylon)

- Blended Slub Fabric (Cotton-Poly, Cotton-Lycra)

- By Application:

- Apparel (T-shirts, Casual Tops, Denim, Dresses)

- Home Textiles (Bedding, Upholstery, Drapery)

- Industrial and Technical Textiles

- By Manufacturing Process:

- Weaving

- Knitting

Value Chain Analysis For Slub Fabric Textiles Market

The value chain for the Slub Fabric Textiles Market begins with the upstream procurement of raw materials, predominantly cotton, synthetic filaments, and specialty fibers. This stage is crucial as the quality and type of fiber directly determine the slub quality and resulting fabric properties. Raw material suppliers, particularly those providing certified organic or recycled fibers, command significant leverage due to the industry’s focus on sustainability. The middle stage involves specialized spinning and texturing processes, where sophisticated machinery introduces the characteristic slubs into the yarn. This is followed by weaving or knitting, and then critical finishing processes such as dyeing and mercerization, which prepare the fabric for final use. Efficient coordination between specialized yarn spinners and textile manufacturers is essential here to maintain desired texture consistency.

The distribution network plays a pivotal role in connecting manufacturers to diverse end-user markets. Distribution channels are typically categorized into direct and indirect routes. Direct sales involve large integrated textile companies supplying fabric directly to major apparel brands or home furnishing manufacturers under long-term contracts, enabling better quality control and customized orders. Indirect channels utilize specialized fabric distributors, agents, and wholesalers who manage inventory and supply smaller-to-mid-sized manufacturers and garment factories, offering geographical reach and flexible order quantities. E-commerce platforms are increasingly serving as direct sales channels for B2B transactions, particularly for specialty and small-batch slub textiles, enhancing market transparency and reducing lead times.

The downstream segment of the value chain is dominated by garment manufacturers, cut-and-sew operations, and home textile producers who transform the slub fabric into final consumer products. Consumer demand, driven by fashion trends and seasonal cycles, dictates the pull across the entire chain. Brand equity, retail positioning, and marketing strategies heavily influence the perceived value and pricing of the final slub textile products. Success in the downstream market relies heavily on the ability to swiftly interpret fashion trends and integrate the unique aesthetic of slub fabric into contemporary designs, ensuring efficient turnover and minimal inventory obsolescence.

Slub Fabric Textiles Market Potential Customers

The primary customers for slub fabric textiles are enterprises engaged in the production of consumer goods where tactile texture and visual variance are key selling propositions. The largest end-user group comprises global apparel brands and private label manufacturers specializing in casual wear, including t-shirts, polo shirts, lightweight sweaters, and, critically, premium denim. These buyers prioritize high-quality cotton or cotton-blend slub fabric for its comfort, breathability, and natural drape, which conveys a sense of laid-back luxury or vintage authenticity. Customization requirements are high, often dictating specific slub length, spacing, and yarn counts to achieve distinct brand aesthetics.

A rapidly growing segment of potential customers is the home furnishings and interior design industry. Manufacturers of upholstered furniture, decorative pillows, drapery, and high-end bedding seek slub fabrics for their ability to add textural depth and organic richness to interiors. In this sector, performance properties such as durability, lightfastness, and resistance to pilling are crucial, driving demand for specialized blended slub fabrics that offer enhanced resilience without sacrificing the characteristic texture. Procurement in this segment often involves longer contract cycles and adherence to stricter technical standards regarding flame resistance and wear ratings.

Furthermore, niche markets such as high-end craft manufacturers and technical textile producers represent emerging opportunities. Craft buyers often source natural slub materials for handmade clothing and accessories, valuing transparency and ethical sourcing. Technical applications, though smaller in volume, leverage engineered slub textiles for specific uses where controlled irregularity can be beneficial, such as certain filtering materials or protective linings, where the unique structure aids in material permeability or surface adherence. These specialized customers require precise technical specifications and consistent material performance, demanding specialized production expertise from suppliers.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 4.5 Billion |

| Market Forecast in 2033 | USD 6.7 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Arvind Ltd., Vardhman Textiles, Parkdale Mills, Toray Industries, Kairav Textiles, Weiqiao Textile, Huafu Fashion, Raymond Group, Shandong Ruyi Technology Group, Bombay Dyeing, Texhong Textile Group, Jiangsu Sunshine Co., Ltd., Bossa Denim, Cone Mills, Mount Vernon Mills, Milliken & Company, Unifi, Inc., Premier Yarns, Indorama Ventures, Reliance Industries Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Slub Fabric Textiles Market Key Technology Landscape

The production of slub fabric relies on highly specialized textile machinery designed to introduce controlled irregularities during the spinning or weaving process. Key technological advancements center around electronic slub attachments (ESA) and sophisticated software control systems integrated into ring spinning frames or rotor spinning machines. These ESA systems utilize variable speed drives and computer-aided controls to periodically alter the drafting speed and feed rate of the yarn, precisely determining the thickness, length, and frequency of the slubs. Modern technology allows for the rapid creation of novel slub patterns and textures, moving far beyond the limitations of traditional mechanical slub attachments, enabling manufacturers to respond instantaneously to designer specifications and complex texture requirements with high accuracy.

Furthermore, innovations in weaving and knitting technology are critical for handling slub yarns effectively and ensuring fabric quality. High-speed air-jet and rapier weaving machines are engineered with optimized weft insertion systems to minimize yarn breakage, which is a common challenge when dealing with irregular slub yarns. In knitting, specialized circular and flat knitting machines are adapted to accommodate the varying thickness of the slub yarn without creating holes or uneven tension in the resultant knitted fabric. The continuous investment in these highly automated, specialized machines drives efficiency improvements, lowers labor costs, and expands the capacity for high-volume production of premium slub textiles, thereby mitigating the inherent complexity associated with these materials.

The integration of digital textile technologies, including advanced CAD/CAM systems, is transforming the design phase. Designers can now simulate the appearance and drape of slub fabrics under different fiber blends and slub parameters before physical production begins, drastically reducing sampling time and material waste. Moreover, advanced finishing technologies, such as plasma treatment and specialized softeners, are applied to enhance the tactile feel and performance attributes (like wrinkle resistance and moisture absorption) of the final slub textile, ensuring it meets the stringent quality standards demanded by high-end apparel and home textile markets while preserving the unique, textured surface characteristic of the slub effect.

Regional Highlights

The global Slub Fabric Textiles Market exhibits significant geographical variance in terms of production volume, consumption patterns, and technological adoption. These regional dynamics are shaped by local labor costs, environmental regulations, domestic consumer preferences, and the presence of integrated textile manufacturing ecosystems.

- Asia Pacific (APAC): APAC is the epicenter of global textile manufacturing and consumption, dominating the slub fabric market. Countries like China, India, Vietnam, and Pakistan possess vast spinning and weaving capacities, benefiting from lower operational costs and established supply chain infrastructure. India, in particular, is a major producer of cotton slub due to its strong domestic cotton cultivation and traditional textile heritage, catering heavily to the domestic market and global exports. Demand is driven by the region's massive and growing population and the burgeoning fast fashion industry, which increasingly favors textured casual wear. The focus here is on high-volume production and increasing automation to maintain competitiveness against rising labor costs.

- North America: North America represents a mature, high-value market characterized by a strong emphasis on premium branding, performance features, and sustainability. While manufacturing output is specialized, concentrating on high-tech textiles and niche denim production (e.g., American-made premium denim), the region is a massive net importer of finished slub fabrics. Consumer trends lean toward organic cotton slub, recycled materials, and functional slub blends used in athleisure and sustainable fashion lines. Retailers demand high traceability and ethical sourcing, influencing sourcing decisions globally and placing significant pressure on suppliers to adhere to stringent compliance standards.

- Europe: Europe is characterized by sophisticated consumer tastes and stringent environmental and quality regulations (such as REACH). The market is segmented between Western Europe, focusing on high-end design, innovative textiles, and niche luxury brands (particularly in Italy and France), and Eastern Europe, which serves as a significant production base for mass-market European apparel. Demand for slub textiles is high in the casual wear and decorative home textiles sectors, often favoring linens and high-quality cotton blends. Sustainability is a primary market differentiator, with European brands actively seeking certifications for eco-friendly slub yarn production processes.

- Latin America: This region shows steady growth, driven by a combination of domestic textile industries (notably Brazil and Mexico) and increasing foreign investment. The market is responsive to global fashion trends, with slub fabric finding strong penetration in the domestic denim and casual apparel segments. Economic stability and disposable income levels heavily influence market dynamics, leading to demand for cost-effective yet aesthetically pleasing slub cotton and polyester blends. Local manufacturers focus on optimizing production costs while gradually adopting modern spinning technologies to improve quality consistency.

- Middle East and Africa (MEA): The MEA region is segmented, with the Middle East focusing on luxury textiles and home furnishings imports, driven by high disposable incomes. Africa, particularly countries like Egypt and Turkey (often grouped geographically or historically in textile analysis), possesses significant textile manufacturing capacity. Turkey serves as a critical bridge between European supply chains and raw material sources, specializing in high-quality cotton processing and garment finishing, making it a key regional player in slub textile production and export to the EU. The African market is growing due to increased local garment production and urbanization.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Slub Fabric Textiles Market.- Arvind Ltd.

- Vardhman Textiles

- Parkdale Mills

- Toray Industries

- Kairav Textiles

- Weiqiao Textile

- Huafu Fashion

- Raymond Group

- Shandong Ruyi Technology Group

- Bombay Dyeing

- Texhong Textile Group

- Jiangsu Sunshine Co., Ltd.

- Bossa Denim

- Cone Mills

- Mount Vernon Mills

- Milliken & Company

- Unifi, Inc.

- Premier Yarns

- Indorama Ventures

- Reliance Industries Ltd.

Frequently Asked Questions

Analyze common user questions about the Slub Fabric Textiles market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is slub fabric and what are its primary characteristics?

Slub fabric is a textile characterized by intentional imperfections in the yarn, featuring sections that are thicker and softer (the slubs) alternating with thinner, tighter sections. This structural variation creates a unique, uneven, and textured surface appearance, often desired for its natural, vintage, or handmade aesthetic, particularly in cotton-based materials.

Which fiber materials are most commonly used to produce slub textiles?

Cotton is the dominant fiber used for slub textiles due to its inherent softness and ability to readily form textural variations. However, slub effects are also frequently integrated into synthetic fibers like polyester and rayon, and increasingly into blended fabrics (e.g., cotton-lycra) to introduce enhanced performance features such as stretch, durability, and better moisture management.

How do technological advancements influence the manufacturing process of slub fabric?

Modern manufacturing utilizes electronic slub attachments (ESA) and computer-aided controls in spinning machinery. These technologies allow for precise manipulation of yarn feed rates and tension, enabling manufacturers to produce highly consistent slub patterns in large volumes, moving beyond older, less reliable mechanical methods while still maintaining the desired artisanal texture.

What are the key drivers for market growth in the Slub Fabric Textiles sector?

Key drivers include strong and sustained consumer demand for comfortable, textured, and unique apparel, the prevailing trend towards sustainable and natural-looking textiles, and the increasing application of slub fabric in high-end home textiles like upholstery and bedding, expanding the market beyond traditional casual wear applications.

Which regions are leading in the production and consumption of slub fabric?

Asia Pacific (APAC), particularly China, India, and Vietnam, leads globally in both the production volume and overall consumption of slub fabric, driven by expansive manufacturing capacities and robust domestic apparel markets. North America and Europe remain key high-value consumption markets, focusing on premium and performance-oriented slub products.

What role does sustainability play in the current Slub Fabric Textiles Market?

Sustainability is a crucial factor, influencing material sourcing and manufacturing decisions. Consumers and brands increasingly prefer slub textiles made from organic cotton, recycled fibers, and eco-friendly blends. This demand drives manufacturers to invest in certified sustainable raw materials and adopt water-saving and non-toxic dyeing processes to meet global environmental compliance standards and consumer ethics.

In which application segment does slub fabric generate the highest revenue?

The Apparel application segment generates the highest revenue for slub fabric textiles. This is primarily due to the high volume consumption in everyday casual wear categories, including t-shirts, polo shirts, lightweight knitwear, and premium denim, where the fabric's unique texture and comfort properties are highly valued by mass-market and designer brands alike.

Are slub fabrics more expensive to produce than standard fabrics?

Generally, yes. Slub fabric production requires specialized spinning machinery (electronic slub attachments), meticulous quality control to ensure consistency in the irregularity, and often involves higher quality, longer-staple cotton fibers to manage the varying thicknesses. These factors, combined with potentially higher rates of yarn breakage during weaving, contribute to a higher overall production cost compared to uniformly spun and woven standard textiles.

How does the slub effect contribute to the aesthetic value of denim?

In denim production, the slub effect is paramount as it contributes significantly to the fabric's vintage and authentic appearance. The uneven threads create natural, high-low contrasts in the indigo dye, resulting in unique fading patterns (e.g., vertical streaking) as the denim wears, which is highly desirable in the premium raw denim market and enhances the perceived durability and character of the garment.

What challenges do manufacturers face in integrating slub yarns into knitted products?

Integrating slub yarns into knitted fabrics presents challenges related to maintaining even loop formation and preventing needle damage or yarn breakages. The varying thickness of the slub threads can lead to uneven tension or stress points in the knitting machine. Manufacturers must use highly specialized knitting equipment and precise tension control systems to successfully produce consistent, high-quality slub knitwear without structural defects.

How is AI being used to optimize slub fabric design and production?

AI is utilized to analyze fashion trends and consumer data to predict the optimal slub density and length for upcoming seasons. In production, AI-powered computer vision systems monitor the spinning process in real-time, allowing for micro-adjustments to the electronic slub attachments, ensuring the precise repeatability and quality control necessary for mass-producing custom-designed textured yarns.

What is the role of the Value Chain’s downstream segment in the Slub Fabric Market?

The downstream segment, comprising garment manufacturers and apparel brands, is responsible for transforming the slub fabric into final consumer products. Their role includes design integration, cutting, sewing, branding, and marketing. Success at this stage relies heavily on interpreting fashion trends and effectively leveraging the unique texture of slub fabric to command premium pricing and consumer interest.

What are the limitations of using 100% slub synthetic fabrics?

While 100% synthetic slub fabrics (like polyester) offer high durability and cost-effectiveness, they often lack the natural breathability and soft hand-feel characteristic of cotton slub. Furthermore, dyeing synthetics can sometimes obscure the desired textural variation if not carefully managed, requiring specialized finishing treatments to mimic the natural aesthetics better achieved with natural fibers.

How does the volatility of raw material prices affect the market?

The Slub Fabric Textiles Market is highly sensitive to the volatility of cotton prices, as cotton remains the preferred raw material. Price fluctuations directly impact the cost of goods sold, forcing manufacturers to either absorb the cost, leading to reduced margins, or pass the increase onto downstream buyers, which can affect the competitiveness of slub fabric compared to uniformly constructed synthetic alternatives.

What opportunities exist for slub fabric in the technical textiles market?

Opportunities exist where the intentional non-uniformity of slub fabric can be leveraged for specific functional requirements. This includes using engineered slub blends in filtering systems or non-woven structures where varying pore sizes are required. The fabric's robust texture can also be utilized in specialized protective linings or composite reinforcement materials requiring unique surface adhesion properties.

What distinguishes woven slub fabric from knitted slub fabric?

Woven slub fabric, typically used in denim, shirting, and upholstery, offers greater structural rigidity and durability, with the slubs creating prominent linear textures. Knitted slub fabric, common in t-shirts and casual tops, offers significantly more stretch, better drape, and enhanced comfort, with the slubs presenting a softer, more rounded textural effect within the loop structure.

How do global trade agreements affect the distribution of slub textiles?

Global trade agreements, such as those impacting duties and tariffs, significantly influence sourcing and distribution. Favorable agreements between major textile producers in APAC and consumption centers in North America and Europe facilitate cheaper imports, increasing the overall accessibility and price competitiveness of slub textiles globally. Conversely, trade barriers can force brands to diversify their supply chains, potentially favoring regional production hubs.

What is the typical shelf life or wear resistance of high-quality slub fabric?

High-quality slub fabric, particularly those made from long-staple cotton or durable blends, possesses excellent wear resistance. However, the intentional thinner sections (non-slub areas) can sometimes be slightly more vulnerable to abrasion than uniform fabric. Generally, if properly manufactured, slub fabrics are durable and their texture often improves over time, becoming softer and developing unique character with washing and wear.

Which specialized finishing techniques are applied to slub textiles?

Specialized finishing techniques include mercerization (especially for cotton, enhancing luster and dye uptake), brushing or napping (to further enhance the soft hand-feel of the slubs), and specialized enzyme washes or bio-polishing. Chemical treatments for wrinkle resistance, moisture-wicking, or stain repellency are also increasingly applied, particularly for performance-oriented slub blends.

How does the rise of athleisure affect the demand for slub textiles?

The athleisure trend drives demand for slub textiles by requiring unique textures in comfortable, performance-oriented clothing. This trend fuels the growth of the Blended Slub Fabric segment, where cotton or rayon slubs are mixed with spandex or polyester to provide the required stretch, durability, and moisture-wicking capabilities while maintaining the desirable natural, textured aesthetic in sportswear.

What are the primary challenges in ensuring consistent slub quality across mass production runs?

The primary challenge is balancing the desired 'randomness' of the slub effect with the necessity of quality standardization. Maintaining consistent slub length, thickness, and frequency across millions of yards requires continuous, real-time monitoring and calibration of the electronic slub attachments, making sophisticated machinery and stringent quality assurance protocols essential.

Why is slub fabric popular in the high-end apparel market?

Slub fabric is favored in high-end apparel because its irregular texture conveys a sense of bespoke craftsmanship and authenticity, differentiating garments from conventional, smooth materials. Its premium feel, drape, and visual depth allow designers to achieve a sophisticated, subtly textured look that appeals to consumers seeking unique, high-quality, and visually engaging textiles.

What is the significance of the Knitting segment within the Slub Fabric Market?

The Knitting segment is highly significant as it caters to the massive market for comfortable casual wear, including t-shirts, polo shirts, and lightweight dresses, where slub texture is immensely popular. Knitted slub fabrics offer superior comfort, stretch, and breathability compared to woven counterparts, driving high volume consumption in the everyday clothing sector.

How do changing consumer aesthetics influence the type of slub yarns manufactured?

Consumer aesthetics heavily influence manufacturing specifications. Current trends often favor subtle, fine slubs for a delicate, natural appearance, moving away from overly thick or prominent slubs. This shifts production focus towards high-precision electronic slub attachments capable of generating extremely fine and controlled textural irregularities, optimizing the fabric for lightweight, soft-hand garments.

What are the major investment areas for companies in the Slub Fabric Textiles Market?

Major investment areas include upgrading spinning and weaving machinery with advanced electronic slub technology for greater precision and flexibility, investing in sustainable raw material sourcing (organic and recycled fibers), and integrating digital technologies (AI/CAD) for rapid trend analysis and prototype design, aiming to enhance efficiency and meet sustainability goals simultaneously.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager