Smart Valve Positioners Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439239 | Date : Jan, 2026 | Pages : 255 | Region : Global | Publisher : MRU

Smart Valve Positioners Market Size

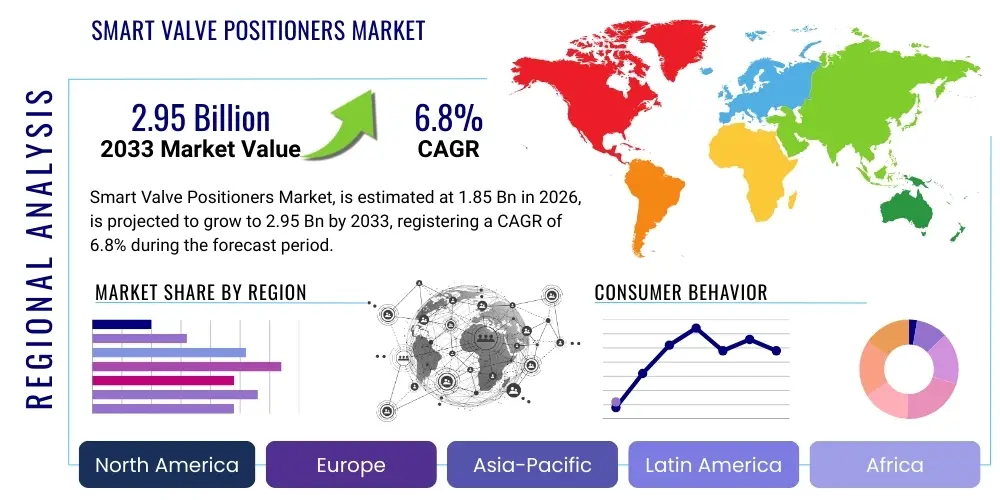

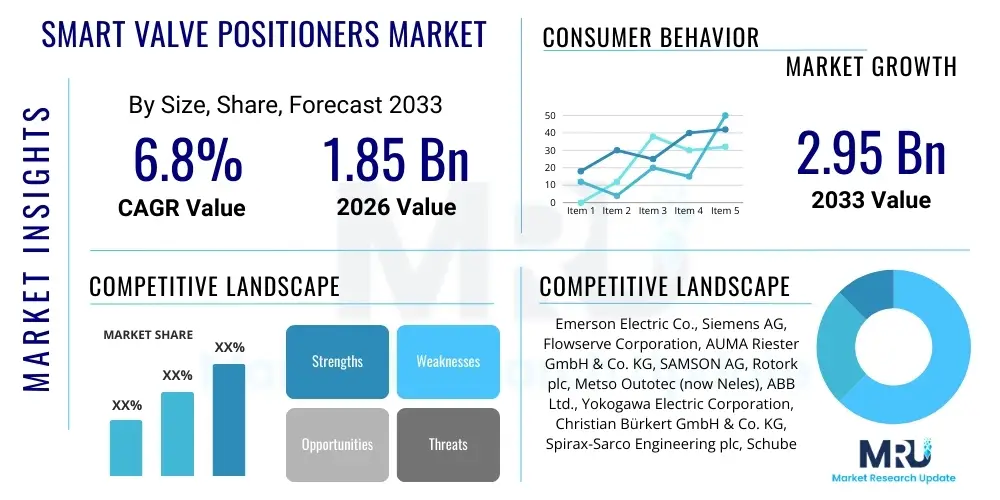

The Smart Valve Positioners Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 1.85 billion in 2026 and is projected to reach USD 2.95 billion by the end of the forecast period in 2033.

Smart Valve Positioners Market introduction

The Smart Valve Positioners Market encompasses advanced control devices designed to accurately position a control valve in response to an input signal, while also providing diagnostic feedback and enhanced operational intelligence. These devices are crucial components in modern industrial automation, enabling precise fluid control in various process industries. Unlike traditional mechanical positioners, smart valve positioners incorporate microprocessors, digital communication capabilities, and sophisticated algorithms to achieve higher accuracy, reliability, and diagnostic capabilities, thereby optimizing process efficiency and reducing maintenance costs.

Smart valve positioners find major applications across a spectrum of demanding environments, including oil and gas extraction and refining, chemical processing, power generation, water and wastewater treatment, pharmaceuticals, and food and beverage manufacturing. Their ability to deliver superior control, coupled with diagnostic data, makes them indispensable for critical processes where precise flow regulation is paramount. The inherent benefits of these intelligent devices include improved process stability, enhanced product quality, reduced energy consumption through optimized valve performance, and proactive maintenance planning, which collectively contribute to significant operational savings and increased plant uptime.

Key driving factors propelling the growth of the Smart Valve Positioners Market include the global emphasis on industrial automation and digitalization, the surging demand for energy efficiency in manufacturing operations, stringent regulatory requirements for process safety and environmental compliance, and the increasing adoption of Industry 4.0 and Industrial Internet of Things (IIoT) technologies. The ongoing need for greater operational transparency and predictive maintenance capabilities across various sectors further solidifies the market's upward trajectory, as industries seek to leverage data-driven insights for optimized asset management and operational excellence.

Smart Valve Positioners Market Executive Summary

The Smart Valve Positioners Market is experiencing robust growth, driven by pervasive industrial automation trends and the escalating need for enhanced operational efficiency across process industries. Businesses are increasingly investing in smart technologies to gain competitive advantages, focusing on real-time data acquisition, predictive maintenance, and seamless integration with broader control systems. The shift towards digital transformation and the adoption of IIoT architectures are fundamentally reshaping demand patterns, favoring smart positioners that offer advanced diagnostic features and connectivity. This trend is further supported by a strong emphasis on sustainability and energy conservation, with smart positioners contributing significantly to optimizing process flows and reducing waste.

Geographically, growth is particularly prominent in Asia Pacific, propelled by rapid industrialization, infrastructure development, and substantial investments in manufacturing and processing capabilities, notably in China, India, and Southeast Asian nations. North America and Europe continue to be significant markets, characterized by early adoption of advanced automation technologies, stringent regulatory frameworks, and a strong drive towards modernizing existing industrial facilities. Latin America, the Middle East, and Africa are also witnessing considerable expansion, largely due to expanding oil and gas projects, chemical industries, and investments in water infrastructure, leading to increased demand for reliable and efficient process control solutions. Each region demonstrates unique drivers and adoption rates, influenced by economic development, regulatory landscapes, and technological readiness.

From a segmentation perspective, the market is seeing strong traction in positioners equipped with advanced communication protocols like HART, Foundation Fieldbus, and Profibus, reflecting the industry’s move towards integrated and intelligent control networks. The demand for electric smart valve positioners is steadily rising due to their energy efficiency and precise control capabilities, though pneumatic variants remain dominant in hazardous environments. Furthermore, the oil and gas, chemical, and power generation sectors continue to be the largest end-users, given the critical nature of their operations and the substantial benefits derived from the accuracy and diagnostic features of smart valve positioners. Emerging segments, such as water and wastewater treatment, are also demonstrating accelerated adoption as utilities seek to modernize infrastructure and improve operational resilience.

AI Impact Analysis on Smart Valve Positioners Market

Common user questions regarding AI's impact on the Smart Valve Positioners Market revolve around how AI can enhance predictive capabilities, improve operational efficiency, and address potential cybersecurity risks. Users are keen to understand if AI will lead to fully autonomous valve control, what benefits it brings to maintenance and diagnostics, and how existing systems can be upgraded for AI integration. There's also curiosity about the cost implications of AI-enabled solutions and the required skillset for managing such advanced systems. These inquiries highlight a collective expectation for AI to transform asset management and process optimization, alongside concerns about implementation challenges and data security within critical industrial infrastructure.

- AI-driven algorithms enable predictive maintenance by analyzing operational data from smart valve positioners, forecasting potential failures before they occur, and significantly reducing unplanned downtime.

- Integration of AI facilitates real-time process optimization through adaptive control strategies, allowing valve positioners to respond dynamically to changing process conditions for enhanced efficiency and throughput.

- AI supports advanced diagnostics by identifying subtle anomalies in valve performance, providing deeper insights into mechanical wear, calibration drifts, and environmental impacts, thus improving troubleshooting accuracy.

- Autonomous control features, powered by AI, can allow smart valve positioners to make independent adjustments based on complex environmental and process variables, leading to more resilient and responsive systems.

- AI enhances cybersecurity protocols within smart positioners by detecting unusual network traffic or unauthorized access attempts, bolstering the protection of critical control infrastructure.

- Machine learning models can optimize energy consumption by ensuring valves operate at their most efficient points, dynamically adjusting to minimize power usage while maintaining process integrity.

- AI-enabled smart positioners contribute to improved safety by providing early warnings for critical deviations, allowing operators to intervene proactively and prevent hazardous conditions.

- The capability for remote monitoring and control is significantly augmented by AI, allowing for more intelligent decision-making from a centralized location, reducing the need for on-site inspections.

- AI facilitates the creation of digital twins for smart valve positioners, enabling virtual testing, simulation, and scenario planning, which accelerates commissioning and optimization cycles.

- Data aggregation and analysis powered by AI provide valuable insights for continuous improvement of valve design, material selection, and overall system performance.

- AI can personalize maintenance schedules based on individual valve performance and operational history, moving beyond generic recommendations to truly condition-based strategies.

- The integration of AI can streamline calibration processes, automating adjustments and verifying accuracy with minimal human intervention, thereby reducing errors and labor costs.

- AI algorithms can learn from operator inputs and process responses, leading to more intuitive and user-friendly interfaces for smart valve positioner management.

- Reduced human error is a direct benefit of AI integration, as routine tasks and complex decision-making are increasingly handled by intelligent systems, improving overall operational reliability.

- AI can facilitate seamless integration of smart valve positioners with other plant-wide automation systems, creating a more unified and intelligent operational ecosystem.

DRO & Impact Forces Of Smart Valve Positioners Market

The Smart Valve Positioners Market is significantly propelled by several robust drivers, primarily the accelerating pace of industrial automation and the widespread adoption of Industry 4.0 principles across global manufacturing and process industries. The increasing emphasis on operational efficiency, productivity enhancement, and reduction of maintenance costs further fuels demand for these intelligent devices. Additionally, stringent safety regulations and environmental compliance standards compel industries to implement more precise and reliable control systems, where smart valve positioners excel by offering superior accuracy, diagnostics, and real-time feedback. The growing need for real-time data and predictive maintenance capabilities to avoid costly downtime is also a critical driver, pushing companies towards digitalized solutions that provide deep operational insights.

However, the market also faces considerable restraints that could temper its growth. The high initial investment cost associated with deploying smart valve positioners and upgrading existing infrastructure presents a significant barrier for small and medium-sized enterprises (SMEs) and industries with limited capital expenditure budgets. Furthermore, the complexity of integrating these advanced devices with legacy control systems and the potential for cybersecurity vulnerabilities pose critical challenges. A shortage of skilled personnel capable of installing, operating, and maintaining sophisticated smart valve positioner systems also acts as a bottleneck, particularly in emerging economies where technical expertise may be limited. These factors collectively require strategic planning and investment in training and infrastructure to overcome.

Despite the challenges, the Smart Valve Positioners Market is replete with substantial opportunities for expansion and innovation. The burgeoning demand for energy-efficient solutions across various sectors offers a fertile ground for market penetration, as smart positioners can significantly optimize energy consumption in fluid control processes. The continuous development of wireless communication technologies and advanced diagnostic capabilities presents avenues for creating more flexible, resilient, and data-rich control environments. Additionally, the vast potential for retrofitting existing industrial plants with smart positioners to modernize their operations and improve asset utilization represents a lucrative opportunity. The expansion of process industries in emerging economies, coupled with government initiatives promoting industrial automation, further broadens the scope for market growth. Collaborations between technology providers and end-users to develop customized, industry-specific solutions also present key opportunities for market players to differentiate and capture niche markets.

Segmentation Analysis

The Smart Valve Positioners Market is extensively segmented across various parameters, including type, communication protocol, actuator type, and end-user industry, reflecting the diverse applications and technological requirements of different industrial environments. This comprehensive segmentation allows for a detailed analysis of market dynamics, growth drivers, and competitive landscapes within specific niches. Understanding these segments is crucial for market players to tailor their product offerings, develop targeted marketing strategies, and identify lucrative growth opportunities. The market's complexity and the specialized needs of different sectors necessitate a granular approach to segmentation, ensuring that solutions are precisely matched to operational demands.

- By Type

- Pneumatic Smart Valve Positioners

- Electric Smart Valve Positioners

- Electro-Pneumatic Smart Valve Positioners

- By Communication Protocol

- HART (Highway Addressable Remote Transducer)

- Foundation Fieldbus

- Profibus

- Modbus

- WirelessHART

- Ethernet/IP

- Other Protocols (e.g., PROFINET, AS-i)

- By Actuator Type

- Linear Actuators (e.g., globe, gate, diaphragm valves)

- Rotary Actuators (e.g., ball, butterfly, plug valves)

- By Industry/End-User

- Oil and Gas

- Chemical and Petrochemical

- Power Generation

- Water and Wastewater Treatment

- Food and Beverage

- Pharmaceuticals and Biotechnology

- Metals and Mining

- Paper and Pulp

- Other Industries (e.g., HVAC, Marine)

- By Region

- North America

- Europe

- Asia Pacific (APAC)

- Latin America

- Middle East and Africa (MEA)

Value Chain Analysis For Smart Valve Positioners Market

The value chain for the Smart Valve Positioners Market begins with upstream activities involving the sourcing and manufacturing of critical components. This includes specialized sensors for position and pressure feedback, high-performance microcontrollers for digital processing, communication modules for various protocols (HART, Fieldbus, Profibus), and robust mechanical parts designed for durability and precision. Raw material suppliers and component manufacturers form the foundational layer, providing essential inputs such as high-grade metals, polymers, and electronic circuitry. Innovation in these upstream segments directly impacts the performance, cost-effectiveness, and technological capabilities of the final smart valve positioner product. Companies in this stage focus on R&D to enhance component reliability, reduce power consumption, and improve integration compatibility, which are vital for the overall product quality and market acceptance.

Midstream activities involve the design, assembly, and testing of the smart valve positioners by specialized manufacturers. This stage focuses on integrating the sourced components into a functional, robust, and intelligent device. This includes firmware development, calibration, quality control, and ensuring compliance with industry standards and certifications (e.g., SIL certification for safety-critical applications). Manufacturers typically invest heavily in advanced production facilities and sophisticated testing methodologies to guarantee the accuracy, reliability, and longevity of their products. This phase also includes packaging and preparing the products for distribution. The efficiency and precision of manufacturing processes directly influence product quality, cost, and time-to-market, making it a critical link in the value chain.

Downstream activities involve the distribution, sales, installation, and after-sales services for smart valve positioners. Distribution channels are diverse, encompassing direct sales teams from manufacturers, a network of authorized distributors, system integrators, and Original Equipment Manufacturers (OEMs) who incorporate these positioners into their larger control systems. Direct channels allow for closer customer relationships and tailored solutions, while indirect channels provide broader market reach and specialized local support. Installation typically involves highly skilled technicians, often from the manufacturer or certified service partners, ensuring proper integration with control valves and plant-wide automation systems. Post-sales services, including technical support, maintenance, calibration, and software updates, are crucial for customer satisfaction and long-term product performance. The effectiveness of these downstream activities significantly influences market penetration, customer loyalty, and overall brand reputation.

Smart Valve Positioners Market Potential Customers

The primary potential customers for Smart Valve Positioners are major players within a wide array of process industries where precise control over fluid flow is critical for operational efficiency, safety, and product quality. This includes multinational corporations in the oil and gas sector, encompassing upstream exploration and production, midstream transportation, and downstream refining and petrochemical processing. These companies rely heavily on smart positioners to manage crude oil, natural gas, and various refined products under extreme pressure and temperature conditions, ensuring optimal throughput and preventing costly shutdowns. Similarly, chemical manufacturers, dealing with complex reactions and hazardous materials, are significant consumers, leveraging smart positioners to maintain strict process parameters and comply with rigorous safety and environmental regulations.

Another substantial customer segment comprises the power generation industry, including thermal, nuclear, and renewable energy plants. Smart valve positioners are integral to controlling steam, water, and fuel flows in turbines, boilers, and cooling systems, thereby maximizing energy output and minimizing operational risks. The water and wastewater treatment sector also represents a growing customer base, as municipal and industrial facilities adopt advanced automation to improve efficiency, reduce chemical consumption, and ensure compliance with discharge standards. In this context, smart positioners help optimize filtration, disinfection, and nutrient removal processes, contributing to sustainable water management practices.

Furthermore, the food and beverage industry, pharmaceutical and biotechnology companies, and the metals and mining sector are increasingly adopting smart valve positioners. Food and beverage manufacturers use them to control hygienic processes, ensure consistent product quality, and manage ingredient flows precisely. Pharmaceutical companies, operating under stringent regulatory frameworks, utilize these devices for sterile processing, batch control, and accurate dosage management. In metals and mining, smart positioners are employed in mineral processing, smelting, and refining operations where robust and accurate control is essential in harsh environments. OEMs and system integrators also represent critical indirect customers, as they incorporate smart valve positioners into larger, integrated control solutions offered to end-users across various industries.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.85 Billion |

| Market Forecast in 2033 | USD 2.95 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces | |

| Segments Covered | |

| Key Companies Covered | Emerson Electric Co., Siemens AG, Flowserve Corporation, AUMA Riester GmbH & Co. KG, SAMSON AG, Rotork plc, Metso Outotec (now Neles), ABB Ltd., Yokogawa Electric Corporation, Christian Bürkert GmbH & Co. KG, Spirax-Sarco Engineering plc, Schubert & Salzer Control Systems GmbH, General Electric (Baker Hughes), Curtiss-Wright Corporation, Nidec Corporation, KOSO America, Badger Meter, Inc., SICK AG, CCI Valves, ARCA Regler GmbH |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Smart Valve Positioners Market Key Technology Landscape

The Smart Valve Positioners Market is characterized by a dynamic and evolving technology landscape, with advancements continuously enhancing their capabilities and integration potential. Core to these devices are advanced microprocessors and digital signal processing units that enable complex control algorithms and diagnostic functions far beyond traditional pneumatic or analog positioners. These embedded systems facilitate highly precise valve positioning, self-calibration, and comprehensive monitoring of valve health and performance. The continuous improvement in processor efficiency and memory capacity allows for more sophisticated data processing at the edge, reducing latency and reliance on cloud-based analytics for immediate control decisions. Furthermore, developments in sensor technology, including highly accurate position feedback sensors and pressure transducers, are vital for the unparalleled precision these devices offer.

Communication protocols form another critical technological pillar, enabling seamless integration into plant-wide Distributed Control Systems (DCS) and SCADA systems. Traditional digital protocols like HART (Highway Addressable Remote Transducer), Foundation Fieldbus, and Profibus continue to dominate, providing robust and reliable data exchange for control and diagnostics. However, there is a growing trend towards industrial Ethernet protocols such as Modbus TCP/IP, EtherNet/IP, and PROFINET, which offer higher bandwidth, faster communication speeds, and easier integration with IT networks, aligning with the broader Industry 4.0 vision. Wireless communication technologies, particularly WirelessHART, are also gaining traction, offering flexibility in installation, reduced wiring costs, and improved accessibility for remote monitoring in challenging or expansive industrial environments. Cybersecurity technologies are becoming increasingly important, with embedded encryption, secure boot processes, and authentication protocols protecting smart positioners from unauthorized access and cyber threats.

Beyond connectivity and processing, the integration of advanced diagnostic and predictive analytics capabilities is a defining characteristic of smart valve positioners. These technologies leverage machine learning algorithms to analyze historical and real-time operational data, identifying anomalies, predicting potential failures, and providing actionable insights for proactive maintenance. Features such as stroke testing, friction monitoring, and response time analysis are becoming standard, offering unprecedented visibility into valve health. Furthermore, the development of modular designs and standardized interfaces is improving interoperability and ease of maintenance, allowing for simpler upgrades and replacements. The convergence of these technologies – sophisticated processing, diverse communication options, and intelligent analytics – is driving the evolution of smart valve positioners from mere control devices to integral components of an intelligent, interconnected industrial ecosystem.

Regional Highlights

- North America: A mature market characterized by early adoption of automation technologies, significant investment in R&D, and stringent regulatory frameworks, especially in the oil and gas, chemical, and power generation sectors. The region benefits from a strong presence of key market players and a high emphasis on predictive maintenance and operational efficiency.

- Europe: Driven by a strong focus on industrial digitalization (Industry 4.0), energy efficiency initiatives, and robust environmental and safety regulations. Countries like Germany, the UK, and France are leading the adoption of smart valve positioners, particularly in chemical, pharmaceutical, and water treatment industries.

- Asia Pacific (APAC): The fastest-growing market due to rapid industrialization, infrastructure development, and increasing investments in manufacturing capabilities across emerging economies such as China, India, and Southeast Asian countries. The region benefits from expanding process industries, growing demand for automation, and government support for advanced manufacturing.

- Latin America: Expected to witness steady growth, primarily fueled by investments in the oil and gas sector, mining, and chemical industries in countries like Brazil and Mexico. Modernization of existing industrial facilities and a push for improved operational efficiency are key drivers.

- Middle East and Africa (MEA): Growth is largely attributed to significant investments in the oil and gas industry, petrochemicals, and water infrastructure projects. Countries such as Saudi Arabia, UAE, and Qatar are leading the adoption to enhance operational reliability and productivity in their resource-rich economies.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Smart Valve Positioners Market.- Emerson Electric Co.

- Siemens AG

- Flowserve Corporation

- AUMA Riester GmbH & Co. KG

- SAMSON AG

- Rotork plc

- Metso Outotec (now Neles)

- ABB Ltd.

- Yokogawa Electric Corporation

- Christian Bürkert GmbH & Co. KG

- Spirax-Sarco Engineering plc

- Schubert & Salzer Control Systems GmbH

- General Electric (Baker Hughes)

- Curtiss-Wright Corporation

- Nidec Corporation

- KOSO America

- Badger Meter, Inc.

- SICK AG

- CCI Valves

- ARCA Regler GmbH

Frequently Asked Questions

Analyze common user questions about the Smart Valve Positioners market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is a smart valve positioner and how does it differ from traditional positioners?

A smart valve positioner is an advanced device that precisely controls a valve's position based on an input signal, while also providing diagnostic data and digital communication capabilities. Unlike traditional, mechanical positioners, smart versions use microprocessors to offer higher accuracy, real-time performance monitoring, predictive maintenance alerts, and seamless integration with modern control systems, thereby enhancing operational efficiency and reliability.

What are the primary benefits of implementing smart valve positioners in industrial processes?

Implementing smart valve positioners offers numerous benefits, including significantly improved control accuracy and process stability, reduced maintenance costs through predictive diagnostics and proactive issue identification, enhanced operational efficiency and energy savings due to optimized valve performance, increased plant safety through reliable control, and seamless integration with Industry 4.0 and IIoT initiatives for data-driven decision making.

Which industries are the major end-users of smart valve positioners?

Smart valve positioners are extensively used across a wide range of process industries. The major end-users include oil and gas (upstream, midstream, downstream), chemical and petrochemical, power generation, water and wastewater treatment, pharmaceuticals and biotechnology, and the food and beverage sectors, where precise and reliable fluid control is critical for operations, safety, and compliance.

What communication protocols are commonly supported by smart valve positioners?

Smart valve positioners typically support various communication protocols to integrate with diverse control systems. Common protocols include HART (Highway Addressable Remote Transducer), Foundation Fieldbus, Profibus, Modbus, WirelessHART, and increasingly, industrial Ethernet protocols like EtherNet/IP. These protocols enable digital communication for control signals, diagnostics, and configuration.

What impact does Artificial Intelligence (AI) have on the future of smart valve positioners?

AI is set to profoundly impact smart valve positioners by enabling more advanced predictive maintenance, autonomous control capabilities, and real-time process optimization. AI algorithms can analyze complex operational data to forecast failures, dynamically adjust valve settings for peak efficiency, enhance diagnostic accuracy, and improve cybersecurity, leading to more resilient, intelligent, and self-optimizing industrial control systems.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager